In the intricate world of dental care, precision isn’t just a preference—it’s an absolute necessity. Every crown, bridge, or aligner designed and crafted in a dental lab must meet exacting standards to ensure optimal patient outcomes. Traditionally, this level of precision relied heavily on skilled craftsmanship and painstaking manual labor. However, with the advent of digital technologies, the landscape of dental model making has undergone a revolutionary shift.

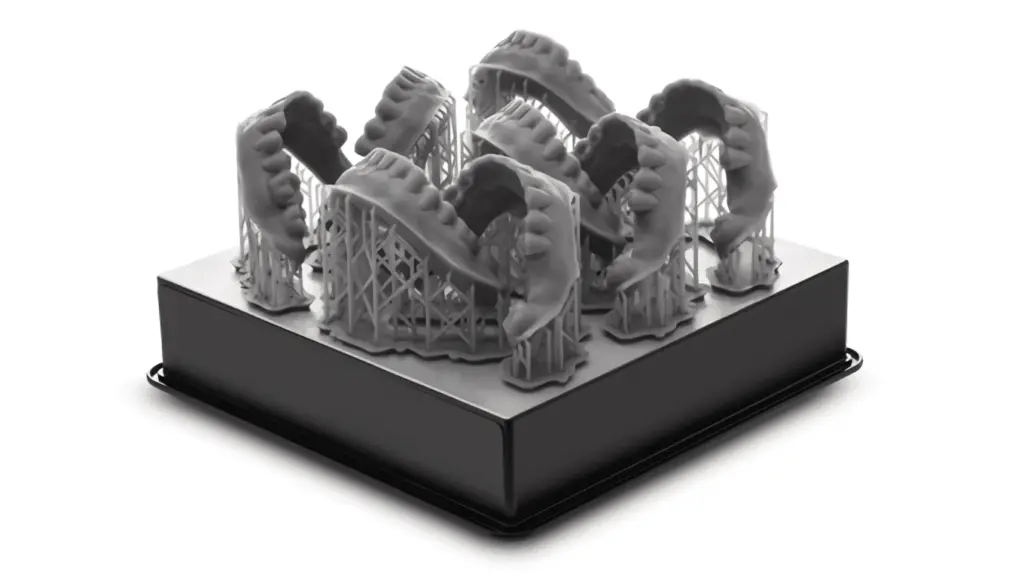

At the forefront of this transformation is DLP (Digital Light Processing) 3D printing, a cutting-edge technology that has swiftly become indispensable in modern dental laboratories. Unlike traditional methods, which often involve time-consuming processes and potential margin for error, DLP 3D printing offers unparalleled accuracy and efficiency. This technology leverages digital designs to create highly detailed dental models with precision measured in microns, ensuring that each piece fits seamlessly into the patient’s treatment plan.

Throughout this article, we will delve into why DLP 3D printers are becoming the cornerstone of dental model making. From understanding the technology itself to exploring its myriad applications in dentistry, we’ll uncover the advantages, considerations, and future implications of embracing DLP 3D printing in dental labs. Join us on this journey through innovation and precision as we explore how DLP technology is reshaping the future of dental care one model at a time.

What is DLP 3D Printing?

In the realm of 3D printing technologies, Digital Light Processing (DLP) stands out as a powerful method that’s revolutionizing dental model making. Unlike traditional methods that involve molding and casting or other 3D printing techniques like FDM (Fused Deposition Modeling) and SLA (Stereolithography), DLP offers unique advantages specifically tailored to the needs of dental applications.

