In this fast-moving 3D printing world, it’s really not hard to realize that SLS technology holds a revolutionary key to innovation and entrepreneurial activity. To think that one can create complex geometries and tough prototypes right from one’s desk is just riveting. The drawback for most budding creators would be the fact that these SLS printers could only be within reach for highly pocketed professionals. Affordable SLS 3D printers will soon be here to make this breathtaking technology accessible to budget-conscious innovators.

The next article takes you deep into the world of affordable SLS printers, and all this knowledge will empower a great investment for any user willing to push the limits in the design and manufacturing world. First off, we get back to the basic details about the printing technology: the benefits, its applications, and then guide you through all those necessary factors to consider while choosing your ideal printer.

We then make a list of the best options for budget SLS printers, enumerating their key features, advantages, and disadvantages, with their respective ideal user profiles. We will put these models in a table to rest that unease in your choice. At the end, I will be sharing user experiences and some tips on maintenance so you are well-prepared with your new printer.

Let us now delve a little deeper into the future of affordable SLS printing and discuss what trends and innovations may just change this landscape. This guide is meant to let you plunge into the world of SLS printing without breaking your bank, no matter whether you are a hobbyist, small businessperson, or engineering student. Now let us embark on this journey to find the best SLS printers available today at an affordable price.

Understanding SLS Printing

SLS is that type of revolutionary technology for 3D prototyping and manufacturing printing. Now, if this entire world of 3D printing is very new to you, doubtlessly a question must be popping up in your mind by now. What is SLS technology and how important is it? In this section, we touch briefly on some basics of the SLS process, its benefits, and common uses before giving you a reason to appreciate it in the present innovation landscape.

What is Selective Laser Sintering (SLS)?

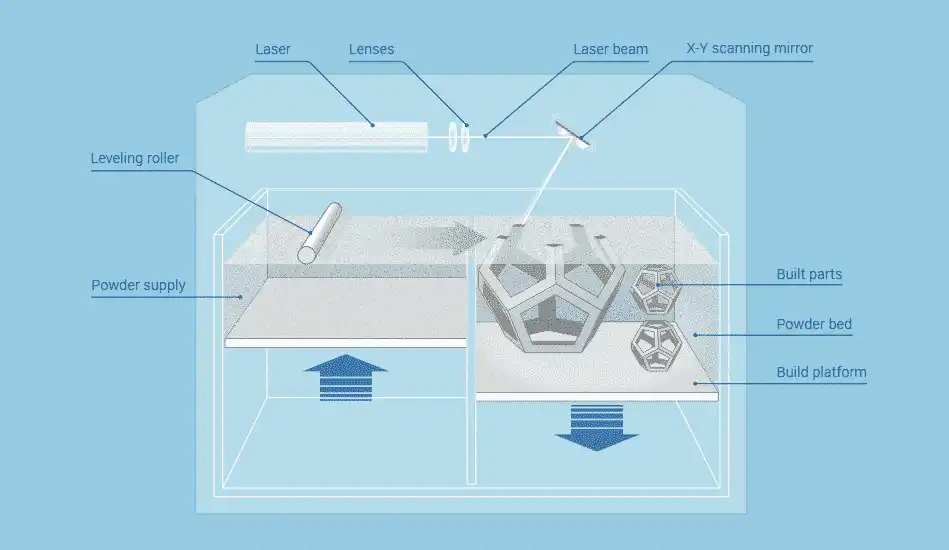

In short, SLS is one type of additive manufacturing process which uses an extremely powerful laser to sinter the powdered material; in this way, solid objects are created layer by layer. The operation in manufacturing with said machine will go on:

- Preparation of Material: A thin layer of powdered material is evenly spread onto the build platform.

- Laser Sintering: It sintered the surface of the powder—that is, information from the 3D model was used to fuse particles in prescribed sections with a laser beam.

- Layering: As one layer nears completion, the platform moves down a bit, and another layer of powder is laid down. This continues until the object is fully built. 4. Cooling and Removal: Once the printing is complete, the chamber cools, and with blowing air around it, the excess powder falls off, revealing your final object.

