Introduction: Why SLA 3D Printing Market Growth Is on Overdrive

Not for very long has any technology or manufacturing process caused so much uproar other than 3D printing. Out of these many techniques, stereolithography has carved a niche due to the precision and versatility it has to offer, making changes in healthcare, automotive, and many other industries. But what is driving this surge in SLA 3D printing market growth, and why should you care? Just consider the case in which you can build complex prototypes overnight or let intricate designs spark to life with an accuracy that cannot be rivaled. This is done by SLA 3D printing: revolutionizing ways of creating things and changing markets. The critical factors that make SLA 3D printing up, though, are basic ideas, leading up to the elements forcing this change indicated in this article

Whether you are an industry professional or an inquisitive learner, this all-encompassing guide aims to usher you into the future of SLA 3D printing.

What is SLA 3D Printing? A Quick Overview

Stereolithography is such an interesting 3D printing additive technology that functions by using a laser to solidify liquid resin into solid parts. Here is a simplified breakdown of how it works:

- Design Development: It all begins with a 3D computer model, usually designed using CAD software.

- Additive Fabrication: Model slicing involves very thin layers, and a UV laser duplicates each and every one on a vat of photopolymer resin.

- The Curing Process: The laser cures the resin, solidifying it into the shape of the object. It is done on a layer-by-layer basis until the entire object is complete. 4. Post-processing: This is the process of cleaning the object—depending on the material used—then further curing for more strength and stability after.

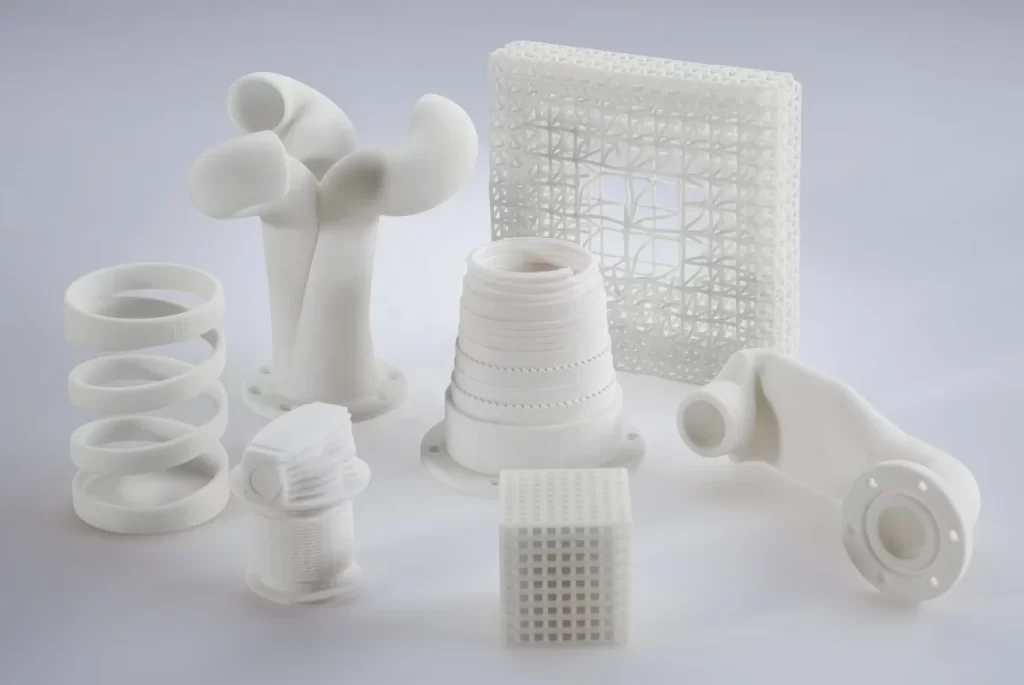

Some of the main features of SLA 3D printing are as follows:

- High Precision: The ability of SLA to fabricate detailed, accurate parts is very high; it thus finds use in applications that require fine details in the parts.

