Imagine holding a miniature replica of the Eiffel Tower in your hand, every intricate detail perfectly captured, or crafting a custom piece of jewelry that’s truly one-of-a-kind. 3D printing technology has revolutionized the way we create and innovate, offering the ability to turn digital designs into tangible objects. Among the various technologies available, Digital Light Processing (DLP) stands out for its precision and efficiency, especially for beginners eager to explore the world of 3D printing. DLP printers use a digital projector screen to flash a single image of each layer all at once, making it significantly faster than other methods that print one point at a time. This method not only speeds up the printing process but also provides an exceptional level of detail, making it ideal for intricate designs.

Choosing the right DLP 3D printer can be a daunting task for beginners, with a plethora of models available, each boasting different features, performance levels, and price points. Whether you’re a hobbyist looking to bring your creations to life, an educator seeking to introduce students to the wonders of 3D printing, or a small business aiming to prototype new products, the right DLP 3D printer can significantly impact your projects.

In this comprehensive guide, we will navigate through the maze of available options to help you find the best DLP 3D printer suited for beginners. We will explore what makes a great beginner-friendly DLP printer, delve into reviews of top picks, and answer common questions to ensure you make an informed decision. By the end of this article, you’ll have a clearer understanding of which DLP 3D printer will best suit your needs, allowing you to start your 3D printing journey with confidence. Let’s dive into the world of DLP 3D printing and uncover the top models that promise ease of use, reliability, and excellent output quality, all crucial for a smooth introduction to 3D printing.

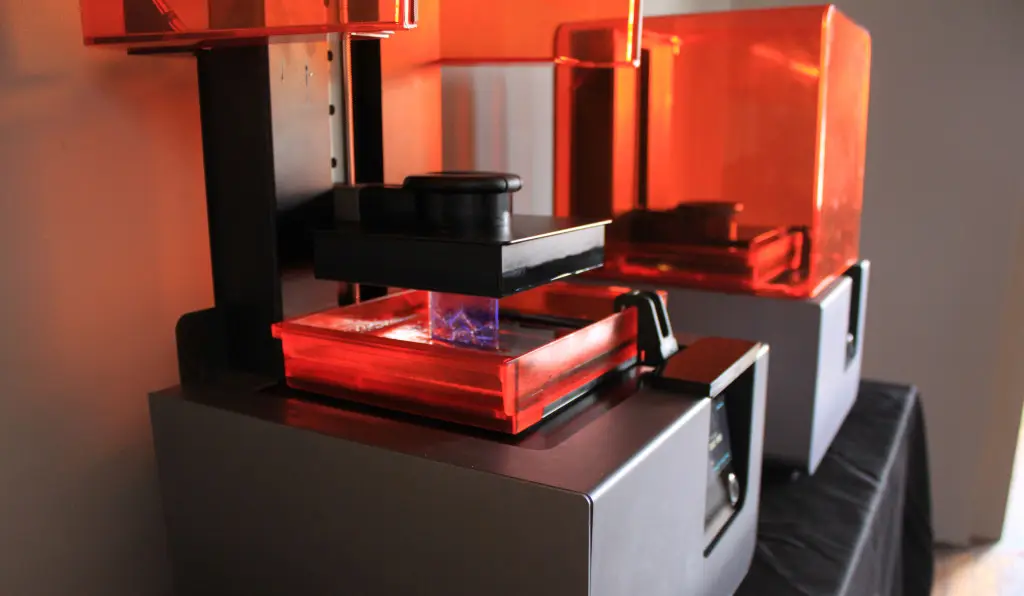

Understanding DLP 3D Printing: The Basics for Beginners

Before diving into the specifics of DLP 3D printers, it’s essential to understand what sets this technology apart from other types of 3D printing and why it’s particularly appealing for beginners. This knowledge will help you make an informed decision when selecting your first 3D printer.

What is DLP 3D Printing?

