The Ultimate Guide to Finding the Best Resin 3D Printers for Highly Detailed Models: Reviews of Top Choices for Hobbyists and Professionals

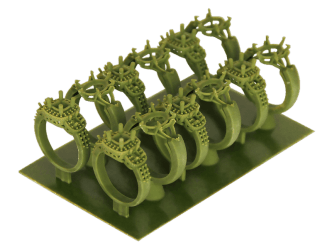

Welcome to our comprehensive guide on the best resin 3D printers! If you’re looking to dive into the exciting world of 3D printing, resin printers are a fantastic choice. With their ability to create highly detailed and precise models, resin 3D printers are perfect for a wide range of applications, from gaming and prototyping to jewelry making and component manufacturing.

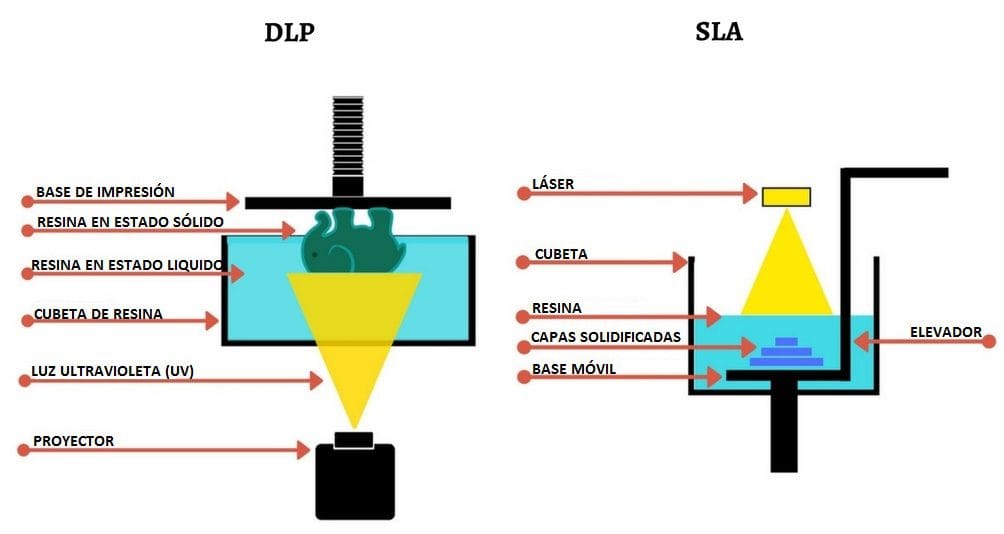

In this guide, we’ll explore the differences between resin 3D printing and filament 3D printing, and why resin printers excel in terms of precision and detail. We’ll also provide recommendations for the best resin 3D printers on the market, taking into account factors such as print volume, resolution, speed, and overall value.But before we dive into the recommendations, it’s important to understand what resin 3D printing is and how it differs from traditional filament-based 3D printing. Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), uses a liquid resin that is cured by a light source, typically a UV laser or LCD screen. This process allows for incredibly fine details and smooth surfaces, making resin printers ideal for creating intricate models and prototypes.

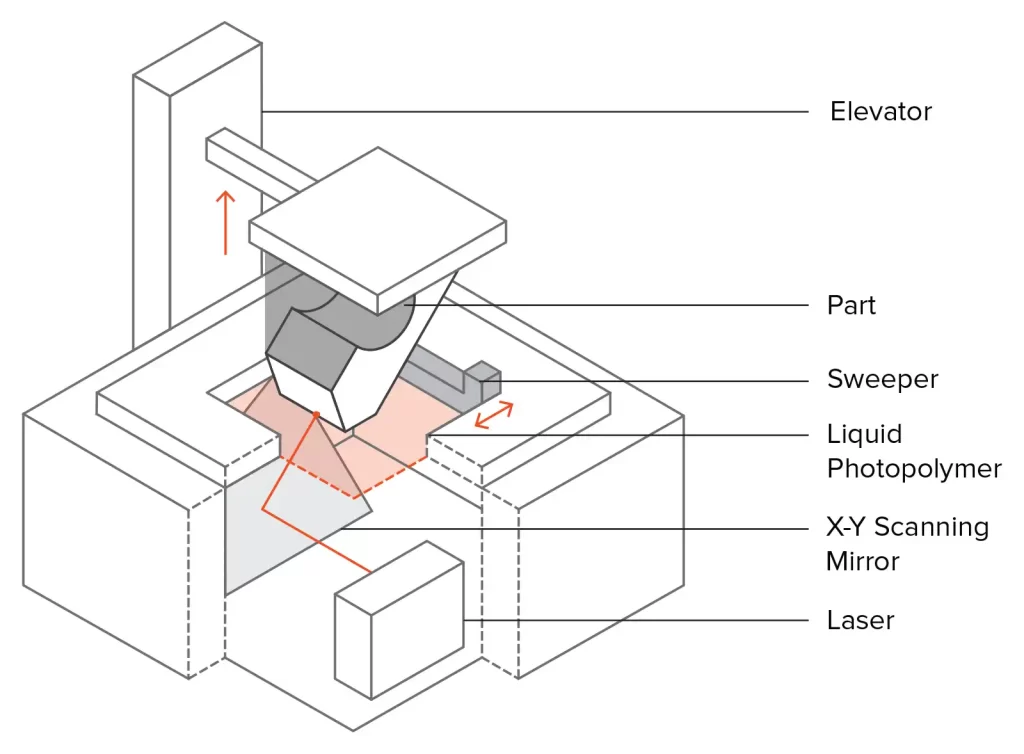

But before we dive into the recommendations, it’s important to understand what resin 3D printing is and how it differs from traditional filament-based 3D printing. Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), uses a liquid resin that is cured by a light source, typically a UV laser or LCD screen. This process allows for incredibly fine details and smooth surfaces, making resin printers ideal for creating intricate models and prototypes.

