In a world where individuality and personalization reign supreme, the ability to customize products to meet specific needs and preferences has become a driving force in both design and manufacturing. Among the various additive manufacturing technologies, Stereolithography (SLA) 3D printing stands out as a game-changer, empowering designers and manufacturers with unparalleled customization capabilities.

SLA 3D printing, with its high precision and ability to produce complex geometries, has revolutionized the way products are conceived, designed, and manufactured. This technology has opened up a new realm of possibilities for customization, enabling the creation of products that are tailored to individual tastes, requirements, and applications.

In this comprehensive blog post, we will delve into the world of SLA 3D printing and explore how it enables customization in product design and manufacturing. We will uncover the advantages of customized products, delve into the process of SLA 3D printing, and showcase real-world examples of how this technology is transforming industries.

From personalized consumer goods to intricate medical devices, SLA 3D printing is pushing the boundaries of customization and unlocking a new era of innovation. Join us as we embark on a journey to discover the transformative power of SLA 3D printing in the realm of customized product design and manufacturing.

Customization in Product Design: Unleashing Individuality and Innovation

In the realm of product design, customization has emerged as a powerful tool to cater to the unique needs, preferences, and aspirations of consumers. SLA 3D printing has become a game-changer in this regard, empowering designers to create products that are truly personalized and tailored to individual tastes.

Benefits of Customized Products:

- Enhanced User Experience: Customized products provide a superior user experience by perfectly aligning with the user’s specific requirements and preferences.

- Increased Customer Satisfaction: When customers can actively participate in the design process and have a say in the final product, they are more likely to be satisfied with the outcome.

- Differentiation from Competitors: Customization allows businesses to differentiate their products from those of their competitors, creating a unique selling proposition.

- Increased Sales and Revenue: By offering customized products that cater to specific market niches, businesses can tap into new customer segments and increase sales and revenue.

How SLA 3D Printing Enables Customization:

SLA 3D printing offers several key advantages that make it ideal for customization in product design:

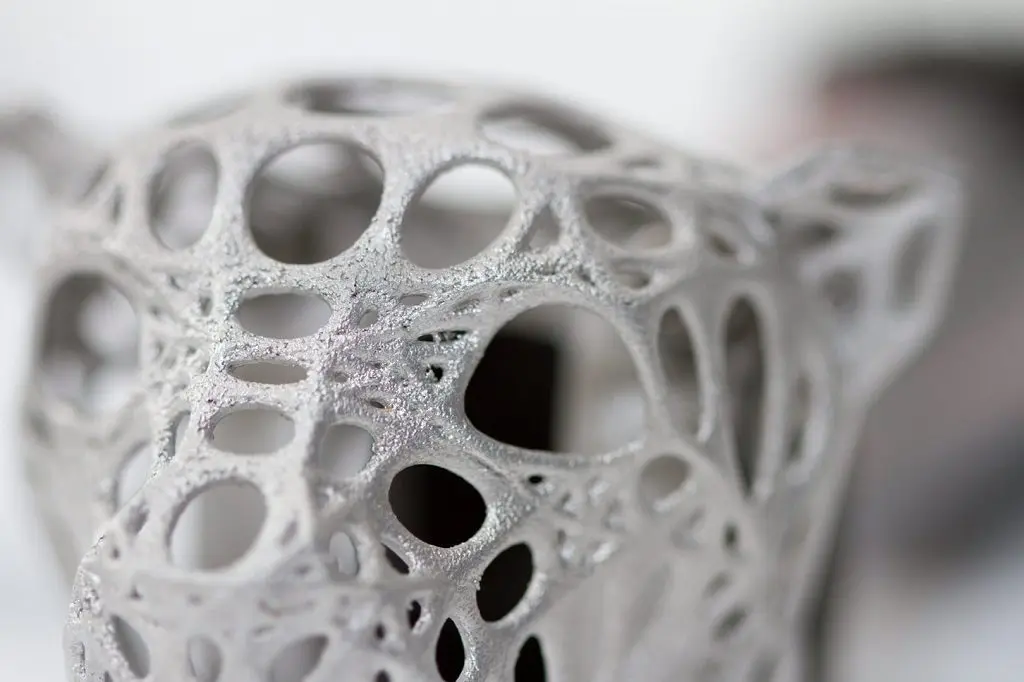

- Design Freedom: SLA 3D printing allows designers to create complex geometries and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods.

