Additive manufacturing, more commonly known as 3D printing, has revolutionized production for companies large and small. One of the most widely used technologies is selective laser sintering (SLS), a powder bed fusion process that uses a laser to selectively fuse material powder into solid parts layer-by-layer. For small and medium-sized enterprises (SMEs), implementing SLS can be transformative – allowing for rapid prototyping, small batch production, and even custom end-use parts production. But with various SLS printers and technologies now available, how can SMEs determine the right system for their needs and budget?

Selecting an SLS 3D printer is an important investment that requires careful evaluation of your business’ specific applications, production goals, and work environment. Whether you’re looking to print high-detail prototypes, durable and functional end-use parts, or a mix of both, the ideal SLS printer is one that fits your throughput needs and material requirements while meeting your quality standards. It should also provide room for operational growth and flexibility as your application needs evolve.This guide covers key factors from build volume to operating costs to help SMEs navigate the selection process. We’ll provide an overview of the SLS printing process, summarize the capabilities and limitations of SLS technologies, and identify major vendors and models worth evaluating. With an understanding of your own criteria and business objectives, you can make an informed SLS printer purchase that slots seamlessly into your manufacturing workflow. Let’s explore how SMEs can find their perfect SLS 3D printing system match.

What is SLS 3D Printing?

Selective laser sintering, commonly known as SLS 3D printing, is a revolutionary additive manufacturing process that produces durable and highly accurate parts from powdered materials. But how exactly does it work? And what are the key benefits that make SLS so valuable for small and medium-sized manufacturers?

How SLS 3D Printing Works

SLS printing works a bit differently from other 3D printing technologies you may be familiar with. Here’s a quick overview of the SLS process:

