Understanding SLA 3D Printing

Stereolithography, or SLA 3D printing, might sound like something straight out of a science fiction novel, but it’s a reality that’s been shaping the landscape of manufacturing for decades. Let’s dive into the intricate world of SLA 3D printing and unravel its layers to understand why it’s become a buzzword in the industry.

The Essence of SLA 3D Printing

SLA 3D printing is a form of additive manufacturing that transforms liquid materials into solid parts, layer by layer, using a light source. It’s a process that has revolutionized prototyping and production by offering precision and detail that were previously unattainable with traditional methods.

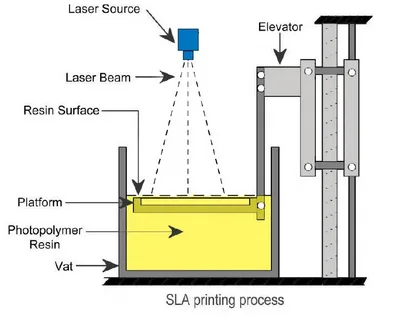

How Does SLA 3D Printing Work?

- Designing the 3D Model: It all starts with a 3D model, designed on a computer using CAD software.

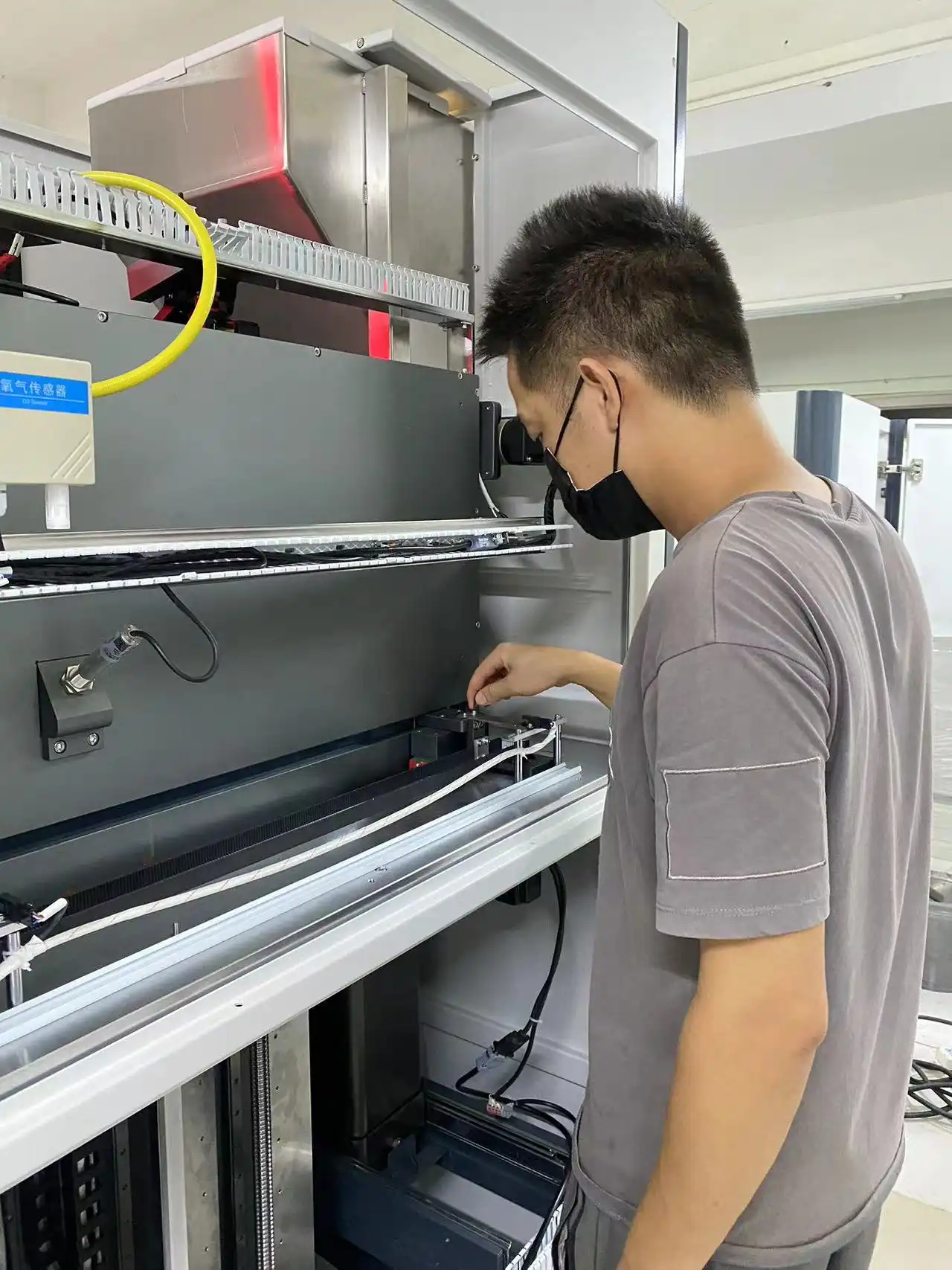

- Preparing the Printer: The SLA printer is prepared, which includes setting up the build platform and ensuring the resin tank is filled with photopolymer resin.