Advantages of SLS Over Other 3D Printing Methods

SLS offers several advantages that make it a preferred choice for many applications:

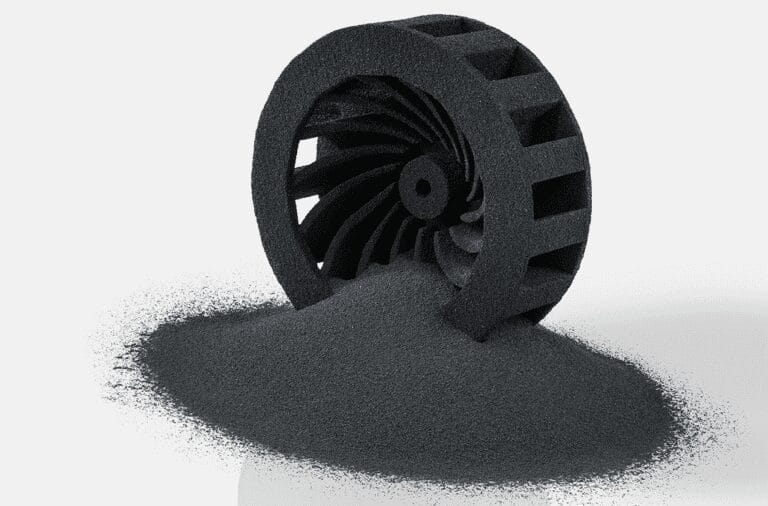

- Complex Geometries: SLS can create intricate designs that would be difficult or impossible with traditional manufacturing methods.

- Material Versatility: A wide range of materials can be used, including various plastics and metals, allowing for diverse applications.

- No Support Structures Needed: The unsintered powder acts as a support for overhangs and complex shapes, eliminating the need for additional support structures.

- Durability: SLS prints are known for their strength and durability, making them suitable for functional parts and prototypes.

| Advantages | Description |

| Complex Geometries | Ability to create intricate designs |

| Material Versatility | Wide range of material options available |

| No Support Needed | Unsintered powder supports overhangs |

| Durability | Strong and functional parts suitable for real-world use |

Common Applications of SLS Printing

SLS printing has found its way into various industries, thanks to its unique capabilities. Here are some common applications:

- Prototyping: Rapidly create functional prototypes for testing and validation.

- Manufacturing: Produce low-volume production runs of custom parts.

- Custom Parts Production: Create tailored components for specific projects, such as medical devices or automotive parts.

- Art and Design: Enable artists and designers to bring their visions to life with intricate and detailed designs.

Industry Applications Table

| Industry | Application |

| Aerospace | Lightweight components for aircraft |

| Automotive | Custom parts and prototypes for vehicle design |

| Medical | Prosthetics and surgical models |

| Consumer Products | Customized goods and unique designs |

| Architecture | Scale models and architectural prototypes |

Knowing SLS printing is super important in case you want to harness what all it can do for your projects. That said, the technology does come with certain pretty impressive benefits and uses, which in turn make it not just for pros but for anyone contemplating creating something. We will delve into what you need to look at while picking up an affordable SLS printer to ensure that you make a clever choice for the realization of your creative vision within this article.

Factors to Consider When Choosing an Affordable SLS Printer

As demand for 3D printing grows, so does the diversity in the line of SLS printers hitting the market. With this in mind, if you happen to consider seeking an affordable SLS printer, there are some critical factors you have to consider. A well-researched decision can save you a lot of time, money, and frustration down the line. We go further to elaborate on the fundamental concerns that help you narrow down the right printer to suit your needs.

1. What is Your Budget?

Determining your budget is the first step in your search for an affordable SLS printer. Prices can vary significantly based on features, brand, and capabilities. Here’s a rough breakdown of what you might expect:

- Entry-Level SLS Printers: $5,000 – $10,000

- Mid-Range Options: $10,000 – $30,000

- High-End Models: $30,000 and above

2. Size and Build Volume

The size of the printer and its build volume are crucial factors. Consider what types of projects you plan to work on:

- Small Projects: If you primarily need to print small prototypes, a compact printer with a smaller build volume may suffice.

