Have you ever been fascinated by the complexity of a 3D printed object and thought about the magic behind its creation? In this article, we lift the veil and invite you to join us on a journey to discover the essence of this captivating process – Stereolithography (SLA) printing materials. Often underestimated, these materials are the unsung heroes that bring our 3D visions to life.

SLA printing is more than just making three-dimensional objects from digital files. It’s an art form, a science, and a revolution, all rolled into one. In this article, we delve into the fascinating world of SLA printing materials. We’ll explore their science, their versatility, their applications, and the challenges they face. Whether you’re a 3D printing enthusiast or a professional, there’s a lot to discover!

The Science Behind SLA Printing

Stereolithography (SLA) printing, the pioneer of all 3D printing technologies, is a marvel that transforms liquid into solid, intricate objects, all via the power of light. But how exactly does it work, and what role do the materials play? Let’s dive right in.

Unraveling the Magic: The SLA Printing Process

SLA printing is an additive manufacturing process, creating objects layer by layer. But unlike other 3D printing types, SLA harnesses the power of light to cure liquid resin into a solid form. This process, known as photopolymerization, is what sets SLA apart.

Here’s a simplified step-by-step guide to the process:

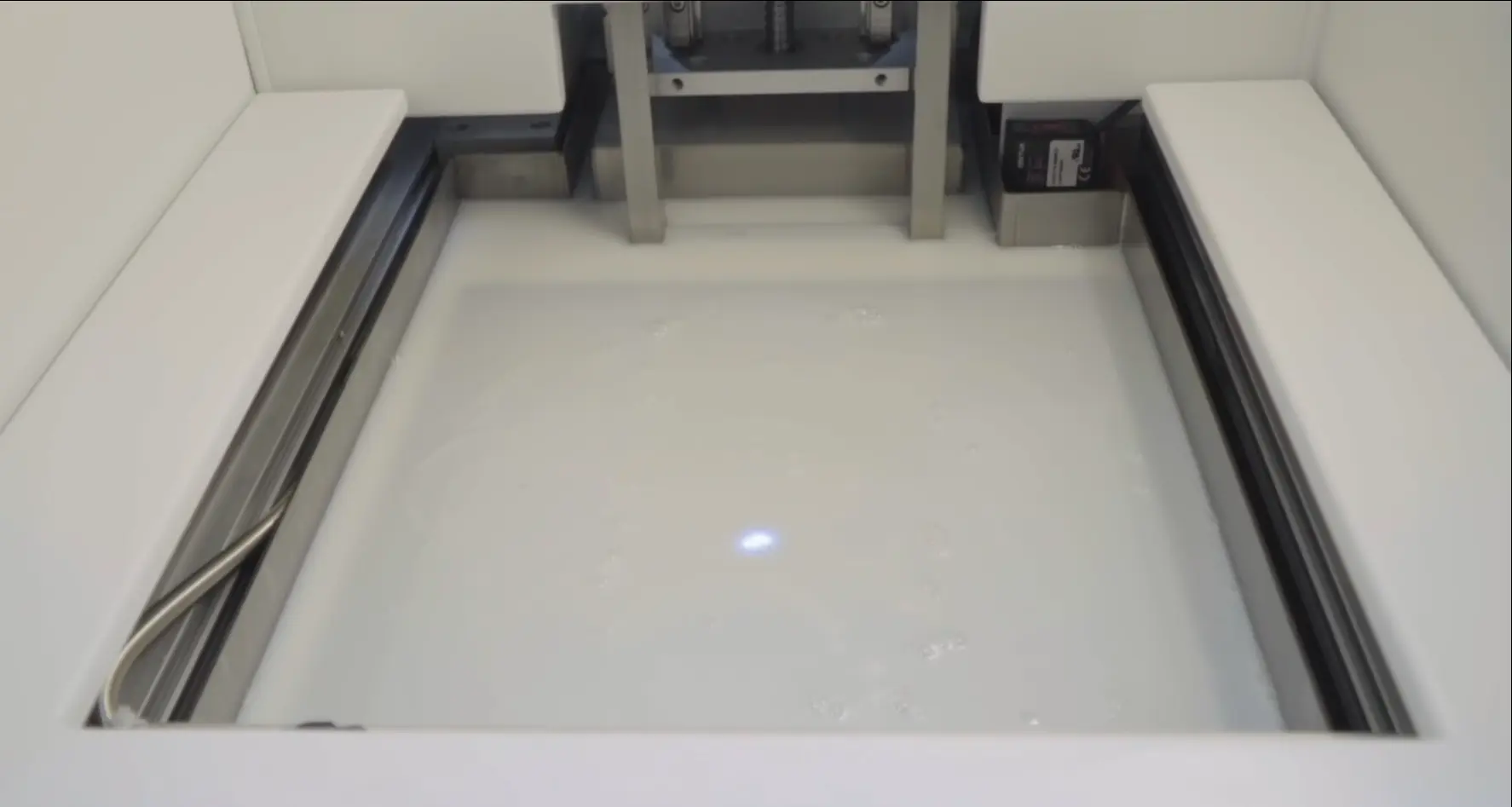

- Layer Preparation: A thin layer of resin is spread over the build platform.

- Light Exposure: The printer’s light source, usually a laser or projector, traces the cross-section of the object onto this resin layer, solidifying it. Any resin untouched by the light remains liquid.

- Layer Creation: Once a layer is complete, the build platform moves up, and a new resin layer is prepared for the next pass of the light source.

- Object Completion: This process repeats itself, layer by layer, until the object is fully formed.

What’s truly fascinating is that the quality of the final print isn’t just about the printer’s precision. A significant part of the magic lies in the materials used – the resins.

SLA Printing Materials: The Unsung Heroes

SLA printing materials are light-sensitive thermoset polymers, commonly known as resins. These resins come in a liquid form but are designed to solidify when exposed to certain wavelengths of light.

Depending on the application, different types of resins are used:

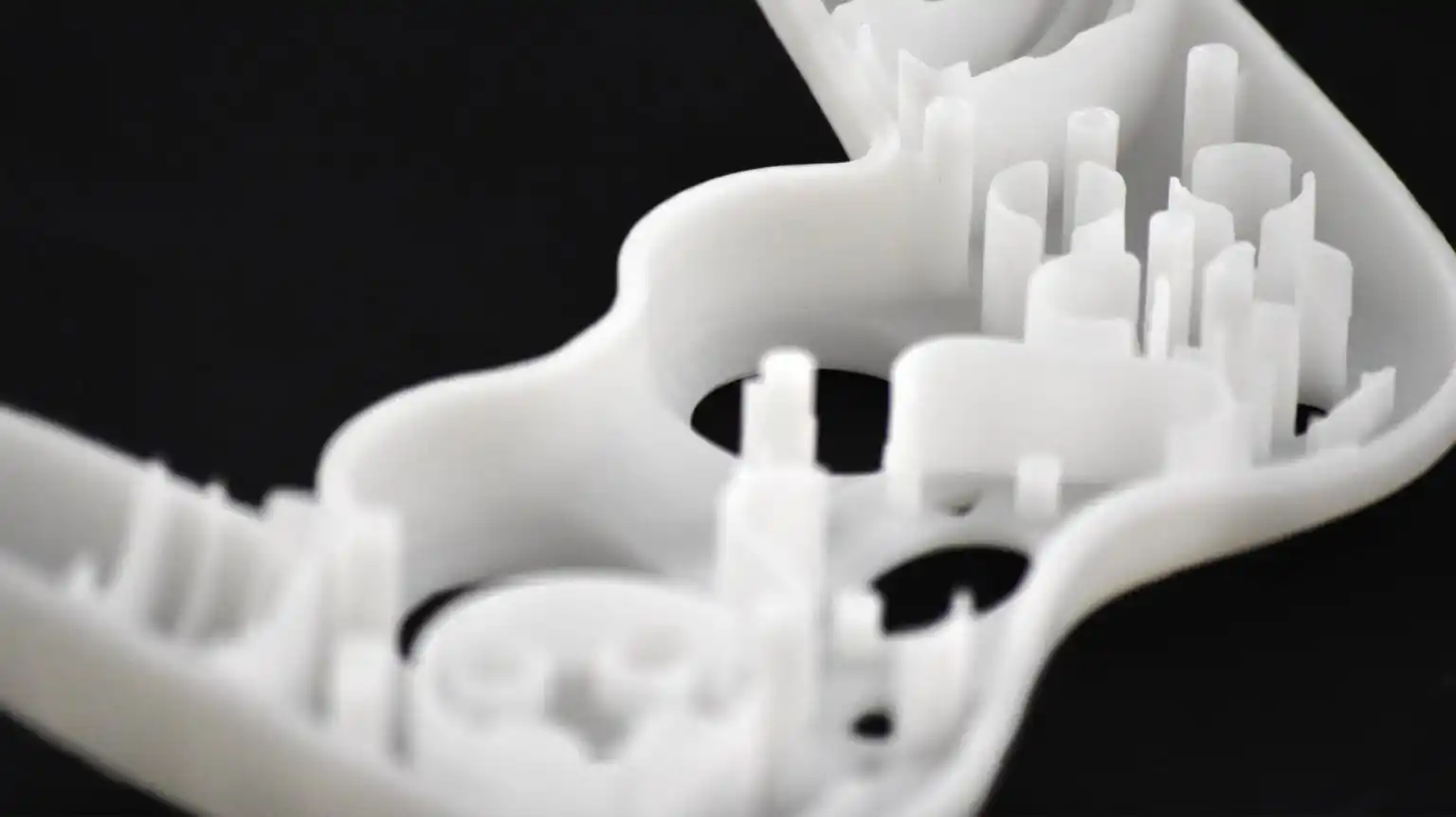

Standard Resins: These are the most common type of SLA resins, ideal for general prototyping and modeling.

