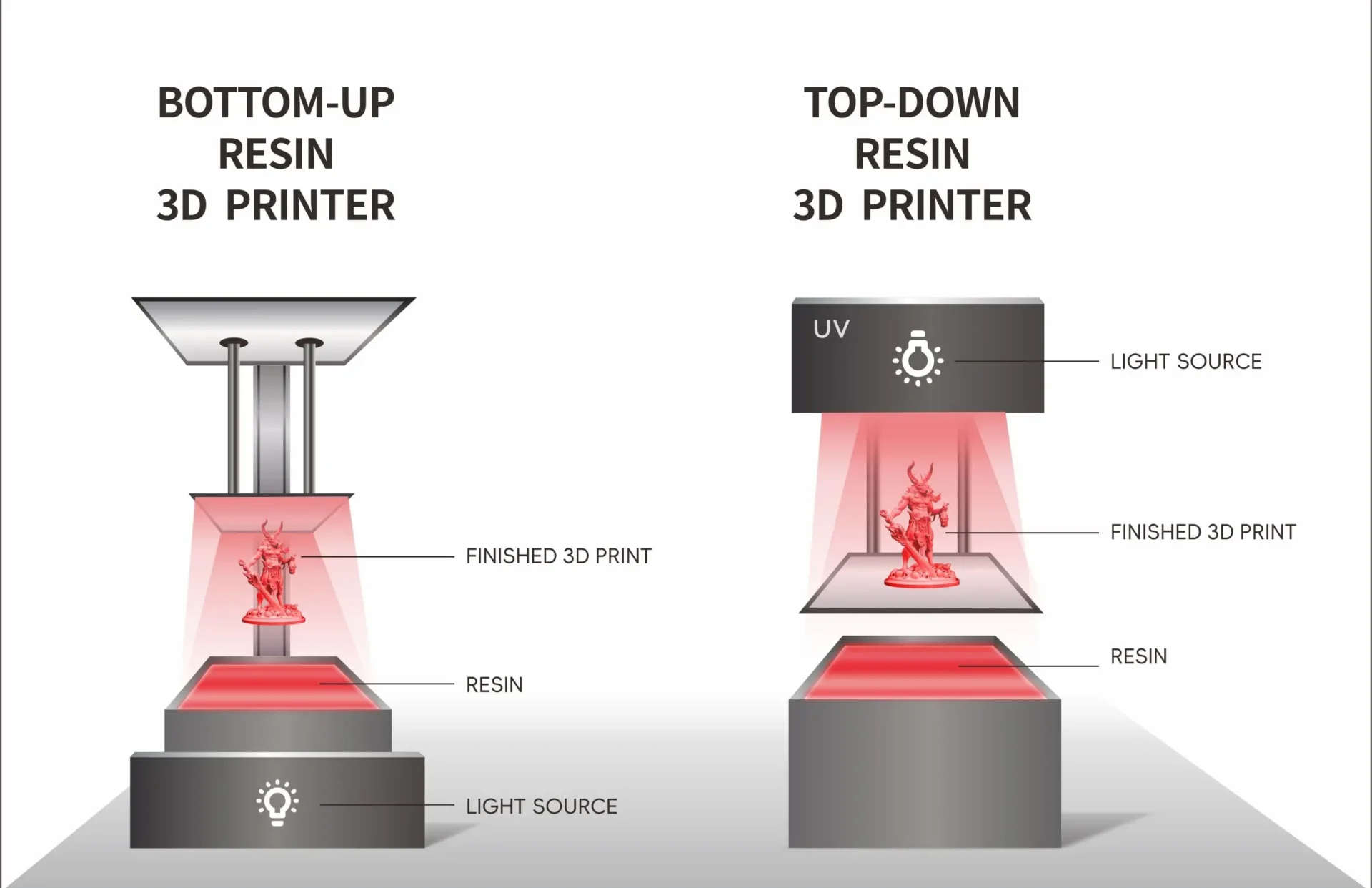

Top-down DLP 3D printing is an advanced additive manufacturing process that uses a digital light projector to cure liquid resin layer by layer from above. This precise, scalable, and efficient method is ideal for producing complex shoe components with unmatched accuracy.

Design iterations are faster, reducing time-to-market.

Lower material waste and streamlined processes cut costs.

