Imagine a school room wherein college students are not just passive recipients of facts however lively creators, engineers, and artists, bringing their thoughts to life with the touch of a button. This isn’t always a scene from a futuristic film; it’s the truth made feasible through Digital Light Processing (DLP) 3D printing. DLP 3D printing in education is a modern-day era that uses a virtual mild projector to treatment photopolymer resin, layer by using layer, to create highly specified and particular 3D items. Unlike traditional additive manufacturing methods, DLP 3D printing gives unheard of pace and accuracy, making it a really perfect device for academic environments.

Importance of Technology in Education

In these days’s hastily evolving international, the integration of technology in schooling isn’t always simply useful; it’s miles vital. Technology fosters an interactive and tasty gaining knowledge of environment, encourages creativity, and equips college students with the capabilities they need for the future. The use of DLP 3-d printing inside the lecture room is a top instance of how generation can remodel education by providing students with fingers-on getting to know stories that go past theoretical know-how.

The Power of Hands-On Learning

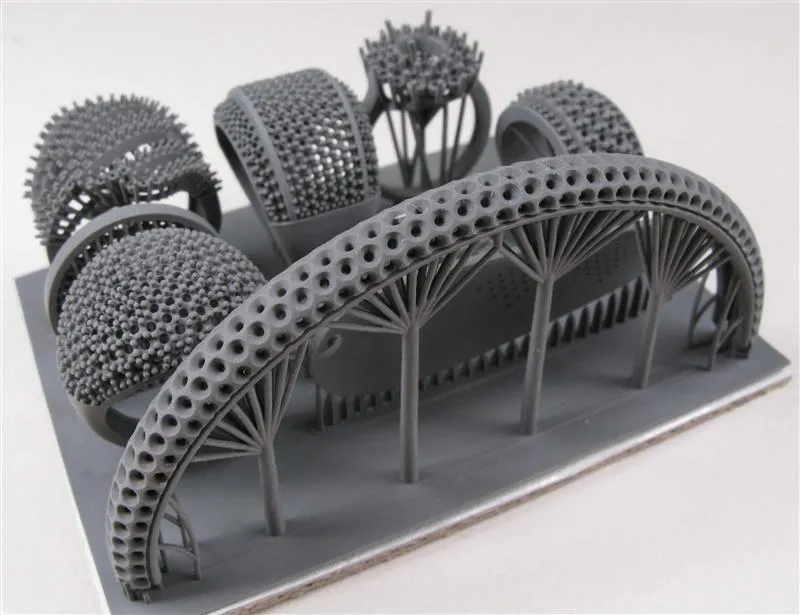

Consider this: A institution of center college college students tasked with designing and constructing their own miniature bridges. They brainstorm, sketch their ideas, after which use DLP 3-D printing to create bodily fashions in their designs. Through this method, they study engineering concepts, fabric homes, and structural integrity in a way this is each attractive and remarkable. This is the energy of arms-on gaining knowledge of thru generation, in which abstract principles are converted into tangible stories.

The Evolution of DLP 3D Printing in Education

The Evolution of 3D Printing Technology

Origins and Early Developments

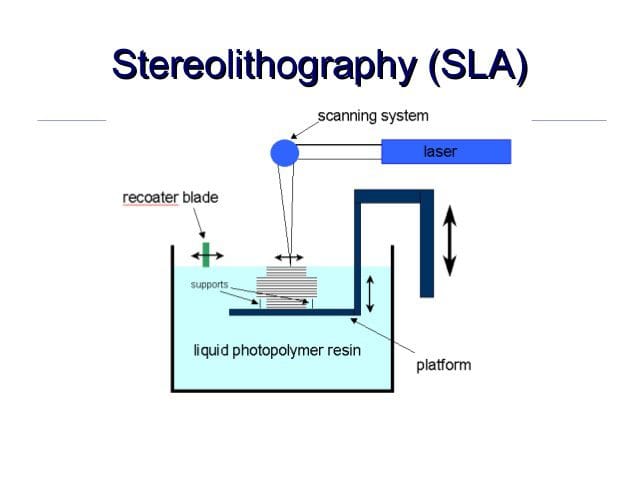

The journey of 3D printing technology began in the 1980s, a period marked by rapid technological advancements. The roots of 3D printing can be traced back to 1984, when Charles Hull invented stereolithography (SLA), a process that allowed the creation of three-dimensional objects using a digital file. This was a groundbreaking development, laying the foundation for various other 3D printing technologies that followed.