- Rapid Prototyping: SLA 3D printing enables rapid prototyping, allowing designers to quickly iterate on their designs and test different concepts before committing to mass production.

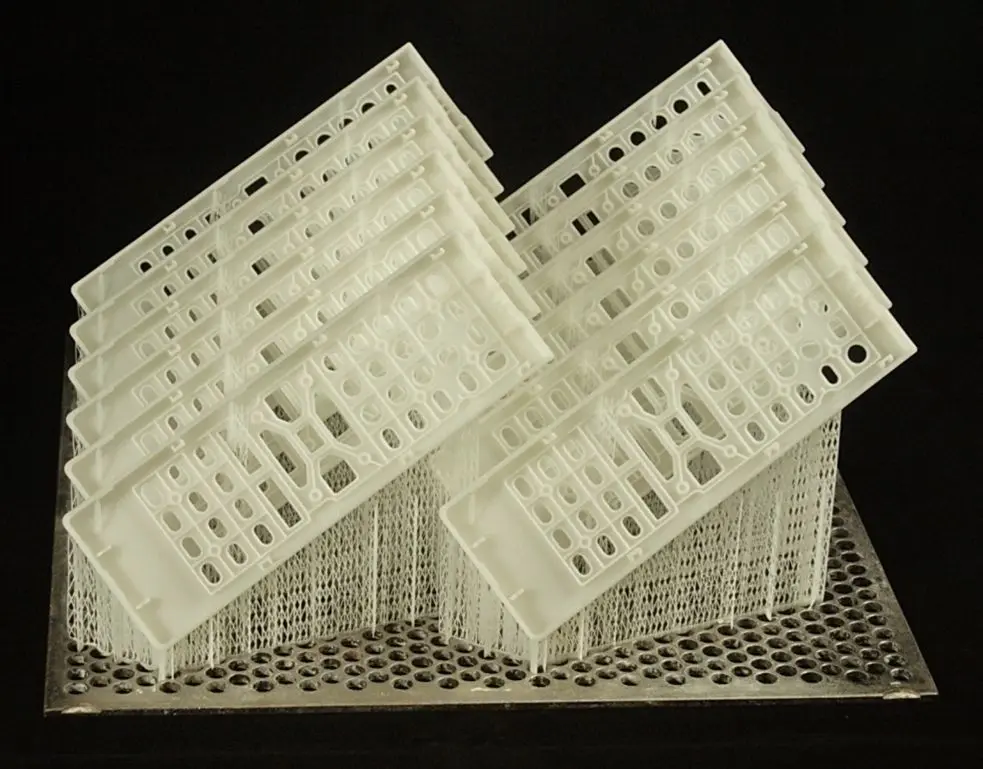

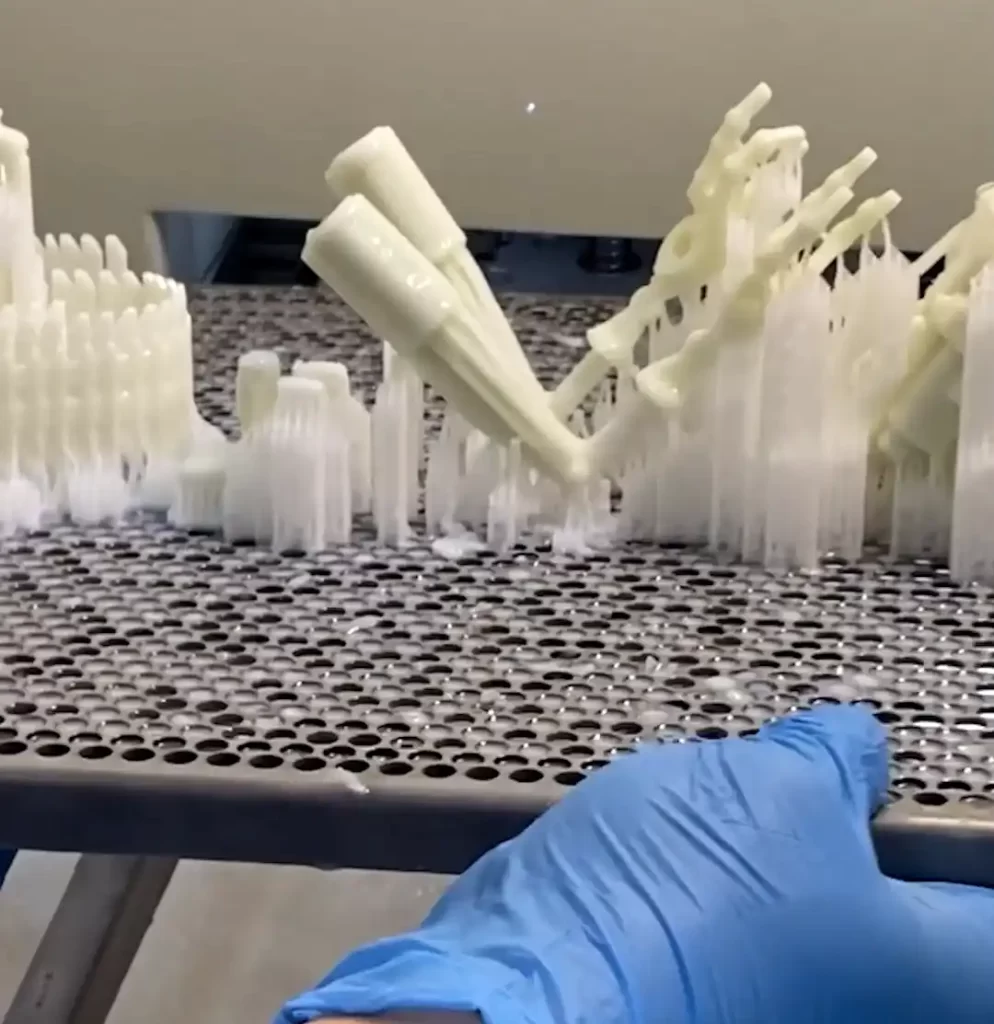

- Mass Customization: SLA 3D printing facilitates mass customization, where each product can be tailored to individual specifications without incurring significant additional costs.

Examples of Customized Products Made Using SLA 3D Printing:

- Personalized Footwear: SLA 3D printing is used to create custom-fit shoes that perfectly match the wearer’s foot shape and provide optimal comfort and performance.

