Imagine being able to print a custom prosthetic based on the doctor’s whim, having surgeons who can work with personalized surgical instruments that best fit specific patients, or even researchers who are able to create intricate tissue structures for regenerative medicine with just the click of a button. This is no movie about the future; in fact, this is the present day, as far as advancement in 3D printing technology goes-mainly DLP and its biocompatible materials.

3D printing has transformed many industries, but possibly the most transformative area is in healthcare. From prosthetics and implants to surgical guides and even tissue engineering, this level of personalization and accuracy is unparalleled with 3D printing. Among the numerous 3D printing technologies available, DLP is unmatched in its ability to make high-resolution, very complex designs with great speed. Biocompatible materials open frontiers in medical applications that were previously unimaginable when combined with DLP.

This article reveals fascinating worlds of biocompatible DLP materials, focusing on their importance, applications, and the future they promise to unfold in healthcare. Be one of those healthcare professionals, a researcher, or even a normal reader who will not only have all queries answered in this comprehensive guide but also know all about reasons these materials bring a revolution to the healthcare segment.

What are Biocompatible DLP Materials?

Biocompatibility Understanding

Most commonly, one of the terms frequently cited when describing medical devices and materials is biocompatibility. But what does it really mean? Biocompatibility can simply be said to be the ability of a material to exhibit a proper response when in the body, meaning that the material should not produce any unfavorable reactions such as inflammation or toxicity.

Biocompatibility Criteria

A material is biocompatible when it meets a number of the following requirements:

- Such a material must not liberate any poisonous substances.

- Non-immunogenicity: The material must not be able to provoke an immune response.

- Non-carcinogenic: A substance that is not cancer-causing.

- Blood compatibility: The material should be compatible with blood.

What is DLP (Digital Light Processing) Technology?

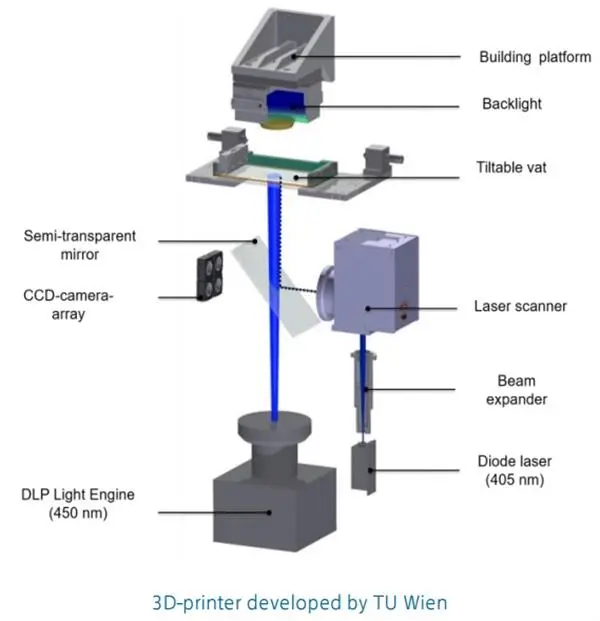

Digital Light Processing (DLP) is a 3D printing technology that uses a digital light projector to selectively cure photopolymer resins. This technology is known for its high resolution and speed, making it ideal for applications that require intricate details and precision.

How DLP Works

- Preparation: The digital model is sliced into thin layers.

- Projection: A digital projector shines light onto a vat of photopolymer resin, selectively curing each layer.

- Layer-by-Layer Construction: The build platform moves, and the process repeats until the object is fully formed.

Types of Biocompatible DLP Materials

Biocompatible DLP materials come in various forms, each suited for specific medical applications. The primary types include:

- Polymers

- Polylactic Acid (PLA): Widely used for its biodegradability and ease of printing.

- Polyethylene Glycol (PEG): Known for its flexibility and biocompatibility in drug delivery systems.

- Composites

- Hydroxyapatite Composites: Used in bone regeneration due to their similarity to natural bone.

- Carbon Nanotube Composites: Offer enhanced mechanical properties and electrical conductivity.

- Ceramics

- Alumina (Aluminum Oxide): Used in dental and orthopedic applications for its strength and biocompatibility.

- Zirconia (Zirconium Dioxide): Known for its toughness and aesthetic appeal in dental restorations.

Why Biocompatible DLP Materials Matter

Advantages Over Traditional Materials

- Customization and Precision: Tailored to the unique anatomy of each patient.

