Welcome to the future of design where imagination takes physical form, right from the comfort of your home or office. Yes, we’re talking about 3D printing – a technology that combines creativity and functionality to redefine how we create things.

Now, if you’re a beginner, stepping into the world of 3D printing might seem daunting. With many different printing technologies out there, how do you choose the right one for you? That’s where we come in. We want to introduce you to the world of Digital Light Processing or DLP – a 3D printing process that can create intricate, high-quality prints at a relatively low cost.

In the upcoming sections of this guide, we’ll dive into the world of DLP 3D printing, why it’s a great choice for beginners, what features to look for when buying your first DLP 3D printer, and our top recommendations. And of course, we’ll share our expert tips to get you started on your DLP 3D printing journey smoothly and successfully.

Understanding DLP 3D Printing

In the realm of 3D printing, DLP or Digital Light Processing stands as a beacon of precision and finesse. This advanced printing technology caters perfectly to individuals who crave high resolution and intricacy in their 3D creations. But how does it work? And what makes it different? Let’s peel back the layers and dive deep into the mechanism of DLP 3D printing.

What is DLP 3D Printing?

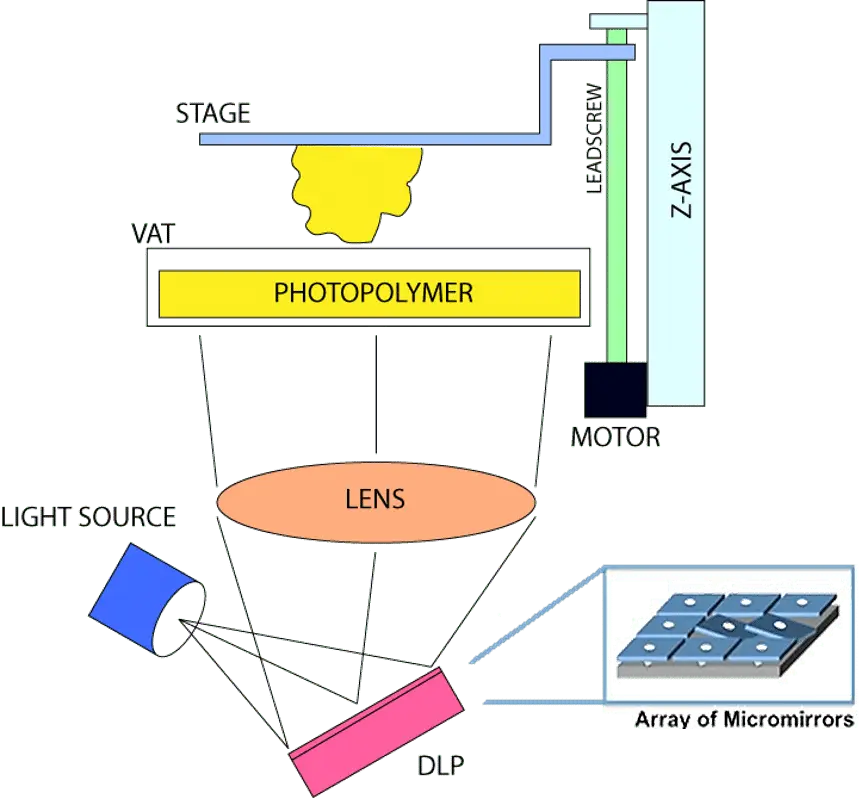

DLP belongs to the Vat Photopolymerization family of 3D printing, where liquid resin in a vat is cured layer by layer using light to form a solid part. The name DLP comes from the original projector technology developed by Texas Instruments that forms the backbone of this 3D printing method.

