In today’s fast-paced industrial landscape, the demand for precision and efficiency in manufacturing processes is at an all-time high. Enter Digital Light Processing (DLP) technology—a game changer in the world of 3D printing that offers unparalleled speed, accuracy, and versatility. Whether you’re a seasoned manufacturer or a newcomer to the industry, choosing the right industrial DLP 3d printer can significantly impact your production capabilities and overall success.

Imagine being able to create intricate prototypes or end-use parts with stunning detail and minimal waste. The right DLP printer not only enhances your creative possibilities but also streamlines your workflow, ultimately saving you time and money. However, with a myriad of options available, selecting the perfect printer can feel overwhelming.

This article aims to guide you through the essential considerations for choosing the right industrial-grade DLP printer. We will explore the intricacies of DLP technology, key factors such as print quality, build volume, and material compatibility, and provide insights into the applications and benefits of DLP printing. By the end of this article, you’ll be equipped with the knowledge to make an informed decision that aligns with your specific needs and goals. Let’s dive in!

Understanding DLP Technology

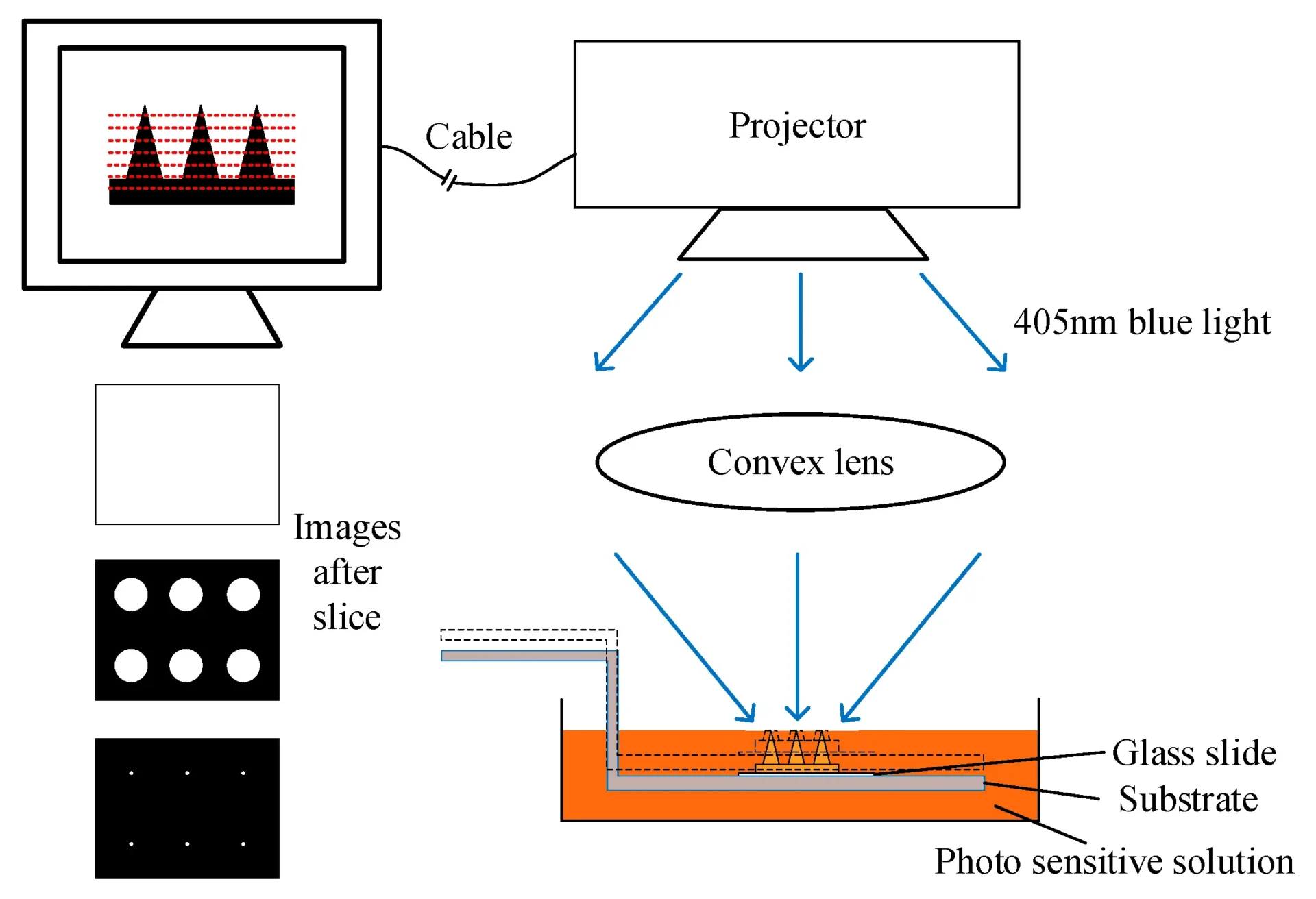

Digital Light Processing (DLP) technology has revolutionized the way we approach 3D printing, especially in industrial applications. Unlike traditional methods that rely on filament or resin extrusion, DLP uses a digital light projector to cure liquid resin layer by layer, creating highly detailed and precise objects. In this section, we will delve into the mechanics of DLP technology, its advantages, and why it stands out in the realm of industrial-grade printers.

What is DLP Technology?

At its core, DLP technology utilizes a digital light source to project images onto a vat of liquid resin. Here’s a step-by-step breakdown of how it works:

- Digital Projection: A digital light projector displays a cross-sectional image of the object to be printed.

- Resin Curing: The light cures the resin in the areas exposed to it, solidifying it into a solid layer.

- Layering Process: Once a layer is cured, the build platform moves downwards, allowing fresh resin to flow over the cured layer.

- Repetition: This process repeats for each layer until the object is complete.

Why Choose DLP Technology?

Applications of Industrial-Grade DLP 3D Printers

- Engineering and Manufacturing

DLP 3D printing facilitates rapid prototyping, allowing engineers to create high-fidelity prototypes that resemble final products. This accelerates the design process and aids in validating concepts before mass production. Manufacturers leverage DLP technology for creating customized tools, molds, and manufacturing support tools, significantly reducing costs and lead times compared to traditional methods. - Dentistry