How DLP 3D Printing Works

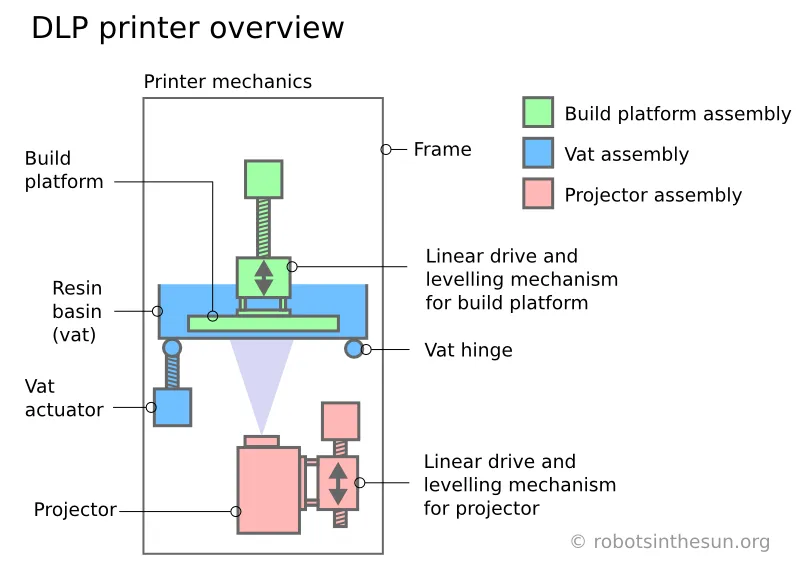

DLP 3D printing utilizes a process that involves the following key components:

1. Digital Design Preparation: Dental models are first designed using specialized CAD (Computer-Aided Design) software. These digital designs serve as blueprints for the 3D printing process.

2. Photopolymer Resin: Instead of using filament or powdered materials, DLP printers utilize photopolymer resins. These resins are sensitive to light, particularly UV light, and solidify when exposed to it.

3. Projection and Solidification: The printer projects UV light onto a vat of liquid resin containing the digital cross-section of the dental model. The UV light selectively cures (solidifies) the resin layer by layer, building the 3D object from the bottom up.

4. Layer-by-Layer Construction: The printer continues to solidify each layer of resin according to the digital design until the entire dental model is completed.

Advantages of DLP 3D Printing in Dental Labs

DLP technology offers several advantages that make it particularly suitable for dental model making:

High Resolution: DLP printers can achieve extremely fine detail and high precision, with layer thickness typically ranging from 25 to 100 microns. This level of resolution ensures that intricate dental structures, such as crowns and bridges, are accurately reproduced.

Speed: Compared to traditional methods like manual modeling or even other 3D printing technologies, DLP is significantly faster. It can produce dental models in a matter of hours, allowing for quicker turnaround times in dental practices.

Accuracy and Consistency: The digital nature of DLP printing minimizes human error associated with manual craftsmanship. Once a design is perfected digitally, each print produced is an exact replica, ensuring consistency across multiple dental pieces.

Material Versatility: DLP printers can work with a variety of photopolymer resins tailored for dental applications. These resins can range in properties from clear, rigid materials suitable for models, to flexible, biocompatible materials used for aligners and surgical guides.

Comparison with Other 3D Printing Technologies

| Aspect | DLP 3D Printing | Other 3D Printing Technologies (e.g., FDM, SLA) |

| Resolution | High, typically 25-100 microns | Variable, typically higher than FDM, lower than SLA |

| Speed | Fast, can produce models in hours | Slower than DLP, varies depending on technology |

| Accuracy | Very high, precise detailing | Varies, generally good but may have visible layer lines |

| Material Types | Photopolymer resins, various types for dental applications | Thermoplastics, metals, ceramics, depending on technology |

| Applications | Dental models, surgical guides, aligners | Prototyping, general purpose manufacturing, some medical uses |

Understanding DLP 3D printing is crucial for grasping its transformative impact on dental model making. This technology not only enhances precision and efficiency but also opens doors to new possibilities in dental care. As we continue to explore its applications and benefits in subsequent sections, it becomes clear that DLP 3D printing is not just a tool but a cornerstone of modern dental laboratory practices.

Benefits of Using DLP 3D Printers in Dental Labs

Digital Light Processing (DLP) 3D printing has emerged as a game-changer in the field of dental model making, offering a multitude of benefits that enhance efficiency, precision, and overall workflow in dental laboratories.