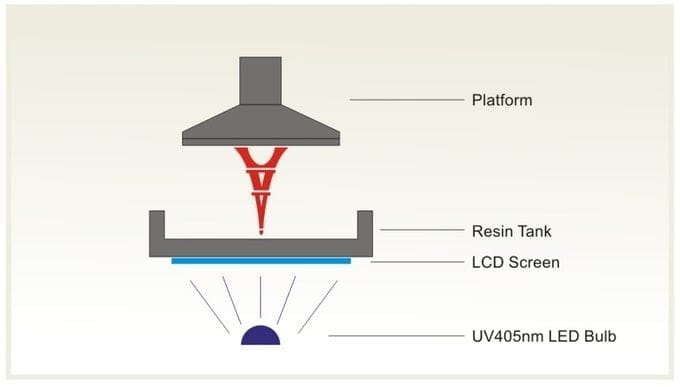

Digital Light Processing (DLP) 3D printing is a type of additive manufacturing technology that uses light and photosensitive polymers. Unlike its close relative Stereolithography (SLA), which uses a laser to cure resin layer by layer, DLP utilizes a digital projector to flash a single image of each layer across the entire platform at once. This method allows DLP printers to produce layers quickly and with high precision.

Key Advantages of DLP 3D Printing

- Speed: Due to the projector flashing an entire layer at once, DLP printing is significantly faster than printers that use a point-by-point approach.

- Detail: The precision of a projector allows DLP printers to achieve exceptionally fine details, making them ideal for intricate jewelry, dental work, and detailed figurines.

- Efficiency: DLP printers generally use less resin than SLA printers as the light exposure is more controlled and consistent.

- Durability: Parts produced by DLP are typically strong with smooth surfaces, which can be beneficial for both functional prototypes and decorative items.

How Does DLP 3D Printing Work?

Here’s a simplified breakdown of the DLP printing process:

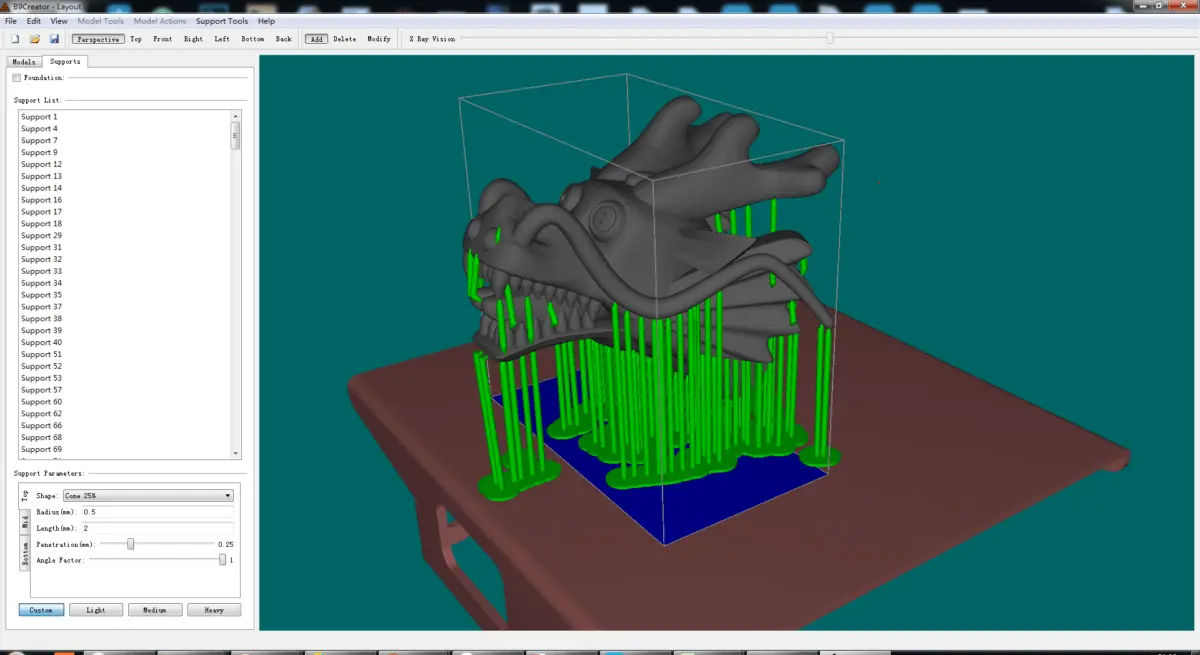

- Preparation: The process starts with a 3D model, typically created or downloaded, and then sliced using software into thin horizontal layers.