- Printing Process:

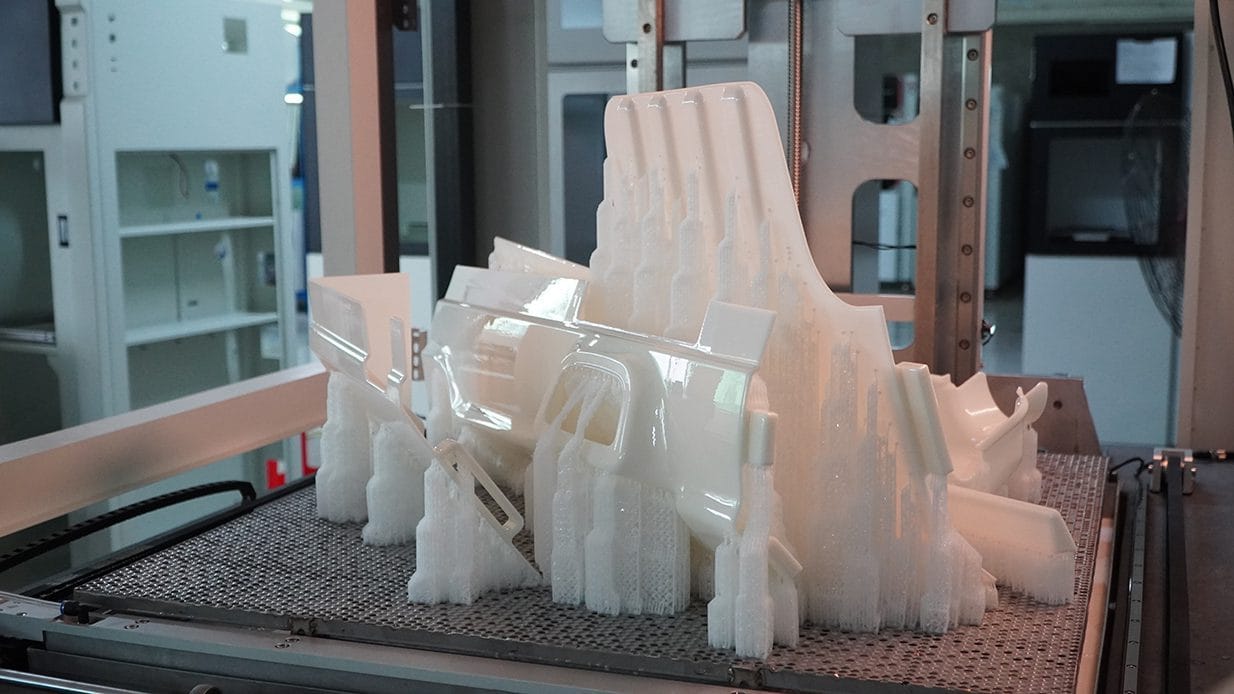

- The build platform dips into the resin.

- A UV laser traces the first layer, solidifying the resin.

- The platform lifts, allowing a new layer of resin to cover the surface.

- The process repeats, building the object layer by layer.

- Cleaning and Curing: The printed object is then cleaned of excess resin and cured under UV light to achieve its final properties.

The Evolution of SLA 3D Printing

SLA 3D printing has come a long way since its inception. The technology was developed in the 1980s by Chuck Hull, who patented the process and founded the company 3D Systems. Over the years, advancements in materials and light sources have expanded the capabilities of SLA printers, making them faster, more reliable, and more accessible.

The Anatomy of an SLA 3D Printer

Understanding the components of an SLA 3D printer can give us insight into its functionality and the intricacies involved in the printing process:

- Resin Tank: Holds the photopolymer resin.

- Build Platform: Where the object is built, layer by layer.

- UV Laser: The light source that cures the resin.

- Galvanometers: Precision mirrors that direct the laser across the resin’s surface.

- Computer: Controls the laser and the build platform.

Materials in SLA 3D Printing

SLA printers use a variety of photopolymer resins, each with unique properties that cater to different applications:

- Standard Resins: Good for general prototyping.

- Engineering Resins: Designed for properties like high strength, flexibility, or temperature resistance.

- Castable Resins: Used for creating molds for casting metal parts.

- Dental and Biocompatible Resins: Safe for medical use.

