The Ultimate Guide to Choosing Between DLP and SLA 3D Printing Technologies

If you’re a 3D printing enthusiast or professional looking to invest in a new 3D printer, you’ve likely come across two popular 3D printing technologies (DLP vs. SLA): DLP (Digital Light Processing) and SLA (Stereolithography). Both technologies have their unique advantages and disadvantages, and deciding which one is right for you can be overwhelming.

But fear not! In this ultimate guide, we’ll dive deep into the world of DLP and SLA 3D printing technologies and help you make an informed decision based on your specific needs and requirements.

We’ll start by defining both technologies and explaining how they work. Then, we’ll compare and contrast DLP and SLA to highlight their key differences and similarities. We’ll also explore various factors to consider when choosing between DLP and SLA, such as application, budget, print quality, print speed, and material compatibility.

By the end of this article, you’ll have a comprehensive understanding of DLP and SLA 3D printing technologies and be able to confidently choose the one that’s right for you. So, let’s get started!

Understanding DLP and SLA: A Comprehensive Guide

When it comes to 3D printing, there are many different technologies available, but two of the most popular are DLP (Digital Light Processing) and SLA (Stereolithography). While both technologies use light to solidify liquid resin into a 3D object, there are significant differences between them that can impact your final print.

In this article, we’ll take a closer look at DLP and SLA 3D printing technologies and help you understand their unique advantages and disadvantages.

What is DLP 3D Printing?