Compared to filament-based 3D printers, resin printers offer superior precision and detail, making them the preferred choice for applications that require high-quality finishes. However, it’s worth noting that resin printers generally have smaller build volumes compared to filament printers, which can limit the size of the objects you can create.In this guide, we’ll help you navigate the wide range of resin 3D printers available on the market by providing detailed reviews and recommendations. We’ll also discuss important factors to consider when choosing a resin printer, such as print volume, resolution, setup and use, value for money, and compatibility with different resins. Whether you’re a hobbyist looking to create stunning gaming miniatures or a small business in need of precise prototypes, this guide will help you find the best resin 3D printer to suit your needs. So, let’s dive in and explore the fascinating world of resin 3D printing!

What Is Resin 3D Printing?

Resin 3D printing is a revolutionary technology that has transformed the world of 3D printing. Unlike traditional filament-based 3D printing, resin 3D printing utilizes a liquid photopolymer resin that is cured layer by layer using ultraviolet (UV) light. This process, also known as vat photopolymerization, allows for the creation of highly detailed and precise objects with smooth surfaces.

In resin 3D printing, a build platform is submerged in a vat of liquid resin. A high-resolution LCD screen or a digital micromirror device (DMD) projects UV light onto the resin, causing it to solidify and adhere to the build platform. The build platform is then raised, and the process is repeated for each layer until the object is complete.