How DLP 3D Printing Works

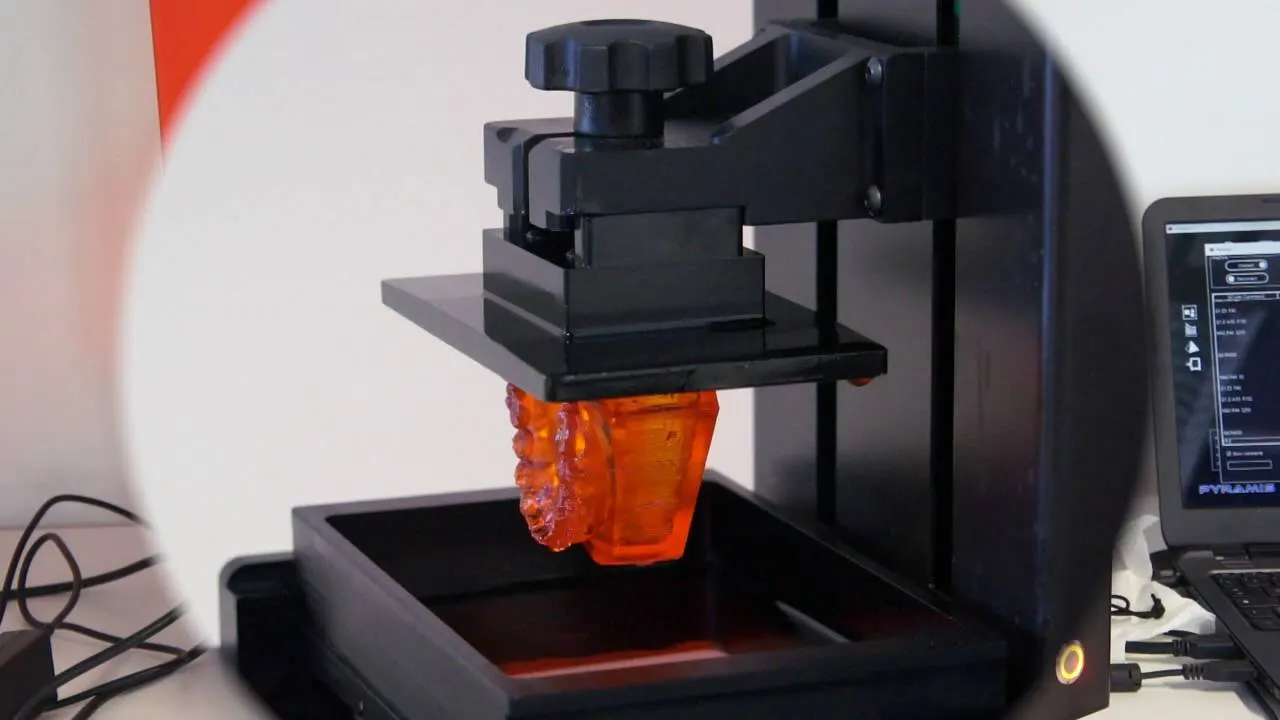

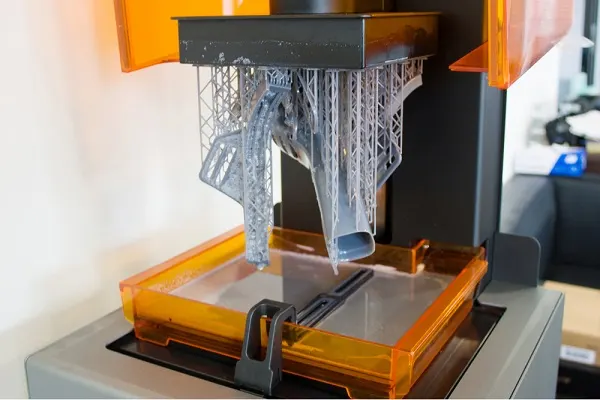

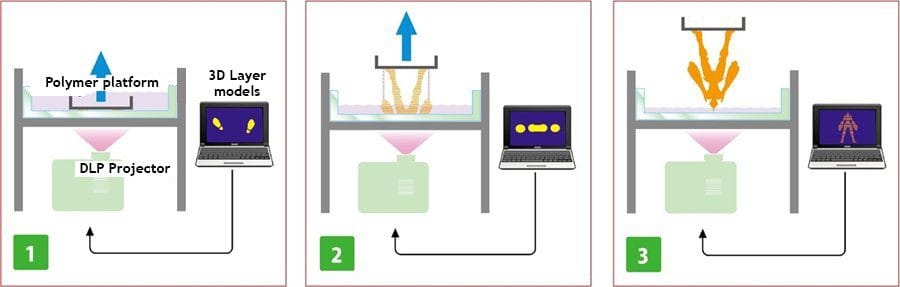

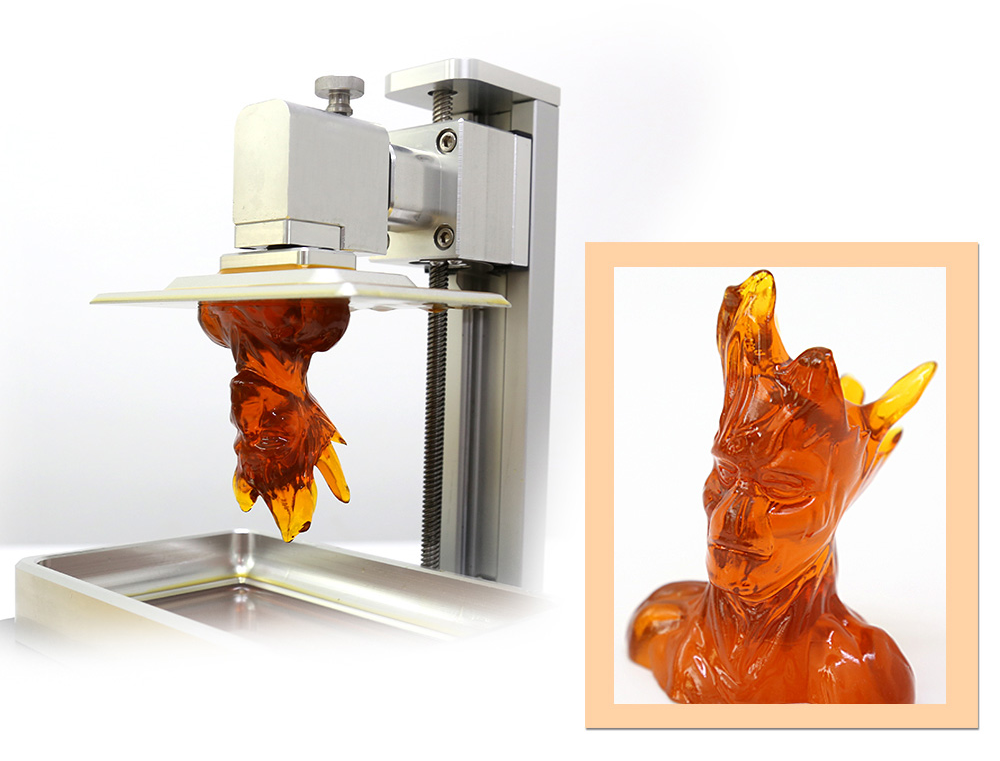

At its core, DLP 3D printing employs a digital projector screen to flash a single image of each layer across the entire platform at once. Specifically, the process involves these following steps:

- Preparation: The build platform submerges into the vat of photopolymer resin.