Key Milestones in 3D Printing

As we explore the historical context of DLP 3D printing, it’s essential to highlight some key milestones that shaped the evolution of 3D printing technology:

| Year | Milestone |

| 1984 | Charles Hull invents stereolithography (SLA). |

| 1988 | Scott Crump develops Fused Deposition Modeling (FDM). |

| 1992 | The first SLA 3D printer is commercialized. |

| 1999 | The first 3D printed organ (a bladder) is successfully implanted in a human. |

| 2005 | The RepRap project is launched, aiming to create a self-replicating 3D printer. |

| 2011 | The first 3D printed car, Urbee, is introduced. |

| 2014 | The first DLP 3D printers become commercially available. |

The Rise of DLP 3D Printing

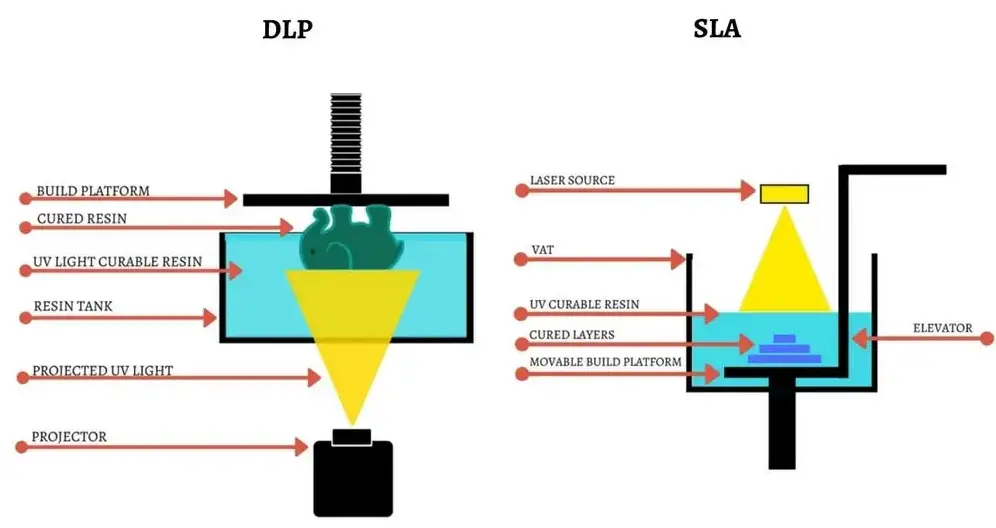

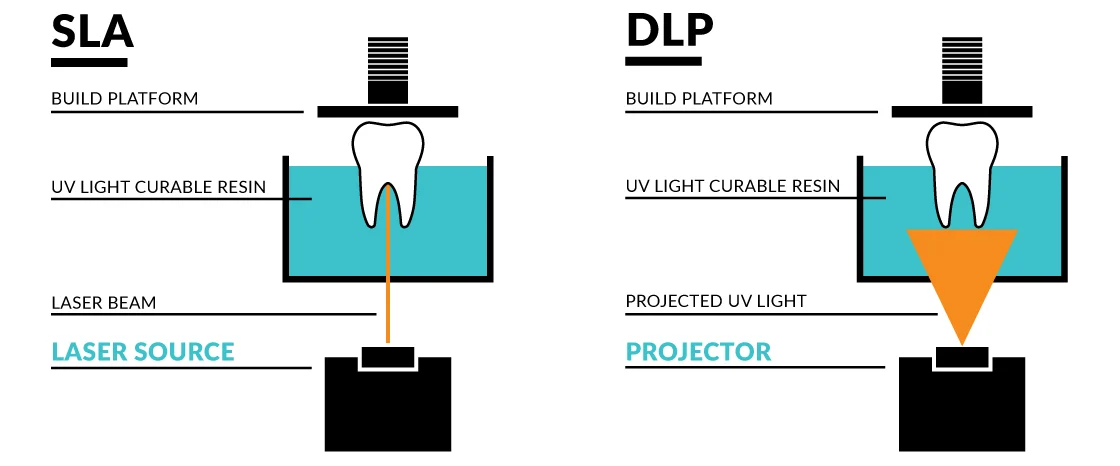

Digital Light Processing (DLP) three-D printing, a subset of vat photopolymerization, emerged as a sizeable innovation within the early twenty first century. Unlike SLA, which uses a laser to therapy resin, DLP makes use of a digital light projector to flash an entire image of a layer right now, bearing in mind quicker print instances and excessive-resolution consequences. This technology speedy gained traction because of its capability to provide particularly precise and accurate prints, making it best for packages requiring precision.

Introduction of DLP 3D Printing in Education

When Did DLP 3D Printing Start Being Used in Education?