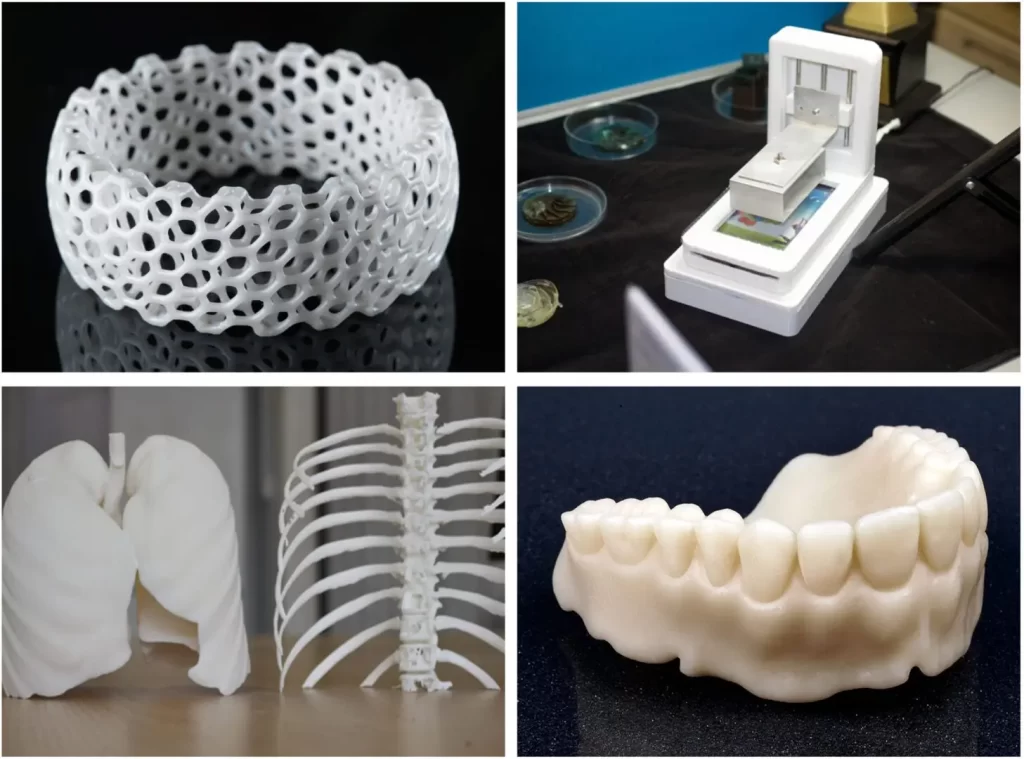

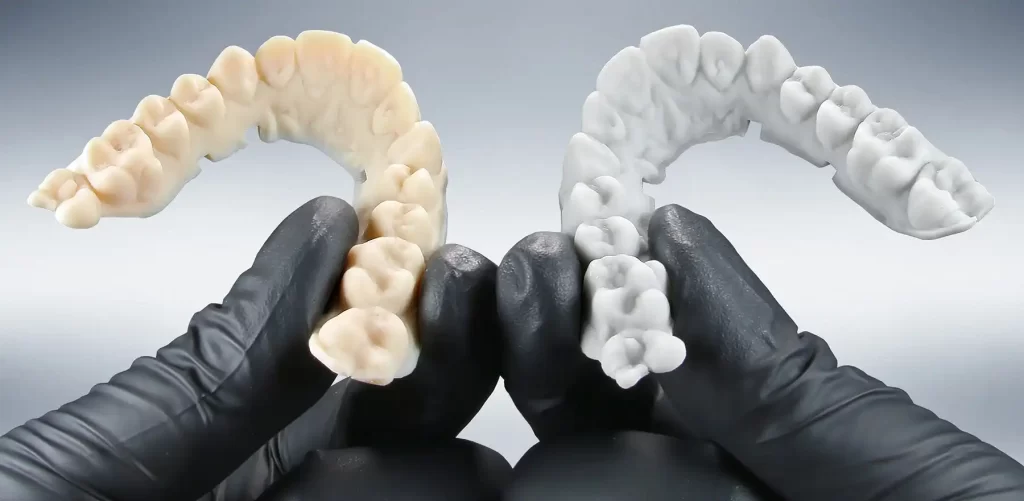

The use of liquid resin in resin 3D printing allows for the creation of complex geometries and intricate details that are difficult to achieve with other 3D printing technologies. The UV light cures the resin with high precision, resulting in smooth surfaces and fine details. This makes resin 3D printing ideal for applications that require high levels of accuracy and detail, such as jewelry making, dental models, and prototyping.

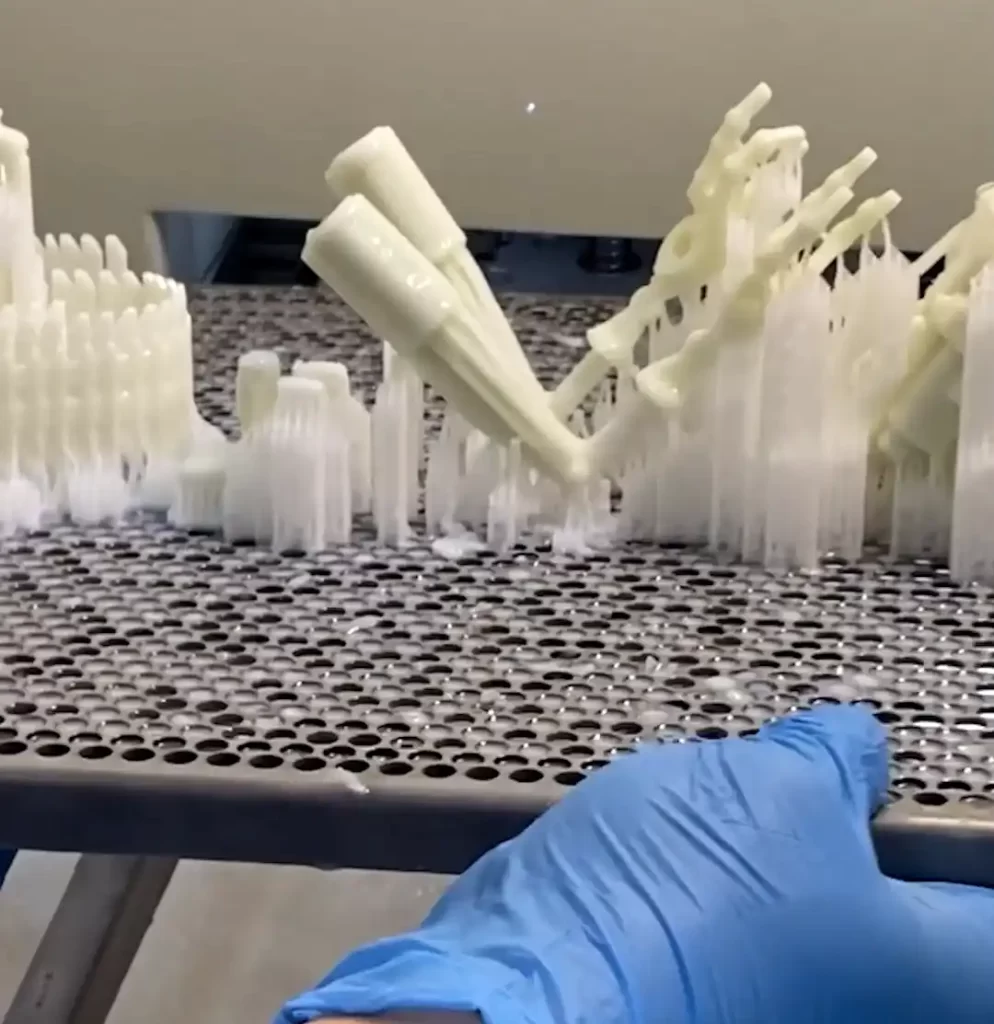

One of the key advantages of resin 3D printing is its ability to produce objects with a wide range of material properties. Resin materials can be formulated to have different mechanical, thermal, and chemical properties, allowing for the creation of functional prototypes and end-use parts. For example, there are resins that are flexible and rubber-like, resins that are heat resistant, and even resins that mimic the look and feel of ceramics or metals.However, it’s important to note that resin 3D printing does have some limitations. The cost of resin materials can be higher compared to filament-based 3D printing, and the process can be messier and more time-consuming due to the need for post-processing, such as washing and curing the printed objects. Additionally, the use of liquid resin and UV light may require additional safety precautions, such as wearing gloves and protective eyewear.Despite these limitations, resin 3D printing has opened up new possibilities in the world of manufacturing, design, and prototyping. Its ability to produce highly detailed and accurate objects has made it a popular choice among professionals and hobbyists alike. With advancements in technology and the availability of a wide range of resin materials, resin 3D printing continues to push the boundaries of what is possible in the world of 3D printing.

