In recent years, the manufacturing landscape has witnessed a technological renaissance, one that promises to redefine how products are designed, prototyped, and produced. At the forefront of this transformation is SLA 3D printing, a technology that marries precision with innovation to create possibilities previously unimaginable. Imagine a world where the intricate components of a high-performance vehicle are crafted with the same ease as a bespoke piece of jewelry, or where life-saving medical devices can be tailored to individual patients with unparalleled accuracy. This is not a distant dream, but a burgeoning reality enabled by stereolithography, often abbreviated as SLA.

The traditional manufacturing processes that have long dominated industries are by no means obsolete, yet they are being challenged and complemented by the versatility and efficiency of 3D printing technologies. Among these, SLA stands out for its ability to produce complex geometries with exceptional surface finish and accuracy, making it a preferred choice for a variety of applications.

Understanding SLA 3D Printing

As we venture into the realm of advanced manufacturing technologies, it’s essential to understand the fundamental processes that drive these innovations. Stereolithography (SLA) 3D printing is one such technology, renowned for its precision and versatility. Whether you’re a seasoned engineer or a curious hobbyist, understanding the intricacies of SLA can offer valuable insights into its capabilities and applications.

What is SLA 3D Printing?

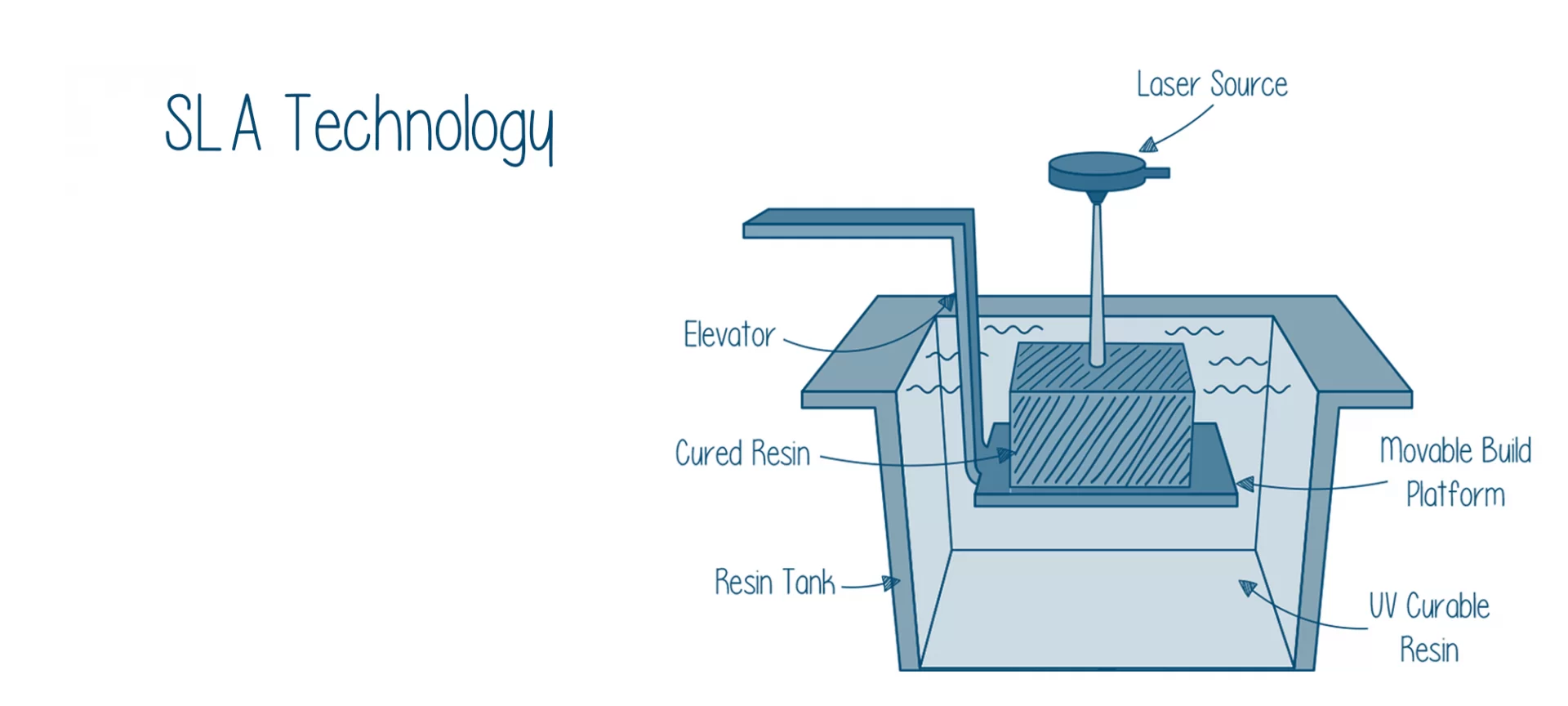

SLA, or **Stereolithography**, is a form of additive manufacturing that uses a laser to cure liquid resin into hardened plastic in a layer-by-layer process. This technology was the first of its kind, invented in the early 1980s, and remains a cornerstone of the 3D printing world due to its ability to produce highly detailed and complex parts.

The SLA Process

- Design Creation: The process begins with a digital 3D model, typically created using CAD software.