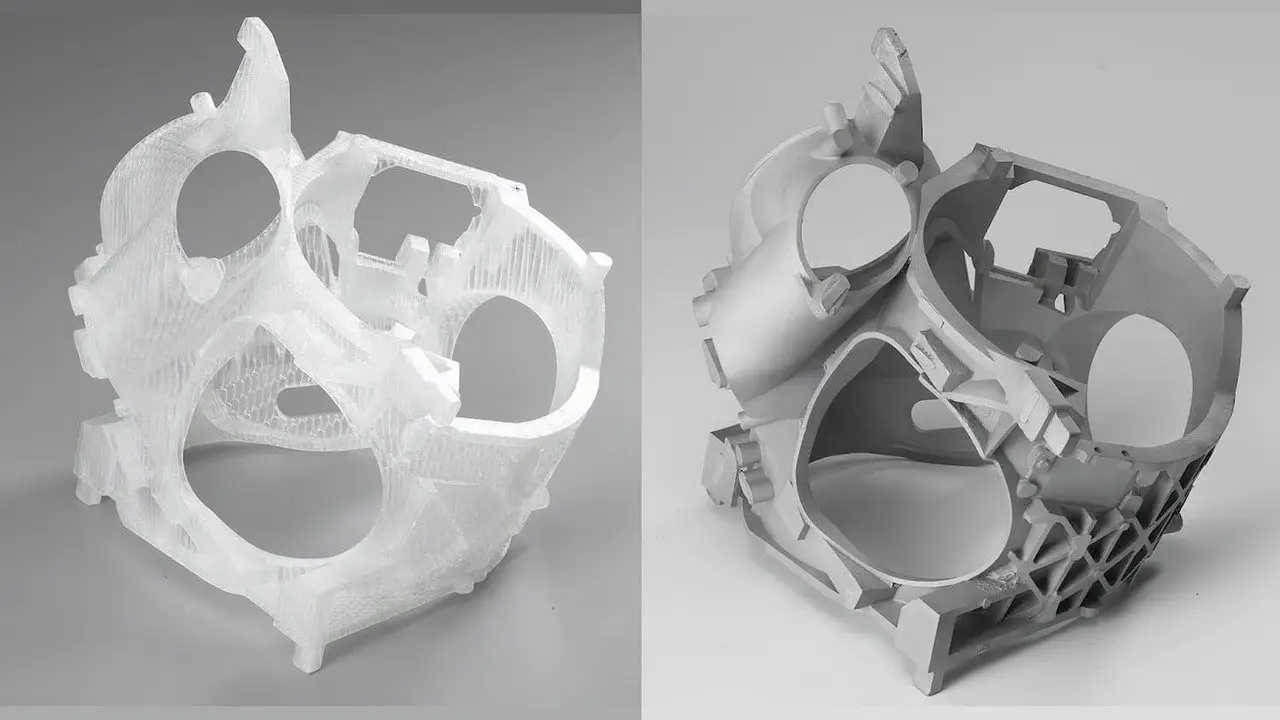

SLA 3D Printing in Action

The applications of SLA 3D printing are vast and varied:

- Prototyping: Quick and detailed prototypes for design verification.

- Dentistry: Custom dental appliances and models.

- Jewelry: Detailed patterns for casting.

- Manufacturing: Complex end-use parts and assembly tools.

Advantages of SLA 3D Printing

SLA 3D printing boasts several advantages that make it a standout choice for many applications:

- High Precision: SLA can produce features as small as 0.3mm.

- Smooth Surface Finish: Parts have a smooth finish that requires less post-processing.

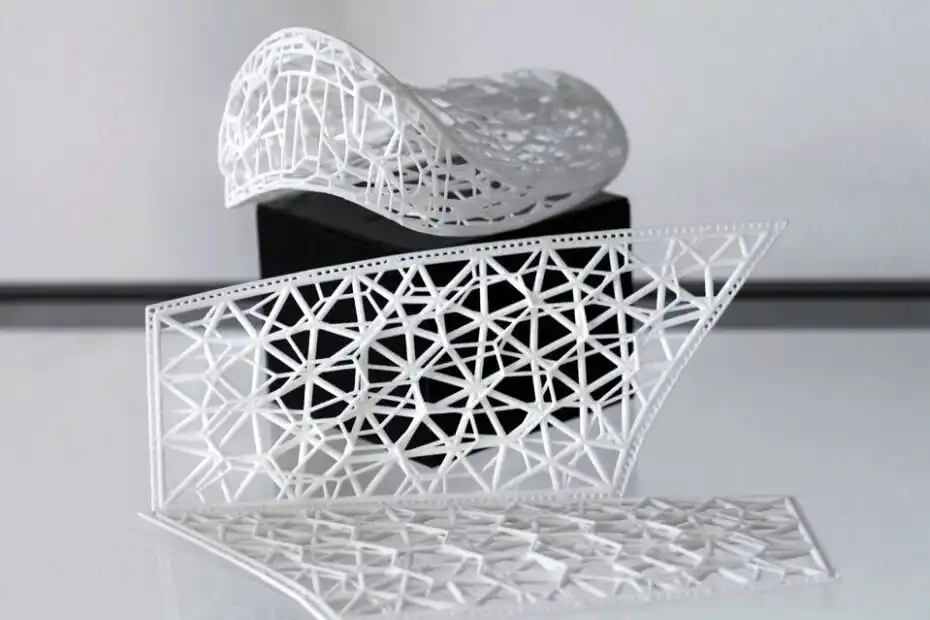

- Complex Geometries: Capable of producing intricate designs that are impossible with traditional methods.

- Wide Range of Materials: A growing library of resins with diverse properties.

Challenges and Considerations

Despite its advantages, SLA 3D printing also comes with its own set of challenges:

- Support Structures: Often required and must be manually removed.

- Resin Handling: Requires careful handling and storage.

- Limited Build Size: Generally smaller than other 3D printing technologies.

In conclusion, SLA 3D printing stands as a beacon of modern manufacturing, offering unparalleled precision and versatility. Its evolution from a prototyping marvel to a production powerhouse is a testament to the relentless pursuit of innovation in the manufacturing sector. As we continue to push the boundaries of what’s possible, SLA 3D printing will undoubtedly play a pivotal role in shaping the future of how we create and produce.

Traditional Manufacturing Methods: A Comparative Look

When considering the cost-effectiveness of manufacturing processes, it’s essential to understand the traditional methods that have been the backbone of production for years. These methods, each with their unique strengths and cost structures, set the stage for a comprehensive comparison with SLA 3D printing.