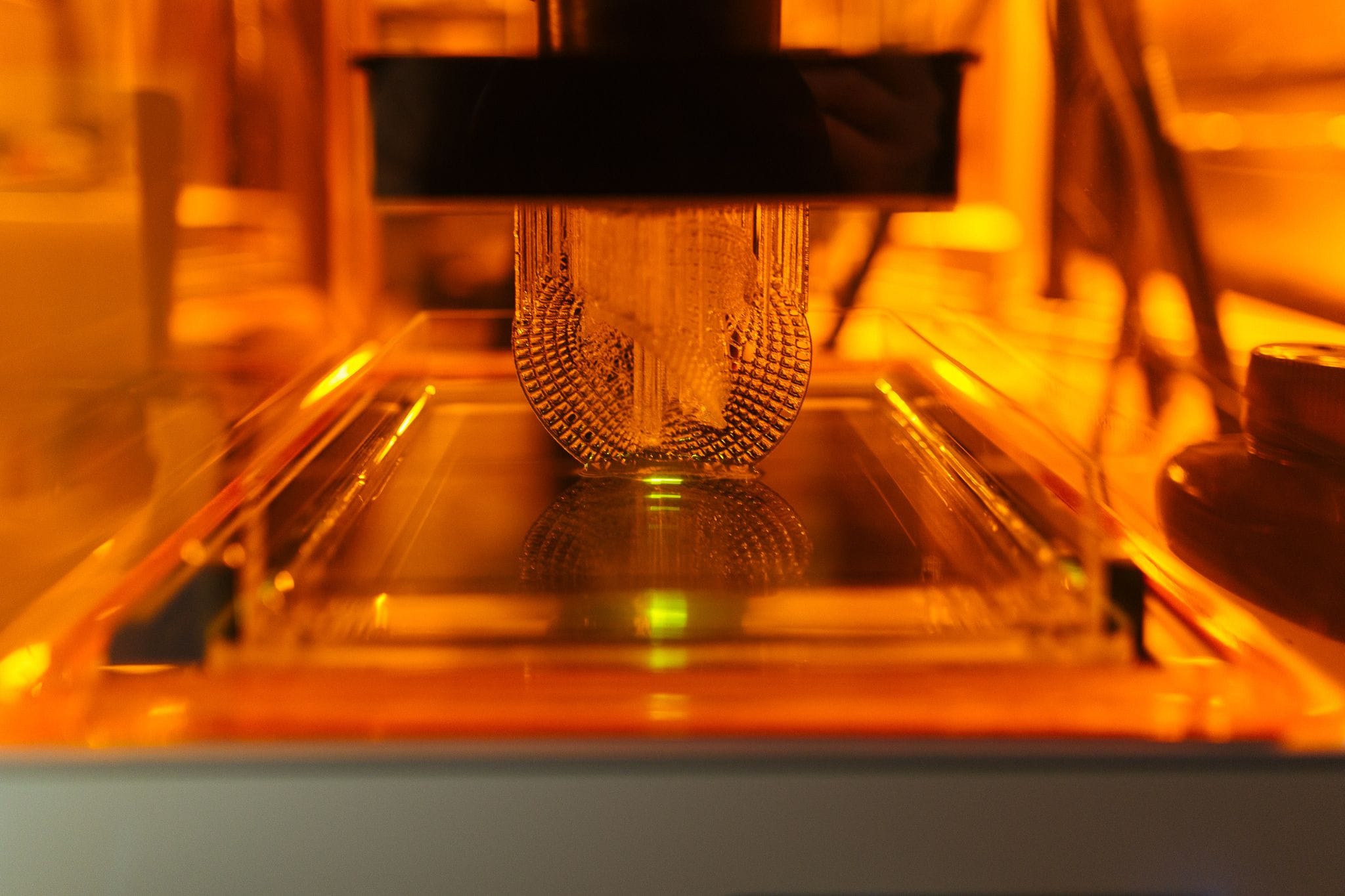

- Printing: The printer’s build platform lowers into a tank of liquid photopolymer resin. A digital projector under the resin tank flashes an image of the first layer, hardening the resin precisely where needed. The build platform then moves up, allowing a new layer of resin to cover the previous one, and the process repeats.