Resin 3D Printing vs. 3D Printing with Filaments

When it comes to 3D printing, there are two main technologies to choose from: resin 3D printing and filament 3D printing. Both have their own unique advantages and applications, making it important to understand the differences between the two.

Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), uses liquid resin that is cured by a light source to create objects layer by layer. This technology allows for incredibly detailed and precise prints, making it ideal for applications that require high levels of accuracy and fine details. Resin 3D printers can produce smooth, high-resolution models with intricate designs, making them a popular choice for jewelry making, prototyping, and small-scale production.

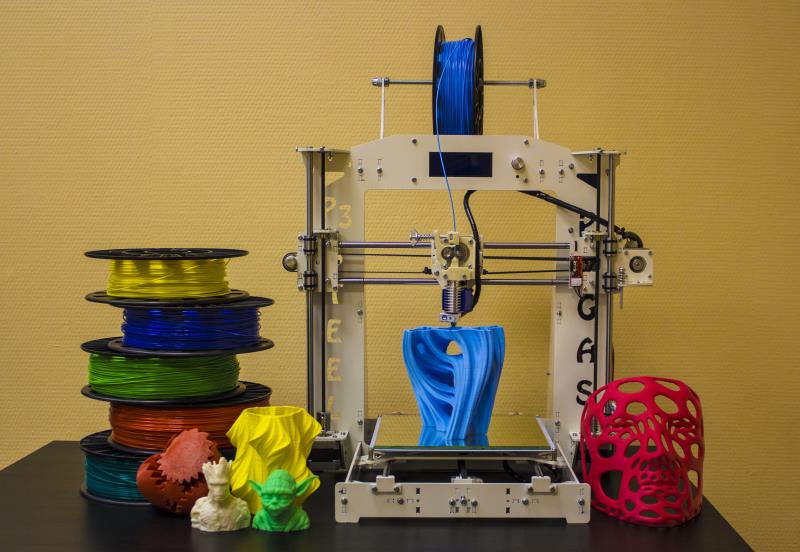

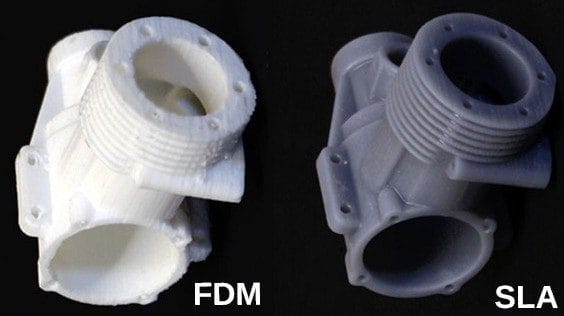

On the other hand, filament 3D printing, also known as fused deposition modeling (FDM), uses a spool of solid plastic filament that is melted and extruded through a nozzle to create objects layer by layer. This technology is more commonly used and more accessible to beginners, as filament printers are generally more affordable and easier to operate. Filament 3D printers are known for their versatility, as they can print with a wide range of materials, including PLA, ABS, PETG, and more. This makes them suitable for a variety of applications, from rapid prototyping to functional parts production.

When it comes to print quality, resin 3D printing has the upper hand. The liquid resin used in resin printers allows for smoother surfaces and finer details, resulting in higher-resolution prints compared to filament printers. However, resin prints may require additional post-processing steps, such as washing and curing, to remove excess resin and achieve the desired final finish. In terms of speed, filament 3D printers are generally faster than resin printers. Filament printers can produce larger prints at a faster rate, while resin printers excel in producing small, highly detailed models. The choice between speed and detail depends on the specific requirements of your project. Another important factor to consider is cost. Resin 3D printers tend to be more expensive upfront, with higher costs for the printer itself and the resin materials. Filament printers, on the other hand, have a lower initial cost and a wider range of affordable filament options. In summary, resin 3D printing and filament 3D printing each have their own strengths and applications. Resin printers offer exceptional detail and precision, making them ideal for intricate designs and small-scale production. Filament printers, on the other hand, are more versatile and cost-effective, making them suitable for a wide range of applications. Ultimately, the choice between resin and filament printing depends on your specific needs and budget.

Resin 3D Printing vs. PLA

When it comes to 3D printing, there are two main technologies to choose from: resin 3D printing and printing with filaments, such as PLA. Each technology has its own advantages and considerations, so it’s important to understand the differences before making a decision. Resin 3D printing, also known as stereolithography (SLA) or digital light processing (DLP), uses a liquid resin that is cured layer by layer using UV light. This technology offers exceptional detail and precision, making it ideal for intricate and complex designs. The final prints have a smooth and polished finish, which is perfect for applications like jewelry, miniatures, and dental models.

On the other hand, printing with filaments, such as PLA (polylactic acid), is the most common form of 3D printing. Filament printers use a heated nozzle to melt and extrude plastic filament, which is then layered to create the final object. This technology is more affordable and accessible, making it popular among hobbyists and beginners. Filament printers are great for larger objects and functional prototypes, but they may not achieve the same level of detail as resin printers.

When it comes to print quality, resin 3D printing is the clear winner. The layer height in resin printing can be as low as 25 microns, resulting in incredibly detailed prints with smooth surfaces. Filament printers, on the other hand, typically have a layer height of around 100 microns, which may result in visible layer lines and less precise details.

