Revolutionizing Automotive Manufacturing with Industrial SLA 3D Printing

At ZONGHEGN3D, we’re not just creating 3D printers; we’re redefining the landscape of automotive manufacturing. Our SLA 3D printing technology stands at the forefront of innovation in the industry, offering unparalleled precision and reliability. From intricate components to sophisticated prototypes, our solutions empower you to accelerate innovation, reduce costs, and enhance product quality. Dive into our technology and embark on a new era of automotive manufacturing

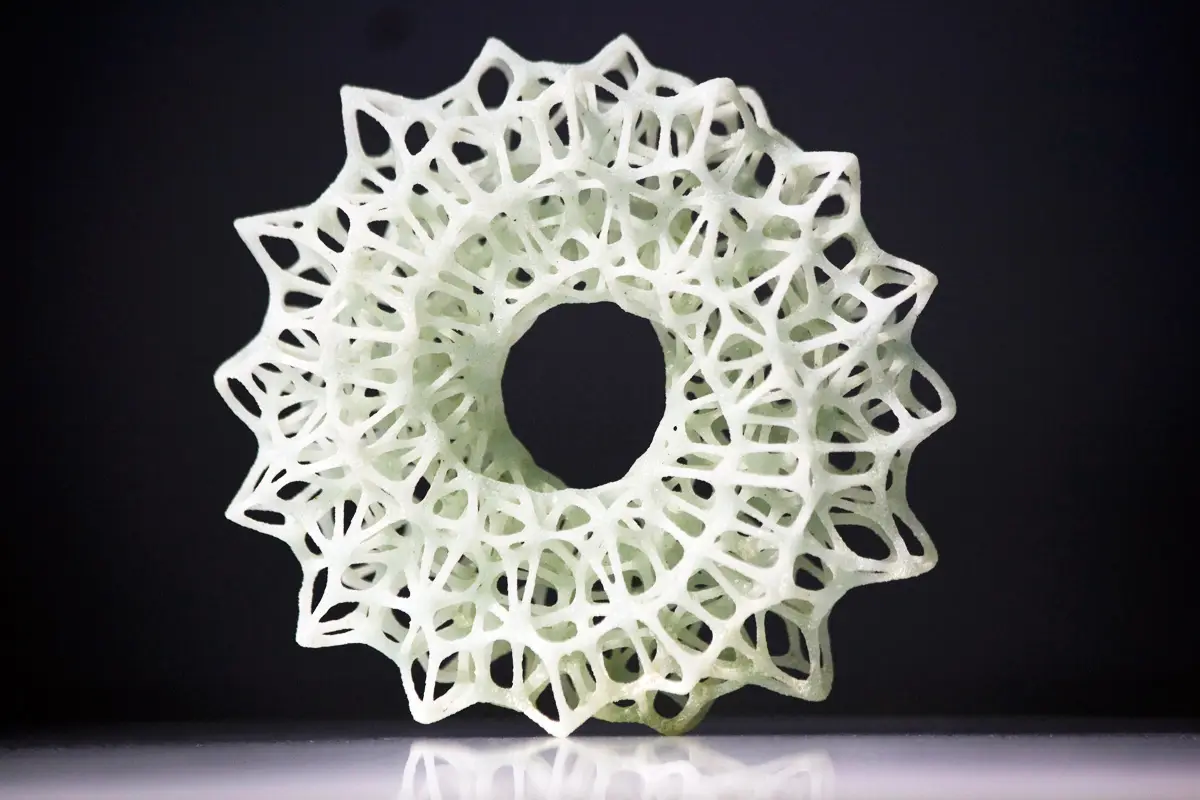

Industrial SLA 3D printing is at the forefront of innovation in the automotive industry, offering unparalleled precision and durability. This cutting-edge technology utilizes light-curing resin to create complex parts and prototypes with exceptional accuracy, opening up new possibilities for vehicle design and production.

Achieve intricate geometries and fine details with high-resolution prints.

Create strong, functional parts suitable for both testing and final products.

Easily adapt to small-batch production or large-scale manufacturing needs.

Uncategorized

Uncategorized

Discover the Future of Car Design and Production

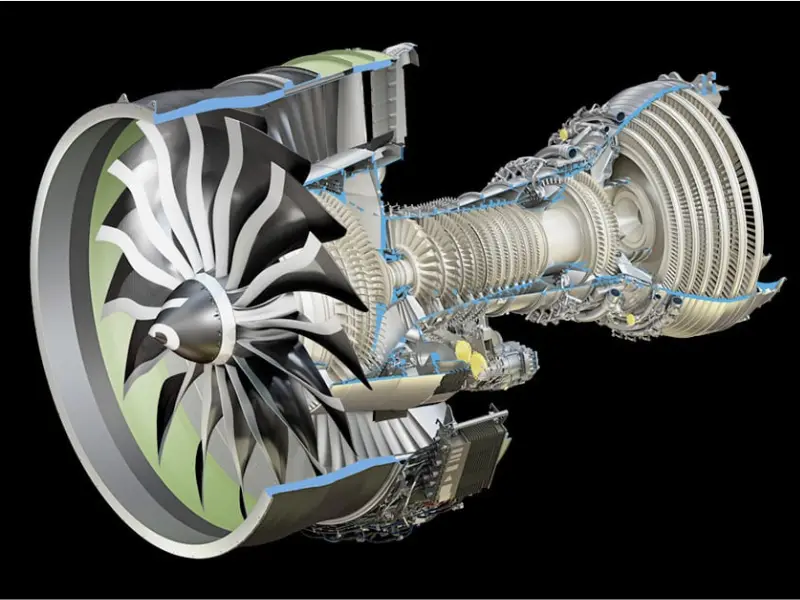

Explore how Selective Laser Sintering (SLS) 3D printing is transforming the automotive industry. From rapid prototyping to on-demand production, learn how this cutting-edge technology is driving innovation, enhancing efficiency, and enabling unprecedented customization in car manufacturing.

With SLS 3D printing, manufacturers can produce customized car parts tailored to specific customer requirements. This includes everything from personalized interior components to unique exterior designs, offering a level of customization that was previously unattainable.

While the initial setup costs for SLS 3D printing can be high, the technology offers significant long-term cost savings. By eliminating the need for tooling and reducing material waste, SLS 3D printing lowers overall manufacturing costs, especially for low-volume or specialized parts.

Additive manufacturing reduces reliance on traditional supply chains by enabling on-demand production closer to the point of use. This flexibility minimizes lead times, inventory costs, and supply chain risks, making the entire manufacturing process more resilient and responsive.

SLS 3D printing enables on-demand production of small batches or customized components without the need for costly molds or tooling. This shift from mass production to on-demand manufacturing allows for greater flexibility and responsiveness to market trends and consumer demands.

By enabling on-site production of spare and wear parts, SLS 3D printing reduces inventory costs and minimizes downtime. This streamlined approach to maintenance ensures that parts are available just in time when needed, enhancing overall operational efficiency.

The precision of SLS 3D printing offers a high degree of design freedom, allowing automotive designers to push the boundaries of creativity. From sleek concept vehicles to intricate interior components, this technology enables the production of advanced and lightweight structures once thought impossible.