- Post-Processing: After printing, the object is rinsed in a solvent to clean off excess resin. It may also be cured in a UV light chamber to ensure the resin fully sets.

Choosing the Right DLP Printer: Factors to Consider

For beginners, the following factors are critical when choosing a DLP 3D printer:

- Ease of Use: Look for printers with user-friendly interfaces, straightforward software, and minimal setup requirements.

- Print Quality and Resolution: Determine the level of detail you need based on the projects you plan to undertake.

- Reliability: Opt for models known for consistent performance without frequent malfunctions.

- Support and Community: A robust user community and good manufacturer support can be invaluable for troubleshooting and learning.

- Price: Balance cost against features and potential for future needs.

Popular DLP 3D Printers for Beginners

Here’s a quick look at some popular DLP 3D printers that are well-suited for beginners, showcasing their key features and price points:

| Printer | Features | Price Range |

| Anycubic Photon Mono 2 | Affordable, reliable, good for beginners | $180 – $290 |

| Elegoo Mars 5 Ultra | Built-in air purifier, fast printing speeds | $290 – $370 |

| Phrozen Sonic Mini 8K | Fast printing speeds due to the monochrome LCD | $480 – $510 |

DLP 3D printing offers a blend of speed, precision, and efficiency that makes it a preferred choice for beginners looking to start their journey into the world of 3D printing. Understanding the basics and what to look for in a printer will equip you with the knowledge needed to choose the right DLP 3D printer that meets your creative needs and budget constraints.

Top Picks: Best DLP 3D Printers for Beginners

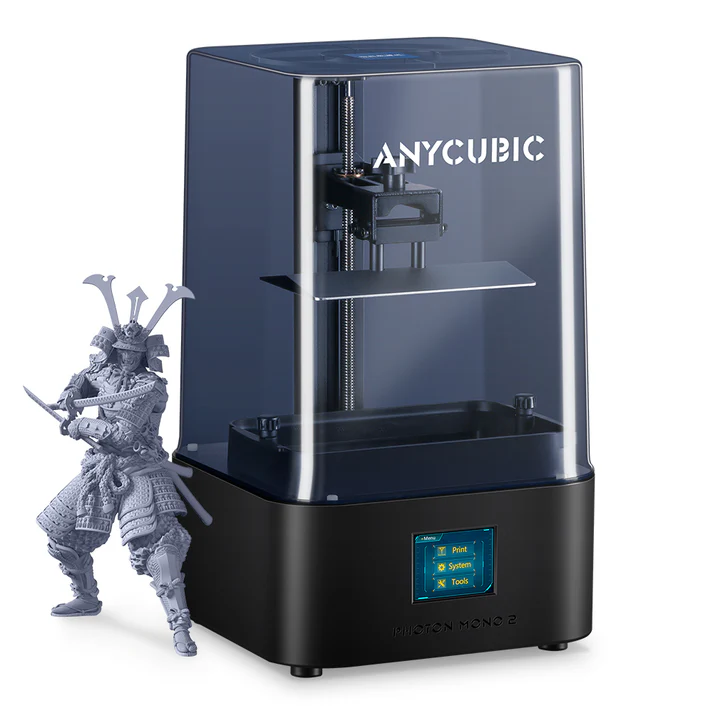

Anycubic Photon Mono 2

Overview The Anycubic Photon Mono 2 is designed for both beginners and experienced users, offering a blend of high resolution and user-friendly features. It utilizes a monochrome LCD screen for faster curing times and improved durability.

Key Features:

- 6.6-inch 4K+ monochrome LCD screen (4096 x 2560 pixels)

- Build volume: 130 x 80 x 165 mm

- Printing speed: Up to 60 mm/h

- Improved light source for better uniformity

Pros:

- High-resolution prints with excellent detail.

- Faster printing speeds compared to previous models.

- User-friendly interface and setup.

Cons:

- Limited build volume compared to larger printers.