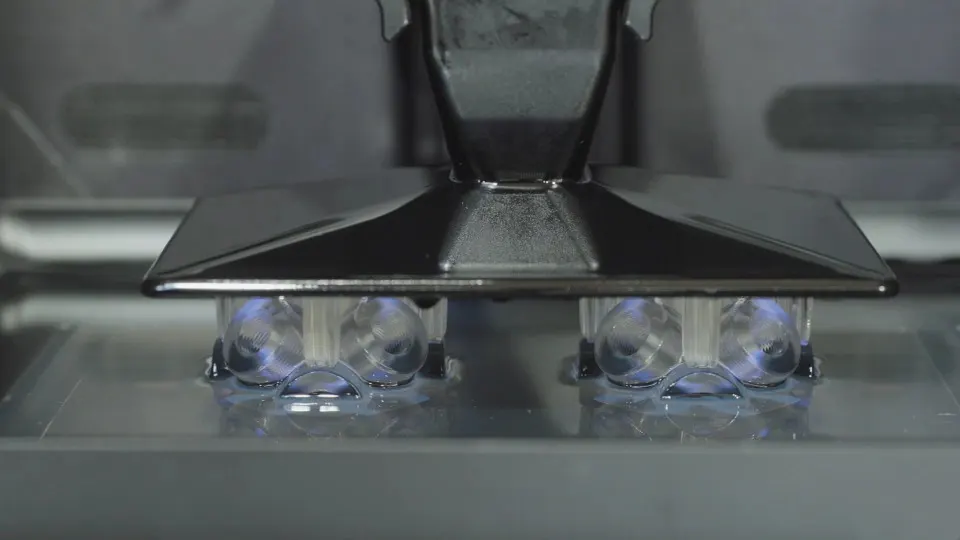

- Printing: The DLP projector, located under the transparent-bottomed vat, flashes a slice of an object’s 3D model, hardening that cross-section of the resin.

- Layer Creation: The platform then lifts, peeling the newly solid layer from the bottom of the tank. It then re-dips into the vat and the projector flashes the next slice.

- Completion: This process repeats layer by layer until the object is complete.

- Post-processing: After printing, the part undergoes cleaning and additional UV curing.

Advantages of DLP 3D Printing

There are several reasons why DLP technology stands out in the pantheon of 3D printing processes. Here are the key advantages:

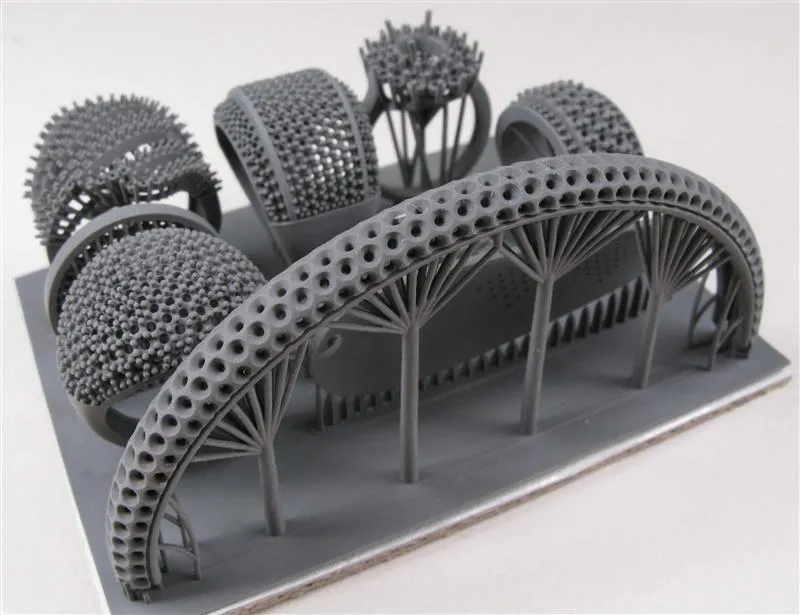

- High Resolution: DLP 3D printers are capable of producing highly detailed parts with smoother finishes.

- Speed: Unlike other processes, DLP can cure an entire layer of the model at once, making it comparatively faster.

- Efficiency: DLP 3D printers are more material-efficient, making them a cost-effective choice.

- Versatility: Available in desktop and industrial scale variations, there is a DLP printer for every need and budget.

Why Choose a DLP 3D Printer as a Beginner?

Stepping into the expansive world of 3D printing, newcomers are often overwhelmed by the range of technologies to choose from. One crucial question emerges: “Where should I begin?” If you’re asking this, we’re here to answer it for you.

Digital Light Processing (DLP) 3D printers are an excellent starting point for beginners. The reasons are many, ranging from their easy learning curve, economical pricing, high-quality results, to speed of printing.

Ease of Learning and Operation

For many beginners, understanding and starting the journey of 3D printing can appear daunting. This is where DLP 3D printers make a difference. The simplicity of their operational concept is a guiding hand for the uninitiated. The mechanism of DLP 3D printing is straightforward:

A digital light projector screen ¬– the heart of a DLP 3D printer – flashes an image of each layer across the entire platform at once, layer by layer until the model is complete. Simple, isn’t it?