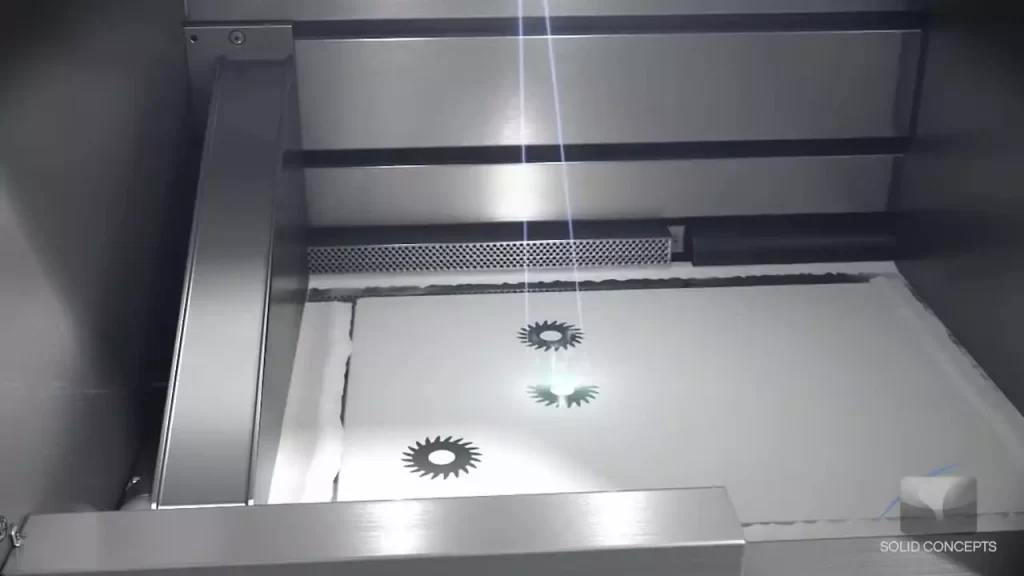

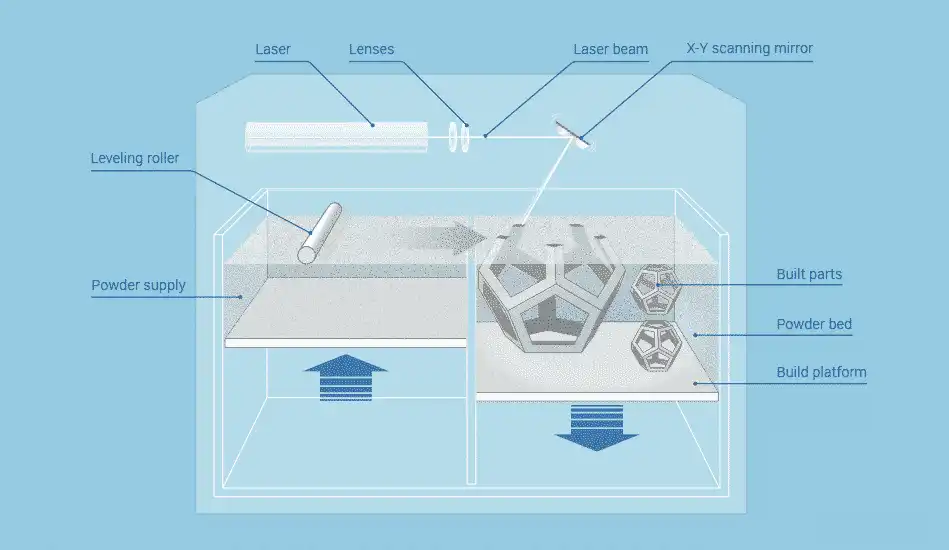

- Powder Bed – SLS printers contain a chamber filled with fine powder. This powder acts as the build material and is spread in thin layers across the build platform.

- Laser Sintering – A laser is precisely guided across the powder bed to selectively fuse (sinter) particles in the pattern of the object layer.

- Lower Platform – After each layer is sintered, the build platform lowers, and a fresh layer of powder is spread across the surface.

- Repeat Layers – This process repeats layer-by-layer until the full object is built up from the sintered powder material.

Remove Object – Once printing is finished, the object is removed from the un-sintered powder bed, leaving supports behind.

That’s the magic behind SLS printing! Parts are built up additively layer-by-layer rather than being carved out of material.

Benefits of SLS Printing

SLS offers some unique advantages that make it a great choice for small manufacturing runs:

No Supports Needed – SLS prints don’t require dedicated support structures since the powder bed itself acts as support. This allows for complex geometries.

Speed – SLS printing is relatively fast compared to other technologies, producing parts in hours rather than days.

- Various Materials – From plastics to flexible materials to composites, a range of powder options exist. Even metal powders can be sintered by some printers.

- Strong Thermoplastics – SLS uses durable engineered plastics like nylons, allowing functional parts production.

- Various Materials – From plastics to flexible materials to composites, a range of powder options exist. Even metal powders can be sintered by some printers.

- Small Batch Production – SLS is ideal for small product runs thanks to low setup costs and uniform high part quality.

For SMEs, these advantages make SLS an appealing technology to adopt. But not all SLS printers are created equal. Finding one that fits your specific needs requires a deeper look into printer capabilities.

Key SLS Printer Considerations for SMEs

You now understand the impressive capabilities of selective laser sintering (SLS) 3D printing. But not every SLS machine matches the needs of small and medium manufacturers. Certain specifications and features are especially critical when selecting an SLS printer. As an SME, run through this checklist of must-have capabilities for your operations:

Sufficient Build Volume

The printer’s build volume – the maximum part size it can produce – is an obvious but critical consideration.

- What part sizes do you expect to print? Will small prototypes be the main application or larger end-use components?

- Look for a build chamber that can accommodate your average part geometry. Otherwise multiple smaller printers may be needed.

Consider scalability too. A printer like the EOS P396 offers both a streamlined 296 x 185 x 420 mm chamber as well as larger 590 x 385 x 420 mm options. This allows upgrading capacity down the road.