Another important consideration is material availability. Filament printers have a wide range of materials to choose from, including PLA, ABS, PETG, and more. Resin printers, on the other hand, are limited to specific types of resins designed for the printing process. However, resin materials are constantly improving, and there are now resins available with different properties, such as flexible, high temperature resistant, and biocompatible. In terms of post-processing, filament prints are generally easier to work with. They can be sanded, painted, and glued just like any other plastic object. Resin prints, on the other hand, require additional steps like washing and curing to remove excess resin and achieve the desired hardness. In conclusion, resin 3D printing offers superior detail and precision, making it ideal for applications that require high-quality prints. Filament printing, on the other hand, is more affordable and versatile, making it a great choice for larger objects and functional prototypes. Ultimately, the choice between resin and filament printing depends on your specific needs and budget.

Best Resin 3D Printers

When it comes to resin 3D printers, there are several options available on the market. In this section, we will explore some of the best resin 3D printers that offer high-quality prints and advanced features.

Nexa3D XiP

The Nexa3D XiP is a professional-grade resin 3D printer that offers ultra-fast printing speeds and a large build volume. With its patented Lubricant Sublayer Photocuring (LSPc®) technology, the XiP delivers high-quality prototypes and final-use parts with exceptional accuracy.

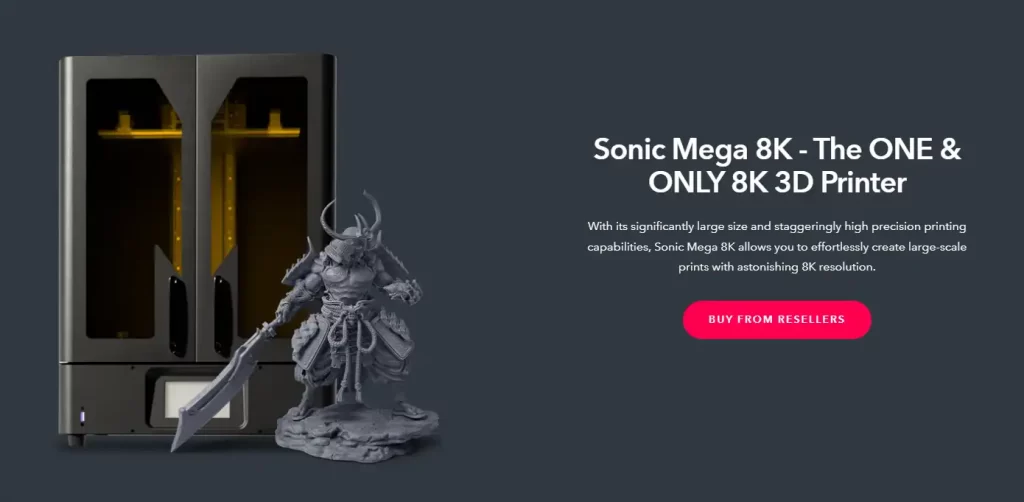

Phrozen Sonic Mega 8K

The Phrozen Sonic Mega 8K is a professional-grade resin 3D printer that provides incredible detail and precision. With its 8K LCD screen, this printer can produce highly detailed models and miniatures with ease.

Creality Halot-One Plus

The Creality Halot-One Plus is an industrial-grade resin 3D printer that offers a large build volume and high-resolution prints. With its 4K LCD screen and advanced features, this printer is perfect for large-scale industrial 3D prints and end-use production parts.

Elegoo Saturn

The Elegoo Saturn is a desktop resin 3D printer that provides a large build volume and fast print speed. With its 8.9-inch 4K mono display, this printer can produce mid-sized to large prototypes with high accuracy and detail.

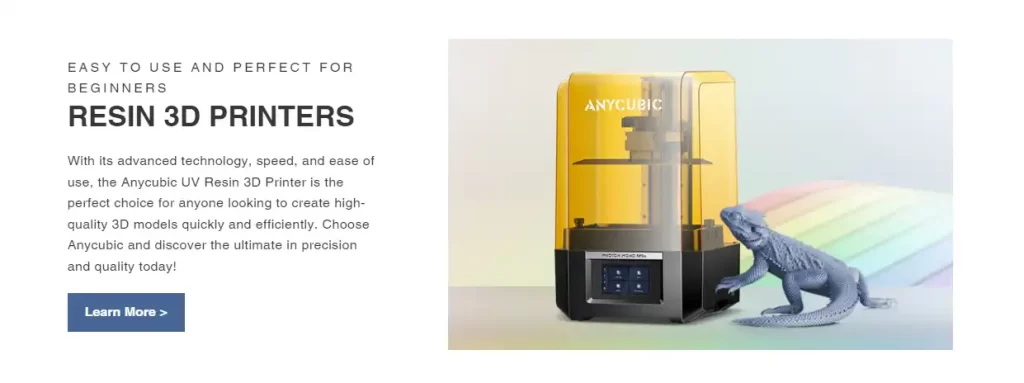

Anycubic Photon M3 Plus

The Anycubic Photon M3 Plus is a desktop resin 3D printer that offers quick print times and a large build plate size. With its 4K LCD resolution and open material platform, this printer provides versatility and high-quality prints.