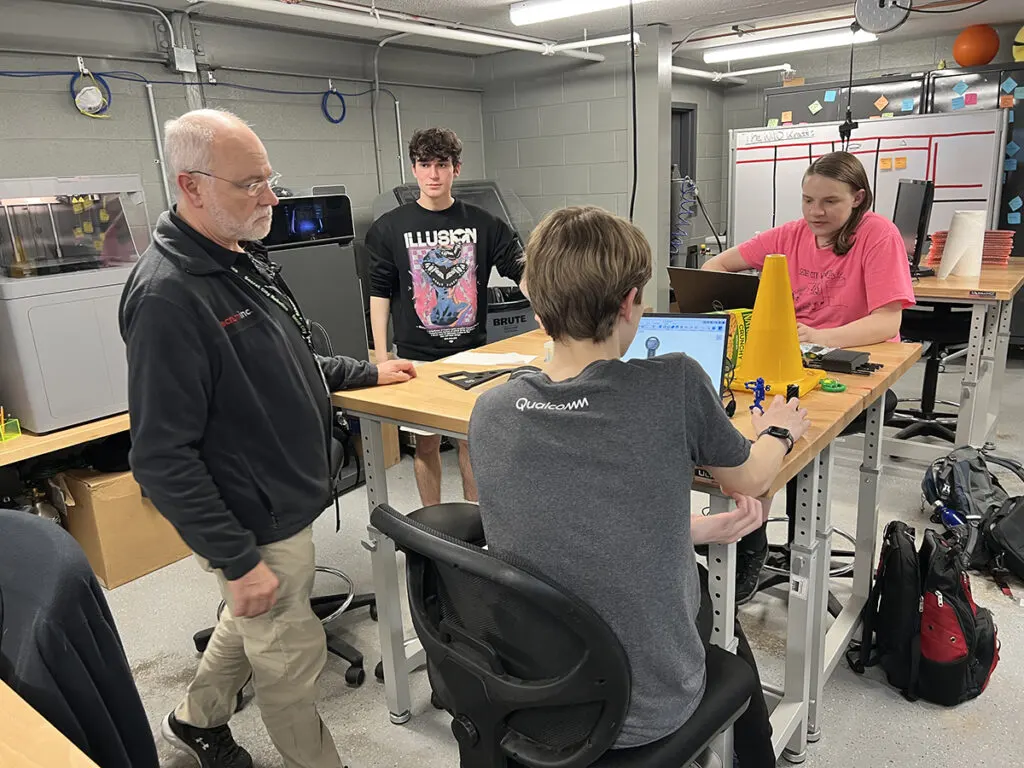

The integration of DLP 3D printing into instructional settings began around the mid-2010s. Early adopters diagnosed the capability of this era to enhance mastering reviews and offer students with palms-on possibilities to explore complicated principles. Pilot packages in numerous schools and universities tested the feasibility and advantages of incorporating DLP 3D printing into the curriculum.

Early Adopters and Pilot Programs

Several pioneering institutions led the way in adopting DLP 3D printing for educational purposes. These early adopters included:

- Universities: Institutions like MIT and Stanford began exploring the educational applications of DLP 3D printing, integrating it into engineering and design programs.

- High Schools: Forward-thinking high schools introduced 3D printing labs, allowing students to engage in creative and technical projects.

- Specialized Programs: Programs focused on STEM education and special education saw significant benefits from incorporating DLP 3D printing.

Impact on Education

The introduction of DLP 3D printing in education has had a profound impact, reshaping traditional teaching methods and empowering students to become active participants in their learning journey. Some notable impacts include:

- Enhanced Engagement: Students are more engaged and motivated when they can physically create and manipulate objects related to their studies.

- Improved Understanding: Complex concepts, particularly in STEM fields, become easier to understand when students can visualize and interact with 3D models.

- Skill Development: Students develop valuable skills such as problem-solving, critical thinking, and creativity through hands-on projects.

The ancient context of DLP 3-d printing in schooling exhibits a fascinating journey of technological innovation and academic transformation. From its origins inside the Eighties to its present day applications in lecture rooms around the world, DLP 3-d printing has tested to be a effective tool for enhancing getting to know experiences. As we pass ahead, the ongoing evolution of this era guarantees even extra possibilities for the future of education.

Technical Aspects of DLP 3D Printing

Core Components and Mechanisms

The Heart of DLP 3D Printing: The Projector

At the core of DLP 3D printing technology is the Digital Light Processing (DLP) projector. Unlike traditional 3D printing methods that use a laser or nozzle to create objects layer by layer, DLP 3D printing employs a digital light projector to flash an entire image of a layer all at once. This technique significantly speeds up the printing process and ensures high precision and accuracy.

Here’s how it works:

- Digital Projection: The projector casts a digital image of the object’s cross-section onto a vat of photopolymer resin.

- Curing Resin: The light from the projector cures (hardens) the resin, creating a solid layer.

- Layer-by-Layer Construction: The build platform moves up incrementally as each new layer is projected and cured.

