In the world of jewelry design and manufacturing, precision and detail are paramount. The advent of 3D printing technology has revolutionized the industry, allowing designers to bring their intricate creations to life with ease. Among the various types of 3D printers available, SLA (Stereolithography) printers have emerged as the go-to choice for jewelry professionals. In this article, we will delve into the world of SLA 3D printers and explore how they are transforming the jewelry industry.

Introduction

In recent years, the jewelry industry has witnessed a significant shift towards adopting 3D printing technology. SLA 3D printers, in particular, have gained popularity due to their ability to produce highly detailed and accurate prints. Whether you are a jewelry designer looking to create intricate prototypes or a manufacturer aiming to streamline production, investing in an SLA 3D printer can revolutionize your workflow.

Understanding SLA 3D Printing Technology

SLA 3D printing is a form of additive manufacturing that uses a liquid resin as the base material. The process begins by creating a 3D model using specialized software. This model is then sliced into thin layers, and the SLA printer uses a laser or projector to selectively cure the liquid resin layer by layer, solidifying it into a three-dimensional object. The cured resin forms the desired shape, and any excess resin is drained away.

Benefits of SLA 3D Printers for Jewelry

SLA 3D printers offer several advantages that make them ideal for jewelry applications:

a. Exceptional Detail and Accuracy: SLA printers can achieve incredibly high levels of detail, allowing for the production of intricate jewelry designs with fine features and delicate textures. The layer resolution of SLA printers is typically in the range of 25-100 microns, ensuring precise replication of even the most intricate designs.

b. Smooth Surface Finish: SLA prints have a smooth surface finish straight out of the printer, reducing the need for post-processing and saving valuable time. This is especially important for jewelry, where a flawless finish is crucial.

c. Wide Range of Materials: SLA printers support a variety of materials specifically formulated for jewelry applications. From castable resins for investment casting to durable resins for functional prototypes, there is a material available to suit every jewelry design requirement.

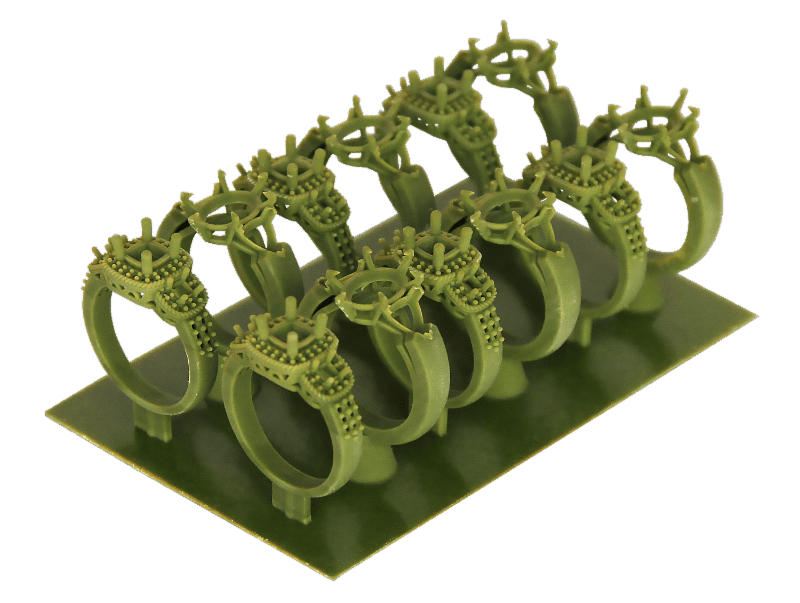

d. Time and Cost Efficiency: SLA 3D printers enable faster production cycles compared to traditional jewelry manufacturing methods. Design iterations can be quickly executed, reducing time to market. Additionally, the ability to print multiple designs simultaneously maximizes productivity.

e. Design Freedom: With SLA 3D printers, designers are not limited by the constraints of traditional manufacturing techniques. Complex geometries, intricate lattice structures, and customized designs can be easily realized, pushing the boundaries of creativity in jewelry design.