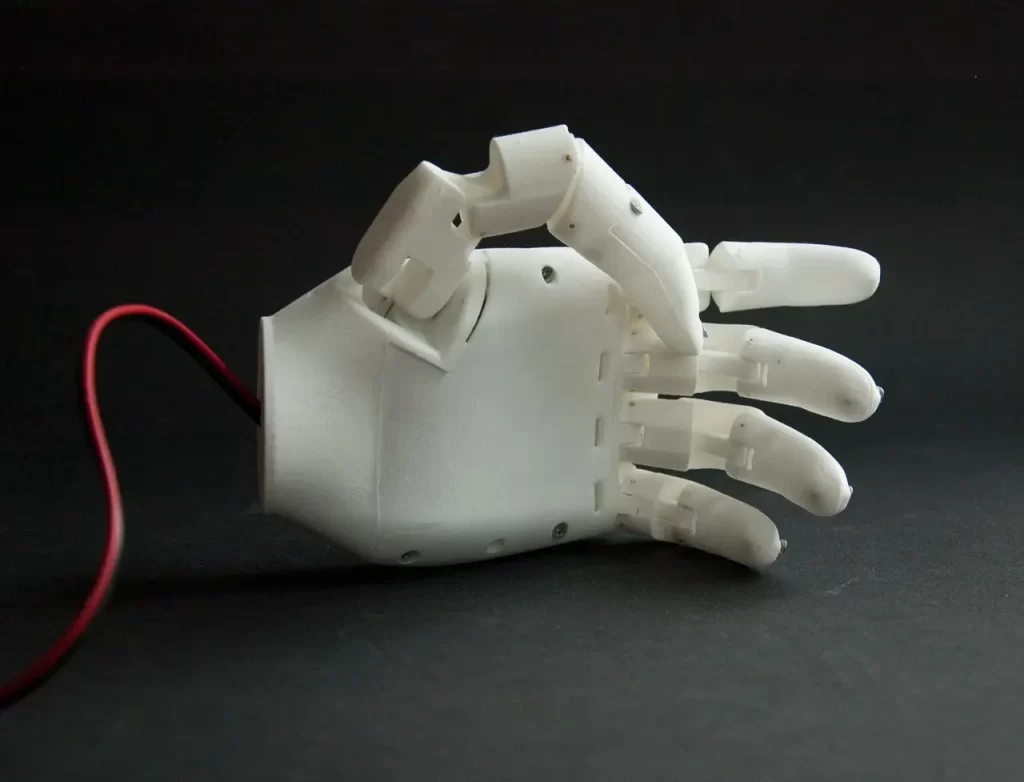

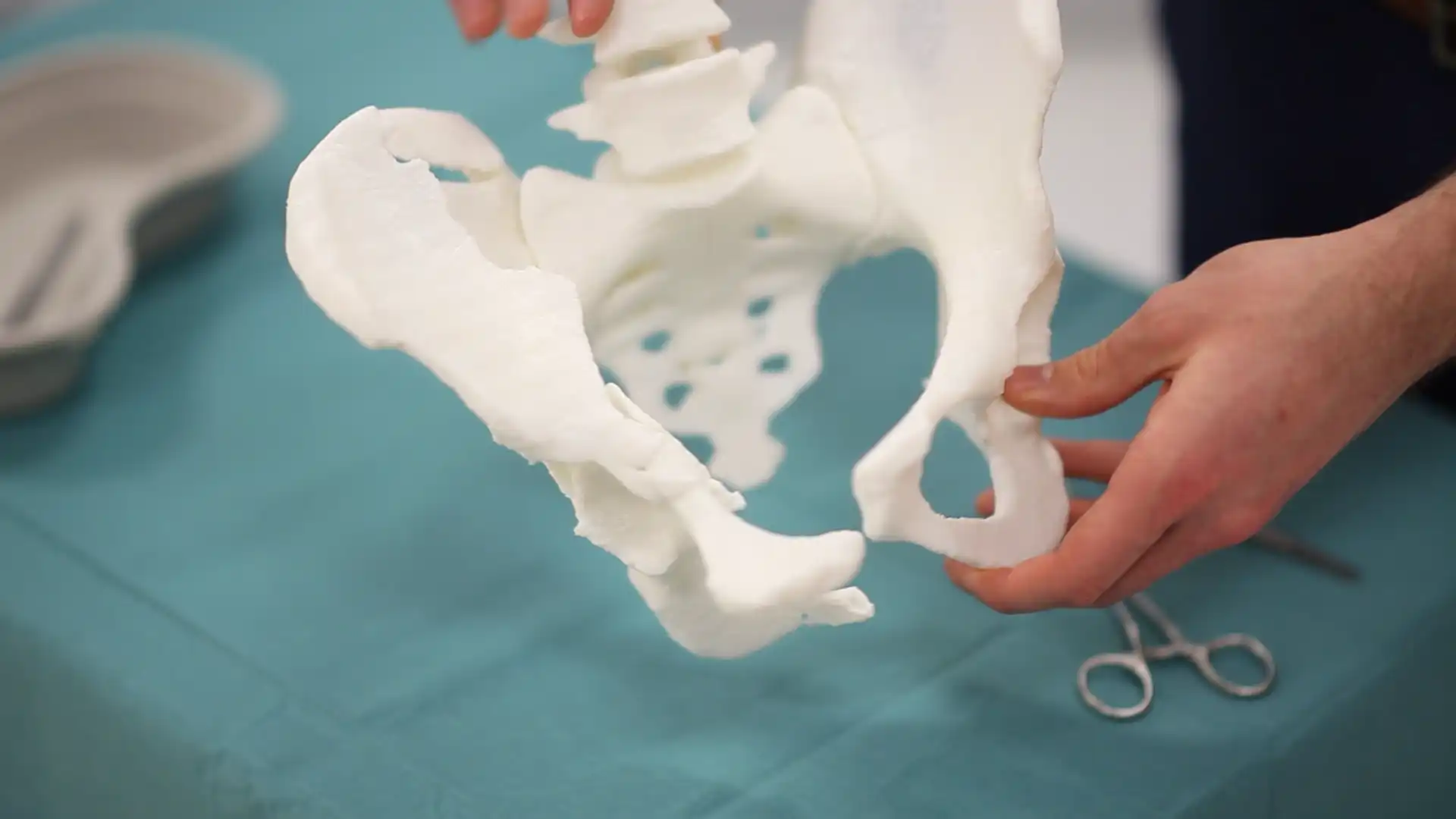

- Medical Devices: SLA 3D printing is employed to produce customized medical devices, such as dental implants, hearing aids, and prosthetics, that are tailored to the patient’s unique anatomy.

- Consumer Electronics: SLA 3D printing is utilized to create customized consumer electronics, such as phone cases, earbuds, and gaming controllers, that reflect the user’s personal style and preferences.

SLA 3D printing is revolutionizing product design by enabling the creation of customized products that meet the evolving needs and desires of consumers. As this technology continues to advance, we can expect to see even more innovative and personalized products emerge in the future.

Customization in Manufacturing: Transforming Efficiency and Quality

SLA 3D printing is not only revolutionizing product design but also transforming manufacturing processes, enabling customization on a scale never seen before. This technology offers several advantages that make it ideal for customized manufacturing:

- Reduced Production Costs: SLA 3D printing eliminates the need for expensive tooling and molds, reducing production costs, especially for small batch production and customized products.

- Shorter Lead Times: SLA 3D printing significantly reduces lead times compared to traditional manufacturing methods, allowing businesses to respond quickly to changing market demands and deliver products to customers faster.

- Improved Product Quality and Consistency: SLA 3D printing produces parts with high precision and accuracy, ensuring consistent quality and reducing the risk of defects.

How SLA 3D Printing Enables Customization in Manufacturing:

SLA 3D printing enables customization in manufacturing through several key factors:

- Design Flexibility: SLA 3D printing allows manufacturers to easily modify designs and produce customized products without disrupting the production process.

- Mass Customization: SLA 3D printing facilitates mass customization, where each product can be tailored to individual specifications without incurring significant additional costs.

- Digital Inventory: SLA 3D printing enables the creation of a digital inventory of products, allowing manufacturers to produce customized products on demand, reducing warehousing costs and lead times.

