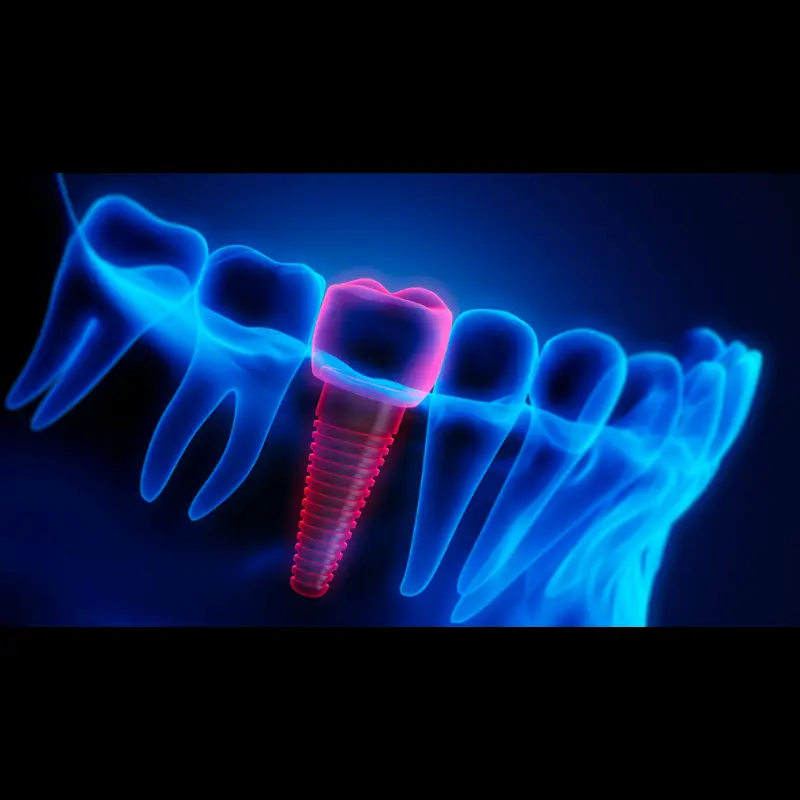

In the dental industry, top-down DLP 3D printing is used to create a variety of dental appliances, including crowns, bridges, dentures, and orthodontic aligners. The technology’s ability to produce highly accurate and customized models makes it a game-changer for dental professionals.

Create precise dental models for aligners and retainers

Produce patient-specific restorations with superior fit and finish

Print custom guides for implant procedures with exact placement accuracy.

Craft full dentures and removable prosthetics faster and more affordably

Traditional methods of creating dental prosthetics are time-consuming and often result in less precise fits. Top-down DLP 3D printing addresses these pain points by offering faster turnaround times, reduced material waste, and highly accurate results. This leads to improved patient satisfaction and more efficient dental practices.

The adoption of top-down DLP 3D printing has brought significant improvements to the dental industry. The technology’s speed and precision reduce the need for multiple adjustments, saving time and resources. Additionally, the ability to produce customized appliances quickly enhances production efficiency, allowing dental labs to handle more cases in less time.

Top-down DLP 3D printing is transforming the dental industry by setting new standards for dental prosthetics and orthodontic appliances. The technology’s benefits, including precision, speed, and cost-efficiency, are attracting more dental practices to adopt it, leading to better care for patients and growth for the industry.

DLP 3D Printing