Resin Materials

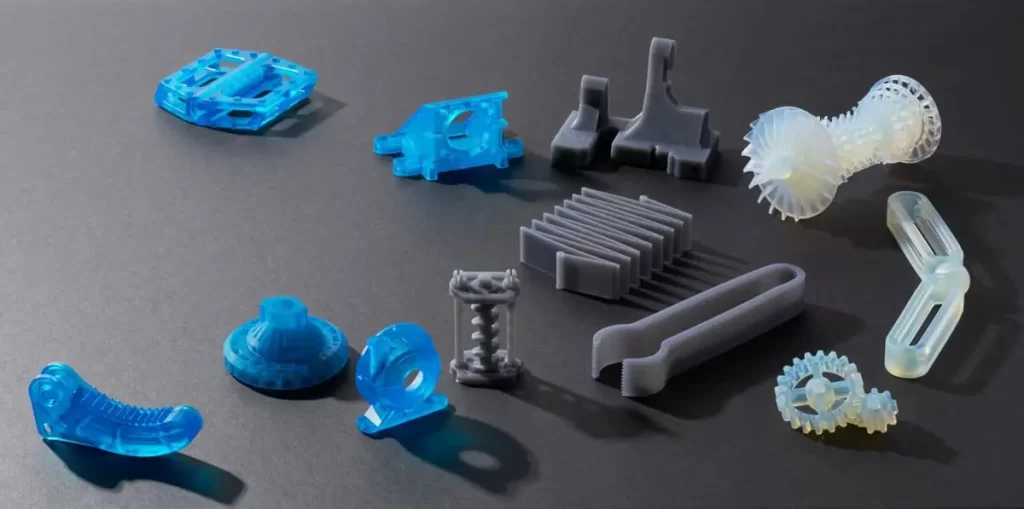

DLP 3D printing uses photopolymer resins, which are liquid materials that harden when exposed to light. Various types of resins are available, each with unique properties suitable for different applications. Some common types include:

- Standard Resins: Ideal for general-purpose printing, offering a balance of strength and detail.

- Tough Resins: Designed for durability and impact resistance, suitable for functional prototypes.

- Flexible Resins: Provide rubber-like flexibility, used for creating soft-touch parts.

- Castable Resins: Used in jewelry and dental industries, these resins can be burned out cleanly to create molds.

Slicing Software

Before a 3D model can be printed, it must be sliced into thin layers using specialized software. Slicing software converts a 3D model into a series of 2D images, each representing a single layer of the object. This software also generates the necessary instructions for the printer to follow, including:

- Layer Thickness: Determines the height of each layer, affecting the print’s resolution and time.

- Exposure Time: Controls how long the resin is exposed to light, influencing the curing process.

- Support Structures: Adds supports to overhanging parts of the model to ensure proper printing.

Popular slicing software for DLP 3D printing includes ChiTuBox, PreForm, and NanoDLP.

Comparison with Other 3D Printing Technologies

DLP vs. FDM (Fused Deposition Modeling)

| Feature | DLP 3D Printing | FDM 3D Printing |

| Precision | High precision and fine details | Lower precision, visible layer lines |

| Speed | Faster due to layer-by-layer projection | Slower, builds layer by layer |

| Material | Photopolymer resin | Thermoplastic filaments |

| Surface Finish | Smooth surface finish | Rougher surface, requires post-processing |

| Applications | Jewelry, dental, miniatures | Prototyping, functional parts |

Understanding the technical aspects of DLP three-D printing is critical for educators and students alike, as it offers insight into how this progressive era works and what makes it particular. From the center additives just like the DLP projector and photopolymer resins to the slicing software program that prepares fashions for printing, every detail plays a crucial function in the technique. Comparing DLP with different three-D printing technology highlights its benefits in speed, precision, and floor end, whilst additionally acknowledging its barriers.

Educational Applications of DLP 3D Printing

STEM Education

How DLP 3D Printing Supports STEM Learning

Science, Technology, Engineering, and Mathematics (STEM) education aims to equip students with critical thinking, problem-solving, and technical skills. DLP 3D printing serves as a powerful tool in this endeavor by providing hands-on learning experiences that make abstract STEM concepts tangible and understandable.

Key ways DLP 3D printing supports STEM learning:

- Visualization of Complex Concepts: Students can create 3D models of molecules, geometric shapes, and engineering components, helping them to grasp complex theories and principles.

- Prototyping and Experimentation: Encourages iterative design and experimentation, allowing students to prototype and test their ideas in real-time.

- Interdisciplinary Projects: Integrates multiple STEM subjects into cohesive projects, fostering a holistic understanding of how these fields intersect.

Examples of STEM Projects Using DLP 3D Printing

- Engineering: Designing and printing bridges, gears, and mechanical parts to learn about structural integrity and mechanical engineering principles.

- Biology: Creating detailed models of organs, cells, and DNA structures to study biological systems and processes.

- Physics: Developing and testing aerodynamic models, such as wings and propellers, to explore principles of flight and fluid dynamics.