- Large Projects: For larger components or multiple items at once, look for a printer with a generous build volume.

Build Volume Comparison

| Printer Type | Typical Build Volume |

| Compact | 150 x 150 x 200 mm |

| Mid-Size | 300 x 300 x 300 mm |

| Large | 500 x 500 x 500 mm and above |

3. Material Compatibility

The materials you can use with your SLS printer will significantly impact your projects. Here are common materials used in SLS printing:

- Nylon: Versatile and durable, perfect for prototypes and functional parts.

- Polypropylene: Lightweight and resistant to chemicals, ideal for specific applications.

- Metal Powders: For high-strength applications, though typically more expensive.

Material Compatibility Table

| Material Type | Properties | Applications |

| Nylon | Strong, flexible, and lightweight | Prototypes, functional parts |

| Polypropylene | Lightweight, chemical-resistant | Custom parts, containers |

| Metal Powders | High strength, durable | Aerospace, automotive components |

4. Print Quality and Resolution

Print quality is a critical factor, especially for detailed projects. Look for specifications that indicate the printer’s resolution, typically measured in microns. The lower the micron value, the finer the details you can achieve.

Print Quality Considerations

- Layer Thickness: Commonly ranges from 50 to 200 microns.

- Surface Finish: Higher-quality printers yield smoother finishes, reducing the need for post-processing.

5. Speed of Printing

Efficiency matters, especially if you plan to produce multiple items or large components. Consider the printer’s speed, typically quantified in cubic centimeters per hour (cc/hr). A faster printer can significantly reduce project turnaround time.

Speed Comparison Table

| Printer Type | Typical Speed (cc/hr) |

| Entry-Level | 10 – 20 cc/hr |

| Mid-Range | 20 – 50 cc/hr |

| High-End | 50+ cc/hr |

6. User-Friendliness and Software

A user-friendly interface can make a world of difference, especially for beginners. Look for printers that come with intuitive software and easy setup processes. Consider:

- Software Compatibility: Ensure the printer is compatible with popular 3D modeling software.

- Ease of Use: Look for features like touchscreen controls and guided setup.

7. Customer Support and Warranty Options

Reliable customer support can save you headaches down the line. Before making a purchase, check the following:

- Warranty Period: A longer warranty can provide peace of mind.

- Support Channels: Look for manufacturers that offer multiple support options (e.g., phone, email, live chat).

Support and Warranty Table

| Support Feature | Description |

| Warranty Period | 1 year (common) to 5 years (premium models) |

| Support Channels | Phone, email, live chat, online forums |

This involves a lot of deliberation in terms of budget, build volume, material compatibility, and customer support. Understanding these elements will help you better choose an affordable SLS printer that fits the bill for your needs and is helpful to bring your creative projects to life. Now that we have discussed this, let’s move with our top picks of budget-friendly SLS printers, giving concrete recommendations for final decisions.

Top Picks for Affordable SLS Printers

With the growing availability of affordable SLS printers, it’s easier than ever to find a model that suits your needs without breaking the bank. In this section, we’ll present our top picks for budget-friendly SLS printers, highlighting their key features, pros and cons, and ideal user profiles. Whether you’re a hobbyist, small business owner, or engineering student, there’s a printer here for you.

1.Formlabs Fuse 1

Overview

The Formlabs Fuse 1 is a powerful SLS printer that delivers high-quality prints at a competitive price. It’s known for its reliability and precision.

- Price: $18,499

- Build Volume: 165 x 165 x 300 mm

- Layer Thickness: 110 microns

- Materials: Nylon 12, Nylon 11

The Fuse 1 is ideal for small businesses and design studios that require reliable, high-quality prints for functional prototypes and end-use parts.

2.Sinterit LisaX

Overview

The Sinterit Lisa is a versatile and compact SLS printer that offers a great balance of quality and affordability. It’s designed for both professionals and enthusiasts.