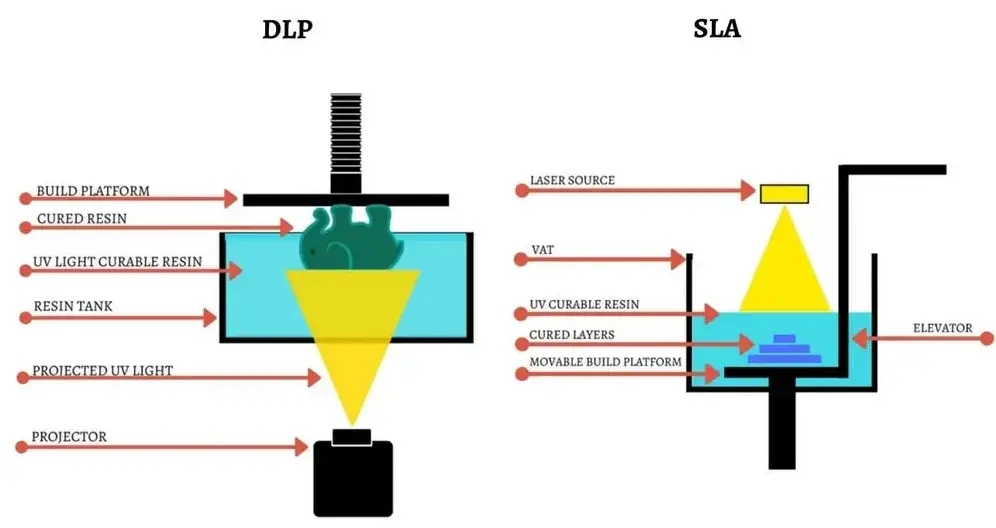

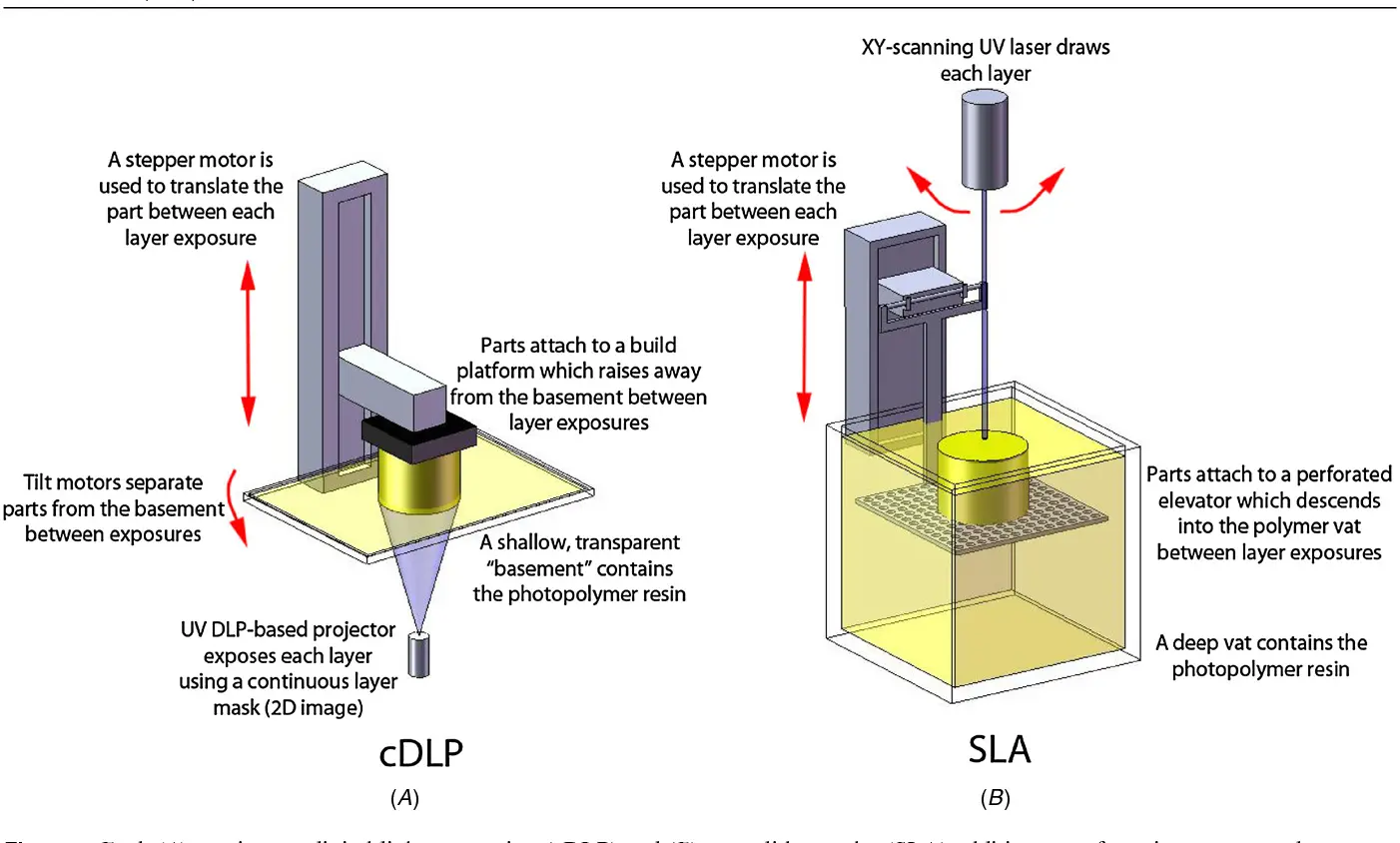

DLP 3D printing uses a digital projector to shine a pattern of ultraviolet (UV) light onto a vat of liquid photopolymer resin. The UV light causes the resin to harden and solidify in the areas where it’s exposed to the light. The object being printed is built up layer by layer until it’s fully formed.

How Does DLP Work?

The process of DLP 3D printing involves the following steps:

- Preparation: The liquid resin is poured into a vat, and the build platform is lowered into the resin.

- Exposure: The digital projector shines a pattern of UV light onto the resin, causing it to harden in the exposed areas.

- Peeling: After each layer is exposed, the build platform is raised slightly, and the newly formed layer is peeled away from the bottom of the vat.

- Curing: Once the print is complete, it’s removed from the vat and placed in a UV curing chamber to fully harden.

Advantages of DLP

DLP offers several advantages over other 3D printing technologies, including:

- High Resolution: DLP can produce incredibly detailed prints with a high level of precision.

- Speed: DLP can print objects much faster than other 3D printing technologies, making it ideal for mass production.

- Material Compatibility: DLP can use a wide range of resins, including flexible and rigid materials.

Disadvantages of DLP

Despite its advantages, DLP does have some disadvantages, including:

- Cost: DLP printers can be expensive, especially those with higher resolutions.

- Limited Build Volume: DLP printers typically have smaller build volumes than other 3D printing technologies.

- Maintenance: DLP printers require regular maintenance to ensure optimal performance.

What is SLA 3D Printing?

SLA 3D printing uses a laser to selectively cure liquid resin into a solid object. The laser moves along the surface of the resin, solidifying it in the desired areas. The object being printed is built up layer by layer until it’s fully formed.

How Does SLA Work?

The process of SLA 3D printing involves the following steps:

- Preparation: The liquid resin is poured into a vat, and the build platform is lowered into the resin.

- Exposure: The laser moves along the surface of the resin, solidifying it in the desired areas.

- Peeling: After each layer is exposed, the build platform is raised slightly, and the newly formed layer is peeled away from the bottom of the vat.