- Chemistry: Printing molecular models to visualize and understand chemical bonds and reactions.

Art and Design

Integrating DLP 3D Printing in Art and Design Curriculum

DLP 3D printing is not limited to the sciences; it also offers immense opportunities in the fields of art and design. By incorporating this technology into the curriculum, educators can expand the creative horizons of their students.

Ways to integrate DLP 3D printing in art and design:

- 3D Sculptures and Models: Students can design and print intricate sculptures, exploring form, texture, and spatial relationships.

- Jewelry and Fashion Design: Enables the creation of custom jewelry pieces and fashion accessories, allowing students to experiment with unique designs and materials.

- Graphic Design: Provides a new dimension to graphic design projects by transforming digital designs into physical objects.

Case Studies of Art Projects Created with DLP 3D Printing

- Sculpture Classes: Students create detailed busts and abstract sculptures, learning about the interplay of light, shadow, and texture in three-dimensional forms.

- Jewelry Workshops: Design and print custom rings, necklaces, and earrings, exploring concepts of symmetry, balance, and aesthetics.

- Fashion Design Studios: Develop avant-garde clothing accessories and footwear, pushing the boundaries of traditional fashion design.

Special Education

Benefits of DLP 3D Printing for Special Education

Students with special needs often require tailored educational tools and resources. DLP 3D printing can create customized, adaptive learning aids that enhance their educational experience and support their unique learning requirements.

Benefits of DLP 3D printing in special education:

- Customized Learning Aids: Create tactile learning aids, such as braille blocks and sensory toys, to support students with visual and sensory impairments.

- Assistive Devices: Develop custom assistive devices, like ergonomic grips and adaptive tools, to aid students with motor skill challenges.

- Inclusive Learning: Ensure all students can participate in hands-on projects, fostering an inclusive learning environment.

Custom Educational Tools and Aids

- Tactile Learning Aids: Printing 3D models of letters, numbers, and shapes for visually impaired students to explore through touch.

- Adaptive Tools: Creating customized grips for pencils, utensils, and other tools to help students with fine motor skill difficulties.

- Communication Devices: Designing and printing communication boards and other AAC (Augmentative and Alternative Communication) devices to support non-verbal students.

DLP 3D printing’s versatility and precision make it an invaluable tool across numerous instructional disciplines. From enhancing STEM training via palms-on projects that bring theoretical concepts to existence, to fostering creativity in art and design, and providing customized answers in special education, the packages are good sized and transformative.

Pedagogical Benefits of DLP 3D Printing

Enhancing Creativity

How DLP 3D Printing Fosters Creative Thinking

Creativity is a crucial skill for students, enabling them to think outside the box and approach problems with innovative solutions. DLP 3D printing serves as a catalyst for creative thinking by providing a platform where imagination meets reality.

WaysDLP 3D printing fosters creativity:

- Design Freedom: Students have the freedom to design and create virtually anything they can imagine, from intricate jewelry to complex architectural models.

- Iterative Design Process: Encourages students to experiment, fail, and improve their designs, fostering a growth mindset.

- Cross-Disciplinary Projects: Combines elements of art, engineering, and science, encouraging students to apply creative thinking across different fields.

Examples of Creative Projects

- Interactive Art Installations: Students design and 3D print components for art installations that incorporate movement, light, and sound.

- Custom Game Pieces: Creating unique board game pieces or parts for custom-designed games, blending creativity with game design principles.

- Personalized Classroom Tools: Designing and printing custom tools or classroom aids, such as unique bookends, nameplates, or teaching aids.

Promoting Hands-On Learning

The Importance of Hands-On Learning

Hands-on learning is an educational approach that emphasizes active participation and experiential learning. It helps students understand and retain complex concepts by engaging multiple senses and providing practical applications of theoretical knowledge.

Benefits of hands-on learning with DLP 3D printing:

- Active Engagement: Students are more engaged when they can physically interact with the materials they are learning about.

- Real-World Applications: Provides practical experience in design, engineering, and manufacturing, bridging the gap between classroom learning and real-world applications.

- Enhanced Retention: Hands-on activities improve memory retention by involving multiple senses and reinforcing learning through action.

Practical Applications in the Classroom

- Engineering Projects: Students design, print, and test various mechanical parts, learning about material properties and engineering principles.

- Biology Models: Creating detailed anatomical models to study human or animal anatomy, providing a tactile learning experience.

- Historical Artifacts: Printing replicas of historical artifacts for history lessons, allowing students to explore and analyze physical objects from different time periods.

Encouraging Collaborative Learning

The Power of Teamwork

Collaborative learning is an educational approach where students work together to achieve common goals. It fosters communication, teamwork, and problem-solving skills, preparing students for collaborative work environments in their future careers.

How DLP 3D printing encourages collaborative learning:

- Group Projects: Students collaborate on design and printing projects, sharing ideas, and dividing tasks based on individual strengths.