In the dental field, DLP printers produce custom dental devices, such as crowns, bridges, and aligners, with high accuracy. This technology improves patient care by minimizing human error and enhancing the consistency and precision of dental products. - Jewelry Design

Jewelry professionals use DLP technology to create intricate designs and prototypes. This method allows for rapid customization and mass production, enabling jewelers to produce detailed pieces without the labor-intensive process of traditional wax sculpting. - Entertainment

In the entertainment industry, DLP technology is employed for creating high-definition models for character modeling, props, and special effects in films and video games. This application allows for detailed and accurate representations that enhance visual storytelling.

Understanding DLP technology is crucial for anyone considering an industrial-grade DLP printer. Its unique approach to 3D printing not only enhances efficiency but also opens up new possibilities for design and production. In the next section, we will explore the key considerations to keep in mind when selecting the right DLP printer for your specific needs.

Key Considerations When Choosing Industrial DLP 3D Printer

Selecting the right industrial-grade DLP printer requires careful consideration of several critical factors. With various models and specifications available, it’s essential to understand what features align with your specific needs. In this section, we will explore the key considerations that can guide your decision-making process when choosing a DLP 3D printer.

1. Print Quality

Print quality is perhaps the most crucial factor to consider. It directly influences the final product’s appearance and functionality. Here are some aspects to evaluate:

- Resolution: Measured in microns, higher resolution means finer details. Look for printers with resolutions below 50 microns for intricate designs.

- Layer Thickness: Thinner layers result in smoother surfaces and better detail. Most DLP printers offer layer thickness options ranging from 25 to 100 microns.

- Material Properties: Different resins have varying capabilities regarding detail reproduction. Research the resin types compatible with the printer.

| Resolution | Layer Thickness | Typical Applications |

| 25 microns | 25-50 microns | Jewelry, dental models |

| 50 microns | 50-100 microns | Prototypes, intricate parts |

| 100 microns | 100 microns | Functional parts, tooling |

2. Build Volume

The build volume refers to the maximum size of the objects you can print. It’s essential to assess your production needs:

- Dimensions: Consider the dimensions of the largest part you plan to produce. Common build volumes range from small (100 x 100 x 100 mm) to large (500 x 500 x 500 mm).

- Future Needs: Think about potential future projects that may require larger prints. Opting for a printer with a larger build volume can save you from needing an upgrade later.