The Cornerstones of Traditional Manufacturing

Let’s explore the most common traditional manufacturing techniques:

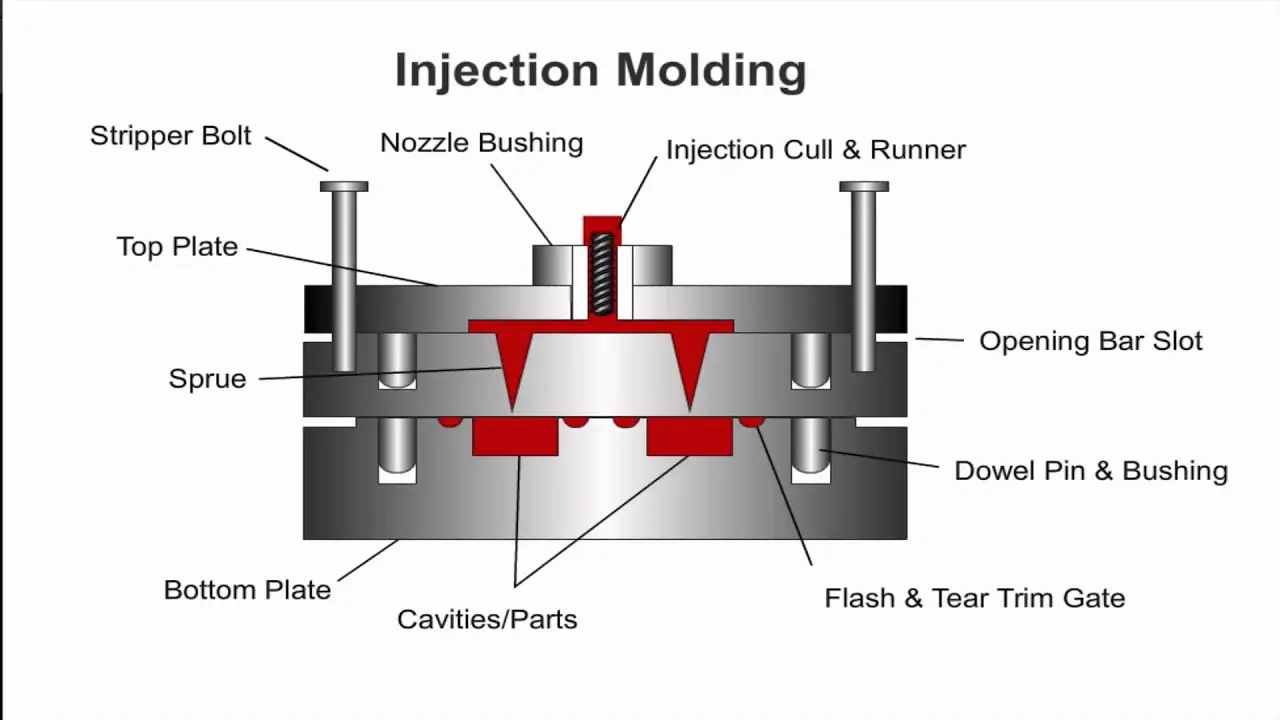

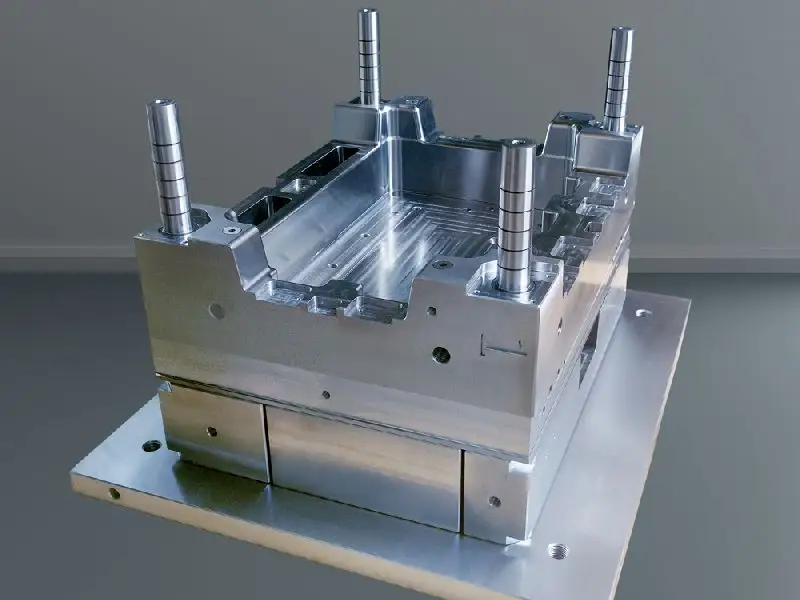

Injection Molding

- Process: Melting thermoplastic pellets and injecting them into a mold cavity.

- Strengths: High volume production, consistent quality, and low per-unit costs.

- Typical Costs:

- Tooling: High initial investment for mold design and creation.

- Materials: Cost varies based on the plastic used.

- Labor: Automated processes reduce labor costs.

- Overhead: Significant due to machinery and maintenance.

CNC Machining

- Process: Subtractive method where material is removed from a solid block using cutting tools.

- Strengths: Precision, versatility in materials, and excellent for metal parts.

- Typical Costs:

- Setup: Moderate, depending on complexity.

- Materials: Higher due to waste from subtractive process.

- Labor: Skilled operators required.

- Overhead: Machinery costs and maintenance.

Die Casting

- Process: Molten metal is forced into a mold cavity under high pressure.

- Strengths: Ideal for high-volume production of metal parts with good dimensional accuracy.

- Typical Costs:

- Tooling: High upfront costs for steel molds.

- Materials: Metal costs can be significant.

- Labor: Automated but requires oversight.

- Overhead: High energy consumption and maintenance.