- Peer Learning: Encourages students to learn from one another, sharing knowledge and skills related to 3D design and printing.

- Problem-Solving: Teams work together to troubleshoot design and printing issues, developing critical thinking and problem-solving skills.

Examples of Collaborative Projects

- Robotics Teams: Students work together to design, print, and assemble parts for a robotics competition, learning about teamwork and mechanical engineering.

- Classroom Dioramas: Groups of students create detailed dioramas of historical events or ecosystems, combining research with 3D printing.

- Community Projects: Collaborating on projects that benefit the community, such as designing and printing custom tools or aids for local organizations.

Building Technical Skills

Developing Future-Ready Skills

Incorporating DLP 3D printing into the curriculum helps students develop technical skills that are highly valued in today’s job market. These skills include 3D modeling, design thinking, and an understanding of modern manufacturing processes.

Technical skills gained through DLP 3D printing:

- 3D Modeling: Students learn to use CAD (Computer-Aided Design) software to create digital models.

- Digital Literacy: Understanding the principles and processes behind digital fabrication and manufacturing.

- Problem-Solving: Developing the ability to troubleshoot and solve technical issues during the design and printing process.

Career Pathways

- Engineering: Skills in 3D printing are highly relevant in fields such as mechanical, aerospace, and civil engineering.

- Product Design: Knowledge of 3D modeling and printing is crucial for careers in industrial and product design.

- Medical Fields: 3D printing is increasingly used in medical fields for creating prosthetics, implants, and anatomical models.

The pedagogical benefits of DLP 3D printing are good sized and multifaceted, enhancing creativity, promoting fingers-on studying, encouraging collaborative efforts, and constructing critical technical skills. By integrating this era into the study room, educators can create a dynamic and attractive gaining knowledge of surroundings that prepares college students for destiny academic and career success.

Implementation Strategies and Challenges of DLP 3D Printing in Education

Strategies for Successful Integration

Assessing Educational Needs

Before integrating DLP 3D printing into the curriculum, it’s essential to assess the specific educational needs and goals. This ensures that the technology is used effectively to enhance learning outcomes.

Steps to assess educational needs:

- Identify Learning Objectives: Determine what skills and knowledge students should gain from using 3D printing.

- Curriculum Alignment: Ensure that 3D printing projects align with existing curriculum standards and learning objectives.

- Resource Availability: Evaluate the availability of resources, including budget, space, and technical support.

Professional Development for Educators

Educators play a critical role in the successful implementation of DLP 3D printing. Providing professional development opportunities ensures that teachers are well-equipped to integrate this technology into their teaching practices.

Professional development strategies:

- Workshops and Training Sessions: Offer hands-on workshops and training sessions to familiarize educators with 3D printing technology and software.

- Online Courses and Webinars: Provide access to online courses and webinars for continuous learning and skill development.

- Collaborative Learning Communities: Establish communities of practice where educators can share experiences, resources, and best practices.

Curriculum Integration

Integrating DLP 3D printing into the curriculum requires thoughtful planning and collaboration among educators.

Approaches to curriculum integration:

- Project-Based Learning: Design projects that incorporate 3D printing into various subjects, such as science, math, art, and history.

- Interdisciplinary Projects: Create interdisciplinary projects that combine elements from different subjects, promoting a holistic learning experience.

- Assessment and Evaluation: Develop assessment criteria to evaluate student learning and the effectiveness of 3D printing projects.

Practical Tips for Classroom Implementation

Setting Up a 3D Printing Lab

Creating a dedicated space for 3D printing enhances the learning experience and ensures smooth operations.

Steps to set up a 3D printing lab:

- Space Allocation: Choose a well-ventilated area with sufficient space for printers, workstations, and storage.

- Equipment Selection: Select appropriate DLP 3D printers and accessories based on educational needs and budget.

- Safety Protocols: Establish safety protocols, including proper handling of resins, ventilation, and emergency procedures.

Managing the Printing Process

Effective management of the printing process ensures that projects run smoothly and efficiently.

Tips for managing the printing process:

- Print Scheduling: Create a schedule to manage print jobs and ensure all students have access to the printer.

- File Preparation: Teach students how to prepare and slice their 3D models for printing.

- Supervised Printing: Monitor the printing process to address any issues that may arise and ensure quality control.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential to keep the 3D printer in optimal condition.

Maintenancetips:

- Regular Cleaning: Clean the printer and build platform regularly to prevent resin buildup and ensure optimal performance.

- Software Updates: Keep the printer’s firmware and slicing software up to date.

- Troubleshooting Guides: Provide students with troubleshooting guides to address common issues, such as print failures or hardware malfunctions.

Addressing Challenges

Budget Constraints

One of the primary challenges of integrating DLP 3D printing into education is budget constraints. However, there are strategies to mitigate costs and make the technology accessible.