- Reduced Surgical Risks: Minimized infection risk and faster recovery times.

- Complex Geometries: Capable of producing intricate designs that traditional methods cannot achieve.

Applications in Healthcare

- Prosthetics and Implants: Custom-fit prosthetics enhance comfort and functionality.

- Surgical Instruments: Personalized surgical guides improve the accuracy of procedures.

- Dental Applications: High-precision dental crowns and bridges.

Tissue Engineering and Regenerative Medicine

- Scaffold Production: Supports the growth of new tissues.

- Organ Printing: Future potential for creating fully functional organs.

Biocompatible DLP materials are now in the foreground of medical innovations, offering unequalled benefits pertaining to customization, precision, and functionality. From prosthetics and implants to the latest areas, such as tissue engineering, these materials will revolutionize healthcare. With continuous research and better technologies continuously emerging, the possibilities of biocompatible DLP materials are limitless and ensure a future in which personalized medicine is the rule rather than the exception.

The DLP Biocompatible Materials: A Game-Changer in Healthcare

The health industry is on a relentless pace toward better, personalized, and less invasive treatments. Biocompatible Digital Light Processing (DLP) materials are at the very frontier of this ongoing revolution, offering innovations without limits. This paper discusses why these materials are said to be game-changers, exploring their importance, diversified applications, and potential to reshape future medicine.

Advantages Over Normal Materials

It’s not only the change from conventional materials to DLP biocompatible materials but going on an edge and taking a transformational leap. Here’s why:

Customization and Detail

- Customized Solution: Patients differ from one another, making it necessary that a tailored medical device be designed for the patient. This ensures better compatibility and effectiveness.

- High Resolution: DLP technology can achieve extremely complex, intricate designs, with a level of precision that conventional methods cannot reach.

Fewer Surgical Risks and Shorter Recovery Times

- Reduced Chances of Infections: The fitting implants and prosthetics made specifically for the patient’s body reduce the chances of infections.

- Faster Recovery: Patients who have gone through personalized surgical instruments and implants recover faster, stay in the hospital for a shorter time, and report better health results overall.

Affordability

- Less Wastage: Accurate manufacturing uses fewer materials.

- Lower Long-Term Costs: While upfront costs might be higher, the long-term benefits of avoiding complications could potentially result in overall cost savings.

Medical Device Applications

Biocompatible materials for DLP have pioneered the way in many medical sub-sectors. Let’s consider a few of the most impactful applications:

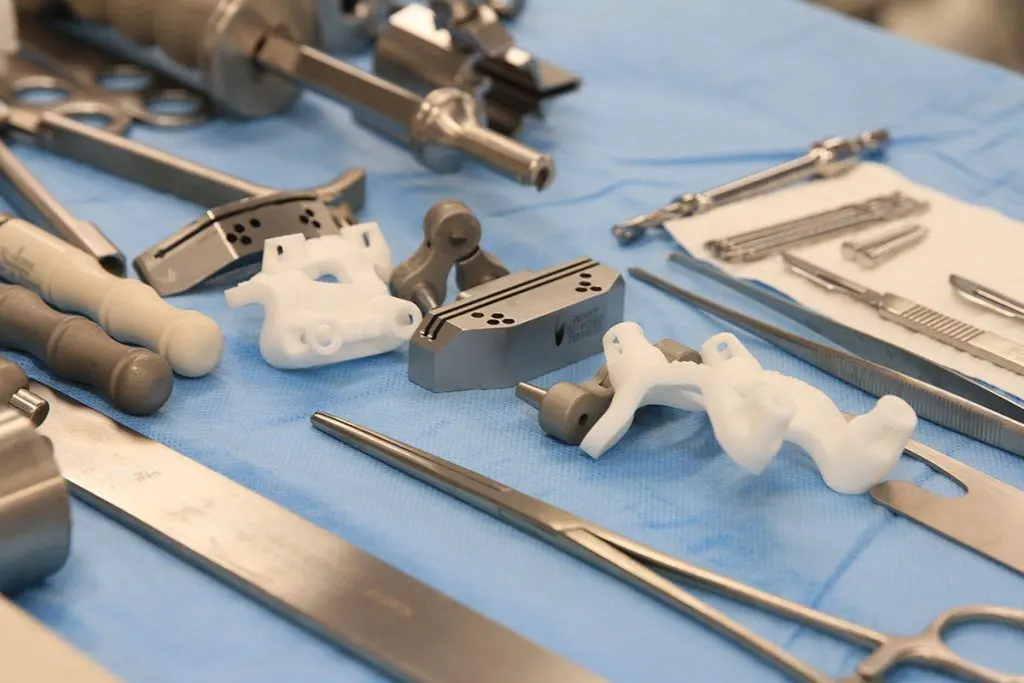

Prosthetics and Implants

- Custom Prosthetics: Customized prosthetics can make life much more comfortable and functional for amputees, thus enhancing quality of life.