Cost Factors in Traditional Manufacturing

When evaluating the cost-effectiveness of these methods, consider the following factors:

- Volume: Economies of scale play a crucial role; higher volumes typically reduce the cost per unit.

- Complexity: Complex parts may require expensive tooling or multiple machining steps.

- Material Waste: Subtractive methods like CNC machining can produce significant waste.

- Energy Use: Traditional methods can be energy-intensive, especially for metals.

- Labor: Automation has reduced labor costs, but skilled technicians are still needed for setup and oversight.

The Cost Breakdown Table

To visualize the cost distribution, here’s a simplified table comparing key cost factors across traditional manufacturing methods:

| Manufacturing Method | Tooling Costs | Material Costs | Labor Costs | Overhead Costs |

| Injection Molding | High | Low | Low | High |

| CNC Machining | Medium | Medium | Medium | Medium |

| Die Casting | High | Medium | Low | High |

Note: These are general estimates and can vary based on specific project requirements.

The Verdict on Traditional Methods

Traditional manufacturing methods have stood the test of time for good reason. They are reliable, well-understood, and when the conditions are right—particularly in high-volume scenarios—they can be incredibly cost-effective. However, the initial costs and inflexibility in design changes can be significant drawbacks, especially for small to medium-sized runs or complex, bespoke items.

In the next section, we’ll delve into the cost analysis of SLA 3D printing. We’ll explore how this modern technology stacks up against the tried-and-true methods we’ve just discussed, and under what circumstances it might offer a more cost-effective solution. Stay tuned to uncover the economic intricacies of SLA 3D printing and its place in the manufacturing landscape.

Cost Analysis of SLA 3D Printing

When it comes to manufacturing, the bottom line often boils down to cost. SLA 3D printing has emerged as a disruptive technology, but how does it fare when we crunch the numbers? Let’s dissect the costs associated with SLA 3D printing and see how it compares with the traditional methods we’ve explored earlier.

Initial Setup Costs

The journey of an SLA 3D printed part begins long before the first layer is cured. Here’s what to consider:

- Printer Acquisition: The cost of an SLA printer can range from a few thousand dollars for entry-level models to tens of thousands for industrial-grade machines.

- Facility Requirements: Unlike some traditional methods, SLA printers don’t require significant space or industrial-grade power inputs, potentially lowering initial facility costs.

Material Costs

Materials in SLA printing are a story of variety and specificity:

- Resins: The cost of photopolymer resins varies widely, from standard resins at a moderate price to specialized, high-performance resins that can be quite costly.

- Waste: SLA printing is additive, so there’s minimal material waste compared to subtractive methods like CNC machining.

Labor Costs

SLA 3D printing is lauded for its automation, but human hands are still essential:

- Design and Preprocessing: Requires skilled professionals to design the model and prepare the printer, although this is often less labor-intensive than setting up traditional manufacturing processes.

- Post-Processing: Cleaning and curing the parts can be laborious, but innovative solutions and automated systems are reducing these demands.

Maintenance and Operational Costs

Keeping an SLA 3D printer running involves several ongoing costs:

- Machine Maintenance: Regular cleaning and occasional parts replacement are necessary but generally less intensive than the upkeep for heavy traditional machinery.

- Resin Management: Proper storage and handling of resins are crucial to avoid spoilage and ensure quality prints.

Economies of Scale in SLA 3D Printing

SLA 3D printing doesn’t scale in the same way traditional methods do:

- Per-Unit Costs: Unlike injection molding, the per-unit cost doesn’t drop dramatically as volume increases, since each item requires the same amount of time to print.

- Batch Printing: Printing multiple parts at once can improve time efficiency, but the savings are not as significant as in high-volume traditional methods.

The Cost Comparison Table

To put it all into perspective, here’s a table that outlines the cost elements of SLA 3D printing:

| Cost Factor | SLA 3D Printing |

| Initial Setup | Moderate |

| Material Costs | Variable |

| Labor Costs | Low to Moderate |

| Maintenance Costs | Low |

| Economies of Scale | Limited |

Note: Costs can vary based on the scale of operation and specific use cases.

The Economic Implications

SLA 3D printing shines in its ability to produce complex, high-precision parts with minimal setup time, making it ideal for low to medium-volume production and prototyping. While the material and initial equipment costs can be higher than some traditional methods, the savings in labor, waste reduction, and the ability to iterate designs rapidly can offset these expenses.

SLA 3D Printing vs. Injection Molding: Short-Run Cost Showdown

When manufacturers consider production methods for short-run batches, the decision often oscillates between SLA 3D printing and injection molding. Both have their merits, but their cost-effectiveness can vary dramatically depending on the project’s scale and complexity. Let’s delve into a detailed cost comparison to determine which method holds the economic edge in short-run production.

The Economics of Injection Molding for Short Runs

Injection molding is a titan of mass production, yet its cost structure can be prohibitive for short runs:

- Tooling Costs: The creation of a mold is expensive, and while this cost is amortized over the number of parts produced, for short runs, it can significantly inflate the per-unit cost.

- Setup Time: Preparing for a production run involves labor and time, which adds to the cost, especially for limited quantities.

- Material Efficiency: Injection molding is material-efficient for large runs, but the benefits diminish with fewer parts.

SLA 3D Printing: A Short-Run Contender

SLA 3D printing, on the other hand, has a different economic profile that can be advantageous for short runs:

- No Tooling Costs: SLA eliminates the need for molds, removing a substantial upfront cost barrier.