3. Speed and Efficiency

In industrial settings, time is money. The speed at which a printer can produce parts is a vital consideration:

- Printing Speed: DLP printers can print an entire layer in one go. Check the specifications for the layer cure time, which typically ranges from 1 to 10 seconds per layer.

- Efficiency: Evaluate the printer’s overall efficiency, including setup time, material usage, and maintenance requirements.

4. Material Compatibility

The materials used in DLP printing can significantly affect the final product’s performance:

- Types of Resins: Ensure the printer supports a variety of resins, including standard, flexible, and high-temperature options.

- Material Properties: Different resins have unique characteristics, such as strength, flexibility, and heat resistance. Choose a printer that accommodates the materials best suited for your applications.

| Material Type | Properties | Best Uses |

| Standard Resin | Rigid, durable | Prototypes, models |

| Flexible Resin | Flexible, rubber-like | Functional parts, grips |

| High-Temperature Resin | Heat resistant | Aerospace, automotive applications |

5. Software and User Interface

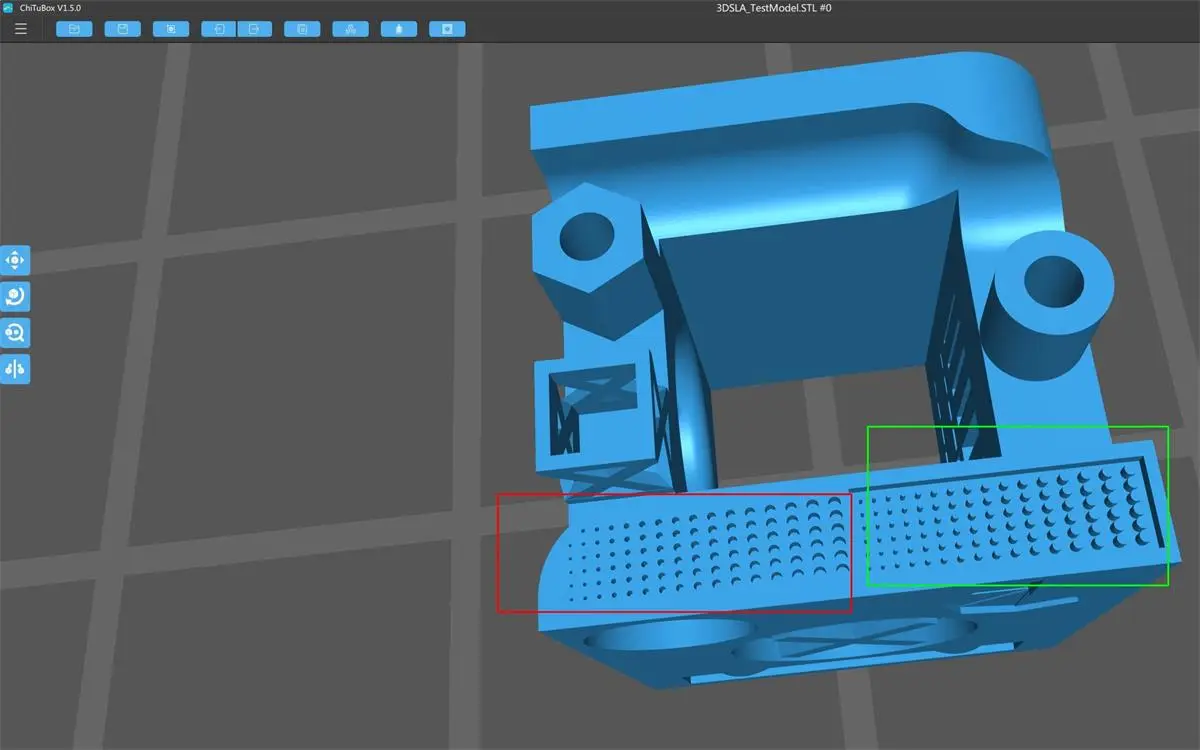

The software that accompanies the printer is crucial for a smooth user experience:

- Slicing Software: Ensure the printer is compatible with reliable slicing software that allows for easy model preparation.

- User Interface: A user-friendly interface can save time during setup and operation. Look for touchscreens and intuitive controls.

6. Maintenance and Support

Regular maintenance is essential for the longevity and performance of your DLP printer:

- Maintenance Needs: Understand the routine maintenance required, such as cleaning the resin vat and updating software.

- Technical Support: Investigate the availability of technical support and resources, such as user manuals and community forums.