- Accuracy and Precision

DLP3D printers excel in producing dental models with exceptional accuracy and precision. Here’s how:

- High Resolution: DLP technology allows for printing with layer thicknesses as fine as 25 microns. This high resolution ensures that even the smallest details of dental structures, such as fine margins on crowns or delicate anatomy on bridges, are faithfully replicated.

- Smooth Surface Finish: The layer-by-layer solidification process of DLP results in smooth surface finishes without visible layer lines. This is crucial for dental models, as it reduces the need for post-processing and ensures the models fit precisely during patient treatments.

- Consistency: Once a dental design is digitally perfected, DLP 3D printers can reproduce it consistently. This eliminates variations that can occur with manual modeling and ensures that every dental piece meets the exact specifications required.

- Speed of Production

Speed is a significant advantage of DLP 3D printing in dental labs:

- Rapid Turnaround: Compared to traditional methods that may take days or weeks, DLP 3D printers can produce dental models within hours. This rapid turnaround time is invaluable for dental practices where timely delivery of custom dental pieces is crucial for patient care.

- Efficiency: By reducing production times, DLP 3D printing allows dental labs to handle higher volumes of orders and meet patient demand more effectively. This efficiency not only enhances workflow but also improves overall practice management.

- Cost-effectiveness

While the initial investment in a DLP 3D printer may seem substantial, the long-term cost-effectiveness of this technology is evident:

- Material Efficiency: DLP 3D printing minimizes material waste compared to traditional subtractive methods or even other additive manufacturing techniques. The precise deposition of resin ensures that only necessary material is used, reducing costs associated with material waste.

- Labor Savings: Automating the production process with DLP technology reduces the need for skilled manual labor traditionally required for intricate dental model making. This translates to cost savings in labor expenses over time.

- Versatility in Materials

DLP 3D printers support a wide range of photopolymer resins tailored for various dental applications:

- Biocompatible Resins: Some DLP resins are specifically formulated to be biocompatible, making them suitable for dental applications such as surgical guides, aligners, and temporary prosthetics.

- Functional Properties: Dental labs can choose resins based on specific functional properties required for different dental pieces, such as transparency for clear aligners or flexibility for night guards.

- Enhanced Workflow Integration

Integrating DLP 3D printing into the dental lab workflow offers several advantages:

- Digital Workflow: From digital design creation using CAD software to direct printing of models, DLP technology supports a seamless digital workflow. This integration reduces errors associated with manual processes and improves overall efficiency.

- Compatibility with CAD Systems: DLP printers are compatible with standard CAD systems used in dental labs, allowing technicians to design and print dental models with ease and precision.

The benefits of DLP 3D printing in dental labs are clear: from unparalleled accuracy and efficiency to cost-effectiveness and versatility in materials. As technology continues to advance, these advantages will only become more pronounced, further cementing DLP 3D printers as essential tools in modern dental practices.

Applications of DLP 3D Printing in Dental Model Making

Digital Light Processing (DLP) 3D printing has revolutionized the way dental models are created, offering versatility and precision that traditional methods cannot match. Here’s a detailed look at how DLP technology is applied across various dental procedures:

- Crowns and Bridges

DLP 3D printing is widely used in the fabrication of dental crowns and bridges:

- Customization: Dental crowns and bridges can be customized to fit individual patient needs perfectly. DLP printers ensure that every detail, from the shape to the surface finish, matches the patient’s dental anatomy.

- Material Options: With a variety of dental-grade resins available, DLP technology allows for the creation of crowns and bridges that are not only durable but also aesthetically pleasing. These materials can mimic the natural translucency and color of teeth, providing a seamless integration with the patient’s smile.

- Clear Aligners

Clear aligners have become a popular choice for orthodontic treatment, and DLP 3D printing plays a crucial role in their production:

- High Precision: DLP printers can produce clear aligners with precise fit and alignment, ensuring optimal treatment outcomes for patients.

- Efficiency: The rapid production capabilities of DLP technology enable orthodontists to deliver custom aligners quickly, reducing treatment times and improving patient satisfaction.

- Surgical Guides

Dental surgeries often require precise planning and execution, which is facilitated by DLP 3D printing:

- Accurate Planning: DLP printers can create surgical guides that assist dentists in placing implants or performing other delicate procedures with pinpoint accuracy.