- Layer Slicing: The model is sliced into thin, horizontal layers by the printer’s software.

- Resin Curing: The SLA printer’s laser selectively cures the resin, solidifying each layer onto the previous one until the entire model is complete.

- Post-Processing: Once printing is complete, the model undergoes several post-processing steps, including cleaning, further curing, and finishing to achieve the desired properties.

Materials Used in SLA 3D Printing

The choice of materials in SLA 3D printing is vast and continually expanding. Some popular resin types include:

- Standard Resins: Ideal for general purposes, offering a balance between cost and performance.

- Tough Resins: Provide enhanced durability, suitable for functional prototypes.

- Flexible Resins: Offer elasticity, perfect for applications requiring flexibility.

- Castable Resins: Used for jewelry and dental applications, capable of being burned out cleanly for casting.

| Resin Type | Characteristics | Common Applications |

| Standard | Economical, good detail | Prototyping, concept models |

| Tough | Durable, impact-resistant | Functional parts, snap-fits |

| Flexible | Elastic, tear-resistant | Wearables, grips, handles |

| Castable | Burn-out capability, clean casting | Jewelry, dental models |

SLA vs. Other 3D Printing Technologies

SLA is not the only player in the 3D printing arena. Here’s how it compares to some of the other popular technologies:

- Fused Deposition Modeling (FDM): While FDM is more cost-effective for larger parts, SLA offers superior surface finish and detail, making it ideal for intricate designs.

- Selective Laser Sintering (SLS): SLS can produce durable parts without the need for support structures, but SLA excels in producing smooth surfaces and fine details.

- Digital Light Processing (DLP): Similar to SLA, DLP uses a light source to cure resin but typically offers faster print times at the expense of slightly lower detail resolution.