7. Cost and Budget

Finally, consider your **budget**. The cost of a DLP printer can vary significantly based on its features and capabilities:

- Initial Investment: Evaluate the upfront cost of the printer, including any additional accessories or materials.

- Total Cost of Ownership: Factor in ongoing costs, such as resin, maintenance, and potential upgrades. A more expensive printer may offer savings in the long run due to efficiency and durability.

Choosing the right industrial-grade DLP printer involves evaluating various factors, from print quality and build volume to material compatibility and cost. Understanding these considerations will empower you to make an informed decision that aligns with your production needs. In the next section, we will explore the diverse applications of industrial-grade DLP printers, showcasing their versatility across different industries.

Applications of Industrial-Grade DLP Printers

Industrial-grade DLP (Digital Light Processing) 3D printers are versatile tools that find applications across various industries due to their high precision, speed, and ability to handle a wide range of materials. Here are some key application areas:

Engineering and Manufacturing

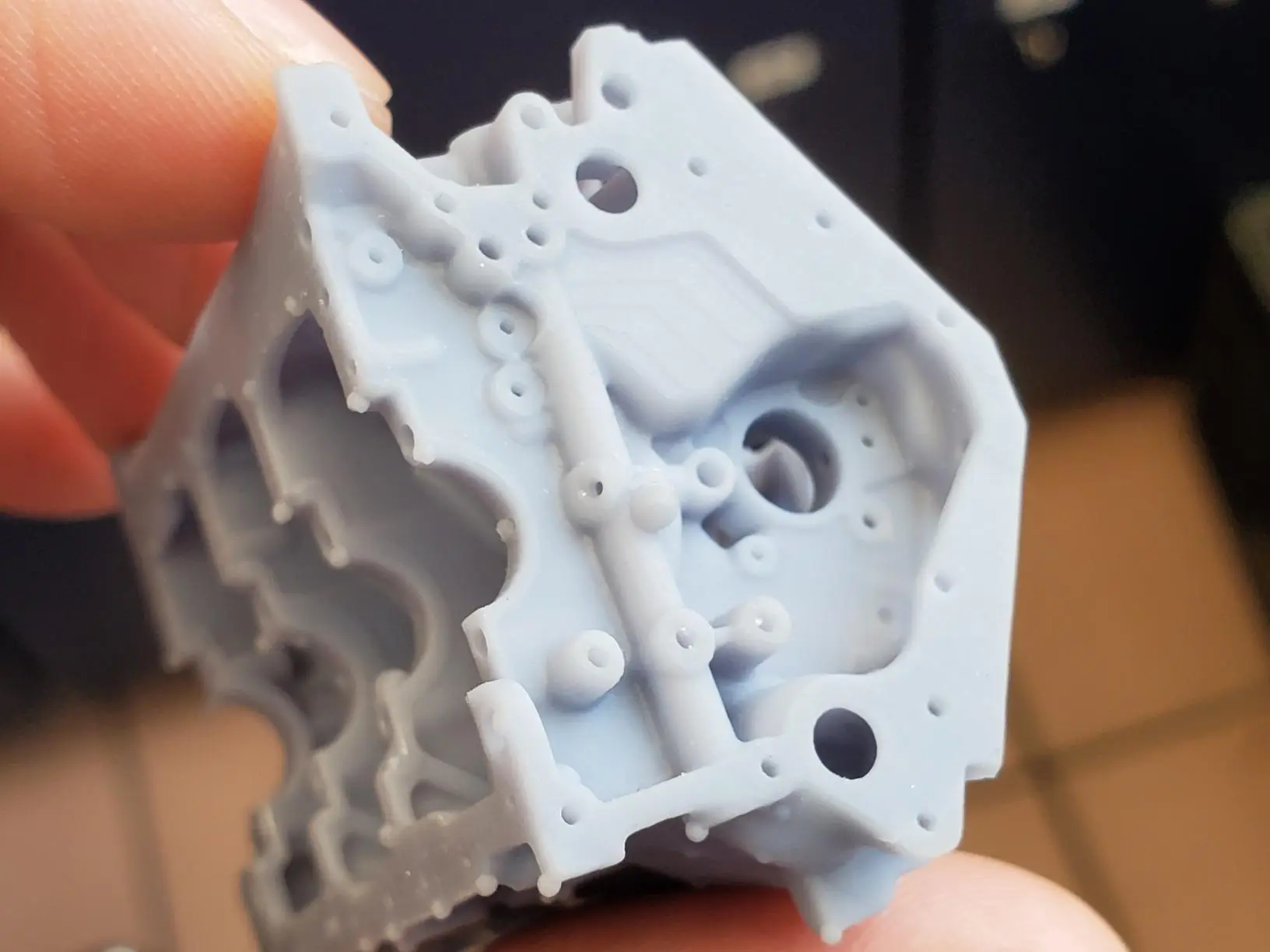

- Rapid prototyping: DLP 3D printing enables the creation of high-fidelity prototypes that closely resemble final products, accelerating the design process and facilitating concept validation before mass production.

