Traditional manufacturing methods often fall short in addressing the unique needs of medical applications. SLA 3D printing tackles these pain points head-on:

SLA 3D printing brings numerous improvements to the medical industry, enhancing both production efficiency and the quality of medical devices:

Explore real-world case studies and success stories that highlight the impact of SLA 3D printing in the medical industry

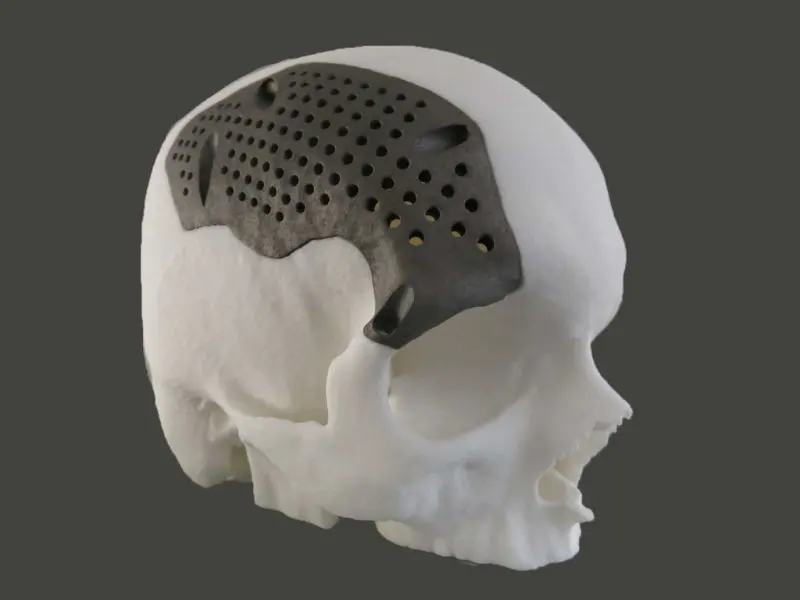

Learn how SLA 3D printing is used to create custom implants that perfectly fit individual patients, improving comfort and functionality.

Discover how SLA 3D printing enables the production of precise surgical tools, enhancing the accuracy and efficiency of medical procedures.

See how SLA 3D printed anatomical models are used for training, education, and research, advancing medical knowledge and practice.

SLA 3D Printing

Ready to transform your medical practice with SLA 3D printing? Dive into our comprehensive case study page to learn more about the applications, benefits, and success stories of this revolutionary technology. Take the first step towards medical innovation and improved patient care.