- Quick Setup: Preparing an SLA print is generally faster and less labor-intensive, reducing initial costs.

- Design Flexibility: SLA allows for easy design iterations without additional costs, which is particularly valuable in the prototyping stage or when customization is required.

Breaking Down the Costs: A Comparative Analysis

To illustrate the cost dynamics between SLA 3D printing and injection molding for short-run production, let’s analyze a hypothetical scenario:

- Production Quantity: 100 units

- Part Complexity: Medium complexity, requiring a moderately intricate mold or print setup

| Cost Component | Injection Molding | SLA 3D Printing |

| Tooling | $5,000 | $0 |

| Material per Unit | $1 | $5 |

| Labor | $500 | $200 |

| Setup Time | $500 | $50 |

| Total Cost | $6,600 | $1,250 |

| Cost per Unit | $66 | $12.50 |

Note: These figures are simplified for illustrative purposes and will vary based on specific project details.

The Verdict

In this scenario, SLA 3D printing offers a clear cost advantage for short-run production. The absence of tooling costs and lower setup time contribute significantly to the reduced per-unit cost. While the material costs for SLA printing are higher, they are offset by the savings in other areas.

The Bigger Picture

It’s important to note that as production quantities increase, the cost advantage may shift. Injection molding becomes more cost-effective at higher volumes due to the spread of tooling costs over more units. However, for short runs, SLA 3D printing is often the more economical choice, providing flexibility and efficiency that traditional methods struggle to match.

Comparing SLA 3D Printing to CNC Machining

When it comes to fabricating parts with intricate designs, manufacturers often weigh the options between SLA 3D printing and CNC machining. Both processes have their own set of advantages and limitations, particularly concerning complexity, waste management, and production speed. Let’s dive into a comparative analysis to understand which method might be more cost-effective under different circumstances.

Suitability for Complex Designs

Complexity is often a key driver in the decision-making process:

- SLA 3D Printing: Excelling at complexity, SLA can produce highly detailed and intricate parts without the need for tool changes or complex fixturing, often at a lower cost for complex geometries.

- CNC Machining: While capable of producing complex parts, the costs can escalate quickly due to the need for specialized tooling and multi-axis machines.

Material Wastage Comparison

Waste not, want not — efficiency is crucial:

- SLA 3D Printing: As an additive process, SLA minimizes waste by using only the material necessary to build the part, plus any required supports.

- CNC Machining: This subtractive process can result in significant material waste, as excess material is cut away from a solid block, which can be costly, especially with expensive materials.

Speed and Turnaround Time

Time is money, and production speed can be a deal-breaker:

- SLA 3D Printing: Generally offers faster turnaround times for small to medium-sized runs due to minimal setup requirements and the ability to print multiple parts simultaneously.

- CNC Machining: For larger production runs, CNC might be faster per part, but the initial setup and tool change times can add up, making it less efficient for small batches.

Cost Analysis Table

To better visualize the cost implications, here’s a comparative table:

| Factor | SLA 3D Printing | CNC Machining |

| Design Complexity | High suitability | Moderate suitability |

| Material Wastage | Low | High |

| Speed (Small Batches) | Fast | Slower |

| Speed (Large Batches) | Moderate | Fast |

Note: The table provides a general overview and may not reflect all specific project conditions.

SLA 3D printing is typically more cost-effective for complex, small to medium-sized runs due to its suitability for complex designs, lower material wastage, and faster turnaround times. CNC machining, while potentially faster for large batch sizes, may incur higher costs due to material wastage and the need for specialized tooling for complex parts.

The Impact of Design on Manufacturing Costs

The design phase is critical in manufacturing, as it can significantly influence the overall costs. With the advent of SLA 3D printing, the impact of design on cost has become even more pronounced. This section will explore the flexibility offered by SLA 3D printing, how design plays a role in cost savings, and present case studies that highlight the cost-effectiveness of SLA 3D printed designs.

Design Flexibility with SLA 3D Printing

SLA 3D printing offers unparalleled design flexibility, which can lead to substantial cost savings:

- Complex Geometries: SLA can easily handle complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

- Customization: It allows for easy customization without the need for new tooling, making it ideal for bespoke solutions or personalized products.

- Iterative Design: Rapid prototyping with SLA means designs can be tested and refined without incurring the high costs typically associated with iterative design in traditional manufacturing.

The Role of Design in Cost Savings

A well-thought-out design can be a game-changer in reducing costs:

- Material Efficiency: Designs optimized for SLA can reduce material usage, lowering the cost per unit.

- Integrated Assemblies: SLA allows for the creation of parts that integrate multiple components into a single print, reducing assembly time and costs.

- Support Structure Optimization: Strategic design can minimize the need for support structures in SLA printing, which reduces material waste and post-processing labor.

Case Studies of Cost-Effective SLA 3D Printed Designs

Real-world examples can best illustrate the cost benefits of SLA 3D printing:

- Custom Dental Devices: SLA 3D printing has revolutionized dental practices by enabling the cost-effective production of custom dental implants, crowns, and bridges with rapid turnaround times.

- Aerospace Component Prototyping: Aerospace companies have utilized SLA to prototype complex, lightweight components, reducing the time and cost of development cycles.

- Automotive Custom Tooling: The automotive industry has adopted SLA for creating custom jigs and fixtures, which can be produced quickly and at a fraction of the cost of traditional tooling methods.

