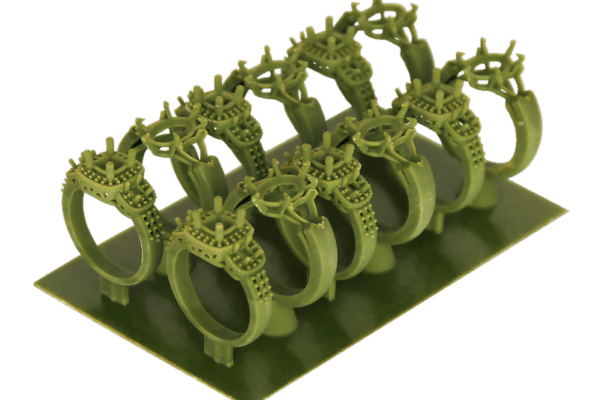

Experience the precision and detail of DLP 3D printing as it creates customized jewelry pieces tailored to individual preferences. From intricate designs to personalized accessories, this technology is redefining jewelry manufacturing.

Witness the speed and efficiency of DLP 3D printing in rapid prototyping. This technology enables quick turnaround times for prototypes and final products, ensuring that innovative jewelry designs reach the market faster than ever before.

DLP 3D printing is an advanced technology that uses digital light projection to cure liquid resins layer by layer, creating highly detailed and precise jewelry designs. This innovative process allows jewelers to produce complex geometries, intricate patterns, and custom pieces with exceptional accuracy and speed. By leveraging DLP 3D printing, jewelry designers can push the boundaries of creativity and meet the unique demands of their customers.

Discover how DLP 3D printing addresses the pain points of traditional jewelry manufacturing by offering intricate design capabilities. This precision ensures that even the most complex designs can be realized with ease.

Learn how DLP 3D printing minimizes material waste and reduces production times, making it a cost-effective solution for jewelry manufacturing. This efficiency translates to lower operational costs and improved resource use.

Streamlined Production Process

Explore how DLP 3D printing streamlines the production process by reducing lead times, minimizing errors, and optimizing resource use. This technology ensures high precision and accuracy, leading to fewer manufacturing defects and improved overall efficiency.

Ready to transform your medical practice with SLA 3D printing? Dive into our comprehensive case study page to learn more about the applications, benefits, and success stories of this revolutionary technology. Take the first step towards medical innovation and improved patient care.