- Curing: Once the print is complete, it’s removed from the vat and placed in a UV curing chamber to fully harden.

Advantages of SLA

SLA offers several advantages over other 3D printing technologies, including:

- High Resolution: SLA can produce incredibly detailed prints with a high level of precision.

- Accuracy: SLA is known for its high accuracy, making it ideal for creating complex geometries.

- Material Compatibility: SLA can use a wide range of resins, including flexible and rigid materials.

Disadvantages of SLA

Despite its advantages, SLA does have some disadvantages, including:

- Cost: SLA printers can be expensive, especially those with higher resolutions.

- Build Time: SLA can take longer to print objects than other 3D printing technologies.

- Maintenance: SLA printers require regular maintenance to ensure optimal performance.

DLP vs. SLA: Key Differences

While both DLP and SLA use light to solidify liquid resin into a 3D object, there are several key differences between the two technologies. Here’s a breakdown of the main differences:

| Factor | DLP | SLA |

| Speed | Faster | Slower |

| Resolution | High | High |

| Cost | Higher | Higher |

| Material Compatibility | Wide range | Wide range |

| Build Volume | Smaller | Larger |

| Maintenance | Regular | Regular |

DLP and SLA are both popular 3D printing technologies that offer high resolution, material compatibility, and accuracy. However, they differ in terms of speed, cost, build volume, and maintenance requirements. By understanding these differences, you can make an informed decision about which technology is right for your specific needs and requirements.

Factors to Consider When Choosing Between DLP and SLA 3D Printing Technologies

Now that we’ve covered the basics of DLP and SLA 3D printing technologies, it’s time to delve deeper into the factors you should consider when choosing between the two. These factors can vary depending on your specific needs and requirements, so it’s important to carefully evaluate each one before making a decision.

Application

One of the most important factors to consider when choosing between DLP and SLA is the application you have in mind. Different applications may require different technologies, so it’s important to choose the one that’s best suited for your specific needs.

For example, if you’re a jewelry maker, you may prefer DLP because it can produce highly detailed prints with intricate designs. On the other hand, if you’re a dental technician, you may prefer SLA because it can create accurate dental models with precise details.

Here are some examples of applications that may be better suited for DLP or SLA:

| Application | Best Suited For |

| Jewelry Making | DLP |

| Dental Models | SLA |

| Prototyping | Either |

| Production Parts | Either |

Budget

Another important factor to consider when choosing between DLP and SLA is your budget. Both technologies can be expensive, especially those with higher resolutions, so it’s important to choose the one that fits within your budget.

Here are some factors to consider when evaluating the cost of DLP and SLA:

- Printer Cost: DLP and SLA printers can vary widely in price, so it’s important to research the cost of different models before making a decision.

- Material Cost: The cost of resin can also vary depending on the type and quality, so it’s important to factor this into your budget.

- Maintenance Cost: Both DLP and SLA printers require regular maintenance to ensure optimal performance, so it’s important to factor in the cost of maintenance when evaluating your budget.

Print Quality

Print quality is another important factor to consider when choosing between DLP and SLA. Both technologies offer high resolution and accuracy, but there are some differences to keep in mind.

For example, DLP can produce prints with a smoother surface finish, while SLA can create prints with more precise details. Additionally, DLP can produce prints with thinner walls and smaller features, while SLA can create prints with thicker walls and larger features.

Here are some factors to consider when evaluating print quality:

- Surface Finish: If you need a smooth surface finish, DLP may be the better choice.

- Detail Level: If you need precise details, SLA may be the better choice.

- Layer Thickness: Both DLP and SLA offer adjustable layer thicknesses, so it’s important to choose the one that meets your specific needs.

Print Speed

Print speed is another important factor to consider when choosing between DLP and SLA. Both technologies can produce prints quickly, but DLP is generally faster than SLA.

Here are some factors to consider when evaluating print speed:

- Batch Size: If you need to print multiple objects at once, DLP may be the better choice because it can produce prints faster.

- Time to Complete Prints: If you need to produce prints quickly, DLP may be the better choice because it can produce prints faster than SLA.

Material Compatibility

Material compatibility is another important factor to consider when choosing between DLP and SLA. Both technologies can use a wide range of resins, but there are some differences to keep in mind.

For example, DLP can use resins with a lower viscosity, which can result in smoother prints. On the other hand, SLA can use resins with a higher viscosity, which can result in more precise prints.

Here are some factors to consider when evaluating material compatibility:

- Resin Types: Both DLP and SLA can use a wide range of resins, so it’s important to choose the one that meets your specific needs.