- Price: $15,490

- Build Volume: 650 x 610 x 1200 mm

- Layer Thickness: 75 – 175 microns

- Materials: Nylon PA12, TPU

The Sinterit Lisa is perfect for professionals in design and engineering who need a reliable printer for prototyping and small-scale production.

3.ZONGHENG3D SLS2030

Overview

The Zongheng3D SuperMaker SLS2030 is an advanced industrial-grade nylon SLS 3D printer designed for rapid prototyping and small batch production. It features a heated chamber that maintains temperatures up to 190°C, ensuring uniform heating and reduced deformation risk when printing with high-performance materials like PA11, PA12, and TPU.

- Price: $39,800

- Build Volume: 200 x 200 x 300 mm

- Layer Thickness: 100 – 300 microns

- Materials: PA11, PA12, TPU and Nylon with GF

The SuperMaker SLS2030 is compatible with STL files and can be operated via a large built-in LED screen or controlled remotely using the in-house developed software that provides online real-time modification of parameters, 3D visualization, and advanced diagnostics.

The choice for work that one can make by using a cheap SLS printer will determine a lot in the projects undertaken and the smooth running of the business. Each printer listed above has some special features and advantages best suited for every user’s needs. Be it a simple enthusiast or expanding one’s capabilities, the options above suit users’ requirements.

Essential Maintenance Tips for SLS Printers

Maintaining your SLS printer is crucial to ensuring its longevity, performance, and print quality. Regular upkeep not only helps prevent issues but also maximizes your investment. In this section, we’ll cover essential maintenance tips, best practices, and common troubleshooting steps to keep your SLS printer running smoothly.

1. Regular Cleaning

Importance of Cleaning

Keeping your printer clean is vital for optimal performance. Dust and debris can affect print quality and lead to mechanical failures.

Cleaning Checklist

- Build Platform: Wipe down after each print to remove any residual powder.

- Powder Chamber: Clean out any leftover material to prevent contamination.

- Optics and Lasers: Regularly check and clean to maintain accuracy.

Cleaning Supplies

| Item | Purpose |

| Soft cloth | For wiping surfaces |

| Isopropyl alcohol | For cleaning optics and sensitive components |

| Vacuum cleaner | To remove excess powder from the chamber |

2. Regular Calibration

Why Calibration Matters

Calibration ensures that your printer operates within the specified tolerances, which is crucial for achieving high-quality prints.

Calibration Steps

- Check the Build Plate Level: Ensure it’s level to avoid uneven prints.

- Verify Laser Alignment: Regularly check that the laser is correctly aligned with the powder bed.

- Test Print: Perform a test print after calibration to confirm settings.

Calibration Frequency

- Monthly: For general use.

- Weekly: For high-volume printing.

3. Monitor Material Usage

Keeping Track of Materials

Understanding your material usage helps prevent unexpected shortages and ensures consistent print quality.

Material Management Tips

- Inventory System: Keep an inventory of materials and their usage rates.

- Storage Conditions: Store powders in a cool, dry place to maintain their integrity.

Material Usage Table

| Material Type | Shelf Life | Storage Conditions |

| Nylon | 12 months | Cool, dry place |

| TPU | 6 months | Airtight container |

| Specialty Powders | Varies (check manufacturer) | Follow specific storage guidelines |

4. Software Updates

Importance of Software Maintenance

Keeping your printer’s software up to date ensures that you have the latest features and bug fixes.

Update Steps

- Check Manufacturer’s Website: Regularly visit for updates.

- Backup Settings: Before updating, back up your current settings.

- Follow Instructions: Carefully follow the update process as outlined by the manufacturer.

Update Frequency

- Quarterly: For general users.

- Monthly: For professional settings with frequent updates.