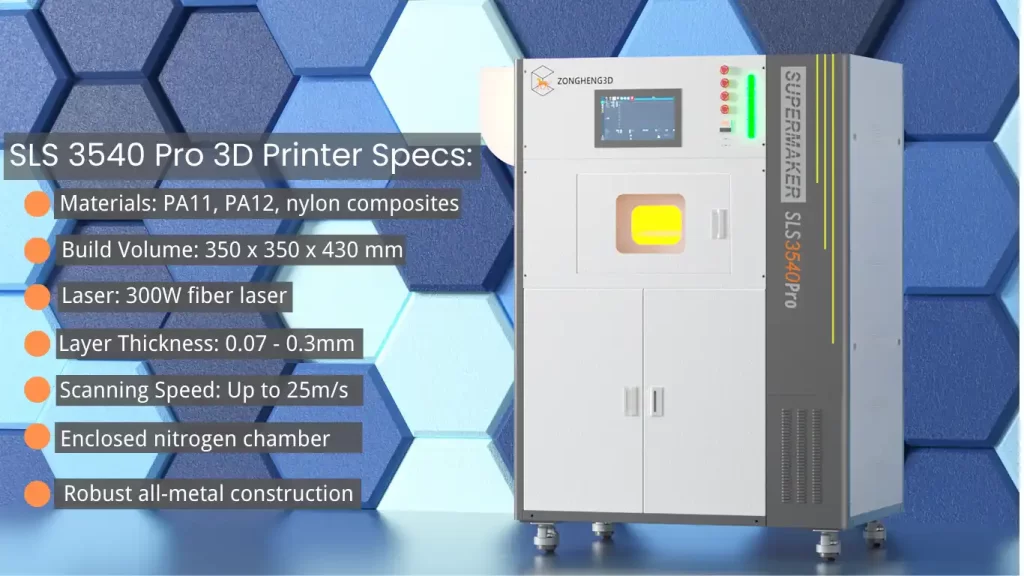

In addition, we have recently launched the SLS 3540PRO, a large-sized SLS printer that offers great value for money. is particularly advantageous for small and medium-sized enterprises to prioritize.

- Layer Thickness: 0.07~0.3mm

- Laser: Fiber Laser 1x300W

- Inert Gas Protection: Nitrogen

- Materials: PA11, 12, Nylon with glass fiber

- Operating Ambient Temperature: 18~30 °c

- German high precision laser

- 350*350*430mm molding size

Material Versatility

Don’t limit your material possibilities. Look for systems with:

- Interchangeable Modules – Open material platforms like those offered by 3D Systems provide flexibility to use various powder materials from plastics to metals.

- Parameter Optimization – Printers like the Sinterit LISA auto-calibrate for new materials, dialing in ideal laser and other settings.

- Material Partners – Manufacturers like Farsoon leverage partnerships to expand available powder materials for their systems.

Accessories – Additional equipment like powder recycling systems conserve materials for improved sustainability and affordability.

Precision and Part Detail

SLS 3D printers vary in precision and capabilities:

- Layer Resolution – Look for machines capable of 50 micron or lower layer heights for smoother surfaces and details. The Sinterit LISA achieves down to just 30 microns.

- Beam Diameter – A tighter laser beam focus as fine as 100 microns yields crisper accuracy.

- Inert Atmosphere – Printers like the EOS P110 use nitrogen purging for minimal oxidation and better material properties.

- Post-Processing – Even with high-end SLS printers, post-processing via sanding, coating, or other methods may be required to achieve perfectly smooth surfaces.

Smart Software and Controls

Don’t underestimate the importance of optimized software and controls:

- Easy Preparation – Look for intuitive model interfaces to orient and set your builds up quickly. The 3D Systems ProX SLS 6100 uses smart default settings for faster job programming.

- Monitoring – Remotely monitor prints and receive alerts if errors occur via app or web interfaces offered by vendors like Formlabs.

- Fluid Controls – Take advantage of advanced settings for tweaking lasers, temperatures, speeds, and more to dial in parts. The EOS P110 features over 20 adjustable parameters.

- Future-Proof – Opt for systems like the Farsoon Flight One with software expandable to add future capabilities.

With robust software that’s tailored for streamlined SLS printing, you can achieve higher reliability and part optimization.

Affordable Operating Costs

The day-to-day costs of SLS printing add up. Manage expenses by:

- Considering material prices – polymers tend to be most budget friendly. Other materials like TPU, composites, or metals carry higher price tags.

- Accounting for secondary equipment needs – powder recycling systems, finishing tools, and more.

- Understanding all recurring fees – maintenance contracts, software licensing, etc.

- Maximizing uptime via reliable printer designs and components. Avoid frequent downtime and repairs.

While SLS printers have higher upfront costs, choosing one with optimized lifecycle value keeps your shop running profitably. By evaluating these key factors – from build volume to materials to operating costs – against the needs of your business, you’ll be equipped to select the right SLS 3D printing system for your small or medium-sized enterprise. Don’t settle on a printer that just meets the bare minimum requirements. Look for one that allows you to fabricate products exactly as you’ve envisioned them and scales seamlessly alongside the growth of your business.