Strategies to address budget constraints:

- Grants and Funding: Apply for grants and funding opportunities specifically for educational technology and STEM initiatives.

- Community Partnerships: Partner with local businesses, universities, and organizations to share resources and expertise.

- Cost-Effective Materials: Opt for cost-effective resins and materials without compromising quality.

Technical Challenges

Technical challenges can arise during the implementation of DLP 3D printing, but proactive measures can help address these issues.

Common technical challenges and solutions:

- Printer Calibration: Ensure the printer is properly calibrated to avoid print failures and ensure high-quality results.

- Software Compatibility: Use compatible slicing software and regularly update it to prevent compatibility issues.

- Technical Support: Provide access to technical support and resources for troubleshooting and maintenance.

Student Accessibility and Inclusion

Ensuring that all students have access to 3D printing technology and can benefit from its educational potential is crucial.

Strategies for promoting accessibility and inclusion:

- Adaptive Tools: Create adaptive tools and resources for students with special needs to ensure they can participate in 3D printing projects.

- Digital Literacy: Provide training and support to help all students develop the necessary digital literacy skills.

- Inclusive Curriculum: Design projects that cater to diverse learning styles and abilities, promoting an inclusive learning environment.

The use of DLP 3D printing in education requires careful planning, resource allocation and ongoing support. By assessing educational needs, providing professional development for teachers, and creatively integrating 3D printing into the curriculum, schools can harness the full potential of this technology. Addressing challenges such as funding constraints, technical issues, and ensuring accessibility and inclusion ensures that all students benefit from the transformative power of DLP 3D printing.

Case Studies and Success Stories of DLP 3D Printing in Education

Case Study 1: Enhancing STEM Education at Oak Ridge High School

Background

Oak Ridge High School, a public school with a strong emphasis on STEM education, sought to enhance their curriculum by incorporating cutting-edge technologies. The administration decided to integrate DLP 3D printing to provide students with hands-on learning experiences in engineering, biology, and physics.

Implementation

Key steps in implementation:

- Teacher Training: Educators attended workshops on 3D printing technology, learning how to operate the printers and integrate them into their lesson plans.

- Curriculum Development: The school developed interdisciplinary projects that utilized 3D printing, aligning them with state STEM standards.

- Resource Allocation: Oak Ridge allocated funds to purchase several DLP 3D printers and necessary materials, ensuring that each STEM classroom had access to the technology.

Outcomes

Positive outcomes observed:

- Increased Engagement: Students showed higher levels of engagement and enthusiasm for STEM subjects.

- Improved Understanding: Hands-on projects helped students better understand complex concepts, such as molecular structures in chemistry and force dynamics in physics.

- Skill Development: Students developed valuable technical skills, including 3D modeling and problem-solving.

Example Projects:

- Engineering: Students designed and printed functional prototypes of simple machines, such as levers and pulleys.

- Biology: Detailed models of human organs were created for anatomy lessons, providing a tactile learning experience.

- Physics: Aerodynamic models, such as gliders, were printed and tested, allowing students to explore principles of flight and air resistance.

Case Study 2: Empowering Creativity at Lincoln Middle School

Background

Lincoln Middle School, known for its strong arts program, aimed to integrate technology into their art and design classes. The school introduced DLP 3D printing to empower students to bring their creative visions to life.

Implementation

Key steps in implementation:

- Professional Development: Art teachers received training on 3D design software and DLP 3D printing techniques.

- Collaborative Projects: The school encouraged collaborative projects that combined art and technology, fostering a multidisciplinary approach.

- Project-Based Learning: Students were assigned various projects that required them to design and print their own creations, from sculptures to custom jewelry pieces.

Outcomes

Positive outcomes observed:

- Enhanced Creativity: Students explored new dimensions of creativity, experimenting with shapes, textures, and materials.

- Cross-Disciplinary Learning: Projects that combined art and technology helped students see the connections between different subjects.

- Student Achievement: Several students received awards in local and national design competitions, showcasing their 3D printed work.

Example Projects:

- Sculpture: Students designed and printed intricate sculptures, experimenting with abstract forms and textures.

- Jewelry Design: Custom rings, necklaces, and bracelets were created, allowing students to explore fashion and design principles.

- Interactive Installations: Groups of students collaborated to create interactive art installations that incorporated 3D printed elements, light, and sound.

Case Study 3: Inclusive Education at Harmony Special Needs School

Background

Harmony Special Needs School sought to enhance their educational programs by providing customized learning aids for students with disabilities. The school introduced DLP 3D printing to create adaptive tools and resources tailored to each student’s needs.

Implementation

Key steps in implementation:

- Needs Assessment: The school conducted a thorough assessment to identify the unique needs of each student and determine how 3D printing could support their learning.