Examples of Customized Manufacturing Applications Using SLA 3D Printing:

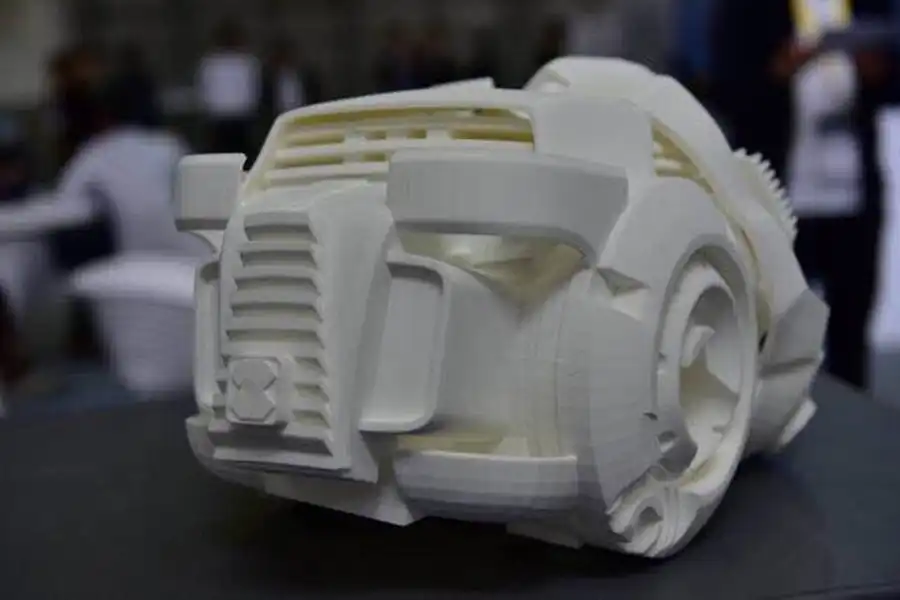

- Automotive: SLA 3D printing is used to create customized automotive parts, such as interior trim, dashboards, and even entire car bodies, tailored to specific customer preferences.

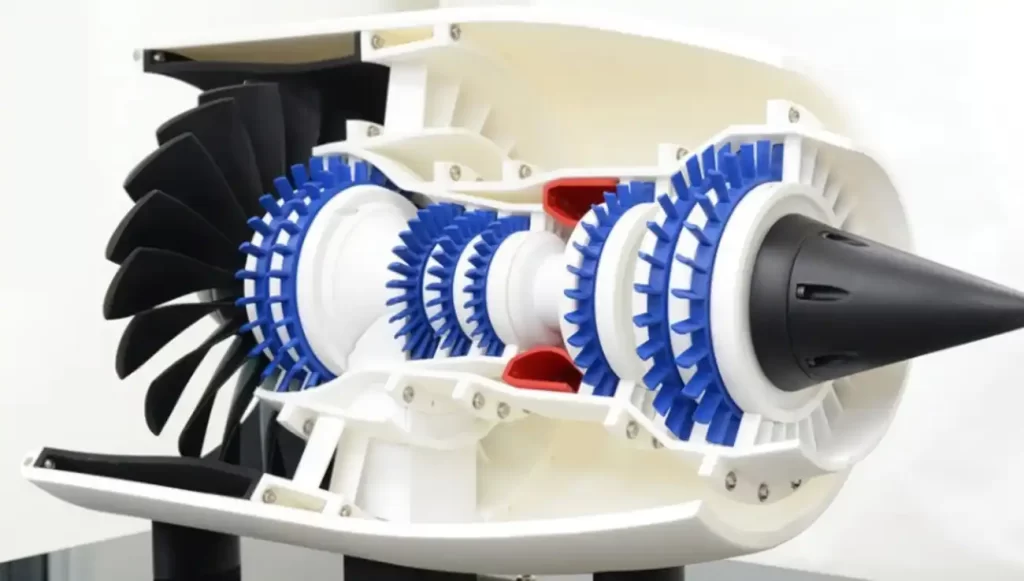

- Aerospace: SLA 3D printing is employed to produce customized aerospace components, such as lightweight brackets, housings, and even aircraft parts, meeting stringent quality and performance requirements.