Notable SLS Printer Vendors and Models

The world of selective laser sintering (SLS) 3D printers is expansive, with innovative companies continuously pushing the capabilities of the technology. For small and medium-sized enterprises exploring SLS solutions, which vendors and specific printer models should you have on your radar? While numerous companies offer SLS 3D printers catered to professionals, a few standout manufacturers provide exceptional technology, reliability, and support. Let’s overview top contenders worth evaluating for your SME’s needs:

EOS

The German 3D printing specialist EOS has long been an innovator in industrial polymer laser sintering. Two of their leading models include:

- EOS P110 – A compact industrial workhorse with a 275 x 275 x 330 mm build volume and 75-micron detail. Modular material options.

- EOS P396 – Their largest system for serial production, with variants from 296 to 590 mm max dimensions.

EOS provides robust metal 3D printers as well but comes with a premium price tag. Their systems offer superb part quality and customizability for professional workloads.

3D Systems

The SLS portfolio by U.S.-based 3D Systems spans small professional printers up to high-volume production systems. Consider:

- ProX SLS 6100 – A professional 381 x 330 x 460 mm building size with excellent software and 80-150 micron layers.

- SLS 380 – Scaling up to 381 × 330 × 460 mm builds, this modular system also supports multiple materials.

Known for reliability and ease-of-use, 3D Systems caters nicely to mid-size organizations. Their SLS materials range from nylons to elastomers to sands and composites.

Sinterit

Poland-based desktop SLS innovator Sinterit offers the brilliant LISA – an affordable and compact printer perfect for SMEs. Key specs:

- Max size of print diagonally: PA – 234 [mm] (9.2 [in]) TPU / TPE – 242 [mm] (9.5 [in])

- High accuracy max print volume:PA – 110 x 160 x 130 [mm] (4.3 x 6.3 x 5.1 [in]) TPU / TPE – 110 x 160 x 145 [mm] (4.3 x 6.3 x 5.7 [in])

- Size of Print Bed:150 x 200 x 150 [mm] (5.9 x 7.9 x 5.9 [in])

The layer height Z (min – max):

0.075 – 0.175 [mm] (0.003 – 0.007 [in])

ZONGHENG3D-SLS 3540 PRO

Final Selection Criteria for Finding the Right SLS Printer

After reviewing key printer considerations and leading options on the market, how do you ultimately determine the best selective laser sintering (SLS) 3D printer for your small or medium-sized business? Carefully developed selection criteria will guide you to the right SLS printing solution. Here are the must-have factors to include in your decision matrix:

Reflect Your Production Requirements

- Consider your likely applications – are small prototypes or larger end-use parts the priority? This defines build volume needs.

- Determine expected production volumes. Is a large serial production system justified or will a compact printer suffice?

- Assess the level of fine details and tolerances required. Does your use case demand ultra-high resolution?

- Weigh importance of print speed. Do you need rapid iterations or is print time flexibility acceptable?

Matching your throughput needs and production expectations is the first litmus test to narrow printer options.

Material and Part Properties

- Catalog your likely material needs – plastics, rubber-like materials, composites, metals, etc.

- Determine mechanical property requirements – tensile strength, heat or chemical resistance, biocompatibility, flexibility, etc.

- Assess importance of fine surface finish and post-processing ease.

- Consider factors like sterilizability and biocompatibility if printing medical or food-safe parts.

Your applications dictate the optimal material characteristics and resulting part quality needed.

Software, Controls, and Automation

- Gauge the level of software sophistication required for your team. Is ease-of-use paramount?

- Evaluate automation features for minimizing technician involvement.

- Assess monitoring and alert capabilities for unattended printing.

- Consider integration requirements with existing software platforms or ERP/MRP systems.

Don’t undervalue optimizing the entire process through smart software and controls.

Operating Costs and Total Cost of Ownership

- Model expected material consumption costs over 12-24 months.

- Factor in secondary equipment, maintenance, operating costs.

- Consider cost per part produced based on printer productivity.

- Evaluate lifecycle longevity – avoid frequent replacements.

While upfront printer cost is critical, ongoing operating costs ultimately dominate. By formally assessing each of your key criteria against printer options, your technology choice will perfectly align with your applications, business scale, and budget. With your ideal SLS 3D printing solution in hand, you’ll be equipped to transform your production and fully leverage the benefits of additive manufacturing.