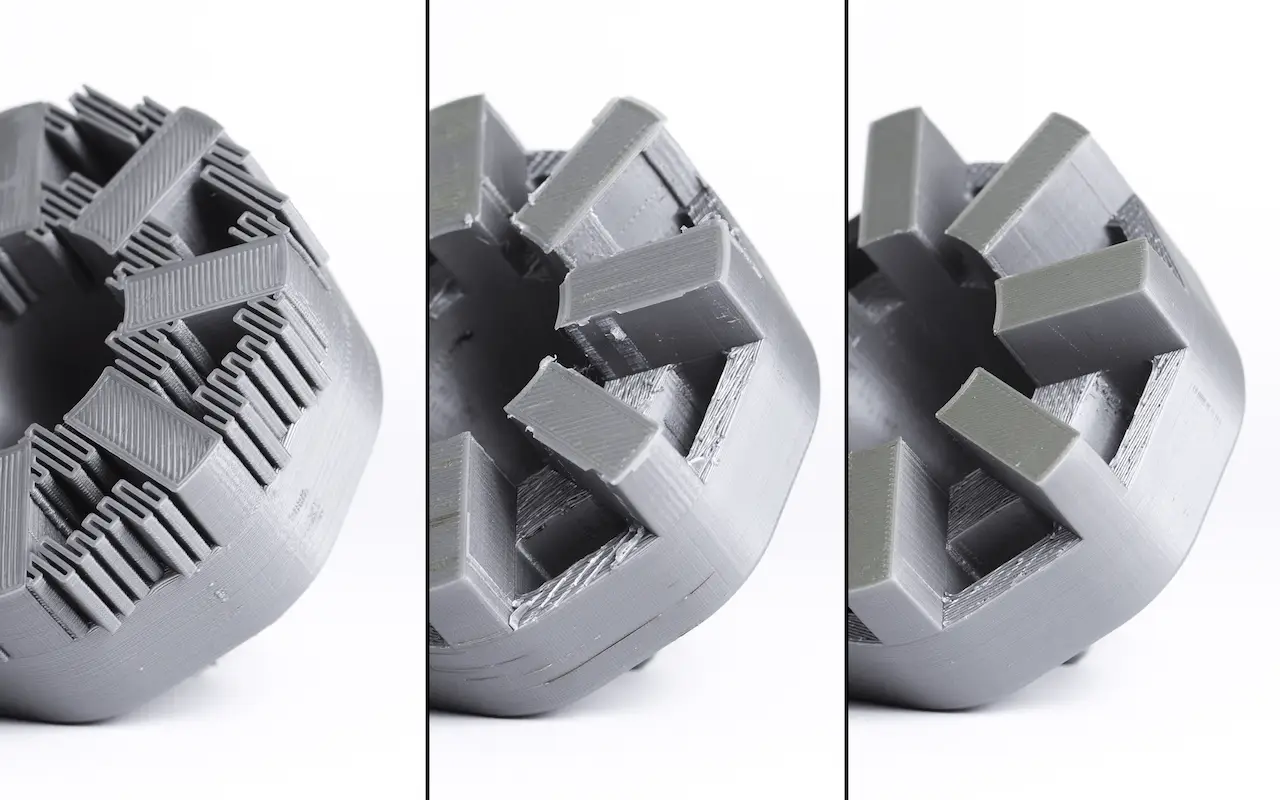

Tough and Durable Resins: For objects that need to withstand stress, like functional prototypes or mechanical parts.