- Flexibility: If you need a flexible material, DLP may be the better choice because it can use resins with a lower viscosity.

- Strength: If you need a strong material, SLA may be the better choice because it can use resins with a higher viscosity.

- Chemical Resistance: If you need a material that can withstand harsh chemicals, both DLP and SLA can use chemically resistant resins.

Choosing between DLP and SLA 3D printing technologies can be a complex decision, but by considering the factors outlined in this article, you can make an informed decision that meets your specific needs and requirements.

Conclusion: Choosing the Right 3D Printing Technology for Your Needs

After exploring the factors to consider when choosing between DLP and SLA 3D printing technologies, it’s clear that both have their own unique strengths and weaknesses. Ultimately, the right technology for you will depend on your specific needs and requirements.

To recap, here are the key factors to consider when choosing between DLP and SLA:

- Application: Consider the specific application you have in mind and choose the technology that’s best suited for your needs.

- Budget: Evaluate the cost of the printer, materials, and maintenance to determine which technology fits within your budget.

- Print Quality: Consider the surface finish, detail level, and layer thickness required for your prints.

- Print Speed: Determine whether you need to produce prints quickly or in large batches.

- Material Compatibility: Choose the technology that can use the resin types and properties required for your prints.

By taking these factors into account, you can make an informed decision about which 3D printing technology is right for you.

However, it’s important to note that no technology is perfect, and both DLP and SLA have their own limitations. For example, DLP printers may have limited build volumes, while SLA printers may require more maintenance. Additionally, both technologies may struggle with certain materials or print geometries.

Relate All in One Industrial-Grade DLP 3D Printing Solutions

Super Maker DM200

Discover The Future Of High-Speed, High-Precision 3D Printing Start-Up machine.

Super Maker DM400

Discover The Future Of High-Speed, High-Precision 3D Printing Start-Up machine.

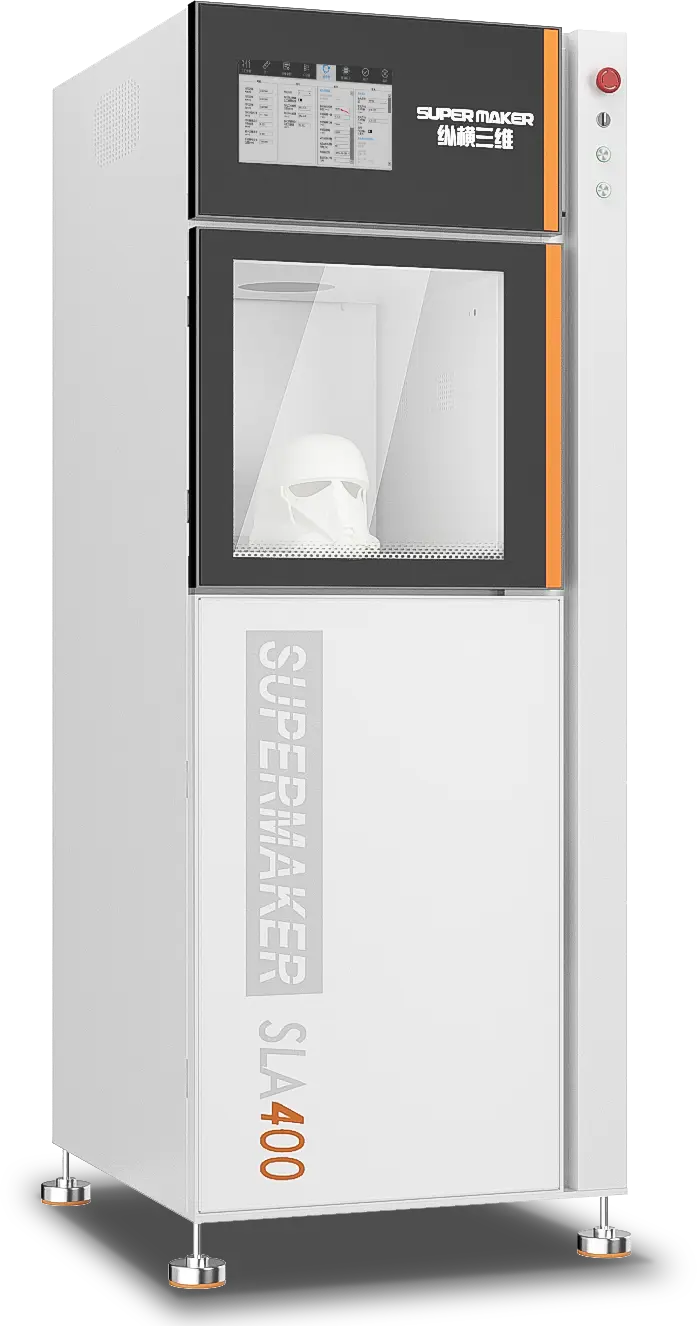

Relate All in One Industrial-Grade SLA 3D Printing Solutions

Super Maker SLA300

Discover Compact Industrial SLA 3D Machine With Constant Temperature and Humidity System