- Requires post-processing for best results.

Elegoo Mars 5 Ultra

Overview The Elegoo Mars 5 Ultra is a powerful resin printer that combines speed and precision, making it ideal for hobbyists and professionals alike. It features advanced technology for enhanced performance.

Key Features:

- 9K monochrome LCD screen (3840 x 2400 pixels)

- Build volume: 218 x 123 x 235 mm

- Printing speed: Up to 150 mm/h

- AI camera for monitoring prints

Pros:

- Exceptional print quality with high detail.

- Fast printing speeds suitable for production.

- Auto-leveling feature for ease of use.

Cons:

- Higher price point compared to entry-level models.

- Some users may find the software complex.

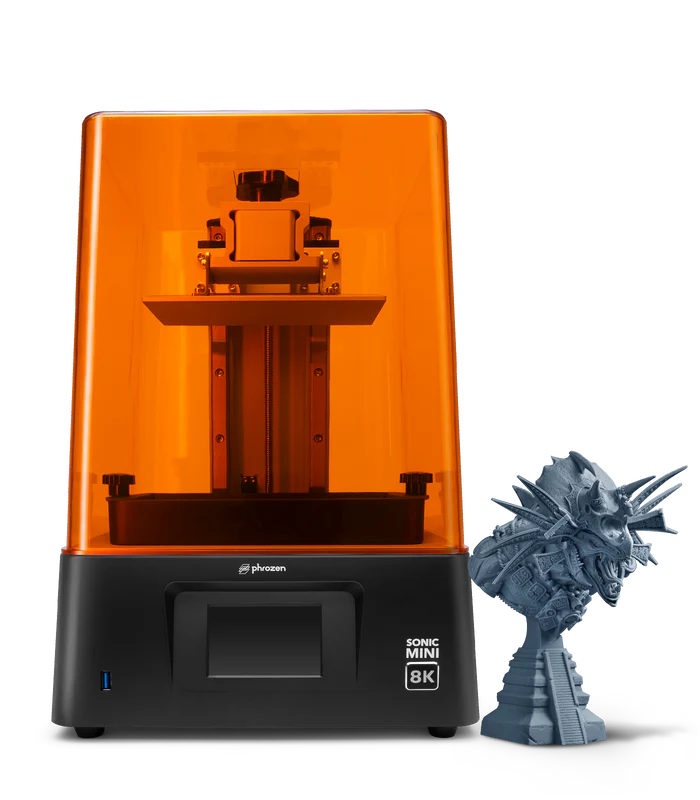

Phrozen Sonic Mini 8K

Overview The Phrozen Sonic Mini 8K is known for its ultra-high resolution and speed, making it a favorite among miniature enthusiasts and professionals. It offers a compact design with impressive capabilities.

Key Features:

- 7-inch 8K monochrome LCD screen (7500 x 3240 pixels)

- Build volume: 165 x 72 x 180 mm

- Printing speed: Up to 80 mm/h

- Dual linear rails for stability

Pros:

- Extremely high resolution for detailed prints.

- Fast printing speeds ideal for miniatures.

- Compact design with a user-friendly interface.

Cons:

- Smaller build volume compared to some competitors.

- Limited material compatibility.

Comparison Table

| Feature | Anycubic Photon Mono 2 | Elegoo Mars 5 Ultra | Phrozen Sonic Mini 8K |

| Screen Resolution | 4K+ (4096 x 2560) | 9K (3840 x 2400) | 8K (7500 x 3240) |

| Build Volume (mm) | 130 x 80 x 165 | 218 x 123 x 235 | 165 x 72 x 180 |

| Printing Speed (mm/h) | Up to 60 | Up to 150 | Up to 80 |

| Price | Approximately $250 | Approximately $270 | Approximately $349 |

| Pros | High detail, fast speed | Exceptional quality, auto-leveling | Ultra-high resolution, compact |

| Cons | Limited build volume | Higher price point | Smaller build volume |

Each of these printers offers unique features and capabilities, making them suitable for different users and applications. The Anycubic Photon Mono 2 is great for beginners, the Elegoo Mars 5 Ultra excels in speed and quality, while the Phrozen Sonic Mini 8K is perfect for those needing ultra-high resolution for detailed prints. Your choice will depend on your specific needs, budget, and printing requirements.