Factors to Consider When Choosing an SLA 3D Printer

a. Build Volume: The size of the build platform determines the maximum dimensions of the jewelry pieces that can be printed. Consider the size of the jewelry designs you typically work with and choose a printer with a suitable build volume.

b. Resolution: The layer resolution determines the level of detail that can be achieved. For intricate jewelry designs, a printer with a high-resolution capability is essential.

c. Material Compatibility: Ensure that the printer supports the specific materials required for jewelry applications, such as castable resins or durable resins.

d. Ease of Use: Look for user-friendly features such as intuitive software interfaces, automatic calibration, and easy material handling. This will streamline your workflow and reduce the learning curve.

e. Support and Service: Consider the availability of technical support and the reputation of the manufacturer for providing timely assistance and reliable service.

Top SLA 3D Printers for Jewelry

Let’s explore some of the top SLA 3D printers that are highly regarded in the jewelry industry:

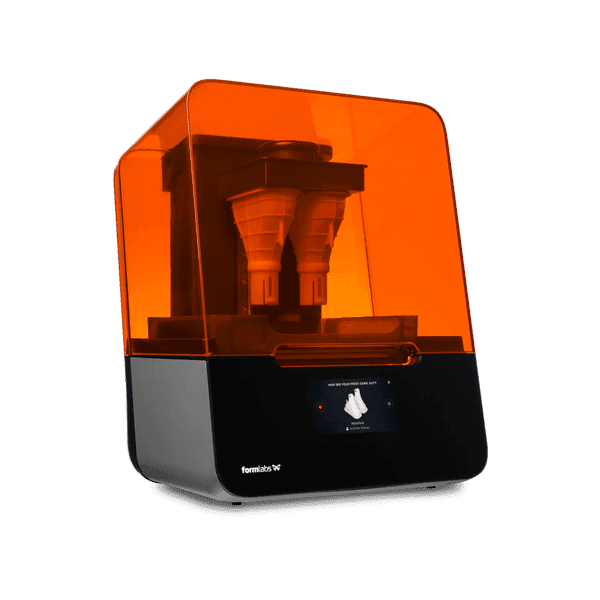

Formlabs Form 3

The Formlabs Form 3 is a professional-grade SLA 3D printer known for its exceptional print quality and ease of use. It offers a large build volume of 145 x 145 x 185 mm and a layer resolution as low as 25 microns. With its advanced Low Force Stereolithography (LFS) technology, the Form 3 delivers accurate and detailed prints consistently.

Peopoly Phenom L

The Peopoly Phenom L is a large-format SLA 3D printer that caters to the needs of jewelry designers and manufacturers. It boasts a massive build volume of 345 x 194 x 400 mm, allowing for the production of larger jewelry pieces or multiple designs in a single print. The Phenom L offers a layer resolution ranging from 10 to 100 microns, offering versatility in print quality.

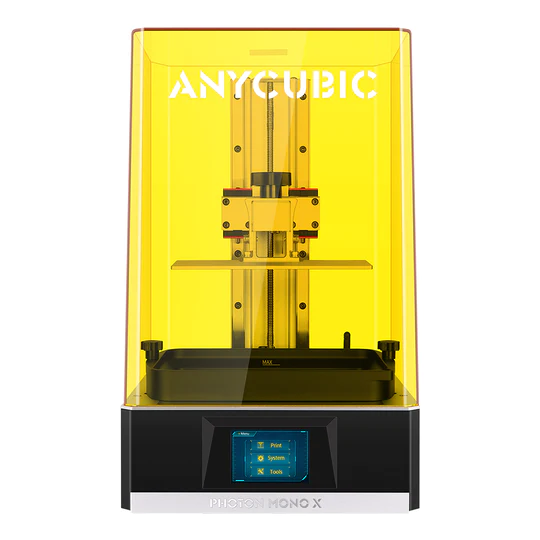

Anycubic Photon Mono- X

The Anycubic Photon Mono X is a budget-friendly SLA 3D printer that doesn’t compromise on performance. It features a large build volume of 192 x 120 x 250 mm and a layer resolution as low as 10 microns, ensuring highly detailed prints. The Mono X also offers fast printing speeds, making it an excellent choice for time-sensitive projects.

Comparison of Features and Specifications

Here is a comparison of the key features and specifications of the Formlabs Form 3, Peopoly Phenom L, and Anycubic Photon Mono X:

| Features | Formlabs Form 3 | Peopoly Phenom L | Anycubic Photon Mono X |

|---|---|---|---|

| Build Volume | 145 x 145 x 185 mm | 345 x 194 x 400 mm | 192 x 120 x 250 mm |

| Layer Resolution | 25-300 microns | 10-100 microns | 10-150 microns |

| Material Compatibility | Various resins | Various resins | Various resins |

| Connectivity | Wi-Fi, Ethernet | USB, Ethernet | USB, Ethernet |

Best Practices for Using an SLA 3D Printer for Jewelry

To achieve the best results when using an SLA 3D printer for jewelry, consider the following best practices:

1.Use support structures strategically to ensure the stability of delicate designs.