Economical Pricing

DLP 3D printers are considered more cost-effective than many of their counterparts. Not only are the printers themselves relatively affordable, but their running costs can be lower due to higher material efficiency. The resin used in DLP printers tends to be less wasteful compared to other 3D printing technologies.

High-Quality and Detailed Prints

With DLP 3D printers, the layer-by-layer curing mechanism enables high precision and intricate detailing in the final print. DLP machines are capable of reproducing intricate designs with an excellent level of detail, making them the preferred choice for industries that require high precision, such as jewelry, dental, and auditory device market.

Speed of Printing

DLP holds an advantage in print speed over other types of 3D printing since it cures an entire layer of the model at once. This is especially beneficial for designs that have a larger cross-sectional area, where DLP substantially speeds up the print time, providing quick and impressive results.

Table: Brief Comparison of DLP and Other 3D Printing Technologies

| 3D Printing Technology | Ease of Learning | Price | Print Quality | Print Speed |

| DLP | High | Low | High | High |

| FDM | High | Low | Moderate | Moderate |

| SLA | Moderate | High | High | Moderate |

Key Features to Consider When Choosing a DLP 3D Printer

Deciding to venture into the realm of 3D printing is one thing. However, choosing the right printer that caters to your specific needs can be a challenge. Here, we assemble the essential components you need to look for when choosing your first Digital Light Processing (DLP) 3D printer.

Printer Size

The size of the printer determines the maximum size of objects you can print. You’ll need to balance your requirements with available space. Desktop DLP3D printers are compact and excellent for small workspaces and homes while industrial-scale DLP printers are suited for larger projects in workshops or labs.

Print Accuracy

Are you looking for highly detailed prints? If so, consider printers that offer high resolution. A high-resolution DLP 3D printer can produce intricate models with a high level of detailing.

Material Compatibility

Check what types of resins the printer is compatible with. While most DLP printers can utilize a wide range of materials, material compatibility can impact print quality and the ultimate use of the printed object.

Software Compatibility

Some DLP printers come with proprietary software, while others are open to third-party ones. Consider what you’re comfortable using, and the features you’ll need from the software.

Post-Processing Needs

Parts printed with DLP printers often require post-processing, including washing and additional UV curing. Some printers come with built-in UV curing units, or you might need to invest in separate tools.

Budget

Last but not least, your budget plays a vital role in your decision. DLP 3D printers can range from a few hundred to several thousand dollars depending on the above features and others like Wi-Fi connectivity, build quality, customer service, and more.

| Feature | Description |

| Printer Size | Choose according to your workspace and project size |

| Print Accuracy | High resolution for intricate models |

| Material Compatibility | Wide material compatibility for diverse projects |

| Software Compatibility | Proprietary or third-party software options |

| Post-Processing Needs | Post-processing tools may be required |

| Budget | A range of options to match your budget |

Top DLP 3D Printers for Beginners: Our Recommendations

Choosing a DLP 3D printer might seem daunting with the plethora of options available. To simplify this process for you, we have put together a list of our top recommendations for DLP 3D printers that are well-suited for beginners.

The Anycubic Photon Zero is an excellent choice for those on a tight budget and don’t want to compromise quality. It’s compact, user-friendly, and delivers excellent print results, making it an ideal choice for those dipping their toes into the world of 3D printing.

The Elegoo Mars 2 Pro is an affordable, beginner-friendly DLP 3D printer. It provides high-quality prints, has a larger build volume, and includes a carbon filtration system to reduce the smell of resin during printing.

The QIDI Tech Shadow 5.5 S combines affordability with high performance. It boasts impressive print quality and is equipped with dual Z-axis linear rails, ensuring smoother and more stable movement.

The NOVA3D Elfin2 is a budget-friendly DLP 3D printer that doesn’t skimp on features. It has a solid metal build, Wi-Fi connectivity, and a user-friendly interactive interface.

The Creality LD-002R is a highly capable DLP printer that’s perfect for beginners. With an excellent print quality and easy assembly process, it’s a great choice for anyone just starting in 3D printing.