- Custom Tool Design: Educators and support staff worked together to design and print customized tools and learning aids.

- Ongoing Training: Teachers and support staff received continuous training on 3D printing technology and adaptive design principles.

Outcomes

Positive outcomes observed:

- Increased Accessibility: Custom learning aids made educational content more accessible to students with various disabilities.

- Enhanced Engagement: Students showed higher levels of engagement and participation in classroom activities.

- Improved Learning Outcomes: Tailored tools and resources helped improve learning outcomes, particularly in reading, writing, and math.

Example Projects:

- Tactile Learning Aids: 3D printed braille blocks and tactile alphabet sets were created for visually impaired students.

- Adaptive Tools: Customized grips for pencils and utensils were designed to support students with fine motor challenges.

- Communication Aids: Communication boards and AAC devices were printed to assist non-verbal students in expressing themselves.

These case studies and success stories highlight the transformative impact of DLP 3D printing in various educational settings. From enhancing STEM education and empowering creativity to providing inclusive learning environments, DLP 3D printing offers endless possibilities for enriching the educational experience.

Resources and Recommendations for DLP 3D Printing in Education

Recommended Software and Tools

3D Modeling Software

To fully utilize DLP 3D printing, students and educators need access to robust 3D modeling software. These tools allow users to design and modify objects before printing.

Popular 3D modeling software:

- Tinkercad: An easy-to-use, web-based application ideal for beginners. It offers a simple interface and a wide range of basic design tools.

- Blender: A powerful, open-source software with advanced modeling, sculpting, and animation features. Suitable for more experienced users.

- Fusion 360: A professional-grade software that offers comprehensive 3D design, engineering, and simulation capabilities. Free licenses are available for educational institutions.

- SketchUp: User-friendly software ideal for architectural and interior design projects. It offers both free and paid versions.

Slicing Software

Slicing software is essential for preparing 3D models for printing. It converts the 3D model into layers and generates the necessary instructions for the 3D printer.

Recommended slicing software:

- ChiTuBox: A popular choice for DLP 3D printers, offering a range of settings to optimize print quality and speed.

- PrusaSlicer: Open-source software that supports various 3D printers and offers advanced slicing features.

- Lychee Slicer: Known for its user-friendly interface and powerful features, including automatic supports and resin profiles.

Educational Resources and Tutorials

Online Courses and Tutorials

Numerous online courses and tutorials are available to help educators and students learn about 3D printing technology and design principles.

Recommended platforms for online learning:

- Coursera: Offers courses on 3D printing fundamentals and advanced techniques, often in partnership with universities.

- Udemy: Provides a wide range of courses on 3D modeling, 3D printing, and specific software tutorials.

- YouTube: Features countless free tutorials on 3D design and printing, covering various software and techniques.

Books and Publications

Books and publications can provide in-depth knowledge and insights into 3D printing technology and its applications in education.

Recommended reading:

- “3D Printing Projects” by DK: A beginner-friendly guide with step-by-step projects for students and educators.

- “The 3D Printing Handbook” by Ben Redwood: A comprehensive resource covering 3D printing technologies, materials, and best practices.

- “3D Printing for Dummies” by Kalani Kirk Hausman and Richard Horne: An accessible introduction to 3D printing, ideal for educators new to the technology.

Funding and Grant Opportunities

Securing funding is often a critical step in implementing DLP 3D printing in educational settings. Various grants and funding opportunities are available to support technology integration in schools.

Potential funding sources:

- National Science Foundation (NSF): Offers grants for STEM education initiatives, including projects involving 3D printing.

- DonorsChoose: A crowdfunding platform where educators can request funding for specific classroom projects and resources.

- Local Community Grants: Many local businesses and organizations offer grants to support educational technology and STEM programs.

Community and Support Networks

Online Communities

Joining online communities can provide valuable support, resources, and networking opportunities for educators and students involved in 3D printing.

Popular online communities:

- Thingiverse: A platform for sharing 3D printable designs and models, with an active community of designers and educators.

- MyMiniFactory: Another repository for 3D models, offering a range of educational resources and community forums.

- Reddit: Subreddits like r/3Dprinting and r/3Dmodeling provide a space for users to share tips, ask questions, and showcase their work.

Professional Organizations

Professional organizations can offer additional resources, professional development opportunities, and networking events for educators.

Notable organizations:

- International Society for Technology in Education (ISTE): Provides resources, conferences, and professional development programs focused on integrating technology into education.

- National Science Teachers Association (NSTA): Offers resources, grants, and professional development opportunities for science educators, including those using 3D printing.

Integrating DLP 3D printing into education offers numerous benefits, from enhancing creativity and hands-on learning to promoting collaboration and technical skill development. By leveraging the recommended software, tools, educational resources, funding opportunities, and community networks, educators can effectively incorporate this transformative technology into their classrooms.