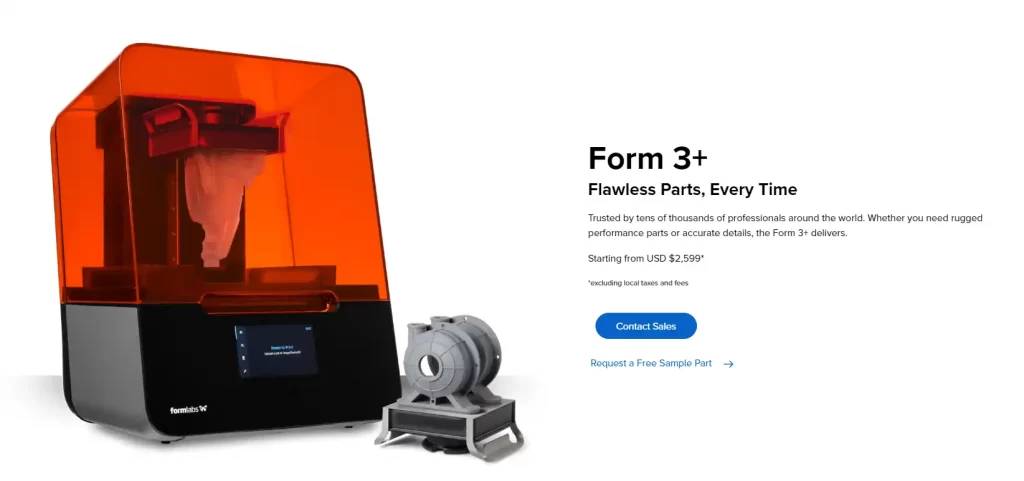

Formlabs Form 3+

The Formlabs Form 3+ is a desktop resin 3D printer that provides high-quality prints and user-friendly features. With its low-force stereolithography technology, this printer can produce prototypes with exceptional detail and accuracy.

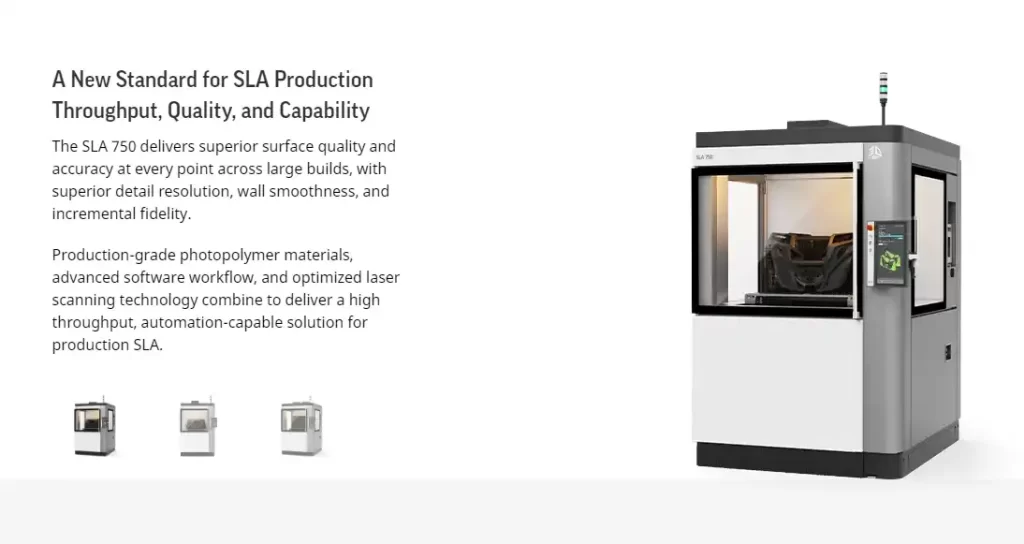

3D Systems SLA 750

The 3D Systems SLA 750 is an industrial-grade resin 3D printer that offers a large build volume and automatic calibration system. With its advanced features and open platform support, this printer is ideal for industrial applications and mass production of resin-based parts.

ZONGHENG3D SLA 300

The ZONGHENG3D SLA 300 is one of the few high performance-to-price ratio industrial-grade SLA 3D printers on the market. It has outstanding stability and an internal constant temperature and humidity system, allowing it to perform optimally in any environment. It is particularly suitable for educational institutions, corporate manufacturing solutions, and startup workshops. The compact machine size is suitable for various product development and design scenarios.

These are just a few of the best resin 3D printers available on the market. Each printer offers unique features and capabilities that cater to different needs and budgets. Whether you’re a professional engineer, designer, or hobbyist, there is a resin 3D printer out there that can meet your specific requirements.

FAQ

What are some recommended models for specific use cases like beginners, businesses, or high-resolution printing?

Recommended 3D Printer Models for Specific Use Cases

Best Resin 3D Printers

When it comes to resin 3D printers, there are several options available on the market. In this section, we will explore some of the best resin 3D printers that offer high-quality prints and advanced features, catering to a variety of needs ranging from professional use to hobbyist levels.

Best Overall

Nexa3D XiP

The Nexa3D XiP is a professional-grade resin 3D printer that offers ultra-fast printing speeds and a large build volume. With its patented Lubricant Sublayer Photocuring (LSPc®) technology, the XiP delivers high-quality prototypes and final-use parts with exceptional accuracy. It’s a fantastic choice for those who need speed and precision combined.