- Smooth Surface Finish: This technology offers a smooth surface finish, hence reducing the extent of post-processing required on the parts.

- Material Flexibility: It enables a great variety of resins with special properties such as flexibility, transparency, or biocompatibility.

Present Market Scenario for SLA 3D Printing

At present, SLA 3D is in the dynamic stage of printing market growth, with technology paired with rising demand across industries.

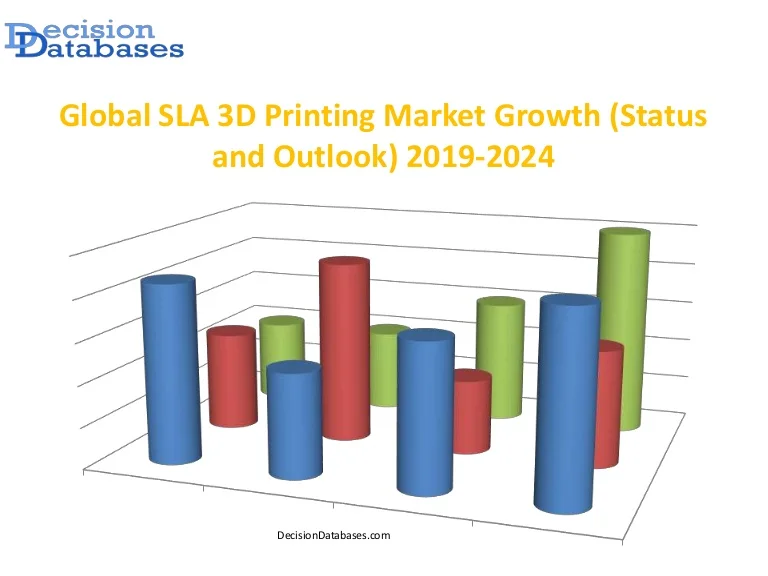

Global Market Size and Growth Rate

SLA 3D printing market size in terms of value can be estimated to be around $1.5 billion by 2024 and is expected to grow at a 20% CAGR in the next five years. Growth will be driven by

- Technological Innovations: Constant enhancements in printer capabilities and materials available expand applications for the technology further.

- Adoption in Industries: Increasing adoption of SLA 3D printing for prototyping and production by industries such as healthcare, automotive, and consumer goods.

- Cost-Effective: Price reduction in SLA printers and materials make this technology more affordable and accessible for small- and medium-sized businesses.

Overview of Key Players

The SLA 3D printing market is populated by a mix of established companies and emerging startups. Some of the key players include:

- 3D Systems: One of the pioneers in 3D printing technology, 3D Systems offers a range of SLA printers and materials, catering to various industries, including healthcare and aerospace.

- Formlabs: Known for its user-friendly desktop SLA printers, Formlabs has gained significant traction among small businesses and educational institutions. The company focuses on providing high-quality resins and a robust ecosystem of software and support.

- XYZprinting: A prominent player in the consumer 3D printing market, XYZprinting offers affordable SLA printers aimed at hobbyists and educational users, making 3D printing accessible to a broader audience.

- EnvisionTEC: Specializing in high-precision SLA printing, EnvisionTEC focuses on applications in dental, jewelry, and industrial sectors. The company is known for its innovative materials and advanced printing technologies.

- Carbon: Carbon has disrupted the SLA market with its Digital Light Synthesis (DLS) technology, which offers faster print speeds and superior material properties. The company targets industries such as automotive, healthcare, and consumer goods.

