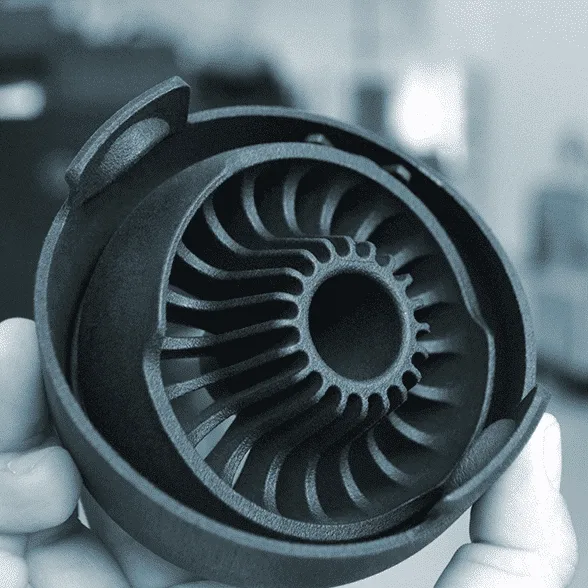

Create intricate designs that traditional manufacturing cannot achieve.

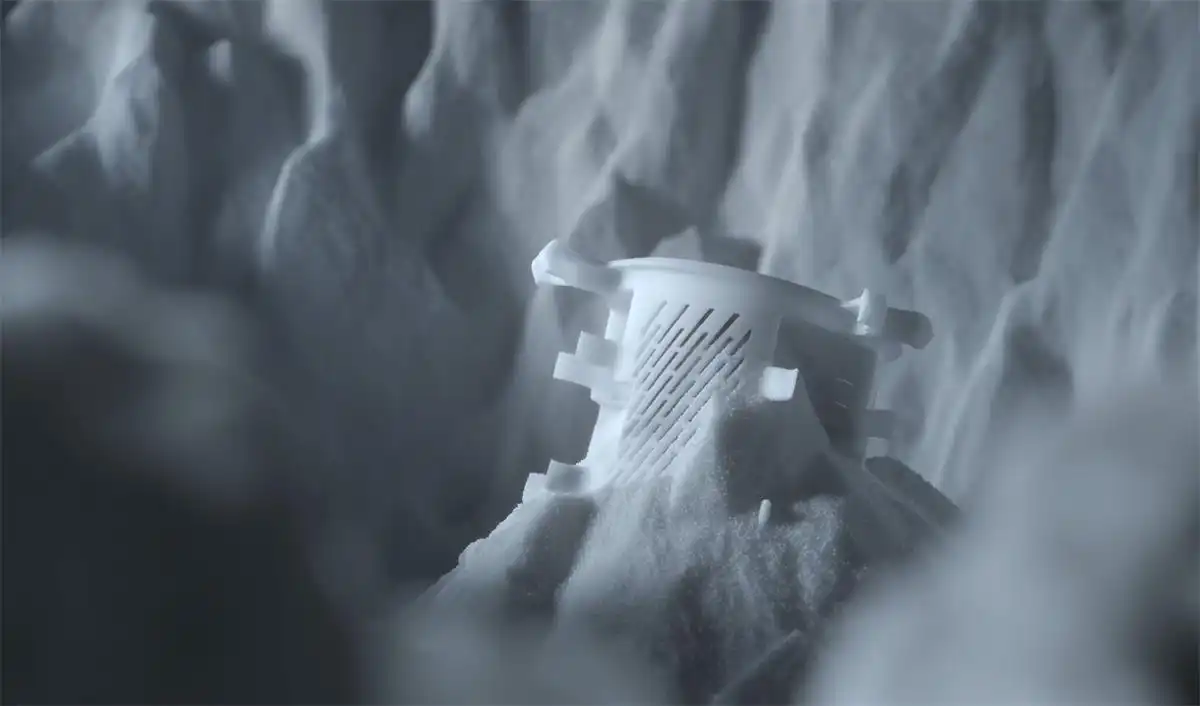

Minimize waste by using only the necessary material for each part.

Accelerate product development cycles with fast iterations and testing.

Manufacture robust components that can be used directly in aircraft.

SLS 3D printing delivers precise, customized aerospace components, transforming manufacturing.

SLS 3D printing accelerates aerospace prototyping, enabling faster market-ready designs.

Selective Laser Sintering (SLS) 3D printing is increasingly becoming a cornerstone technology in the aerospace industry. Its ability to produce lightweight, complex, and durable components aligns perfectly with the demands of modern aerospace engineering.

Explore how SLS 3D printing streamlines the production process by reducing lead times, minimizing errors, and optimizing resource use. This technology ensures high precision and accuracy, leading to fewer manufacturing defects and improved overall efficiency.

See how SLS 3D printing is driving innovation in the aerospace industry by enabling the development of advanced aerospace designs. These innovative designs improve performance, durability, and safety.

Understand the role of SLS 3D printing in personalized aerospace components. This technology allows for the creation of customized parts that cater to specific needs and requirements, revolutionizing the way aerospace components are designed and manufactured.

Discover how SLS 3D printing is enhancing research and development in the aerospace industry. With faster and more accurate prototyping, this technology accelerates aerospace innovations and brings them to market more quickly.

Discover the advantages of SLA 3D printing today.