For Print Farms

Phrozen Sonic Mega 8K

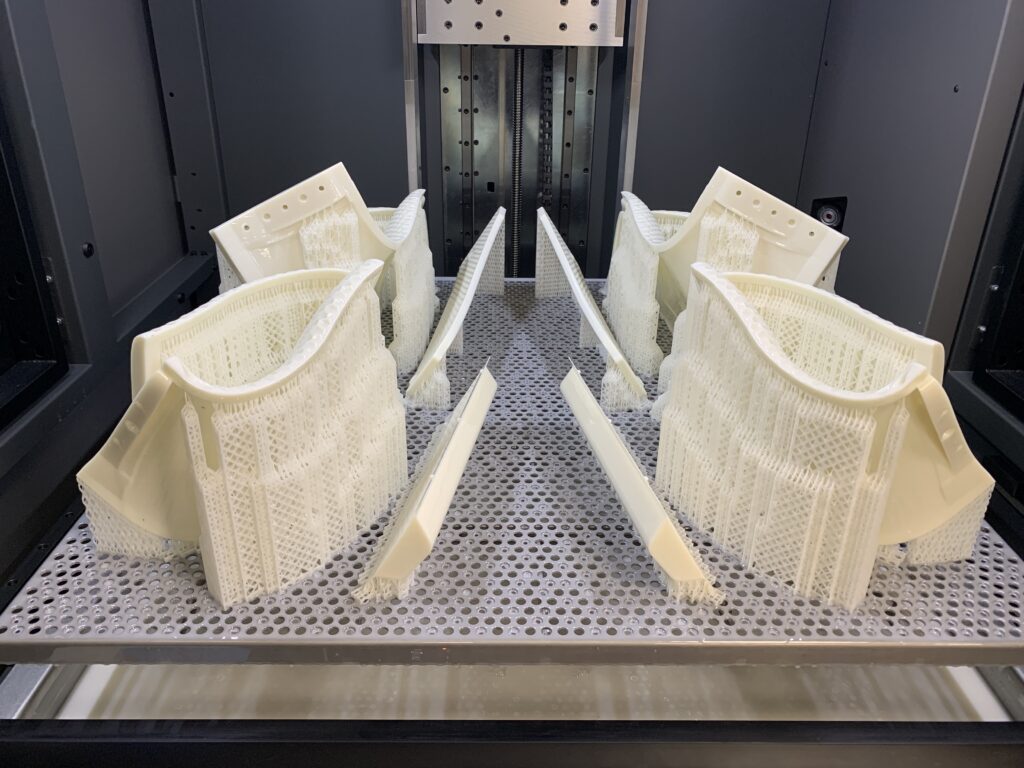

The Phrozen Sonic Mega 8K is perfect for anyone looking to upsize their resin printing or produce resin prints at a commercial scale, making it ideal for print farms. It provides incredible detail and precision with its 8K LCD screen, allowing for the creation of highly detailed models and miniatures effortlessly.

Best for High-Resolution

Creality Halot-One Plus

The Creality Halot-One Plus is an industrial-grade resin 3D printer that offers a large build volume and high-resolution prints. With its 4K LCD screen and advanced features, this printer is perfect for large-scale industrial 3D prints and end-use production parts, capturing those super-crisp details with ease.

Best for Beginners

Elegoo Saturn

The Elegoo Saturn is a desktop resin 3D printer that provides a large build volume and fast print speed, making it an excellent option for beginners. Its 8.9-inch 4K mono display offers high accuracy and detail without overwhelming complexity, ensuring an easy start for first-time resin users.

Best for Versatility

Anycubic Photon M3 Plus

The Anycubic Photon M3 Plus is a desktop resin 3D printer that offers quick print times and a large build plate size. With its 4K LCD resolution and open material platform, this printer provides versatility and high-quality prints, suitable for various projects that require flexibility in materials.

Best for Business

Formlabs Form 3+

The Formlabs Form 3+ is a desktop resin 3D printer that provides high-quality prints and user-friendly features. With its low-force stereolithography technology, this printer can produce prototypes with exceptional detail and accuracy, making it a valuable asset for business environments seeking premium quality.

Best for Large Format

3D Systems SLA 750

The 3D Systems SLA 750 is an industrial-grade resin 3D printer that offers a large build volume and automatic calibration system. With its advanced features and open platform support, this printer is ideal for industrial applications and mass production of resin-based parts, catering to serious hobbyists and small-volume production needs.

Best for Educational and Startup Settings

ZONGHENG3D SLA 300

The ZONGHENG3D SLA 300 is one of the few high performance-to-price ratio industrial-grade SLA 3D printers on the market. It boasts outstanding stability and an internal constant temperature and humidity system, allowing it to perform optimally in any environment. Particularly suitable for educational institutions, corporate manufacturing solutions, and startup workshops, its compact size fits various product development scenarios.

These are just a few of the best resin 3D printers available on the market. Each printer offers unique features and capabilities that cater to different needs and budgets. Whether you’re a professional engineer, designer, or hobbyist, there is a resin 3D printer out there that can meet your specific requirements.

What are the benefits and challenges of using resin 3D printers?

Benefits and Challenges of Using Resin 3D Printers

Benefits:

- High Resolution and Detail: Resin 3D printers excel at producing highly intricate models. They employ a technology that involves curing liquid resin with UV light, achieving impressive detail precision. This allows for models with resolutions as fine as 0.035mm, making them ideal for projects requiring intricate features.

- Cost-Effective Options: Over recent years, resin printers have become more affordable, with many models available under $300. This makes them accessible to hobbyists and professionals alike, providing a gateway into high-detail model creation without a substantial initial investment.

Challenges:

- Post-Processing Requirements: After printing, models require additional handling to achieve the final desired result. This post-processing can involve cleaning, curing, and occasionally painting, which adds time and effort to the workflow.

