As the world of 3D printing continues to evolve, two technologies have emerged as frontrunners in the additive manufacturing race: Resin 3D printing and Fused Deposition Modeling (FDM). These two methodologies have distinct advantages and disadvantages, as well as specific applications that cater to different needs. In this in-depth article, we’ll explore the ins and outs of Resin 3D printing vs FDM, answering all your burning questions and helping you decide which technology is the best fit for your projects.

Resin 3D Printing vs FDM: An Overview

Resin 3D Printing

– Also known as Stereolithography (SLA) or Digital Light Processing (DLP)

– Uses a photosensitive liquid resin

– Cured by UV light

– Ideal for intricate and complex designs

– Higher resolution and smoother surface finish

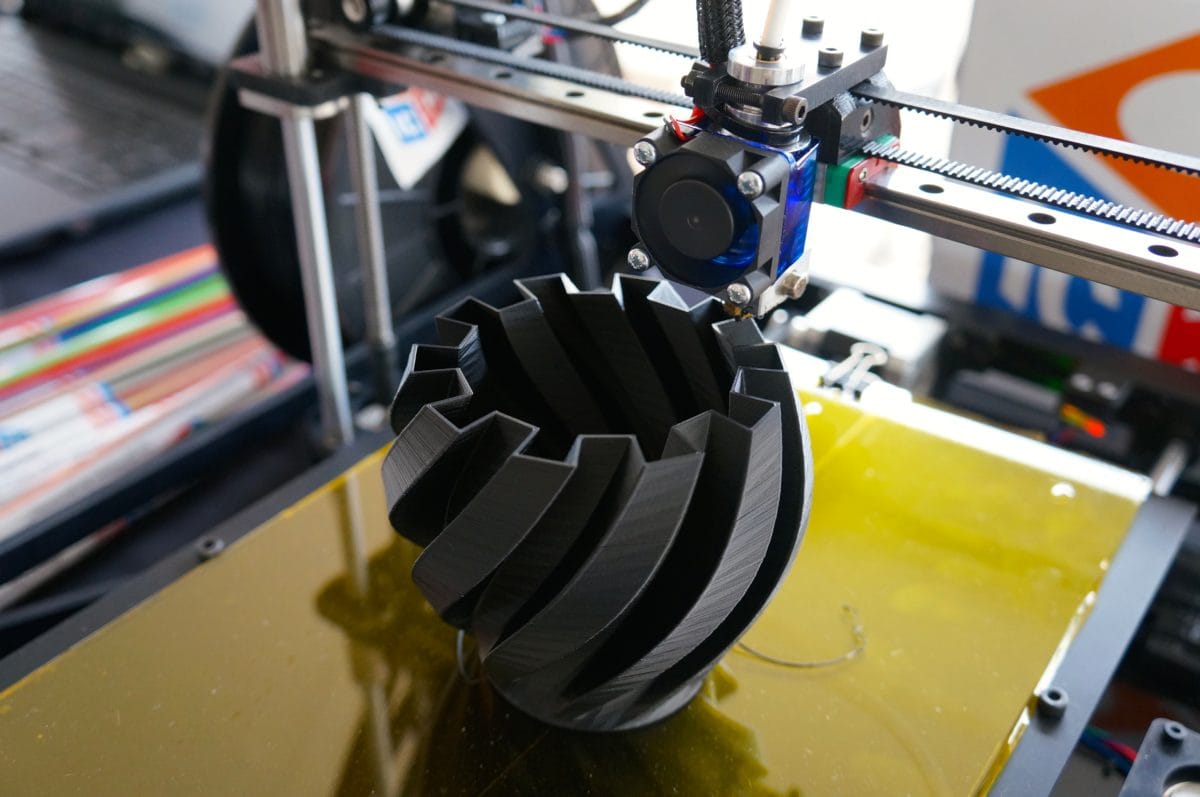

Fused Deposition Modeling (FDM)

– Most common type of 3D printing

– Uses thermoplastic filaments

– Layer-by-layer deposition

– Suitable for functional prototypes and larger objects

– Cost-effective and user-friendly

Key Differences between Resin 3D Printing and FDM

1. Printing Material and Process

Resin

Filaments

– Resin 3D printing: The process involves a vat of liquid photopolymer resin that solidifies when exposed to UV light. A high-resolution projector or laser beam selectively cures the resin, building the object layer by layer.

– FDM: In this technique, a heated nozzle extrudes thermoplastic filaments, which are deposited layer-by-layer onto a build platform. The material cools and solidifies, forming the object.

2. Resolution and Surface Finish

– Resin 3D printing: Due to its UV light curing process, resin 3D printing offers high-resolution prints and smooth surface finishes, making it ideal for intricate, detailed objects and visually appealing prototypes.

– FDM: While FDM technology is improving, it generally produces prints with visible layer lines and a rougher surface finish. Post-processing is often required for a smoother appearance.

3. Strength and Durability

– Resin 3D printing: Resin prints can be brittle, especially when exposed to sunlight or UV light over time. However, some specialized resins are designed to offer increased durability and flexibility.

– FDM: FDM-printed objects are generally more robust due to the use of thermoplastic materials, making them better suited for functional prototypes and end-use parts.

4. Cost and Accessibility

– Resin 3D printing: While resin printers have become more affordable, the cost of resin materials remains higher than FDM filaments. Additionally, resin printing requires more post-processing and has a steeper learning curve.

– FDM: FDM printers and materials are generally more affordable and accessible, making them a popular choice for hobbyists and beginners.

FAQs: Resin 3D Printing vs FDM

1. Q:Which is faster: Resin 3D printing or FDM?

A:Depending on the model complexity and layer height, FDM printing can be faster than resin printing. However, factors like print orientation and support structures can affect the print time for both methods.

2. Q:Is Resin 3D printing safe?

A:Resin 3D printing involves handling liquid chemicals, which can be toxic if ingested or come into contact with skin. Always follow the manufacturer’s safety guidelines and use proper protective equipment when working with resin.

3. Q:Can I use both Resin 3D printing and FDM for the same project?

A:Absolutely! Combining the strengths of both technologies can enhance the final result. For instance, you can use FDM for functional parts and resin printing for intricate details or high-quality surface finishes.