Practical Tips and Considerations for Using DLP 3D Printers

Embarking on your 3D printing journey with a DLP printer brings a blend of excitement and challenge, particularly for beginners. To ensure a smooth and

rewarding experience, here are essential tips and considerations that can help you get the most out of your DLP 3D printer.

Understanding the Importance of Resin Handling

Safe Resin Handling:

- Wear Protective Gear: Always wear gloves and protective eyewear when handling resin. Resin can be toxic and cause skin irritation.

- Proper Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Spill Management: Be prepared with paper towels and isopropyl alcohol to clean up any spills quickly and safely.

Choosing the Right Resin:

- Type of Resin: Different projects require different types of resins. Standard resins are good for general use, while specialized resins like castable or flexible types serve specific applications.

- Color Matters: The color of the resin can affect the details of your prints. Lighter colors often show more detail and are easier to post-process.

Calibration and Maintenance

Keep Your Printer Calibrated:

- Regular Calibration: Check and calibrate your printer regularly to ensure accuracy. Misalignment can lead to print failures.

- Z-axis Calibration: Pay particular attention to the Z-axis calibration as it is crucial for layer precision.

Maintaining Your Printer:

- Clean Regularly: Keep the resin tank and build plate clean. Resin leftovers can cause future prints to fail or adhere incorrectly.

- Update Firmware: Ensure your printer’s firmware is up-to-date to take advantage of the latest improvements and fixes.

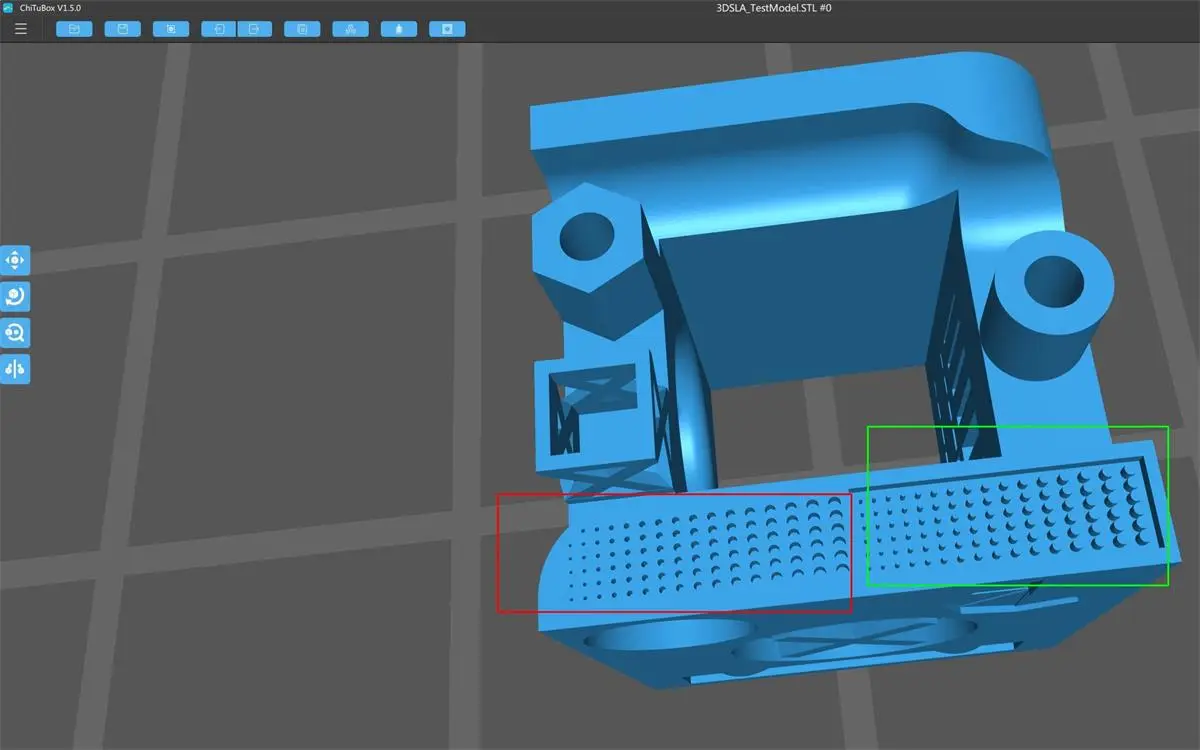

Slicing Software Mastery

Choosing Slicing Software:

- Compatibility: Make sure the slicing software is compatible with your DLP printer. Some printers come with proprietary software, while others might be compatible with third-party options.