- Handling and Safety Precautions: Working with resin mandates careful handling due to the nature of the materials involved. Specifically, UV resin can be hazardous, necessitating the use of gloves and masks to ensure safe use. This aspect may pose difficulties for beginners or households with small children.

- Initial Learning Curve: While the technology offers high rewards in terms of print quality, it can initially be complex for newcomers to 3D printing. Understanding and mastering the necessary software and equipment settings can require time and practice.

Alternatives and Considerations

If the challenges of resin printers seem daunting, filament-based printers might be a more suitable choice, especially for beginners. For those prioritizing budget over precision detail, exploring budget-friendly options could be beneficial. Always consider the nature of your projects and household when selecting a 3D printing solution to ensure it aligns with your needs and skills.

What should a buyer know about LCD types when purchasing a resin 3D printer?

Choosing the Right LCD for Resin 3D Printers

When purchasing a resin 3D printer, understanding the type of LCD—either Mono or RGB—can significantly affect both print speed and quality.

- Mono LCDs: These screens excel in speed. They allow more UV light to penetrate efficiently, requiring shorter exposure times per layer. This results in quicker print times and often extends the printer’s longevity due to reduced stress on the screen.

- RGB LCDs: Typically more affordable, these are slower because they filter light through additional color layers. The extra filtering means longer exposure times per layer, slowing down your printing process.

Key Considerations:

- Print Speed: If speed is a priority, mono LCDs are the optimal choice as they drastically cut down layer exposure time.

- Budget Constraints: For those who need a more cost-effective solution, an RGB LCD might be more suitable, although it comes with slightly slower performance.

- Durability: Mono LCDs often have a longer lifespan due to reduced exposure times, which can translate into a better investment over time.

Conclusion

When deciding between mono and RGB LCDs, weigh the importance of speed against your budget. Mono LCDs provide faster print times, while RGB alternatives offer lower initial costs. Your choice can make a notable difference in your 3D printing experience.

Things to Consider Before Buying the Best Resin 3D Printers

When it comes to choosing the best resin 3D printer, there are several important factors to consider. Whether you’re a beginner or an experienced user, these considerations will help you make an informed decision and find the perfect printer for your needs.

Print Quality and Resolution

One of the most important factors to consider is the print quality and resolution of the printer. The resolution determines the level of detail and precision that can be achieved in your prints. Higher resolution printers will produce smoother and more detailed models, but they may also come with a higher price tag. Consider the level of detail you require for your projects and choose a printer with a resolution that meets your needs.

Print Volume

The print volume refers to the maximum size of the objects that can be printed. If you plan on printing larger models or multiple models at once, you’ll need a printer with a larger print volume. Consider the size of the objects you plan to print and choose a printer with a print volume that can accommodate your needs.

Connectivity Options

Consider the connectivity options offered by the printer. Some printers offer Wi-Fi or Ethernet connectivity, allowing you to control and monitor your prints remotely. This can be a convenient feature, especially if you plan on using your printer in a different room or location. Additionally, check if the printer is compatible with the software you plan to use for slicing and preparing your models for printing.

Ease of Use and Setup

Consider the ease of use and setup of the printer. Look for a printer that is easy to set up and calibrate, especially if you’re a beginner. Consider the user interface and controls of the printer and choose one that is intuitive and user-friendly. Additionally, check if the printer comes with any software or resources that can help you get started and troubleshoot any issues that may arise.

Safety Features

Lastly, consider your budget and the price of the printer. Resin 3D printers can range in price from affordable entry-level models to more expensive professional-grade machines. Determine your budget and choose a printer that offers the best value for your money. Remember to consider the long-term costs of consumables, such as resin and replacement parts, when calculating the overall cost of the printer.By considering these factors, you can find the best resin 3D printer that meets your needs and helps you achieve high-quality prints with ease. Whether you’re a hobbyist or a professional, investing in the right printer will ensure that you can bring your ideas to life with precision and detail.

Conclusion

Resin 3D printing has revolutionized the world of 3D printing, offering unparalleled precision and detail. With their ability to create highly detailed and accurate models, resin printers are perfect for a wide range of applications, from prototyping and jewelry making to gaming and component manufacturing. Compared to filament-based printers, resin printers excel in terms of print quality, producing smooth surfaces and fine details that are difficult to achieve with other technologies.Throughout this guide, we’ve provided recommendations for the best resin 3D printers on the market, taking into account factors such as print volume, resolution, speed, and overall value. From the professional-grade Nexa3D XiP to the desktop-friendly Elegoo Saturn, there’s a resin printer out there for every need and budget.But choosing the right printer is just the first step. Selecting the right resin is equally important. We’ve highlighted some of the best resins for 3D printers, each with its own unique properties and characteristics. Whether you’re looking for high detail, strength, flexibility, or eco-friendliness, there’s a resin on our list that will meet your needs. When it comes to resin 3D printing, size and resolution matter. Consider the build volume and resolution of the printer that best suits your specific needs. A larger build volume allows for the creation of bigger projects, while a higher resolution ensures finer details in your prints. Strike a balance between size, resolution, and other features that are important to you. Before making a final decision, consider important factors such as print quality, connectivity options, ease of use, safety features, and price. These considerations will help you find the best resin 3D printer that meets your specific requirements and budget. In conclusion, resin 3D printing has opened up a world of possibilities in manufacturing, design, and prototyping. Its ability to produce highly detailed and accurate objects has made it a popular choice among professionals and hobbyists alike. With advancements in technology and a wide range of resin materials available, the possibilities are endless.