- Custom tooling: Manufacturers leverage DLP technology to produce customized tools, molds, and manufacturing support equipment at lower costs and shorter lead times compared to traditional methods.

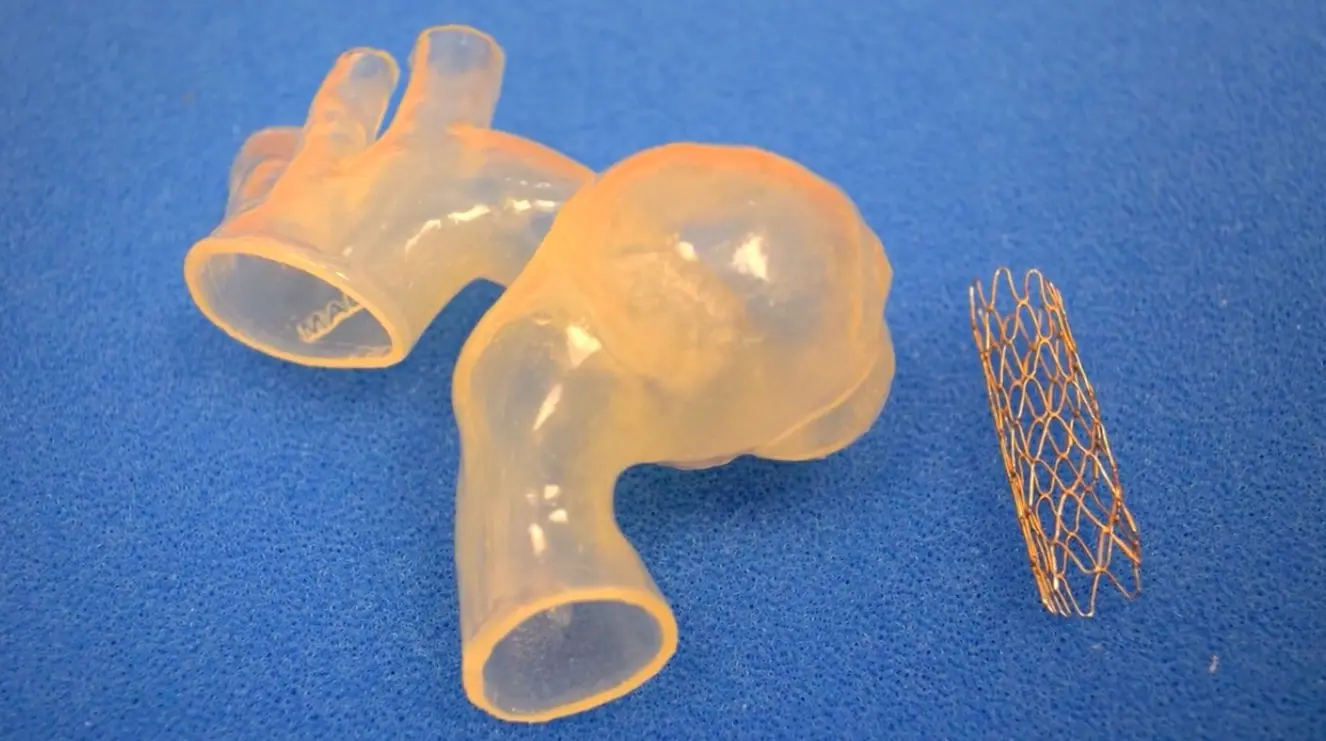

Healthcare

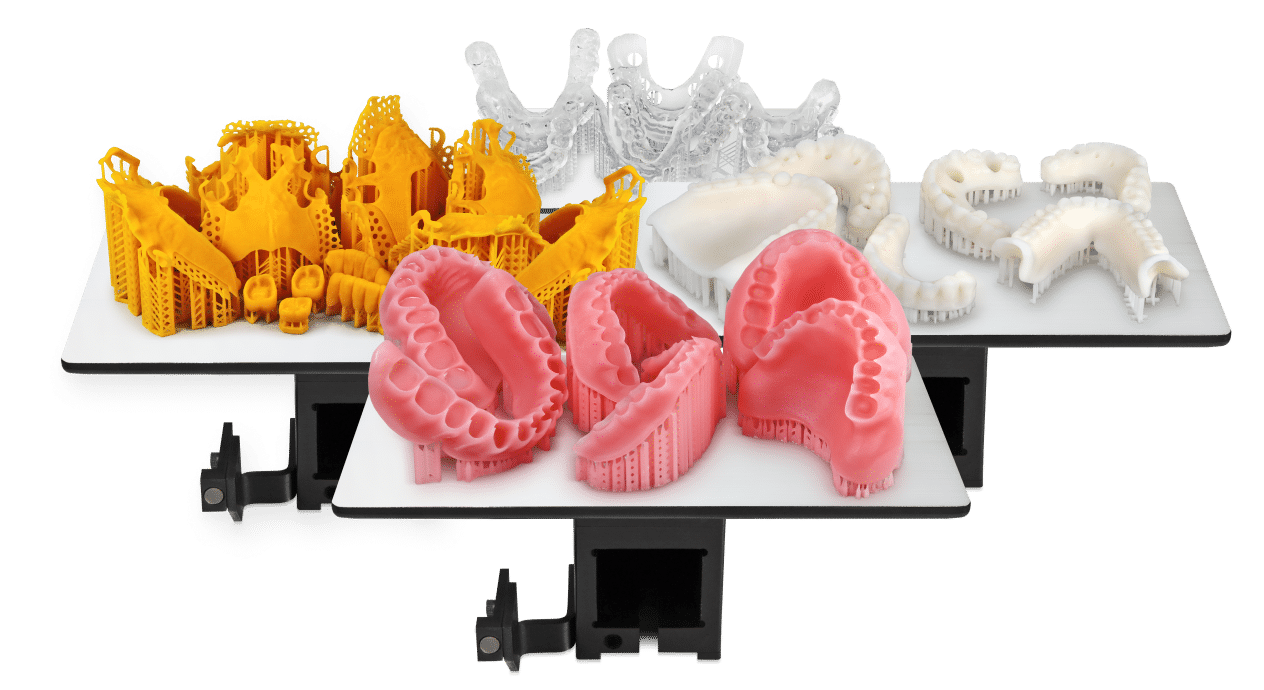

- Custom medical devices: DLP 3D printers are used to manufacture custom prosthetics, implants, and assistive devices tailored to individual patient needs, improving patient outcomes and reducing production costs.

- Dental applications: DLP technology is employed in digital dentistry to produce custom crowns, bridges, aligners, and other dental devices with high accuracy, consistency, and precision.

Jewelry and Luxury Goods

- Rapid jewelry design: Jewelers use DLP 3D printing to quickly create intricate prototypes, enable mass customization, and produce detailed final products without the labor-intensive process of traditional wax sculpting.

- Luxury goods: The high resolution and speed of DLP 3D printing make it suitable for creating high-end, customized products in the luxury goods industry, such as personalized accessories and limited-edition items.

Entertainment and Creative Industries

- Character modeling and props: DLP 3D printing is used to create high-definition models for character modeling, props, and special effects in films, video games, and other media, enhancing visual storytelling.

- Personalized products: The ability to rapidly produce customized products makes DLP 3D printing valuable in the creation of unique, one-of-a-kind items for the fashion, art, and design industries.

Research and Education

- Rapid prototyping for research: DLP technology enables researchers to quickly create experimental models and components, accelerating the pace of innovation and discovery in fields such as materials science, engineering, and biotechnology.

- Educational applications: DLP 3D printers are used in educational settings to provide hands-on learning experiences, create teaching aids, and encourage students to explore the possibilities of additive manufacturing.

The versatility of industrial-grade DLP 3D printers allows them to be applied in a wide range of industries, from engineering and manufacturing to healthcare, luxury goods, entertainment, and research. As the technology continues to evolve, new applications and use cases are likely to emerge, further expanding the impact of DLP 3D printing in the industrial landscape.

