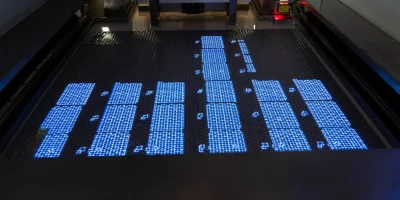

The technological development of SLA 3D printing is a technological change that subverts the traditional production logic. Change the traditional subtractive manufacturing of cutting, grinding and engraving materials , and adopt the “bottom-up” material superposition and lamination integrated additive manufacturing. From raw materials to finished products, SLA 3D printing technology eliminates the manufacturing process for raw materials, and can manufacture very complex and fine structures. The SLA series 3D printers developed and produced by Zongheng 3D can quickly help various industries shorten the product development cycle and accelerate the speed of new products to market.

![]()

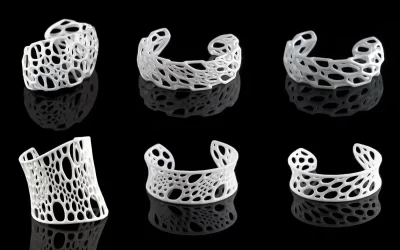

Especially for the jewelry industry, the use of the series of SLA 3D printers developed and produced by our company can get rid of the traditional planning processing and time constraints such as plate-making, gluing molds, and glue-opening molds. Import the designed conceptual product model into the printer to get a complete physical model within a few hours. After confirmation, it can be sent to the manufacturer for production, which greatly speeds up the new product iteration efficiency and increases the brand’s competitive advantage.

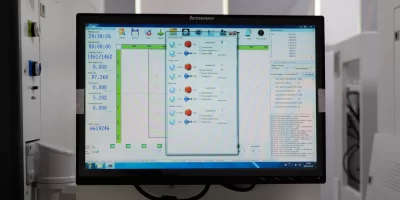

The core laser scanning components of our series of SLA 3D printers use galvanometers imported from Germany. The lasers are independently developed by our company with specific wavelengths. The large-format equipment has variable spot technology. The scanning speed reaches 6000mm/s to 10000mm/s, and the printing accuracy is 0.05 to 02mm range, and the printing process is stable, and the finished-product rate is over 98%. It can print a complete high-precision concept jewelry entity within a few hours, reshape the data model on the computer, and provide technical support for printing concept jewelry model samples. Using technical methods to help jewelry designers to achieve creative freedom without the concerns of sample processing, the real WYSIWYG.

At the same time, SLA 3D printing technology eliminates the traditional process, which provides a good opportunity for the jewelry industry to achieve personalization and customization. Consumers can directly participate in the design and implementation of jewelry models in the early stage, independently transform creativity into physical models, and give unique meanings and connotations to the models. Immersive experiences increase consumers’ trust and goodwill towards brands. Even a one-to-one customized business model can be established to achieve precise marketing.

The development of SLA 3D printing technology has greatly shortened the sample development cycle of the jewelry industry and provided an opportunity for a new business development model. Zongheng 3D has been committed to researching SLA 3D printing technology for many years, constantly developing and iterating new SLA 3D printing prototypes, from pre-production manufacturing to post-terminal sales, helping more jewelry companies to complete the manufacturing transformation of new product design and development. At the same time, it provides a new way of thinking for the future large-scale production and personalized customization service .