2.Optimize orientation and positioning to minimize the need for support structures and reduce post-processing efforts.

3.Follow manufacturer guidelines for resin handling, storage, and post-curing processes to ensure optimal print quality and material properties.

4.Regularly calibrate and maintain your printer to ensure consistent performance.

5.Experiment with different materials and settings to find the optimal combination for your specific jewelry designs.

Maintenance and Care Tips

To prolong the lifespan of your SLA 3D printer and ensure its optimal performance, follow these maintenance and care tips:

1.Clean the printer regularly, removing any resin residue or debris that may affect print quality.

2.Keep the build platform clean and level to ensure accurate prints.

3.Replace consumables such as resin tanks and build platforms as recommended by the manufacturer.

4.Store resin bottles in a cool, dark place to prevent degradation.

5.Follow the manufacturer’s guidelines for proper storage and disposal of resin and cleaning solutions.

Future Trends in SLA 3D Printing for Jewelry

The field of SLA 3D printing for jewelry is continuously evolving. Some future trends to watch out for include:

-

01

Advancements in material options, including new formulations with improved properties and aesthetics.

-

02

Integration of artificial intelligence and machine learning algorithms to optimize print settings and improve efficiency.

-

03

Smaller and more affordable SLA printers for individual jewelers and small businesses. Enhanced post-processing techniques to further streamline the finishing process.

SLA 3D printers have revolutionized the jewelry industry, allowing designers and manufacturers to create intricate and personalized pieces with ease. The exceptional detail, smooth surface finish, and design freedom offered by SLA printers make them an invaluable tool for jewelry professionals. By considering the factors mentioned and exploring the top SLA 3D printers available, you can choose the perfect printer to bring your jewelry designs to life.

FAQs

Q1: Can SLA 3D printers produce functional jewelry pieces?

A:Yes, SLA 3D printers can produce functional jewelry pieces using durable resins specifically formulated for jewelry applications.

Q2: How long does it take to print a jewelry piece using an SLA 3D printer?

A:The printing time depends on factors such as the size, complexity, and layer resolution of the jewelry piece. Smaller and less complex designs typically take a few hours, while larger and more intricate pieces may take several hours or even days.

Q3: Can SLA 3D printers print multiple jewelry designs simultaneously?

A:Yes, many SLA 3D printers offer the option to print multiple designs simultaneously, maximizing productivity and efficiency.

Q4: Are SLA 3D printers suitable for mass production of jewelry?

A:SLA 3D printers are well-suited for small to medium-scale production of jewelry. For large-scale production, alternative manufacturing methods may be more cost-effective.

Q5: Can SLA 3D printers produce molds for investment casting?

A:Yes, SLA 3D printers can produce highly detailed molds for investment casting using castable resins specifically formulated for this purpose.

Q6: How do SLA 3D printers compare to other types of 3D printers for jewelry applications?

A:While SLA 3D printers excel in producing highly detailed and accurate prints, other types of 3D printers such as DLP (Digital Light Processing) and SLS (Selective Laser Sintering) also have their own advantages and may be more suitable for specific jewelry applications. It is essential to consider the specific requirements of your designs before choosing a 3D printer.

Q7: Can SLA 3D printers print with different colors?

A:SLA 3D printers typically print in a single color at a time. However, post-processing techniques such as painting or dyeing can be used to add color to the printed jewelry pieces.

Q8: Is it necessary to post-cure SLA 3D printed jewelry pieces?

A:Post-curing is an essential step for SLA 3D printed jewelry pieces as it ensures the full curing of the resin, resulting in optimal material properties and stability.

Q9: Can SLA 3D printers print with precious metals?

A:SLA 3D printers cannot directly print with precious metals such as gold or silver. However, they can be used to create detailed prototypes or molds for investment casting in precious metals.

Q10: What software is required to prepare models for printing on an SLA 3D printer?

A:Various software options are available for preparing models for SLA 3D printing, including Formlabs PreForm, Peopoly Moai, and Anycubic Photon Workshop. These software packages allow for model slicing, support generation, and customization of print settings.