- Features: Look for software that offers detailed support customization, layer height adjustment, and interactive previews.

Most Pop Slicing Software:

1. CHITUBOX

Overview: CHITUBOX is a widely used slicing software optimized for SLA, DLP, and LCD 3D printing. It is known for its user-friendly interface and powerful features, making it suitable for both beginners and professionals.

- Key Features:

- Fast slicing speed

- Intelligent support generation

- Model editing tools

- Compatibility with various resin printers

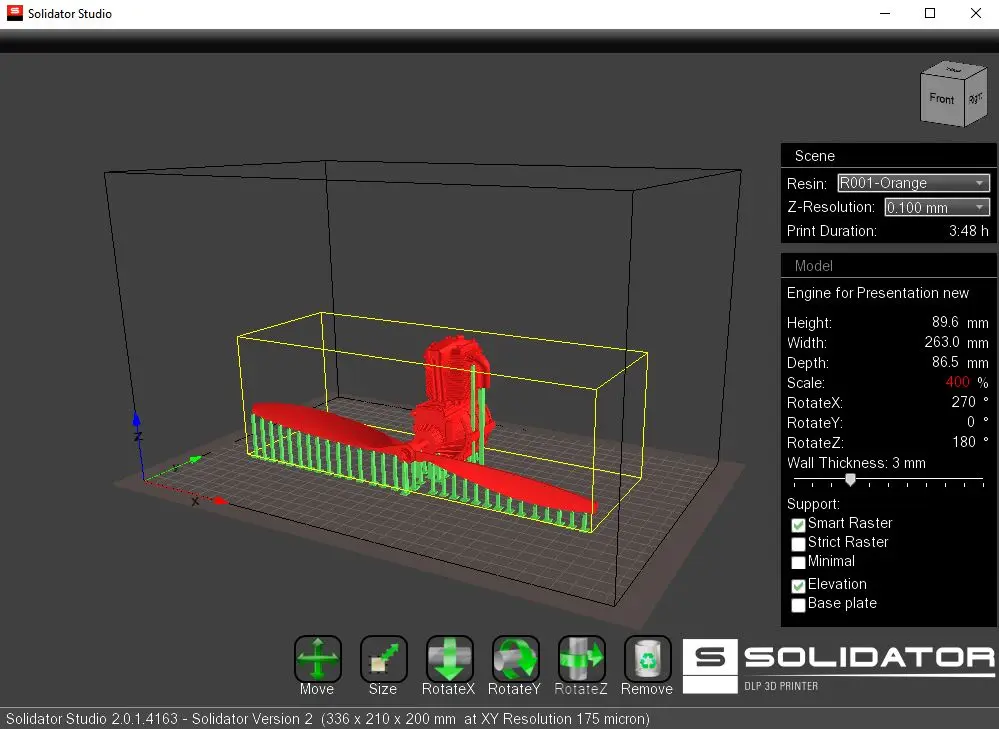

2. Lychee Slicer

Overview: Lychee Slicer is a modern slicer developed by Mango3D, designed for LCD and DLP printers. It offers a clean interface and advanced features for efficient slicing.

- Key Features:

- Intuitive user interface

- Advanced support generation

- Multi-model slicing capabilities

- Free version available with a Pro upgrade option

3. Photon Workshop

Overview: Photon Workshop is a free slicing software developed by Anycubic specifically for their Photon series of printers. It is designed to provide a straightforward slicing experience.

- Key Features:

- Simple interface for easy navigation

- Supports multiple file formats

- Basic support generation tools

Optimizing Print Settings:

- Layer Height: Smaller layer heights can produce finer details but increase print time.