Flexible and Elastic Resins: These resins produce prints that can bend or stretch without breaking.

High-Temperature Resins: Best suited for objects that need to resist high temperatures.

Selecting the right resin for your project is critical to achieving the desired print characteristics.

Materials Used in SLA Printing

We’ve unraveled the magic behind the SLA printing process, and now it’s time to venture deeper into the heart of the matter – the materials. Understanding the variety of resins available and their unique properties can significantly impact the quality and functionality of your 3D printed objects. So let’s embark on this material exploration journey together.

Choosing the Right Material for Your Project

Selecting the optimal resin for your project can be the difference between a perfect print and a failed one. Here are some factors to consider:

Purpose of the Print: What will the printed object be used for? Functional parts require tough resins, whereas display models may only need standard resins.

Environmental Conditions: Consider the operating environment. High-temperature resins are needed for objects exposed to heat.

Mechanical Properties: Assess the mechanical demands. Will the object need to withstand stress, impact, or bending?

Detail and Finish: The level of detail and surface finish required can influence the choice of resin.

Comparison Table of SLA Resins

Here’s a handy comparison table to help you choose the right resin for your needs:

| Resin Type | Best For | Key Properties |

| Standard Resins | General Prototyping | Smooth finish, brittle |

| Tough/Durable Resins | Functional Prototypes | High impact resistance, durable |

| Flexible/Elastic Resins | Wearables, Soft Components | Rubber-like, bendable |

| High-Temperature Resins | Engine Components, Molds | Thermal resistance, heat stable |

| Castable Resins | Jewelry, Dental Prosthetics | Clean burnout, excellent casting |

As technology advances, so do the materials available for SLA printing.Understanding the variety of SLA printing materials is crucial for optimizing your 3D printing projects. Each resin type brings unique properties that can enhance the functionality, durability, and aesthetics of your prints.

Industrial Applications of SLA Printing

Having covered the critical role of materials, it’s time to explore how these materials are being used across various industries.This high-precision machine has transformed manufacturing workflows across multiple sectors.

Case Study: SUPERMAKER SLA300 Industrial Printer

To understand the industrial applications of SLA printing, let’s start with a case study of the SUPERMAKER SLA300 Industrial Printer. This high-precision machine has transformed manufacturing workflows across multiple sectors.

Key Features:

Extreme Low Cost Machine and Materials

Build in Constant Temperature Humidity

7*24-Hour Monitoring and Removable Resin Tank

- Large Build Volume: Capable of producing large parts in a single print.

- High Precision: Produces detailed and accurate parts.

- Material Versatility: Supports a wide range of resins for different applications.

Industries Benefiting from SUPERMAKER SLA300:

Automotive: Used for prototyping and manufacturing custom parts.

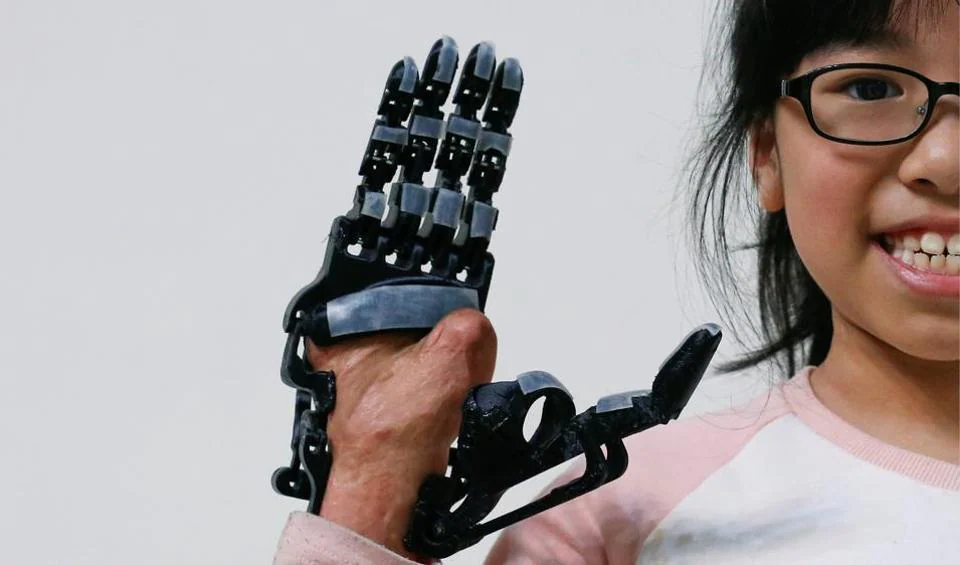

Healthcare: Produces medical models and prosthetics.