Relate All in One Industrial-Grade DLP 3D Printing Solutions

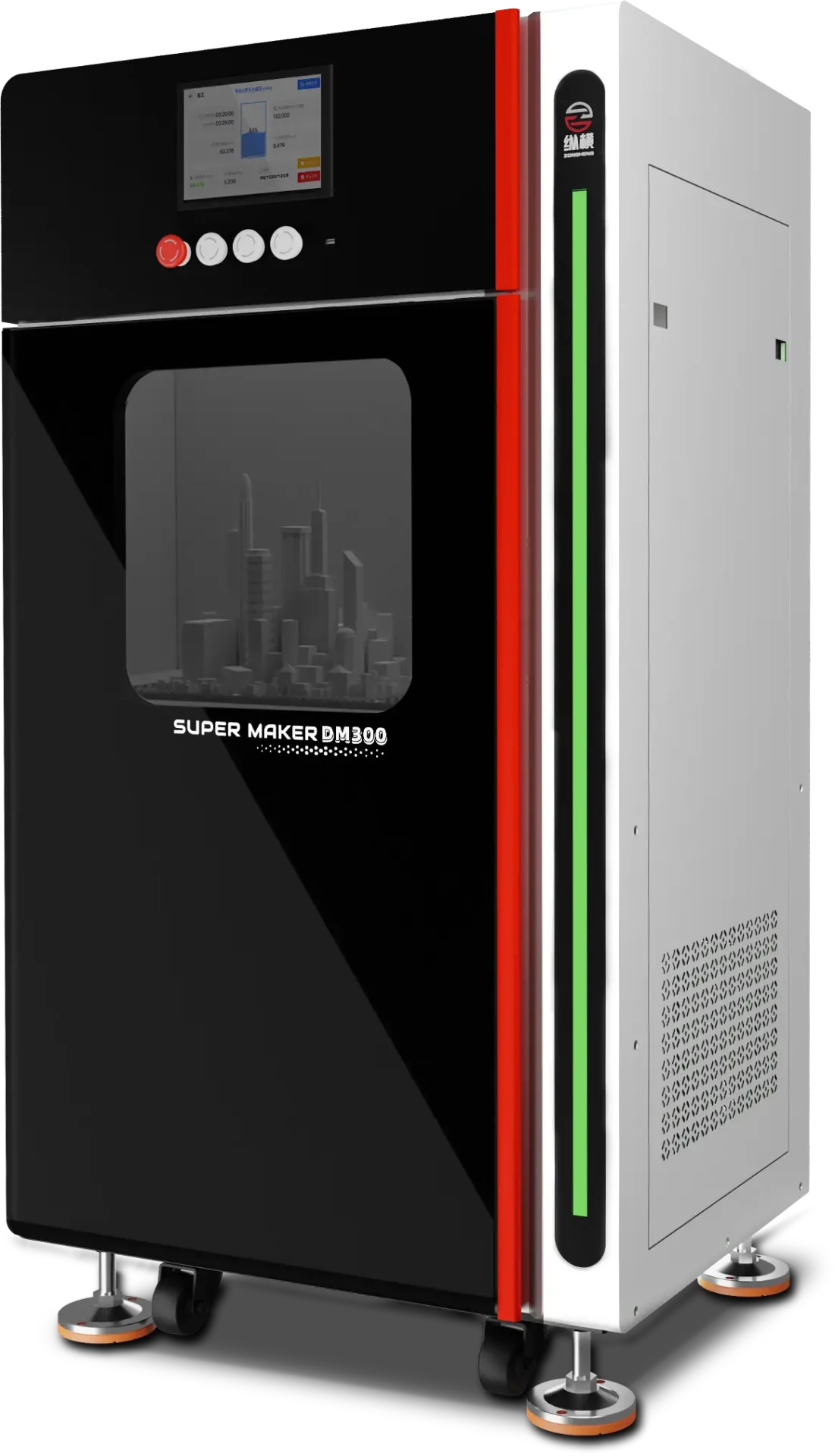

Super Maker DM200

Discover The Future Of High-Speed, High-Precision 3D Printing Start-Up machine.