5. Troubleshooting Common Issues

Common Problems and Solutions

Even with regular maintenance, issues may arise. Here are some common problems and their solutions:

| Issue | Possible Cause | Solution |

| Poor print quality | Dust on optics | Clean optics with isopropyl alcohol |

| Misalignment | Calibration issues | Re-calibrate the printer |

| Inconsistent layer adhesion | Material contamination | Clean the powder chamber thoroughly |

When to Seek Professional Help

If you encounter persistent issues that you cannot resolve, it’s best to contact the manufacturer’s support team for assistance.

6. Scheduled Maintenance

Importance of a Maintenance Schedule

Establishing a regular maintenance schedule can help prevent issues before they arise.

Suggested Maintenance Schedule

| Task | Frequency |

| Clean build platform | After every print |

| Clean powder chamber | Weekly |

| Calibration | Monthly |

| Software updates | Quarterly |

These are the tips that will keep your SLS printer in good condition and hence can always produce quality prints even after many years. Any typical owner of an SLS printer should make routine cleaning and calibration a normal habit, keeping observations on material usage.

Common Applications of SLS Printing

Selective Laser Sintering (SLS) printing has gained significant traction across various industries due to its versatility and ability to create complex geometries. In this section, we’ll explore some of the most common applications of SLS printing, highlighting how this technology is transforming manufacturing, prototyping, and design.

1. Prototyping

Rapid Prototyping

SLS printing is widely used for rapid prototyping, allowing designers and engineers to create functional prototypes quickly and cost-effectively.

Benefits

- Speed: SLS printers can produce prototypes in a matter of hours.

- Complex Geometries: The ability to create intricate designs that would be difficult or impossible with traditional manufacturing methods.

- Material Variety: A range of materials can be used, enabling prototypes that closely match final products.

Industries Utilizing Prototyping

- Automotive: For testing parts and assemblies.

- Aerospace: Creating lightweight components for aircraft.

- Consumer Electronics: Developing ergonomic designs for new devices.

2. End-Use Parts

Production of Functional Components

SLS printing is increasingly being used to produce end-use parts that are functional and durable, suitable for various applications.

Advantages

- Strength and Durability: SLS parts have excellent mechanical properties, making them suitable for functional use.

- Customization: Parts can be easily customized to meet specific requirements.

- Reduced Waste: The additive nature of SLS printing minimizes material waste compared to subtractive manufacturing.

Applications for End-Use Parts

- Medical Devices: Custom implants and prosthetics tailored to individual patients.

- Industrial Equipment: Replacement parts for machinery that require quick turnaround times.

- Consumer Products: Customizable items like eyewear frames and footwear.

3. Tooling

Creating Jigs and Fixtures

SLS printing is effective for producing tooling, such as jigs and fixtures, that aid in the manufacturing process.

Benefits of SLS Tooling

- Cost-Effective: Reduces the need for expensive molds and tooling setups.

- Rapid Production: Tooling can be produced quickly, allowing for faster production cycles.

- Precision: High accuracy in creating complex tooling designs.

Industries Benefiting from Tooling

- Manufacturing: For assembly line processes and quality control.

- Aerospace: Creating specialized tools for aircraft assembly.

- Automotive: Producing fixtures for assembly and testing.

4. Aerospace and Defense

Specialized Components

The aerospace and defense industries utilize SLS printing for creating specialized components that require high strength and lightweight characteristics.

Key Advantages

- Weight Reduction: SLS allows for the production of lightweight parts without compromising strength.

- Complex Designs: Capable of producing geometries that enhance aerodynamic performance.

- Material Properties: Use of high-performance materials suitable for harsh environments.

Applications in Aerospace and Defense

- Aircraft Components: Lightweight brackets, housings, and ducts.

- Defense Equipment: Custom parts for military vehicles and equipment.

- Space Exploration: Components for satellites and spacecraft.

5. Architecture and Art

Creating Models and Sculptures

SLS printing is also used in architecture and art for creating detailed models and sculptures.

Benefits

- Detail and Precision: High-resolution prints capture intricate details.

- Material Flexibility: Various materials can be used to achieve specific aesthetic qualities.

- Rapid Iteration: Designers can quickly produce and modify models.