- Dental Implants: Dental implants are fitted for ultra-precision fit and long life.

Surgical Instruments

- Personalized Surgical Guides: Custom surgical guides make procedures more accurate and improve outcomes.

- Custom Instruments: Instruments designed for particular surgeries can add to the efficiency and safety of an operation.

Dental Applications

- Crowns and Bridges: High-resolution DLP printing makes the fabrication of aesthetically pleasing dental reconstructions in high strength possible.

- Orthodontic Appliances: Treatment is more effective and comfortable due to the use of custom-fit braces and retainers.

Tissue Engineering and Regenerative Medicine

One of the most exciting frontiers for the application of biocompatible DLP materials is in tissue engineering and regenerative medicine.

Scaffold Fabrication

- Support Structures: Through the utilization of DLP materials, scaffolding can be printed to help grow new tissue for organ repair and regeneration.

- Biodegradability: Most biocompatible DLP materials are designed to be biodegradable and not require surgical removal.

Organ Printing

- Complex Tissue Structures: For some researchers, the goal is to eventually print complex tissue structures using biocompatible DLP materials to develop fully functional organs.

- Future Potential: Organ printing, if developed, has the potential to revolutionize transplant medicine by resolving organ shortages and reducing rejection rates.

Pharmaceuticals

Biocompatible DLP materials are adding new dimensions to innovation in the pharmaceutical sector.

Personalized Medicine

- Custom Drug Formulations: 3D printing enables tailor-made drug formulations, highly specific to individual patient needs.

- More Effective Drug Delivery: Advanced, biocompatible materials can design drug delivery systems that release medication at controlled rates, minimizing side effects and increasing efficacy.

Drug Delivery Systems

- Targeted Delivery: Customizable drug delivery systems can target specific areas in the body, increasing treatment efficiency and reducing systemic side effects.

- Biodegradable Carriers: DLP-based materials can be engineered to degrade within the body, allowing for controlled drug release.

Challenges and Limitations

While these biocompatible DLP materials hold great promise, there are challenges:

Technical Difficulties

- Material Properties: Finding the right balance between mechanical strength, flexibility, and biocompatibility can be challenging.

- Printing Resolution: Although DLP offers high resolution, achieving consistent quality across different materials and designs can be difficult.

Regulatory and Ethical Implications

- Regulatory Approval: Navigating the complex regulatory landscape for new medical devices or materials can be costly and time-consuming.

- Ethical Considerations: The development of new materials and technologies in medical applications raises ethical concerns related to patient safety and long-term effects.

Economic Factors

- Material Cost: High-quality biocompatible DLP materials can be expensive.

- Accessibility: Ensuring these advanced materials and technologies are accessible to healthcare providers and patients worldwide is a significant challenge.

Translating biocompatible DLP materials from the bench to the bedside faces a number of challenges, none of which, however, is insurmountable. Only when the technical, regulatory, ethical, and financial challenges are made real sense of and then met will the full potential of such game-changing materials be disclosed. In continued innovation and collaboration, the promise of biocompatible DLP materials for the revolution of healthcare becomes increasingly within reach.

Recent Breakthroughs and Future Prospects

Pioneering the Next Frontier in Biocompatible DLP Materials

The field of biocompatible Digital Light Processing (DLP) materials is rapidly evolving, driven by groundbreaking research and technological advancements. This article explores the most recent breakthroughs in the field and offers a glimpse into the future prospects that hold the potential to revolutionize healthcare. From novel materials to innovative applications, let’s dive into the exciting developments shaping the future of biocompatible DLP materials.

Recent Breakthroughs

Novel Biocompatible Materials

The quest for new biocompatible materials is at the heart of recent advancements. Researchers are continuously exploring and developing materials that meet the stringent requirements of medical applications.