- Medical: SLA 3D printing is utilized to create customized medical devices and implants, such as dental crowns, surgical guides, and prosthetics, tailored to the patient’s unique anatomy.

SLA 3D printing is transforming manufacturing by enabling customization on a scale never seen before. As this technology continues to advance, we can expect to see even more innovative and efficient customized manufacturing applications emerge in the future.

Materials and Design Considerations for SLA 3D Printing Customization:

The choice of materials and careful consideration of design guidelines are crucial for successful SLA 3D printing customization.

Materials for SLA 3D Printing:

SLA 3D printing offers a wide range of materials with varying properties to suit different applications and customization needs:

- Resins: SLA resins come in a variety of formulations, including standard, tough, flexible, and biocompatible resins, allowing for customization of mechanical properties and functionality.

- Additives: Additives can be mixed with resins to enhance specific properties, such as strength, flexibility, or color.

- Fillers: Fillers, such as metal powders or ceramic particles, can be added to resins to create composite materials with unique properties.

Design Guidelines for SLA 3D Printing Customization:

To ensure successful SLA 3D printing customization, it is important to follow certain design guidelines:

- Wall Thickness: Wall thickness should be sufficient to provide adequate strength and avoid warping or deformation during printing.

- Support Structures: Complex geometries may require support structures to prevent sagging or collapse during printing.

- Orientation: The orientation of the part on the build platform can affect the surface finish and mechanical properties of the final product.

- Post-Processing: SLA 3D printed parts may require post-processing steps, such as curing, sanding, or painting, to achieve the desired surface finish and properties.

Optimizing SLA 3D Printed Parts for Specific Applications:

To optimize SLA 3D printed parts for specific applications, consider the following factors:

- Mechanical Properties: Choose the appropriate resin and design parameters to achieve the desired mechanical properties, such as strength, stiffness, and toughness.

- Environmental Factors: Consider the environmental conditions in which the part will be used, such as temperature, humidity, and exposure to chemicals.

- Functional Requirements: Take into account the specific functional requirements of the part, such as electrical conductivity, biocompatibility, or optical properties.

By carefully selecting materials and following design guidelines, manufacturers can optimize SLA 3D printed parts for a wide range of customized applications.

Challenges and Limitations of SLA 3D Printing for Customization:

While SLA 3D printing offers immense potential for customization, it also comes with certain challenges and limitations:

Challenges:

- Material Properties: The properties of SLA resins may not be suitable for all applications, especially those requiring high strength, flexibility, or temperature resistance.

- Support Structures: Complex geometries may require intricate support structures, which can be difficult to remove and may leave marks on the final product.

- Post-Processing: SLA 3D printed parts may require extensive post-processing, such as curing, sanding, and painting, which can add to the production time and cost.

Limitations:

- Size and Complexity: SLA 3D printers have a limited build volume, which restricts the size of the parts that can be produced. Additionally, complex geometries with overhangs or intricate details may be difficult to print successfully.

- Speed and Throughput: SLA 3D printing is relatively slow compared to other additive manufacturing technologies, which can limit its suitability for mass production.

- Cost: SLA 3D printers and materials can be expensive, especially for large-scale customization.

Overcoming Challenges and Limitations:

Despite these challenges and limitations, there are ways to overcome them and leverage SLA 3D printing for successful customization:

- Material Development: Ongoing research and development efforts are leading to the development of new SLA resins with improved properties and performance.

- Design Optimization: Careful design and optimization can minimize the need for support structures and reduce post-processing requirements.

- Hybrid Manufacturing: SLA 3D printing can be combined with other manufacturing technologies, such as CNC machining or injection molding, to produce parts with complex geometries and enhanced properties.

By addressing these challenges and limitations, manufacturers can harness the full potential of SLA 3D printing for customized product design and manufacturing.