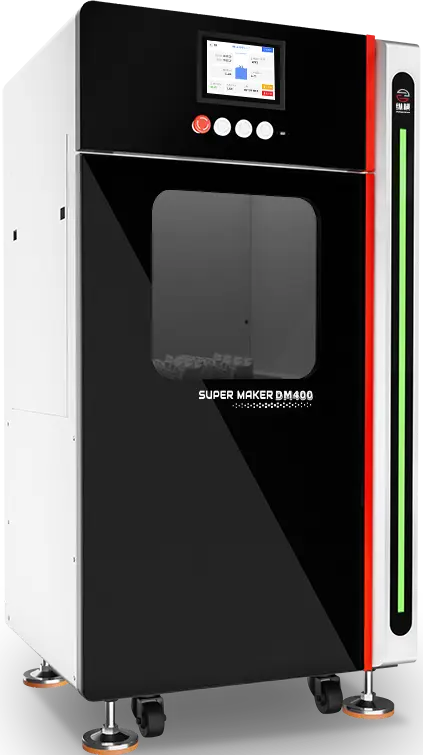

Super Maker DM400

Discover The Future Of High-Speed, High-Precision 3D Printing Start-Up machine.

Future Trends in DLP Technology

As the landscape of 3D printing continues to evolve, Digital Light Processing (DLP) technology stands at the forefront of innovation. With advancements in materials, software, and hardware, DLP is poised to reshape various industries. In this section, we will explore the future trends in DLP technology and their potential impact on manufacturing and production.

1. Advancements in Material Science

The development of new and improved materials is crucial for expanding the capabilities of DLP printers. Future trends include:

- Biocompatible Resins: The healthcare sector will benefit from materials that are not only biocompatible but also biodegradable, enhancing patient safety and environmental sustainability.

- High-Performance Resins: New formulations that offer superior strength, flexibility, and heat resistance will enable the production of parts suitable for demanding applications, such as aerospace and automotive.

- Multi-Material Printing: The ability to print with multiple materials in a single job will allow for greater design complexity and functionality.

| Material Type | Future Developments | Potential Applications |

| Biocompatible Resins | Enhanced safety and sustainability | Medical devices, implants |

| High-Performance Resins | Improved mechanical properties | Aerospace, automotive components |

| Multi-Material Resins | Complex designs with varying properties | Consumer products, custom tooling |

2. Integration with AI and Automation

Artificial intelligence (AI) and automation are set to revolutionize the DLP printing process:

- Smart Printing: AI algorithms can optimize print settings in real-time, improving efficiency and reducing material waste.

- Predictive Maintenance: Integrating AI can help predict when maintenance is needed, minimizing downtime and enhancing productivity.

- Automated Workflows: Automation in post-processing and quality control will streamline operations, allowing for faster turnaround times.

3. Enhanced Software Solutions

The software that drives DLP printers is evolving to meet the demands of modern manufacturing:

- User-Friendly Interfaces: Future software will offer more intuitive interfaces, making it easier for users to design and manage prints.

- Advanced Slicing Algorithms: Improved slicing algorithms will optimize print paths and reduce printing times while maintaining quality.

- Cloud-Based Solutions: Cloud integration will allow for remote monitoring and management of printers, enabling more flexible production environments.

4. Sustainability and Eco-Friendly Practices

Sustainability is becoming increasingly important in manufacturing, and DLP technology is no exception:

- Recyclable Materials: The development of recyclable and eco-friendly resins will reduce the environmental impact of 3D printing.

- Energy Efficiency: Future DLP printers will focus on energy-efficient operations, minimizing power consumption during printing.

- Waste Reduction: Innovations in design and printing processes will aim to significantly reduce material waste.

5. Expansion into New Industries

As DLP technology matures, we can expect to see it penetrate new markets:

- Construction: Large-scale DLP printers may be used for creating building components or even entire structures.

- Food Industry: 3D printing of food using DLP technology could revolutionize food production and customization.

- Fashion and Textiles: DLP printers may enable the creation of intricate textile patterns and customized fashion items.

6. Customization and Personalization

The demand for personalized products is on the rise, and DLP technology is well-suited to meet this need:

- Tailored Solutions: DLP printers will allow for the production of customized products that cater to individual preferences, from jewelry to consumer electronics.

- Rapid Response to Trends: The fast turnaround times of DLP printing will enable companies to quickly adapt to changing market trends and consumer demands.

The future of DLP technology is bright, with numerous trends poised to enhance its capabilities and applications. As advancements in materials, software, and automation continue to emerge, DLP printers will play an increasingly vital role in various industries. In the final section, we will summarize the key points discussed in this article and highlight the importance of embracing DLP technology for future manufacturing needs.