Photosensitive resin 3D printer refers to SLA industrial 3D printer, also known as light curing 3D printer, as processing raw material. It has powerful modeling functions and can produce products of various geometric shapes, which are widely used in the field of plate production.

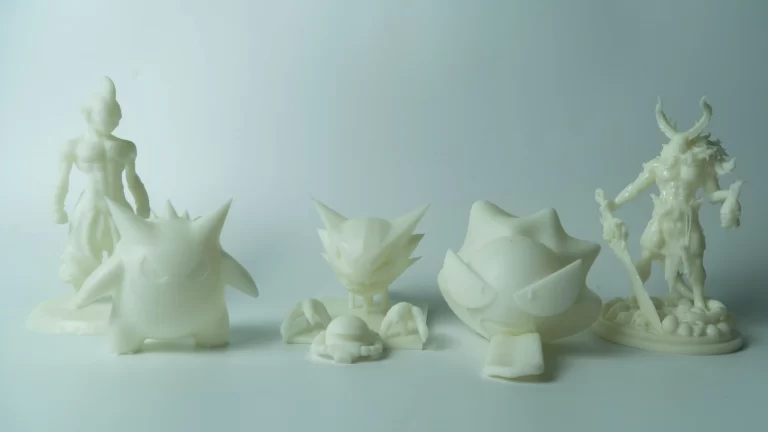

Three stages of hand-made, CNC engraving and 3D printing greatly improve the production efficiency. SLA stereolithography technology is currently a more suitable 3D printing technology, which is very suitable for the field of figure production.

Due to its own limitations, SLA 3D printers can only print special materials similar to ABS plastics – photosensitive resins. Therefore, the photosensitive resin 3D printer is mainly used for the production of plastic plate models, but it cannot be used for the production of metal plate models.

1: Appearance figure model.

The exterior cardboard is mainly used to check the appearance size, and the requirements for other materials are not high. Photosensitive resin 3D printers can print plates of any shape with higher resolution. The more difficult it is to manufacture, the lower the efficiency and cost of 3D printing. Most of the appearance figures are now realized with 3D printers.

2: Structural figure model.

Manual sheets have certain requirements on the strength of the material. The photosensitive resin 3D printer can meet the production of some structural prototypes. If you have special requirements for strength, you can use the complex molding technology or SLS nylon 3D printer.

3: Small batch customization.

For some users with small demand, if it is only suitable for general interior decorations, light-curing 3D printers can be used. If special plastic materials are required, or high temperature resistance and high strength requirements are required, silicone compound molding and low-voltage perfusion process must be used.

4: Soft plastic figure model.

Photosensitive resin consumables are divided into soft materials and hard materials. Many times, figures use hard materials, and a few figures use soft, elastic materials. At this time, soft photosensitive resin 3D printers are useful, usually used to make figures with silicone properties. Photosensitive resins have excellent toughness, abrasion resistance and elasticity, and are widely used in the shoe mold industry and in the production of wearable 3D printed shoes.

5: Transparent figure model.

In the past, the transparent figure model was generally engraved with acrylic materials by CNC machine tools, but now it is almost replaced by light-curing 3D printers. Translucent or fully transparent effects can be produced, and other colors can be added based on transparency. Divided by industry, photosensitive resin 3D printers can be applied to hand mold manufacturing processes in almost all walks of life. The printer can be fully applied to the construction of internal and external layouts such as building sand tables, household appliances, medical equipment, and computer digital.