Market Share Analysis

The SLA 3D printing market is competitive, with various players holding different market shares based on their product offerings, technological advancements, and customer base. According to recent market analysis, the following companies hold significant shares in the SLA market:

| Company | Market Share (%) | Key Strengths |

| 3D Systems | 25% | Established brand, diverse applications |

| Formlabs | 20% | User-friendly products, strong community |

| Carbon | 15% | Innovative technology, rapid production |

| EnvisionTEC | 10% | High precision, specialized applications |

| XYZprinting | 8% | Affordable solutions, broad accessibility |

| Others | 22% | Various emerging players and niche markets |

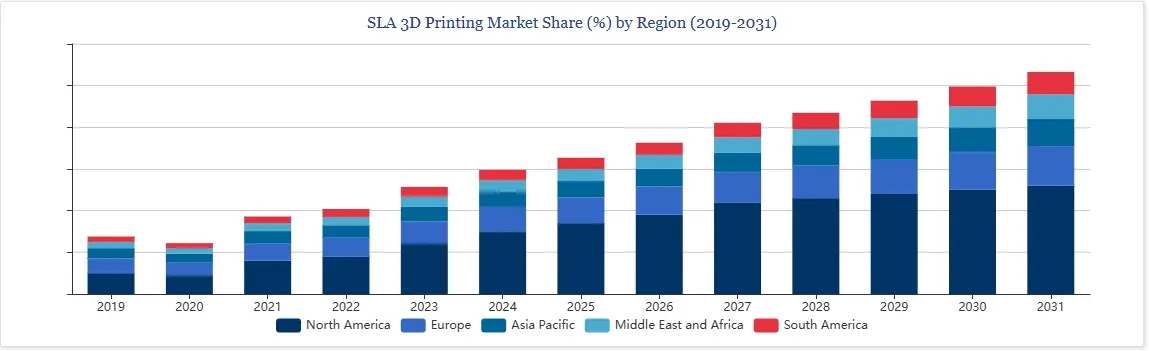

The SLA 3D printing market is witnessing diverging growth trajectories across territories:

| Region | Market Share | Key Drivers |

| North America | 35% | Strong presence of key players, technological advancements |

| Europe | 30% | Growing adoption in automotive and healthcare sectors |

| Asia-Pacific | 25% | Increasing investments in manufacturing and R&D |

| Rest of the World | 10% | Emerging markets with potential for growth |

Driving Forces Behind the Growth of the SLA 3D Printing Market

One needs to look at the major influencing factors that act as driving forces for this growth in the SLA 3D printing market. These include:

Technological Innovations

Due to continuous technological innovation that improves SLA technology’s capacities and applications, it has been one of the principal drivers behind the growth of the SLA 3D printing market. Some key innovations include:

• High resolution of the printer .

• Faster printing speeds: A new development in hardware and software has drastically reduced the time taken for printing via SLA, hence increasing its efficiency for production.

• More material options: The continuous development of new resins with a variety of different properties from flexible to heat-resistant to biocompatible materials further expands the area of application for SLA. More rapid adoption within industries.

Increasing Industry Adoption

SLA 3D printing is quickly being adopted by a variety of industries that feel it has the potential to really revolutionize manufacturing processes. Notable sectors include:

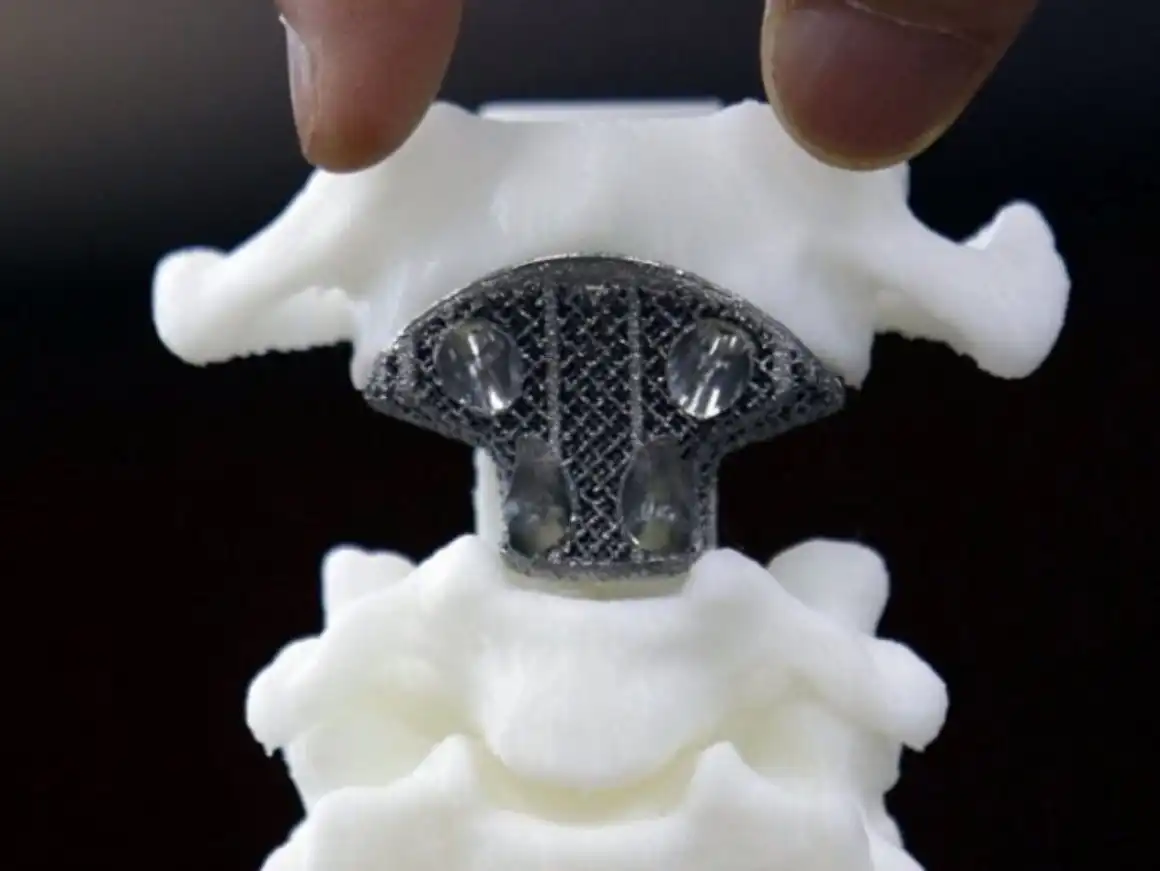

Healthcare: from custom prosthetics and dental moulds to surgical guides, SLA technology is able to offer customized solutions with a shorter lead time.

Automotive: used for prototyping complex parts that let a design team work through several design iterations much faster, shortening the time to market.

Consumer Goods: The ability to create detailed designs with a smooth finish makes SLA very suitable for jewelry, eyewear, and other consumer goods production.

Cost Efficiency and Accessibility

The cost of SLA 3D printers and associated materials is continually going down. This increase in affordability makes the technology more accessible to SMEs and individual makers. Some key drivers of cost efficiency include:

• Pocket-Friendly Desktop SLA Printers: Companies like Formlabs and XYZprinting, offer economical desktop printers that can make quality 3D printing quite accessible.

• Lower Material Costs: With improved formulations of resin and mass production of the same, material costs have come down, hence slashing the overall cost of production.

Supportive ecosystem and community.

This is served by a rich and packed ecosystem of software, services, and community engagement around SLA 3D printing:

- Better Software: The design software and software for slicing are becoming more user-friendly, which makes 3D printing more and more accessible for non-experts.

- Online Communities and Resources: forums, social media groups, online courses—so much exists for the beginner and expert user.

Challenges Confronting the SLA 3D Printing Market

While the SLA 3D printing market is growing at a rapid pace, it is not completely immune to challenges. Being aware of these challenges will, therefore, be important to businesses, investors, and enthusiasts who want to see their way through the intricacies of this fast-moving industry.

Material Limitations

One of the major problems in the SLA 3D printing market pertains to limitations associated with the number of available materials. SLA technology is almost completely dependent on photopolymer resins, and this may further limit its applications to some extent in certain industries. The main concerns are the limited material properties since, although many resins are available on the market, they may not introduce mechanical properties for some applications, such as high-impact resistance or thermal stability.

High cost of specialized resins: High-performance resins are extremely expensive, making it difficult to use them in a few of the cost-sensitive applications.

