Discover the Future of High-Speed, High-Precision 3D Printing

Deeply Know about top-down technology advantage

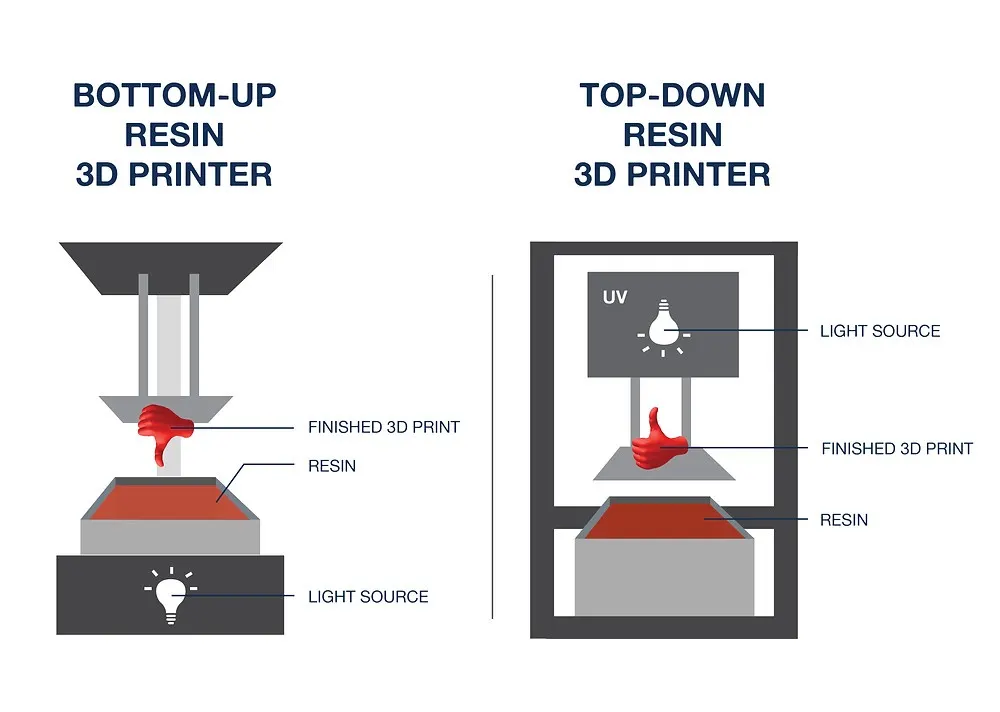

Top-down DLP (Digital Light Processing) 3D printers are a specific type of resin-based 3D printing technology where the light source, typically an LED or UV laser, is positioned above the build platform and projects the image directly onto the surface of the resin. This is in contrast to bottom-up DLP systems, where the resin cures from the bottom up, beneath a transparent build plate.

Reduced Resin Exposure: Since the uncured resin is shielded by the build platform, there’s less exposure to light, which can help preserve the resin for longer periods without it prematurely curing.

Improved Surface Finish: Top-down DLP can produce parts with a potentially smoother finish on the bottom surface, as this surface is in direct contact with the build platform and not subject to the stair-stepping effect that can occur when layers are built up.

Controlled Curing: By projecting the light directly onto the resin, it’s easier to control the curing process, leading to more consistent results and potentially higher resolution prints.

Potentially Faster Printing: In some cases, top-down DLP can offer faster printing because the entire layer cures at once, rather than curing as the light sweeps across the layer in a bottom-up system.

What's the differences between top-down and bottom-up DLP 3D printers?

Light Exposure and Resin Curing Process

Light Exposure and Resin Curing Process

| Product Model | Super Maker DM200 |

|---|---|

| Printing Volume | 192*108*120mm (can be customized) |

| 3D Technology | Digital Light Processing |

| Machine Dimension | 570*480*800mm |

| Net Weight | Around 65kg (excluded materials) |

| Light Source | 4K Projector |

| Printing Technology | Top-Down DLP 3D Printing |

| WaveLenght | 405nm |

| Z Axis Accuracy | 0.002mm |

| Layer Thickness | 0.03-0.15 |

| Printing Speed | 6-8 second/layer |

| Resin Tank | Removable & Replaceable |

| Power Supply | 220V,50HZ |

| Slicing Software | Voxeldance-Tango |

| Resin | Standard Resin,Dental Resin, Flexible resin, Jewelry Resin, High Temperature Resin, High Toughness Resin, Water Washable Resin, Transparent Resin |

| Super Maker DM200 |

Key Benefits:

Dental laboratories and clinics are increasingly adopting 3D printing technologies to improve efficiency and patient outcomes.

This case study examines how a large dental laboratory implemented a top-down DLP 3D printer, specifically the Super Maker DM200, to revolutionize their production of dental models, aligners, and other dental appliances.

A leading consumer electronics company was looking to streamline their product design process, particularly for creating functional prototypes of small, intricate devices. They implemented a top-down DLP 3D printer, specifically the Carima DM400A, to address their rapid prototyping needs.

Get in touch with our experts to find the right DLP solution for your needs

Whether you’re a dental professional, a hobbyist, or an industrial designer, we have the perfect material to bring your ideas to life.

Each resin is optimized for 405nm wavelength DLP 3D printers, ensuring exceptional detail, smooth surface finish, and reliable performance.