The flexibility of SLA 3D printing in the design phase plays a pivotal role in reducing manufacturing costs. By enabling complex designs, customization, and efficient material usage, SLA can offer significant cost savings over traditional manufacturing methods. The case studies presented demonstrate the practical and economic advantages of incorporating SLA 3D printing into the design and production process.

Prototyping with SLA 3D Printing

Prototyping is a crucial stage in product development, and SLA 3D printing has emerged as a powerful tool in this arena. This section will delve into the advantages of using SLA for prototyping, compare its costs with traditional prototyping methods, and discuss how the speed of iteration with SLA can impact overall project costs.

The Advantages of SLA for Prototyping

SLA 3D printing brings several benefits to the table when it comes to prototyping:

- High Detail and Precision: SLA printers are capable of producing prototypes with fine details and a high-quality surface finish, which is essential for accurate testing and presentation.

- Wide Range of Materials: A variety of resins are available for SLA printing, allowing for prototypes that can simulate the properties of the final product.

- Design Versatility: The ability to create complex and intricate designs without additional cost allows designers to explore more creative solutions.

Cost Comparison with Traditional Prototyping Methods

When it comes to costs, SLA 3D printing stands out:

- Lower Initial Costs: Unlike traditional methods that often require expensive molds or tooling, SLA printing has minimal setup costs, making it more accessible for small businesses and startups.

- Material Efficiency: SLA uses only the material necessary to create the prototype, leading to less waste and lower material costs.

- Reduced Labor Costs: The automated nature of SLA printing requires less manual labor compared to traditional methods, which can be labor-intensive.

Speed of Iteration and Its Impact on Overall Costs

The ability to iterate quickly is one of the most significant cost-saving aspects of SLA 3D printing:

- Rapid Prototyping: SLA printers can produce prototypes in a matter of hours or days, not weeks, allowing for a faster design cycle.

- Immediate Feedback: Quick iterations mean design flaws can be identified and corrected early in the development process, saving time and money.

- Market Readiness: Accelerated prototyping can lead to a shorter time-to-market, which is crucial in a competitive business landscape.

SLA 3D printing offers a range of advantages for prototyping, including high precision, a broad selection of materials, and the ability to produce complex designs quickly and cost-effectively. When compared to traditional prototyping methods, SLA often leads to lower costs, faster iterations, and a more streamlined development process. These benefits collectively contribute to a more efficient path from concept to market-ready product.

Production Runs: SLA 3D Printing vs. Traditional Methods

As SLA 3D printing technology matures, its role in production runs is increasingly being compared to traditional manufacturing methods. This section will cover a break-even analysis for SLA 3D printing, assess its scalability for mass production, and discuss how customization impacts costs.

Break-even Analysis for SLA 3D Printing

Understanding when SLA 3D printing becomes cost-effective is crucial:

- Lower Upfront Costs: SLA 3D printing requires no tooling, which can significantly reduce upfront investment compared to methods like injection molding.

- Break-even Point: The break-even point occurs when the cost of SLA 3D printing equals the cost of traditional manufacturing, considering both production and setup costs. This point will vary depending on the complexity and quantity of the parts.

Scalability of SLA 3D Printing for Mass Production

Scaling production with SLA 3D printing presents unique considerations:

- Batch Production: SLA 3D printing is well-suited for small to medium batch production, where it can be more cost-effective and faster than traditional methods.

- Speed Limitations: For very high volumes, the speed of SLA printing may become a limiting factor, although this is continually improving with technological advancements.

Customization and Its Effect on Cost

Customization is a significant advantage of SLA 3D printing:

- Tailored Products: SLA 3D printing allows for easy customization without additional costs, making it ideal for niche markets or personalized products.

- Cost Implications: While traditional methods often incur significant costs for customization due to the need for new molds or tooling, SLA 3D printing maintains a consistent cost structure regardless of design changes.

SLA 3D printing offers a competitive alternative to traditional manufacturing methods, especially for small to medium production runs that require high detail or customization. The break-even analysis shows that while SLA may not yet be the go-to for high-volume production, its lower upfront costs and flexibility make it a strong contender in a variety of scenarios. Customization, in particular, can be a game-changer, offering cost stability in a market that increasingly values personalized products.

Post-Processing and Finishing Costs

After printing, SLA 3D printed parts often require post-processing to achieve the desired finish and functionality. This section will explore the post-processing requirements for SLA prints, compare finishing costs with other manufacturing methods, and evaluate the time and labor involved in post-processing.

