Introduction

3D printing, also known as additive manufacturing, has been a game-changer in the manufacturing industry. It has revolutionized the way products are made by narrowing down the bridge between product design and production. Injection molding, on the other hand, is a popular manufacturing process used to create products in bulk production. By combining the power of 3D printing with injection molding, manufacturers can produce high-quality and precise products in the most efficient and cost-effective manner. In this guide, we’ll take a closer look at how to use 3D printing for injection molding.

Steps for Using 3D Printing for Injection Molding

The process of using 3D printing for injection molding can be broken down into three main stages: designing the product, printing the mold, and injection molding the part.

Designing the Product

The first step is designing the product using Computer-Aided Design (CAD) software. This software allows for intricate design details that traditional manufacturing methods may not be able to achieve. It is important to create multiple iterations of the design and ensure that the final product is fit for injection molding.

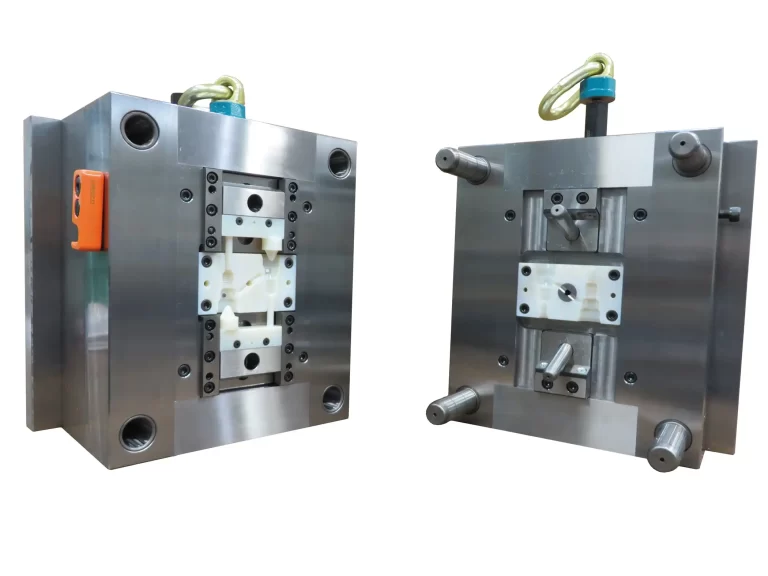

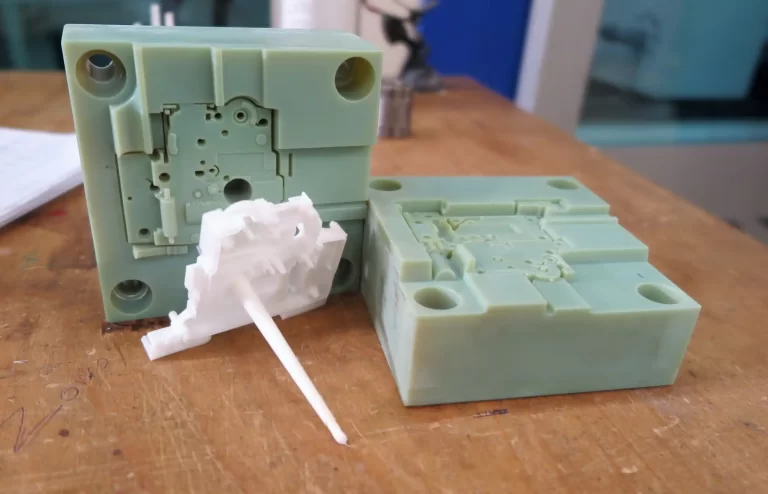

Printing the Mold

Once the product design is completed, the mold is printed using the appropriate 3D printer and material. It is crucial to understand the design requirements for the mold and print it in the appropriate orientation to ensure its effectiveness.

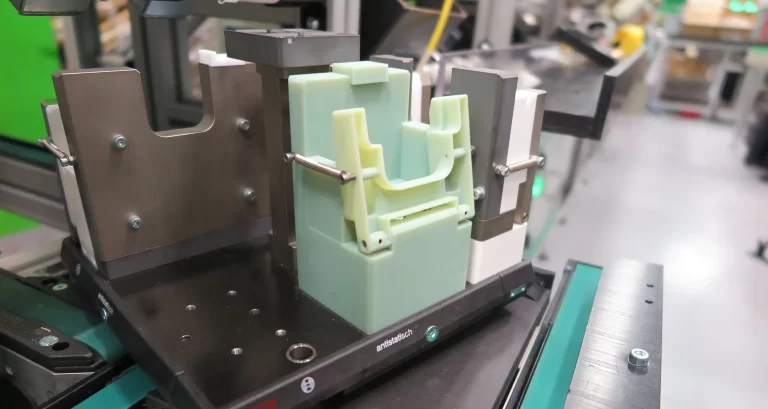

Injection Molding the Part

After the mold is printed, it is then used in the injection molding process to manufacture the final product. The injection molding machine is prepared, and the appropriate plastic material is selected to begin the process. The machine is run, and the final product is produced in bulk.

Factors to Consider when Using 3D Printing for Injection Molding

When considering using 3D printing for injection molding, there are several factors to consider. These include tolerance requirements, mold material selection, and cost considerations. By taking these factors into account, manufacturers can ensure that they produce high-quality products that are cost-effective and meet the required specifications.

Benefits of Using 3D Printing for Injection Molding

Using 3D printing for injection molding offers several benefits, including faster product development, lower costs, and easier changes to the design. With this technology, manufacturers can produce products more efficiently and at a lower cost, making it an attractive option for mass production.

Conclusion

With its efficiency, cost-effectiveness, and improved customization capabilities, 3D printing has revolutionized the manufacturing industry. Combining 3D printing and injection molding offers a more efficient and cost-effective manufacturing process that produces high-quality, precise products. Manufacturers should consider trying 3D printing for injection molding to experience its many benefits.