Benefits of SLA Printing in Industry

SLA printing offers several advantages that make it suitable for industrial applications:

- Precision: SLA printers can produce highly detailed and accurate parts, essential for complex designs.

- Speed: Rapid prototyping accelerates the product development cycle.

- Flexibility: Wide range of materials allows for diverse applications.

- Cost-Effectiveness: Reduces the need for expensive tooling and molds.

Supporting Data and Statistics

To fully appreciate the impact of SLA printing, consider the following data:

| Industry | Application | Benefit |

| Automotive | Prototyping | Faster development cycles |

| Healthcare | Medical Models | Improved surgical outcomes |

| Aerospace | Lightweight Components | Enhanced fuel efficiency |

SLA printing is not just a niche technology; it’s a transformative tool reshaping various industries. From automotive to healthcare and aerospace, the precision, speed, and versatility of SLA printing materials are driving innovation and efficiency. As we continue to explore and develop new materials, the potential applications of SLA printing will only expand further.

Challenges and Limitations of SLA Printing Materials

As we continue our exploration of SLA printing materials, it’s crucial to address the challenges and limitations faced in this field. Understanding these obstacles enables us to appreciate the technological advancements and drives us toward innovative solutions. Let’s dive into the common issues, environmental considerations, and how SLA stacks up against other manufacturing techniques.

Common Issues in SLA Printing Materials

Despite the many advantages of SLA printing, it’s not without its challenges. Here are some common issues:

- Shrinkage: During the curing process, resins can shrink, leading to dimensional inaccuracies.

- Post-Processing: SLA prints often require extensive post-processing, including washing, curing, and sanding.

- Layer Adhesion: Poor layer adhesion can compromise the structural integrity of the finished product.

- Material Brittleness: Many standard resins are brittle and can easily break under stress.

Addressing These Issues

Improved Resins: Development of tough and flexible resins helps mitigate brittleness.

Precision Calibration: Regular calibration of the printer can reduce shrinkage and improve layer adhesion.

Automated Post-Processing: Innovations in automated washing and curing systems streamline post-processing.

Environmental Considerations

SLA printing materials also pose certain environmental challenges:

- Waste Generation: Uncured resin can be hazardous and must be disposed of carefully.

- Energy Consumption: SLA printers consume significant energy, especially during the curing process.

- Non-Biodegradable Materials: Most resins are not biodegradable, contributing to environmental pollution.

Sustainable Solutions

Eco-Friendly Resins: Development of biodegradable and recyclable resins.

Energy-Efficient Printers: Advances in printer technology to reduce energy consumption.

Proper Waste Management: Implementing strict waste management protocols to handle uncured resins.

Comparison with Other Manufacturing Technologies

Comparing SLA with other additive manufacturing (AM) and traditional manufacturing technologies helps highlight its unique challenges and strengths.

Additive Manufacturing Technologies

| Feature | SLA Printing | FDM Printing | SLS Printing |

| Precision | High | Moderate | High |

| Material Variety | Moderate | High | High |

| Post-Processing | Extensive | Minimal | Moderate |

| Speed | Moderate | Slow to Moderate | Fast |

| Cost | Moderate to High | Low to Moderate | High |

Traditional Manufacturing Technologies

| Feature | SLA Printing | Injection Molding | CNC Machining |

| Precision | High | Very High | Very High |

| Material Variety | Moderate | Very High | Very High |

| Speed | Moderate | Fast | Variable |

| Cost for Small Batches | Low to Moderate | High | High |

| Customization | High | Low | Moderate to High |

While SLA printing materials offer incredible versatility and precision, they come with their own set of challenges. Shrinkage, brittleness, and extensive post-processing are common hurdles, while environmental concerns add another layer of complexity. However, with ongoing advancements in materials and technology, these issues are being addressed, paving the way for more sustainable and efficient SLA printing.

Conclusion

As we draw our exploration of SLA printing materials to a close, it’s clear that this technology holds immense potential. From the intricate interplay of light and resin to the diverse industrial applications and cutting-edge innovations, SLA printing is a testament to the power of modern engineering.

The remarkable versatility and continuous innovation in SLA printing materials make this technology a cornerstone of modern manufacturing. Whether you’re a hobbyist, a professional, or an industry leader, understanding and leveraging these materials can elevate your projects to new heights.