SLA and FDM are the two main types of 3D printing technology.

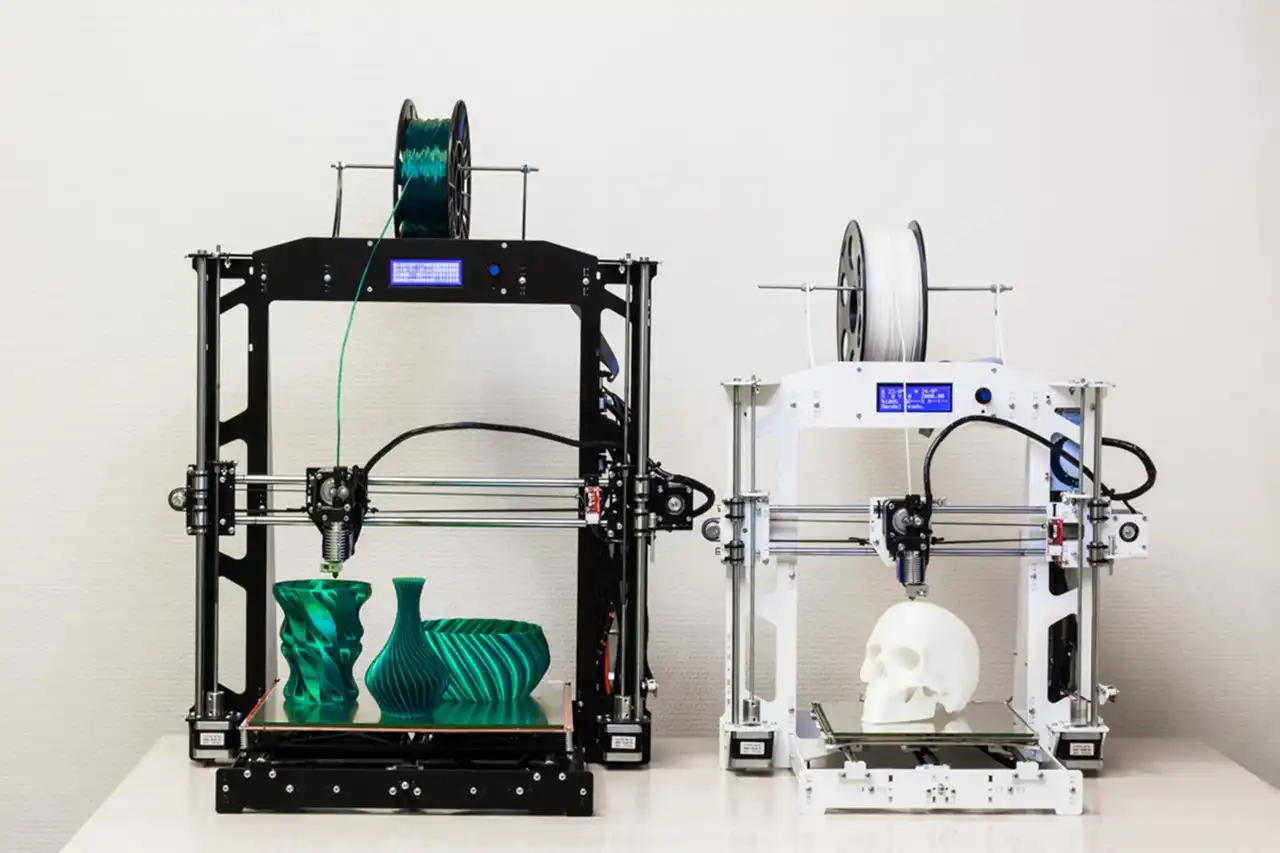

While both technologies can produce identical models, they have different advantages and disadvantages.

Both methods of 3D printing have advantages and disadvantages.

Designers prefer SLA because it produces intricate parts that can be printed at high resolutions. SLA produces parts with smoother surfaces and better finishes than other methods. SLA is better suited for parts with complex geometries, such as medical implants, jewelry posts, and architectural models. It can also produce small components with excellent surfaces and be used to make parts and assemblies.

SLA 3D printing has become the most popular method of industrial manufacturing. The material’s maturation has resulted in a more distributed production model. Advanced resins have expanded the number of possible applications beyond prototyping and into production.

SLA 3D printing is also important in the aerospace industry. This industry includes many industries such as aerospace, satellite manufacturing, and space. A company must launch a product quickly so that users can provide feedback. Prototypes must be functional and durable in order for the final product to function properly. SLA 3D printers produce more appealing parts than FDM 3D printers.

SLA has a higher quality and is more precise in terms of quality.

SLA printers use resin with a lower XY resolution and smaller layer heights.also use photopolymers that cure quickly.SLA prints have an additional advantage in that they require post-curing to achieve maximum strength. Curing resins in the sun is completely free. SLA 3D printers are primarily used in closed laboratories. These processes are difficult to automate, which is why high-tech industries use the most expensive machines.

But it’s different now. Our SLA series machines have their own constant temperature and humidity system, which can be used without special environment.

In terms of printing support, FDM and SLA differ significantly.

FDM prints, for example, require galvos support. These aid in focusing the laser beam across the entire model’s cross section. SLA parts must be post-processed under ultraviolet light. SLA parts are not the same as FDM parts. They have an internal cavity, which is why they do not solidify once printed. You can use any infill pattern or density to fill this cavity.

Because the layers are only 100 microns thick, SLA printers can produce very fine detail.

The layers also form quickly and chemically bond together, resulting in a uniform material object.

Each type of 3D printing system has advantages and disadvantages. SLA is less expensive, but FDM offers a lower-cost consumable set and better prints. Both printers can print in a variety of polymers and composites, including nylon carbon fiber. This material is light but extremely strong. This material is ideal for creating prototypes and fixtures that can be used in production environments.