To overcome these limitations, it’s important to choose a reputable manufacturer with a track record of producing high-quality 3D printers. Look for manufacturers that offer technical support, maintenance services, and a wide range of materials to ensure that you can produce high-quality prints consistently.

FAQs: Answering Your Questions About DLP and SLA 3D Printing Technologies

If you’re still unsure about which 3D printing technology is right for you, here are some frequently asked questions that may help you make a decision:

What is the difference between DLP and SLA?

DLP (Digital Light Processing) and SLA (Stereolithography) are both 3D printing technologies that use liquid resin to create solid objects. However, they differ in the way that the resin is cured. DLP uses a digital projector to shine a pattern of light onto the resin, while SLA uses a laser to cure the resin layer by layer. This results in different print qualities, speeds, and costs.

Which technology is faster, DLP or SLA?

Generally, DLP is faster than SLA because it can cure entire layers of resin at once, while SLA cures the resin layer by layer using a laser. However, the speed of both technologies can vary depending on the printer model, material, and print settings.

Which technology has better resolution, DLP or SLA?

The cost of DLP and SLA printers can vary widely depending on the specific model, material, and print settings. Generally, DLP printers can be more expensive upfront, but they may offer faster print speeds and lower material costs in the long run. SLA printers may be less expensive upfront, but they may require more maintenance and have higher material costs. It’s important to evaluate the total cost of ownership, including printer cost, material cost, and maintenance cost, to determine which technology is more cost-effective for your needs.

Can DLP and SLA use the same materials?

DLP and SLA printers can use similar types of liquid resin, but the specific material properties may differ. DLP printers may be better suited for resins with a lower viscosity, while SLA printers may be better suited for resins with a higher viscosity.DLP printers use 405nm resin materials, SLA printers use 355nm resin materials. It’s important to evaluate the specific material properties required for your application to determine which technology is best for you.

Which technology is better for jewelry making, DLP or SLA?

Both DLP and SLA can be used for jewelry making, but DLP may be better suited for producing intricate designs with a smooth surface finish. SLA may be better suited for producing accurate models with precise details. It’s important to evaluate the specific needs of your jewelry-making application to determine which technology is best for you.

Which technology is better for dental models, DLP or SLA?

Both DLP and SLA can be used for dental models, but SLA may be better suited for producing accurate models with precise details. DLP may be better suited for producing models with a smooth surface finish. It’s important to evaluate the specific needs of your dental modeling application to determine which technology is best for you.

Which technology is better for prototyping, DLP or SLA?

Both DLP and SLA can be used for prototyping, but DLP may be better suited for producing prototypes with a smooth surface finish and thin walls. SLA may be better suited for producing prototypes with precise details and thick walls. It’s important to evaluate the specific needs of your prototyping application to determine which technology is best for you.

Which technology is better for production parts, DLP or SLA?

Both DLP and SLA can be used for production parts, but DLP may be better suited for producing parts with a smooth surface finish and thin walls. SLA may be better suited for producing parts with precise details and thick walls. It’s important to evaluate the specific needs of your production part application to determine which technology is best for you.

What are the maintenance requirements for DLP and SLA printers?

Both DLP and SLA printers require regular maintenance to ensure optimal performance. This includes cleaning the build platform, replacing consumables, and calibrating the printer. The specific maintenance requirements can vary depending on the printer model and usage.

What are some tips for getting the best results with DLP and SLA printers?

To get the best results with DLP and SLA printers, it’s important to follow the manufacturer’s guidelines for proper usage and maintenance. This includes using the correct material properties, adjusting the print settings as needed, and using proper support structures. It’s also important to regularly clean and maintain the printer to ensure optimal performance.

By answering these frequently asked questions, we hope that you now have a better understanding of the differences between DLP and SLA 3D printing technologies and can make an informed decision about which technology is right for you. Whether you’re a hobbyist looking to print intricate jewelry pieces, a dental technician creating accurate dental models, a product designer prototyping new designs, or a manufacturer producing high-quality parts, choosing the right 3D printing technology can help you achieve your goals and bring your ideas to life.