Case Studies and Applications of SLA 3D Printing for Customization:

SLA 3D printing is being used in a wide range of industries to enable customization in product design and manufacturing. Here are a few notable case studies and applications:

Automotive:

- Customized Car Parts: SLA 3D printing is used to create customized car parts, such as interior trim, dashboards, and even entire car bodies, tailored to specific customer preferences. For example, the German automotive manufacturer BMW uses SLA 3D printing to produce customized interior parts for its high-end vehicles.

Medical:

- Patient-Specific Medical Devices: SLA 3D printing is employed to produce customized medical devices and implants, such as dental crowns, surgical guides, and prosthetics, tailored to the patient’s unique anatomy. This enables better fit, improved functionality, and reduced recovery time. For instance, the medical device company Stryker uses SLA 3D printing to create customized joint implants that perfectly match the patient’s bone structure.

Consumer Goods:

- Personalized Footwear: SLA 3D printing is used to create custom-fit shoes that perfectly match the wearer’s foot shape and provide optimal comfort and performance. Companies like Feetz and Wiivv offer personalized 3D printed shoes based on individual foot scans.

Aerospace:

- Customized Aircraft Parts: SLA 3D printing is utilized to produce customized aircraft parts, such as lightweight brackets, housings, and even entire aircraft components. This enables rapid prototyping, reduced lead times, and improved performance. For example, the aerospace company Airbus uses SLA 3D printing to create customized parts for its aircraft, reducing production time and costs.

These case studies showcase the diverse applications of SLA 3D printing for customization across various industries. As the technology continues to advance, we can expect to see even more innovative and groundbreaking applications emerge in the future.

Future of SLA 3D Printing in Customization:

The future of SLA 3D printing in customization is incredibly promising, with ongoing advancements and emerging trends shaping the landscape of this technology:

- Material Innovations: Research and development efforts are focused on developing new SLA resins with enhanced properties, such as improved strength, flexibility, and biocompatibility, expanding the range of applications for customized products.

- Multi-Material Printing: SLA 3D printers with multi-material capabilities are becoming more accessible, enabling the creation of customized products with different materials and properties in a single print job.

- Design Software Advancements: Design software specifically tailored for SLA 3D printing is evolving, making it easier for designers to create complex and intricate geometries for customized products.

- Integration with Other Technologies: SLA 3D printing is increasingly being integrated with other technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), streamlining the customization process and improving efficiency.

- Mass Customization: SLA 3D printing is poised to revolutionize mass customization, enabling the production of customized products at scale, meeting the growing demand for personalized goods.

- Sustainability: SLA 3D printing offers opportunities for sustainable customization, as it reduces material waste and enables the use of eco-friendly materials, contributing to a more circular economy.

These advancements and trends indicate that SLA 3D printing will continue to play a pivotal role in customization, empowering designers and manufacturers to create innovative and personalized products that cater to the unique needs and preferences of consumers.

Conclusion:

SLA 3D printing has emerged as a transformative technology that is revolutionizing customization in product design and manufacturing. Its ability to produce complex geometries, enable rapid prototyping, and facilitate mass customization has opened up a world of possibilities for businesses and consumers alike.

Customized products offer numerous benefits, including enhanced user experience, increased customer satisfaction, differentiation from competitors, and increased sales and revenue. SLA 3D printing enables customization in both product design and manufacturing, reducing production costs, shortening lead times, and improving product quality and consistency.

While there are challenges and limitations associated with SLA 3D printing, such as material properties, support structures, and post-processing requirements, ongoing advancements in materials, design software, and integration with other technologies are addressing these issues.

Case studies and applications across various industries, from automotive and medical to consumer goods and aerospace, demonstrate the diverse potential of SLA 3D printing for customization. The future of SLA 3D printing in customization is incredibly promising, with material innovations, multi-material printing, design software advancements, and integration with other technologies driving the technology forward.

SLA 3D printing is empowering designers and manufacturers to create innovative and personalized products that cater to the unique needs and preferences of consumers. As the technology continues to evolve, we can expect to see even more groundbreaking applications and transformative products emerge in the years to come.