Produce high-quality, functional parts with our Industrial-Grade advanced SLS technology

In the fast-paced world of modern manufacturing, staying ahead of the competition requires cutting-edge technology that delivers precision, efficiency, and versatility. Our SLS 3D printers are engineered to meet these demands, offering unparalleled performance and reliability.

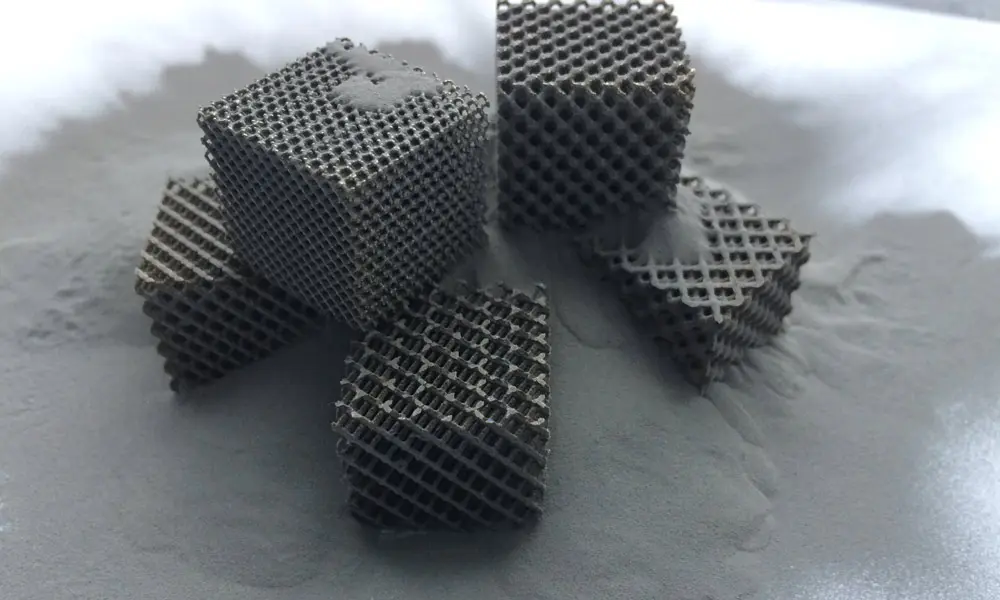

Unlock limitless possibilities with our SLS technology. Create complex geometries, intricate structures, and functional parts that were previously impossible or cost-prohibitive to manufacture.Our printers enable you to push the boundaries of innovation and bring your most ambitious designs to life.

Unparalleled Design Freedom

Maximize your production output with our high-speed SLS 3D printers. Our advanced systems offer industry-leading build rates and large build volumes, allowing you to produce more parts in less time.Streamline your workflow and meet tight deadlines with ease.

High Productivity for Rapid Manufacturing

Find your industry application field

"Implementing SLS technology has been transformative for our prototyping and production processes. We've reduced development time by 40% and achieved a 25% weight reduction in key components, directly impacting fuel efficiency in our latest aircraft designs."

—— Dr. Emily Chen

"SLS technology fulfills all the requirements for the complex geometries of our parts, including durability, texture, and form possibilities. Additionally, it offers low costs and fast manufacturing for prototyping."

*Reduced costs and time savings in production

*Enhanced design freedom and innovation capabilities—— Stephan Eugster

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SLS technology has revolutionized the prototyping phase of manufacturing:

Get in touch with our experts to find the right SLS solution for your needs

Selective Laser Sintering (SLS) technology has revolutionized the 3D printing landscape, and at the heart of this revolution lies an impressive array of materials. These powdered substances, when fused by high-powered lasers, transform into robust, functional parts with properties that often rival or surpass those of traditionally manufactured components.