Post-Processing Requirements for SLA Prints

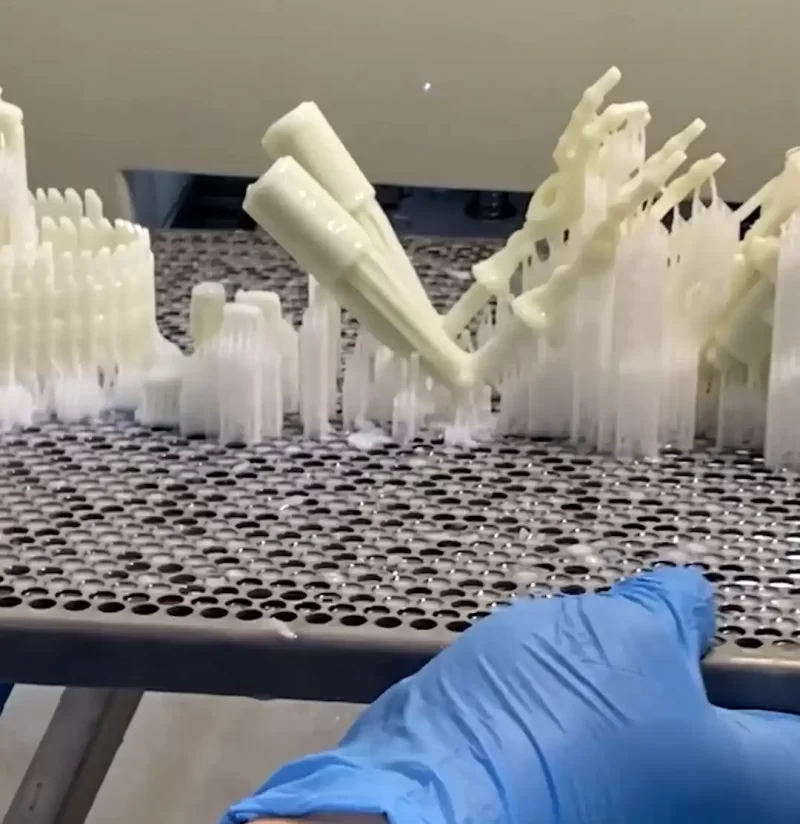

SLA 3D printing necessitates several post-processing steps:

- Cleaning: Freshly printed parts must be cleaned of excess resin, typically using isopropyl alcohol or a specialized cleaning solution.

- Curing: UV light is used to fully cure and harden the resin, which can be done in a UV curing chamber.

- Support Removal: SLA prints often require supports that must be manually removed and the surface finished to smooth any marks left behind.

Comparison of Finishing Costs with Other Methods

Finishing costs can vary widely between SLA 3D printing and traditional methods:

- Material Waste: SLA printing generally produces less waste than subtractive methods, which can reduce material costs.

- Labor Intensity: While traditional methods may require less manual finishing, the labor costs for SLA post-processing can be significant, depending on the complexity of the cleanup and the level of surface finish required.

Time and Labor for Post-Processing

The time and labor involved in post-processing are important cost factors:

- Manual Effort: Post-processing SLA prints is often labor-intensive, requiring skilled technicians to achieve high-quality finishes.

- Time Consumption: The time taken for cleaning, curing, and finishing can add up, especially for parts with intricate details or large batch sizes.

Post-processing is an integral part of the SLA 3D printing process and can contribute substantially to the overall costs of production. While SLA printing offers a high degree of design freedom and material efficiency, the manual labor and time required for post-processing must be carefully considered. Companies must balance the benefits of SLA’s precision and customization capabilities with the post-processing demands to determine the most cost-effective approach for their production needs.

Case Studies: Cost-Effective SLA 3D Printing

To illustrate the practical benefits of SLA 3D printing, this section will present real-world examples that showcase significant cost savings and analyze successful applications of the technology.

Real-World Examples of Cost Savings with SLA 3D Printing

Several companies have leveraged SLA 3D printing to reduce costs:

- Custom Dental Devices: A dental lab utilized SLA printing to produce custom dental devices, slashing material costs by 70% compared to traditional methods.

- Prototyping Consumer Electronics: An electronics company adopted SLA for rapid prototyping, cutting their prototype development costs by half while also accelerating their time-to-market.

Analysis of Successful SLA 3D Printing Applications

The success of SLA 3D printing in various industries can be attributed to several factors:

- Medical Industry: Customization is critical in medical applications. SLA printing’s ability to produce bespoke implants and surgical guides at a lower cost is a significant advantage.

- Aerospace and Automotive: These sectors benefit from SLA’s ability to create complex, lightweight structures that would be costly or impossible to produce with traditional manufacturing.

The case studies demonstrate that SLA 3D printing can lead to substantial cost savings across different industries, particularly where customization and complex geometries are involved. By analyzing these real-world applications, it is evident that SLA 3D printing is not only a viable option for prototyping but also for end-use production in certain scenarios. The technology’s flexibility, speed, and precision offer a competitive edge, especially for companies looking to innovate and reduce costs.

The Future of SLA 3D Printing in Manufacturing

Exploring the trajectory of SLA 3D printing, this section will examine the technological advancements poised to influence production costs and forecast the adoption of SLA printing across various industries.

Technological Advancements and Their Potential Impact on Costs

Innovations in SLA 3D printing are expected to drive cost efficiencies:

- Faster Printing Technologies: Developments in print speed can reduce production time, leading to lower labor costs and higher throughput.

- Advanced Materials: New resin formulations can result in stronger, more durable parts, potentially decreasing the need for post-processing and expanding the range of applications.

- Automation in Post-Processing: Automated cleaning and curing systems are set to minimize manual labor, further reducing costs.

Predictions for SLA 3D Printing Adoption in Various Industries

The future of SLA 3D printing looks promising across sectors:

- Healthcare: Custom prosthetics and biocompatible implants are areas where SLA’s precision and customization could see increased adoption.

- Consumer Goods: As consumers demand more personalized products, SLA 3D printing is likely to become more prevalent for small-batch, custom manufacturing.

- Automotive and Aerospace: The need for lightweight, complex components could see these industries continue to integrate SLA printing into their manufacturing processes.

Conclusion

The ongoing advancements in SLA 3D printing technology are setting the stage for broader adoption and more cost-effective manufacturing solutions. As the technology continues to evolve, it is likely to become an increasingly attractive option for industries that value customization, complexity, and precision. The potential for reduced costs and increased efficiency could see SLA 3D printing becoming a more integral part of the manufacturing landscape in the years to come.