Invisalign is a product that mainly depends on 3D technology, whether it’s 3D dynamic design software for orthodontic solutions or 3D printers for dental molds. There are two types of 3D printers that provide precision dental mold prototypes for invisible braces: DLP and SLA. Which light-curing 3D printer is best for manufacturers of invisible braces?

1.Molding accuracy comparison

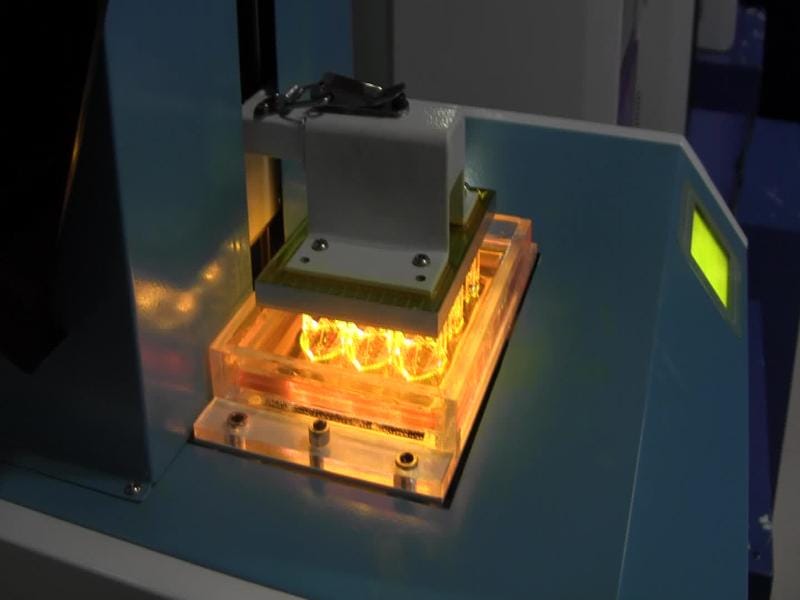

DLP light-curing 3D printer, the principle of laser projection molding; and SLA light-curing 3D printer, it is laser scanning point to line to surface molding. Theoretically speaking, there should be no difference between the two molding accuracy. In fact, DLP 3D printers will occur in the printing process of astigmatism, especially the edge part will be blurred. While SLA3D printers can ensure that all places can Avenue 0.05mm precision.

2.Capacity and efficiency comparison

DLP belongs to surface molding, SLA belongs to point to line to surface molding, in terms of individual dental mold products, DLP printing speed is much faster. However, DLP printing size is generally within 300mm, which is a desktop 3D printer, and the one-time printing of dental models is in single digits. The orthodontic braces for a single patient often require dozens of pairs, which means someone needs to be at the machine all the time to operate it.

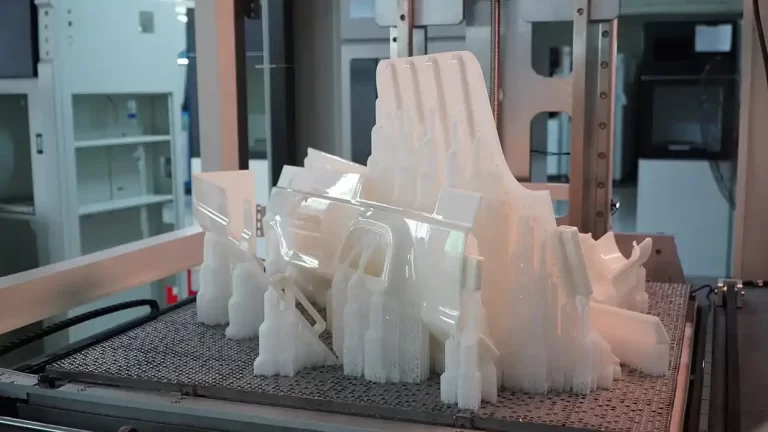

The SLA3D printer, whose printing size is currently up to 1700mm or more, is an industrial grade 3D printer that can achieve mass production of dental molds. Take a conventional 600*600*400mm model as an example, it can print 50-60 pairs of dental molds at a time. One person can man 10 machines, invisible braces manufacturers only need a small number of personnel can mass produce precision dental mold prototypes, and unlimited environment and time for mass production.

3.Machine service life

DLP model hardware cost is low, the failure rate is high, the service life is also short, often less than six months will occur in the decline in accuracy and other phenomena. While the SLA3D printer used accessories cost high, long service life, the overall structure is rigorous, especially the laser, double side fully sealed design, a grain of dust can not enter, to ensure a lasting and reliable accuracy.

Many invisible braces manufacturers who just started their business often choose the cheap DLP because of the price, which leads to the later occurrence of accuracy reduction, mass production can not be delivered in time, which is not worth the loss.