Forget FDM: Why SLA 3D Printing Produces the Most Accurate and Detailed 3D Prints

The advent of 3D printing technology has brought about a remarkable revolution in the realm of prototyping and product manufacturing. Its impact on these processes has been nothing short of transformative. Nevertheless, it is important to acknowledge that not all 3D printing methods are crafted with the same level of excellence and precision. Variations exist among these methods, each possessing its own unique set of strengths and limitations. Fused deposition modeling (FDM) has long reigned as the preeminent 3D printing technique, yet stereolithography (SLA) 3D printing bestows numerous pivotal benefits in terms of print quality and precision. “In this article, we shall delve into the rationale behind the supremacy of SLA 3D printing in generating unparalleled precision and intricate details in 3D prints.”

Liquid Resin Unlocks Higher Resolution

The first reason SLA 3D printing beats FDM is resolution. An SLA 3d printer uses liquid photopolymer resin that solidifies when exposed to UV light. This resin hardens layer by layer to build your 3D model. Since the resin is a liquid, it can achieve much finer layers than the filament used in FDM printers.

Typical FDM printers have a layer resolution of around 0.1 to 0.3 millimeters. In contrast, SLA printers can achieve layer heights as small as 0.025 millimeters – up to 10 times finer. This higher resolution translates into smoother surfaces, sharper corners and edges, and more accurate details in your 3D prints.

Minimal Distortion and Warping

Another advantage of SLA 3D printing is dimensional accuracy. Since the resin remains in a liquid state until it is cured by the UV light, there is minimal warping or distortion as the layers build up. This allows SLA prints to achieve near-perfect dimensional accuracy, often within 0.2%.

In comparison, the filament used in FDM printers must be heated and cooled with each layer. This thermal cycling can cause the previous layers to warp or distort, reducing the dimensional accuracy of the final print. FDM prints typically only achieve around 0.4% to 0.8% accuracy.

Superior Surface Finish

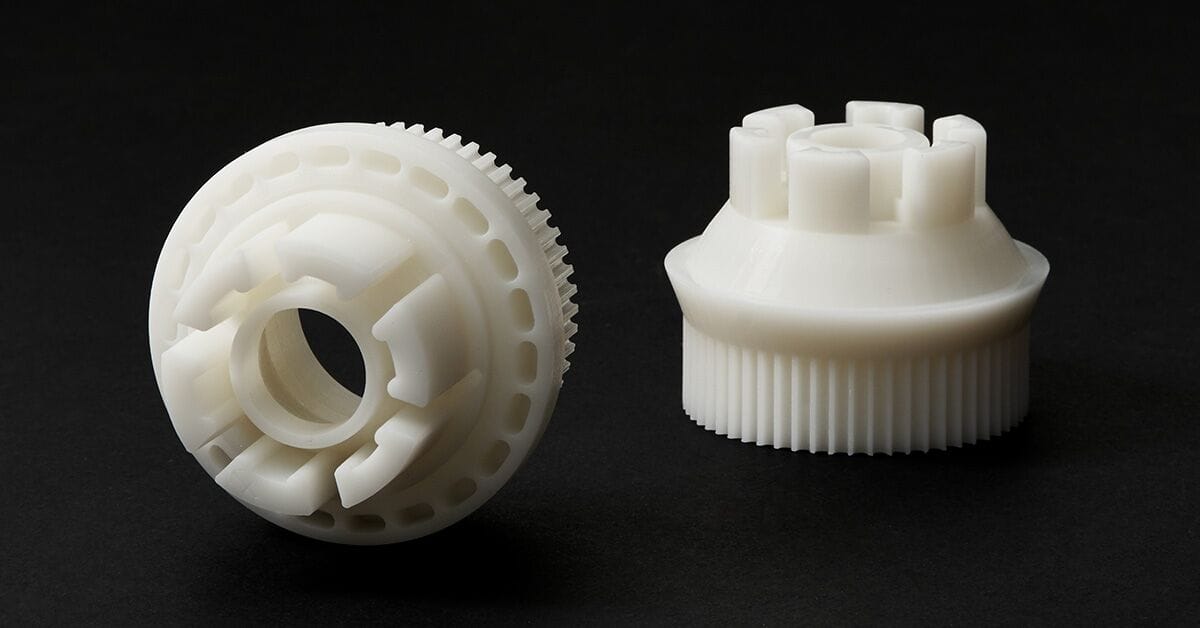

The surface finish of SLA 3D prints is also significantly better than FDM. Since the resin hardens into a smooth, glass-like finish, SLA prints require little to no post-processing sanding or finishing.

FDM prints, on the other hand, have a layering effect that results in a rougher surface texture. They typically require extensive sanding and finishing to achieve a smooth surface comparable to SLA.

Faster Print Speeds and Larger Build Volumes

While SLA 3D printers were once much slower than FDM, that gap has narrowed in recent years. Modern SLA printers can achieve print speeds on par with – and in some cases faster than – FDM printers.

SLA printers also offer larger build volumes, allowing you to print larger and more complex parts in one piece. Many high-end SLA printers now have build volumes of 12 x 12 x 16 inches or more.

In summary, SLA 3D printing offers several key advantages over FDM when it comes to print quality, accuracy and surface finish. The liquid photopolymer resin used in SLA printers unlocks higher resolutions, smoother surfaces, and more accurate dimensions. While SLA printers were once much slower, modern machines have print speeds and build volumes comparable to – and in some cases better than – FDM 3D printers. If you need the most accurate and detailed 3D prints possible, SLA 3D printing is hard to beat.