- Supports: Learn to properly place supports to prevent print failures, especially for complex models.

Post-Processing Techniques

Cleaning and Curing:

- Cleaning: Wash your printed parts in isopropyl alcohol or a specialized cleaning solution to remove uncured resin.

- UV Curing: Cure your prints under UV light to achieve the final hardness and stability.

Finishing Touches:

- Sanding: Sand the surfaces gently if necessary to eliminate layer lines.

- Painting: If desired, you can paint your models to add color or enhance details.

Troubleshooting Common Issues

Common Problems and Solutions:

- Prints Not Adhering: Check the build plate alignment and re-level if necessary. Consider increasing the base layer cure time.

- Incomplete Prints: Ensure your resin tank isn’t low and that the projector’s light path is unobstructed.

- Rough Surfaces: Adjust the exposure settings, particularly for the early layers, to ensure proper curing.

Mastering the use of a DLP 3D printer involves not only learning how to print but also understanding the materials, maintaining the equipment, and refining the post-processing techniques. By adhering to these practical tips and considerations, you will enhance your printing success rate, ensure the longevity of your printer, and most importantly, enjoy the creative process. Ready to turn your digital designs into reality? Your DLP 3D printer is a gateway to endless possibilities.

Common Questions Answered: DLP 3D Printing for Beginners

When starting out with DLP 3D printing, it’s natural to have many questions about the technology, the process, and how to achieve the best results. Here we address some of the most common queries that beginners often have, providing clear and concise answers to help you feel more confident as you embark on your 3D printing journey.

1. What is the difference between DLP and SLA 3D printing? Answer: DLP (Digital Light Processing) and SLA (Stereolithography) are both resin-based 3D printing technologies, but they differ mainly in how the resin is cured. SLA uses a laser to trace and harden each layer of resin, making it very precise but somewhat slow. In contrast, DLP uses a digital projector that exposes an entire layer of resin to light at once, significantly speeding up the printing process. DLP tends to be faster and more efficient, especially for larger objects, whereas SLA can achieve slightly finer details.

2. How long does it take to print with a DLP printer? Answer: The print time on a DLP printer depends on several factors, including the size and complexity of the model, the height of each layer, and the settings used. A small and simple object can take just a few hours to print, while more complex or larger items can take overnight or longer. The advantage of DLP over other technologies is its ability to cure entire layers simultaneously, which generally makes it faster than SLA and FDM (Fused Deposition Modeling) printers for most tasks.

3. What materials can I use with a DLP 3D printer? Answer: DLP printers use photopolymer resins, which are available in various formulations to suit different applications. Standard resins are commonly used for general printing, but there are also specialized resins such as flexible, castable, durable, and high-temperature resins, each providing unique properties that are beneficial for specific applications.

4. Are DLP printers suitable for creating functional parts? Answer: Yes, DLP printers can create functional parts, especially when using specific resins designed for mechanical properties such as durability or flexibility. However, it’s important to consider the limitations of resin-based parts in terms of strength and temperature resistance compared to materials like metals or thermoplastic filaments used in FDM printers.

5. What are the maintenance requirements for a DLP printer? Answer: Maintaining a DLP printer involves regular cleaning, ensuring the resin tank is clear of debris, and the build plate is correctly calibrated. The resin tank itself may need replacing periodically, as the clear bottom can become clouded over time, affecting print quality. Firmware updates and mechanical checks should also be performed regularly to keep the printer running smoothly.

6. How do I dispose of used resin and cleaning solvents? Answer: Resin and solvents should be disposed of according to local regulations, as they can be hazardous to the environment. Never pour uncured resin or solvents down the drain. Instead, cure any remaining resin by exposing it to sunlight or UV light and then dispose of it as solid waste. Used solvents can often be filtered and reused several times before disposal.

Understanding these fundamentals will help alleviate some of the uncertainty that comes with starting DLP 3D printing. With this knowledge, beginners can more confidently select and operate their DLP 3D printers, ensuring both successful prints and a safe, enjoyable experience in the world of additive manufacturing. Keep these answers in mind as you explore the capabilities and potential of your DLP 3D printer.