- Nanocomposite Hydrogels: These materials combine the flexibility of hydrogels with the strength of nanoparticles, offering improved mechanical properties and biocompatibility. They are particularly promising for tissue engineering and drug delivery systems.

- Bioactive Glass Ceramics: Known for their ability to bond with bone, these materials are being used to create scaffolds for bone regeneration. Their unique properties promote cell growth and tissue integration.

- Silk-Based Polymers: Silk is a natural biopolymer known for its biocompatibility and mechanical strength. Recent research has focused on using silk-based polymers for applications in wound healing and tissue scaffolding.

Advanced DLP Techniques

Innovations in DLP printing technology are enhancing the capabilities and applications of biocompatible materials.

- Multi-Material Printing: Recent advancements allow for the simultaneous printing of multiple materials, enabling the creation of complex, multi-functional structures. This technique is particularly useful for creating composite implants and devices.

- High-Speed Printing: Improvements in DLP projector technology have significantly increased printing speeds, making it feasible to produce custom medical devices more quickly and efficiently.

- Micro-DLP Printing: This technique enables the creation of microscopic structures with high precision, opening up new possibilities in areas like microfluidics and cell culture scaffolds.

Future Prospects

Personalized Medicine

The future of biocompatible DLP materials is closely tied to the rise of personalized medicine, which aims to tailor treatments to individual patients.

- Custom Implants and Prosthetics: Advances in DLP technology will enable the production of highly personalized implants and prosthetics that perfectly match the patient’s anatomy, improving comfort and functionality.

- Patient-Specific Drug Delivery Systems: Personalized drug delivery systems that release medication at controlled rates tailored to the patient’s needs are on the horizon, promising more effective and targeted treatments.

Regenerative Medicine and Tissue Engineering

The potential for biocompatible DLP materials in regenerative medicine is immense.

- Organ Printing: While still in the experimental stage, the ability to print functional organs using biocompatible DLP materials could revolutionize transplant medicine. Researchers are making progress in printing complex tissue structures and vascular networks, bringing us closer to this goal.

- Advanced Scaffolds: Future scaffolds will be designed to mimic the natural extracellular matrix more closely, promoting better cell growth and tissue integration. These scaffolds could be used for regenerating a wide range of tissues, from skin to cartilage.

Integration with Other Technologies

The integration of biocompatible DLP materials with other cutting-edge technologies is set to create new possibilities.

- Bioprinting: Combining DLP technology with bioprinting techniques can enable the creation of complex tissue structures that integrate living cells with biocompatible scaffolds.

- Smart Materials: The development of smart, biocompatible materials that can respond to environmental stimuli (e.g., temperature, pH) will open up new applications in areas like drug delivery and wound healing.

- Internet of Medical Things (IoMT): Integrating biocompatible DLP materials with IoMT devices could lead to the creation of smart implants and prosthetics that provide real-time data on patient health and device performance.

Challenges Ahead

While the future is bright, several challenges remain that must be addressed to fully realize the potential of biocompatible DLP materials.

Technical Hurdles

- Material Development: Developing new materials that meet the complex requirements of medical applications remains a significant challenge.

- Scalability: Ensuring that advanced DLP printing techniques can be scaled up for widespread clinical use is crucial.

Regulatory and Ethical Considerations

- Approval Processes: Streamlining regulatory approval processes for new materials and technologies will be essential for bringing innovations to market more quickly.

- Ethical Frameworks: Establishing robust ethical frameworks to guide the development and use of new technologies will help ensure patient safety and equitable access.

Recent breakthroughs, along with future prospects concerning biocompatible DLP materials, have been incredibly promising; thus, opening new horizons for healthcare in a wide array of applications. Advancing from personalized medicine to regenerative therapies, the frontiers in this field are thus leading the way to a new epoch in medical innovations. While there are still challenges to overcome, continuous research and development bring us closer to tapping the full potential of biocompatible DLP materials and thus secure a future wherein medical treatments will be more effective, personalized, and accessible than ever.

The prospects for biocompatible materials in the DLP technology of the future are therefore bright and full of promise. The research that enters new biocompatible materials, advanced manufacturing techniques, and finds new applications is sure to bring major advances in the future. Coordinated research efforts, further R&D investment, and integration of DLP technology with other emerging technologies act as the catalyst that enables the growth of biocompatible materials. With these challenges being addressed and the seized opportunities, the stakeholders are going to be able to unlock the fuller potential of DLP material and open up new vistas for medical innovation and improved patient care.