Here’s a brief comparison of the four models:

| Printer Model | Print Volume | Special Features | Estimated Price |

| Anycubic Photon Zero | 9754150mm | Compact, User-Friendly | $169 |

| Elegoo Mars 2 Pro | 12980160mm | Carbon Filtration System | $299 |

| QIDI Tech Shadow 5.5 S | 11565150mm | Dual Z-Axis Linear Rails | $269 |

| NOVA3D Elfin2 | 13070150mm | Wi-Fi Connectivity | $210 |

| Creality LD-002R | 12870160mm | Easy assembly, Fast slicing | $199 |

Get Started With Your DLP 3D Printer: A Beginner’s Guide

Congratulations on choosing your first DLP 3D printer! Now, it’s time to transform your creative ideas into tangible objects. Before you dive in, here’s a step-by-step guide to help you get started with your exciting 3D printing journey.

Step 1: Set Up Your Printer

Start by unboxing the printer and setting it up as per the manufacturer’s instructions. Make sure to handle all the parts carefully during setup. Consider keeping the printer in a well-ventilated space due to the resin’s odor during printing.

Step 2: Install the Resin Vat and Build Platform

Next, install the resin vat and build platform, ensuring the screws are manually tightened. Follow the instructions manual closely during these steps to avoid any mishaps.

Step 3: Level the Build Plate

Leveling the build plate correctly is a crucial step, as it plays a significant role in the success of your 3D prints. Again, follow the manual or look up online tutorials to ensure this step is done correctly.

Step 4: Add the Resin and Adjust Settings

Pour the resin into the vat, making sure not to overfill it. Put on protective gloves and glasses for this step for safety. Afterward, turn on your printer and adjust the necessary settings according to your project requirements.

Step 5: Start Your First Print

Prepare a 3D model using the slicer software and load the file into the printer. Once the file is loaded, you can start your print! Keep your protective gloves on as you manually lower the build plate into the resin vat.

Here’s a summary of the steps in a checklist for quick reference:

| Step | Process |

| 1 | Set Up Your Printer |

| 2 | Install the Resin Vat and Build Platform |

| 3 | Level the Build Plate |

| 4 | Add the Resin and Adjust Settings |

| 5 | Start Your First Print |

After Printing: Clean Up and Post-Processing

Once your print is finished, carefully remove the model from the build platform. Rin out any uncured resin under warm water or using isopropyl alcohol. Cure the model under UV light and make sure to dispose of any leftover resin properly.

Remember, practice makes perfect! Don’t be disheartened if your first few prints don’t turn out as expected. Keep experimenting, practice, and soon enough you’ll be a master at 3D printing with your DLP printer.

Outro: Expanding Your 3D Printing Horizons

Congratulations! You’ve just taken the exciting leap into the world of DLP 3D printing. This guide aimed to help you understand the intricacies of DLP 3D printing, assist in your printer selection, and get you started on your first print.

Now that you’ve begun your journey, there is an entire world of possibilities to explore. 3D printing can be an incredible hobby or a lucrative business venture. Whichever path you choose to follow, remember, the key to mastering this skill lies within patience, creativity, and constant learning.

Don’t limit your exploration to just DLP 3D printing; there are several different types of 3D printing technologies such as FDM, SLS, and SLA, each with its unique capabilities. As you expand your skills, you might want to delve into these other technologies as well.

| 3D Printing Technology | What It’s Good For |

| FDM (Fused Deposition Modeling) | Cost-effective, great for beginners, wide range of filament materials available. |

| SLS (Selective Laser Sintering) | Provides excellent detail, strength and durability, ideal for functional parts and prototypes. No need for support structures. |

| SLA (Stereolithography) | Exquisite detail and smooth surfaces, perfect for small, intricate parts and molds. |

Keep learning, keep experimenting, and most importantly, keep creating. The world of 3D printing is vast and ever-evolving, and there are always new techniques, materials, and technologies coming up. Join online communities, share your work, learn from others, and contribute your insights.

In this rapidly advancing tech world, DLP 3D printing can open up a universe of creative possibilities. It boosts productivity, saves cost, and most importantly, it empowers anyone to turn their innovative ideas into physical reality.