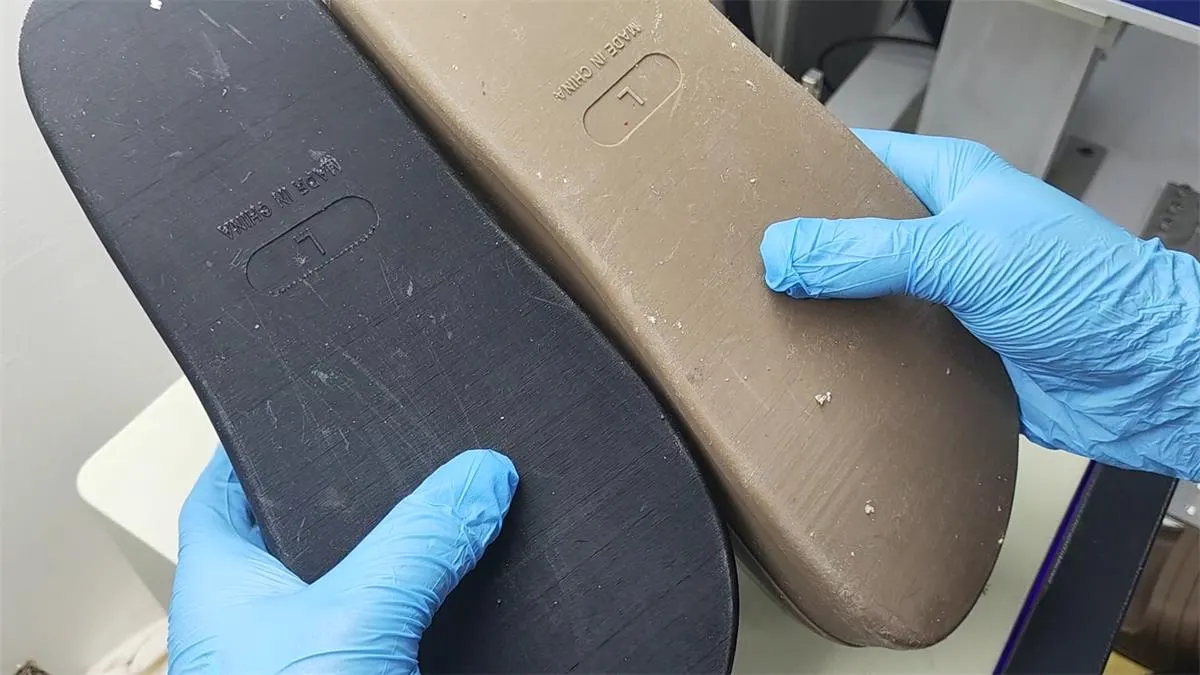

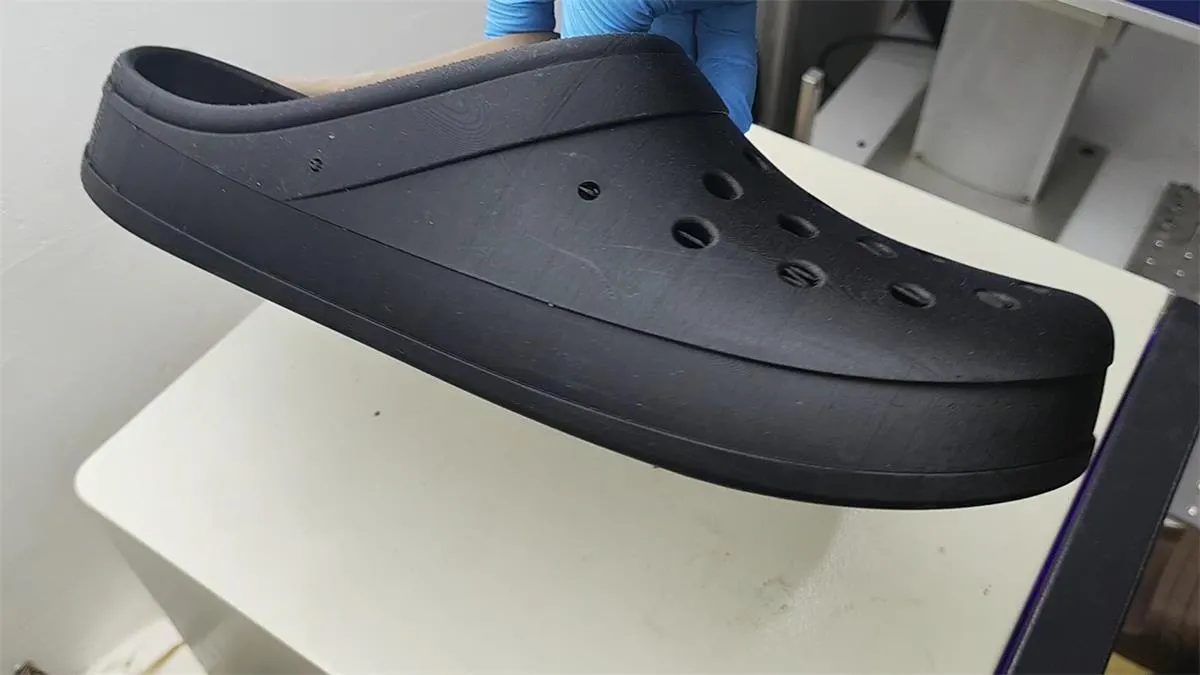

Complex geometries and custom fits become feasible.

Minimizes material usage and energy consumption.

Automating Key Processes: Reducing manual labor and human error.

Increasing Throughput: Multi-part production in a single print run.

Custom Fit Solutions: On-demand printing for personalized footwear.

On-Demand Manufacturing: Produce what’s needed when it’s needed.

Supply Chain Flexibility: Shorter, localized production reduces logistics costs.

Sustainability Leadership: A path toward zero-waste, eco-conscious production.