- Patient-specific Design: Each surgical guide is designed based on the patient’s unique anatomy, ensuring that the surgery is both efficient and minimally invasive.

- Temporary Prosthetics

In cases where patients require temporary prosthetics, DLP 3D printing offers a reliable solution:

- Quick Turnaround: Dental labs can quickly produce temporary crowns, bridges, or dentures using DLP technology, allowing patients to maintain aesthetics and functionality while waiting for permanent restorations.

- Customization: Temporary prosthetics can be tailored to match the patient’s natural teeth in terms of shape, size, and color, enhancing comfort and appearance.

- Educational Models

DLP 3D printing is also valuable in dental education and training:

- Anatomical Models: Dental schools and training programs use DLP printers to create detailed anatomical models for teaching purposes. These models help students understand dental anatomy and practice various procedures in a simulated environment.

- Demonstration Tools: DLP-printed models can be used by dentists to visually demonstrate treatment plans and procedures to patients, enhancing patient education and informed consent.

The applications of DLP 3D printing in dental model making are diverse and impactful, spanning from routine dental procedures to advanced surgical applications and educational tools. As technology continues to advance, DLP printers will play an increasingly crucial role in enhancing patient care, treatment outcomes, and the overall efficiency of dental practices.

Future Trends and Innovations

The field of dental model making continues to evolve rapidly, driven by advancements in DLP (Digital Light Processing) 3D printing technology. Here are some emerging trends and innovations shaping the future of DLP 3D printing in dental labs:

- Enhanced Material Options

- Biocompatible Resins: Continued research and development are expanding the range of biocompatible resins available for DLP printing. These resins will offer improved properties such as durability, flexibility, and biocompatibility, meeting diverse dental application needs.

- Functional Materials: Expect to see advancements in DLP resins tailored for specific dental functions, such as antimicrobial properties for surgical guides or enhanced clarity for clear aligners. These materials will enhance treatment outcomes and patient comfort.

- Integration with Digital Workflows

- Digital Dentistry: DLP 3D printing will increasingly integrate with other digital technologies in dentistry, such as intraoral scanners and CAD/CAM systems. This seamless integration will streamline the entire treatment workflow from diagnosis to final restoration.

- Automation: Automation in DLP printers will improve efficiency and accuracy, reducing manual intervention required during printing and post-processing. Automated systems will optimize resin usage and minimize waste, further enhancing cost-effectiveness.

- Customization and Personalization

- Patient-specific Designs: Advances in software capabilities will enable more intricate and patient-specific dental designs. Dentists will be able to create customized prosthetics and appliances tailored to each patient’s unique anatomy and preferences.

- Mass Customization: DLP 3D printing will support mass customization of dental devices, allowing dental labs to efficiently produce large volumes of custom-fit aligners, crowns, and other prosthetics without compromising on quality or precision.

- Advancements in Print Speed and Resolution

- High-Speed Printing: Future DLP printers will continue to enhance print speed without sacrificing print quality. This advancement will further reduce turnaround times for dental models and improve workflow efficiency in busy dental practices.

- Ultra-high Resolution: Expect to see DLP printers capable of achieving even finer resolution, pushing the boundaries of detail reproduction in dental models. Ultra-high resolution will support the creation of intricate anatomical features and surface textures.

- Sustainability Initiatives

- Bio-based Resins: There is a growing focus on developing bio-based resins derived from renewable sources for DLP printing. These resins will reduce environmental impact and offer sustainable alternatives to traditional petroleum-based materials.

- Recycling Programs: Dental labs will adopt recycling programs for unused or failed prints, minimizing material waste and promoting eco-friendly practices in dental model making.

The future of DLP 3D printing in dental labs is poised for remarkable advancements, driven by innovation, integration with digital workflows, customization capabilities, and sustainability initiatives. As these trends continue to unfold, DLP technology will play an increasingly pivotal role in enhancing patient care, treatment outcomes, and operational efficiency in dental practices worldwide.