Applications in Architecture and Art

- Architectural Models: Creating scale models for presentations and client approvals.

- Art Installations: Unique sculptures and installations that push the boundaries of design.

- Historical Replicas: Reproducing artifacts and historical structures for educational purposes.

Flexibility of application is said to be provided many times with SLS printing: from prototyping, through to end-use parts and tooling, through to perhaps even art. The geometrical complexity, an option for huge waste reduction, and customization of SLS prints could have posed tremendous potential in modern manufacturing and design.

Future Trends in SLS Printing

As technology continues to evolve, Selective Laser Sintering (SLS) printing is poised for significant advancements that will enhance its capabilities and applications. In this section, we’ll explore the future trends in SLS printing, highlighting innovations that could shape the industry and expand its use across various sectors.

1. Enhanced Material Development

New Materials for SLS Printing

The development of new materials is a key trend that will drive the future of SLS printing. Innovations in material science are leading to the creation of advanced powders with improved properties.

Potential Advancements

- Biocompatible Materials: Expanding the use of SLS in the medical field with materials suitable for implants and prosthetics.

- High-Performance Polymers: Development of materials that can withstand extreme temperatures and harsh environments, suitable for aerospace and automotive applications.

- Recyclable Powders: Focus on sustainability with materials that can be recycled, reducing waste and environmental impact.

2. Integration of AI and Automation

Smart SLS Printing Systems

The integration of artificial intelligence (AI) and automation is set to revolutionize the SLS printing process, making it more efficient and user-friendly.

Benefits of AI and Automation

- Predictive Maintenance: AI can monitor printer performance and predict maintenance needs, reducing downtime.

- Automated Calibration: Systems that automatically calibrate printers for optimal performance, ensuring consistent print quality.

- Data-Driven Insights: AI analytics can provide insights into material usage and print performance, helping users optimize their processes.

3. Expansion of Multi-Material Printing

Advancements in Multi-Material Capabilities

The future of SLS printing includes advancements in multi-material printing, allowing for the combination of different materials in a single print.

Advantages of Multi-Material Printing

- Functionality: Creating parts with varying properties (e.g., rigidity and flexibility) in one print cycle.

- Complex Assemblies: Reducing the need for assembly by printing multi-part assemblies as a single component.

- Customization: Enhanced customization options for end products, catering to specific user needs.

4. Increased Speed and Efficiency

Innovations in Printing Speed

Future SLS printers are expected to feature advancements that significantly increase printing speed and efficiency.

Potential Developments

- Improved Laser Technology: Utilizing higher-powered lasers or multiple lasers to reduce print time.

- Faster Cooling Systems: Innovations that speed up the cooling process, allowing for quicker layer solidification.

- Batch Processing: Ability to print multiple parts simultaneously, maximizing throughput.

5. Greater Accessibility and Affordability

Making SLS Printing More Accessible

As technology advances, the cost of SLS printers and materials is expected to decrease, making the technology more accessible to a wider audience.

Implications of Increased Accessibility

- Small Businesses and Startups: More companies will be able to leverage SLS printing for prototyping and production.

- Educational Institutions: Schools and universities can incorporate SLS technology into their curricula, fostering innovation and hands-on learning.

- Hobbyists and Makers: The rise of affordable SLS printers will empower DIY enthusiasts to explore advanced 3D printing techniques.

6. Sustainability Initiatives

Focus on Sustainable Practices

The future of SLS printing will likely emphasize sustainability, with a focus on reducing environmental impact.

Sustainable Practices to Watch

- Eco-Friendly Materials: Development of biodegradable and recyclable materials for SLS printing.

- Energy-Efficient Processes: Innovations aimed at reducing energy consumption during the printing process.

- Waste Reduction: Strategies to minimize waste generated during printing and post-processing.

Conclusion

The future of SLS printing is great, for continuous development in materials, technology, and processes keeps it right at the forefront regarding the recasting of its applications and capabilities. As more industries look onto this technology, efficiency will increase with accessibility and sustainability in consideration.