Environmental Issues

One of the growing concerns of environmental issues of SLA 3D printing is associated with disposal and recycling of photopolymer resins. The primary environmental issues are:

Waste management: Uncured resin and the support structure disposal can contribute to environmental pollution.

Recycling Limitations: Very few current processes can recycle SLA material, resulting in generated wastes.

Skill Gap and Training

In the SLA 3D printing market, there exists a skill gap; that is, the number of trained professionals needed for operating and servicing this technology is low. Key challenges are:

Complexity of Technology: Special knowledge and skills are required to perform SLA 3D printing; this might act as a major barrier to new users.

Lack of Training Programs: More extensive training programs should be introduced to help a person develop the requisite skills.

Regulatory and Compliance Issues

One of the major challenges for the SLA 3D printing market is navigating the regulatory and compliance issues, especially in the healthcare and aerospace industries. Some of the major regulatory challenges are:

- Certification Processes: Certification of SLA-printed products is time-consuming and costly.

- Compliance with Standards: It is tricky and lengths in time when trying to ensure that SLA printed parts meet the industry standards and regulations.

Future Prospects and Opportunities in the SLA 3D Printing Market

Growth patterns of the SLA 3D printing market leverage future prospects and opportunities as the industry unfolds. Improving technology, broadening applications, and rising interest from industries point to a bright future for SLA 3D printing.

Technological Advancements

The future of SLA 3D printing is sure to be bright, with continuous technological advancement promising to bring even greater capabilities and applications into the hands of users. A few key areas include:

Smart Printing Solutions: AI and IoT integration may be applied to achieve smart printing solutions that optimize print quality, reduce wastage, and improvise in user experience.

Next-Generation Printers: The next generation of SLA printers will operate at higher resolutions and print at faster speeds, both of which will bring increased reliability and expand the range of applicability for these devices.

Growing Applications

As SLA technology matures, the growing applications across industries shall lead to an opportunity of fresh growth and innovation. The key areas of expansion are:

- Bioprinting: SLA technology is set to enter the domain of bioprinting, enabling the construction of complex tissue structures and pushing further the boundaries of regenerative medicine.

- Aerospace and Defense: With the right level of precision and reliability, SLA printing is ideal for making lightweight, high-performance components in aerospace and defense.

- Education and Research: SLA printers make their way into schools and research labs as learning tools that greatly enhance hands-on experiences among both students and researchers while supporting leading-edge research.

Market Expansion and Accessibility

The geographical outreach and accessibility of the SLA 3D printing market are on the rise in emerging markets and, hence, are expected to contribute towards the growth of the market in general. Some of the major drivers for market expansion include:

- Affordability: With the dropping prices of SLA printers and their associated materials, it can become more economical for a large number of people.

- Rising Awareness: With growing awareness about SLA technology and its associated advantages, more and more industries have come to the forefront to adopt this innovative approach.

Conclusion

The growth of the SLA 3D printing market underlines the transformative power of technology in manufacturing and design. With precision, versatility, and an ever-expanding application base, SLA 3D printing is surely going to have a very important role in shaping the future for industries. Among the drivers for this market, as we have explored above, are technological development, increasing adoption in industries, and a fit ecosystem. The problems to be faced will, therefore, pertain to material and regulatory challenges if this growth is to be maintained. To businesses, investors, and any enthusiasts seeking to capitalize on the SLA 3D printing market, the dynamics behind it may be of great importance. From innovating in your business field to fresh creative applications, the future of SLA 3D printing shines bright with so much promise.

Reference source:

1.https://www.cognitivemarketresearch.com/sla-3d-printing-market-report

2.https://www.globalinforesearch.com/reports/2034284/sla-3d-printer

3.https://www.orbisresearch.com/reports/index/global-sla-3d-printing-market-research-report-2024

4.https://www.linkedin.com/pulse/sla-3d-printing-market-size-emerging-growth-2024-2031-dixse/

5.https://www.linkedin.com/pulse/sla-3d-printing-market-size-projection-growth-insights-qwozf/