Advantages of SLA 3D Printing

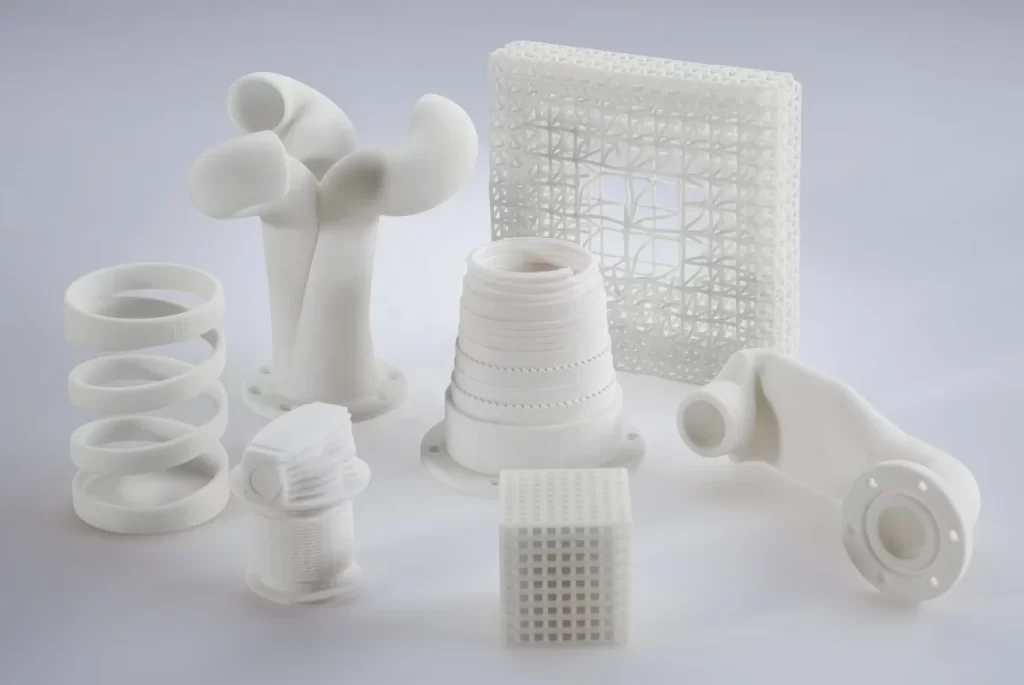

SLA 3D printing offers a host of advantages that make it a preferred choice for various applications:

- Precision and Accuracy: Capable of producing intricate details with high dimensional accuracy.

- Superior Surface Finish: Provides smooth surfaces that often require minimal post-processing.

- Material Versatility: A wide range of resins available to meet specific application needs.

SLA 3D printing represents a fusion of art and engineering, allowing creators to push the boundaries of design and functionality. As industries continue to embrace this technology, understanding its capabilities and limitations can unlock new avenues for innovation and growth. Whether producing a prototype for a groundbreaking device or crafting a unique piece of art, SLA 3D printing serves as a powerful tool in the modern manufacturer’s toolkit.

Impact on the Automotive Industry

The automotive industry is no stranger to innovation. From the assembly line revolution of the early 20th century to the autonomous vehicles of today, this sector has continually evolved to meet changing demands and technological advancements. Now, SLA 3D printing is poised to be the latest transformative force, offering substantial benefits and new opportunities in automotive manufacturing.

Current Applications of SLA 3D Printing in Automotive

SLA 3D printing has already found its place within the automotive industry, particularly in the areas of:

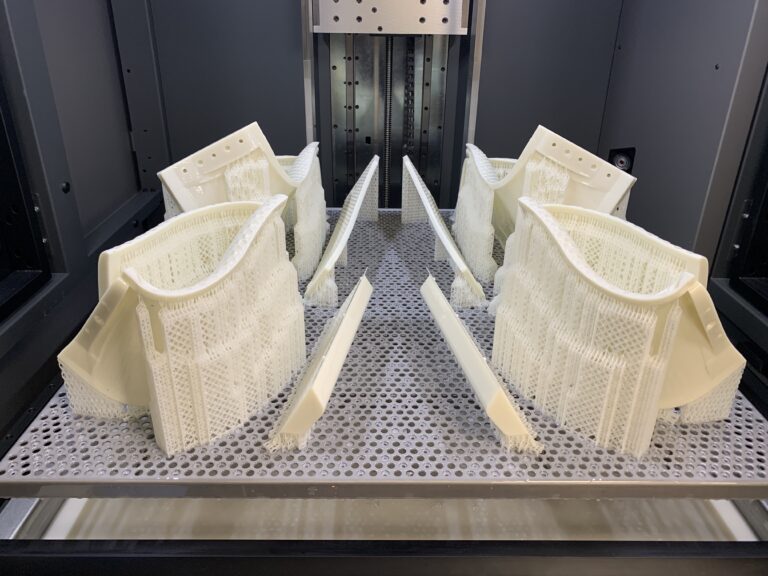

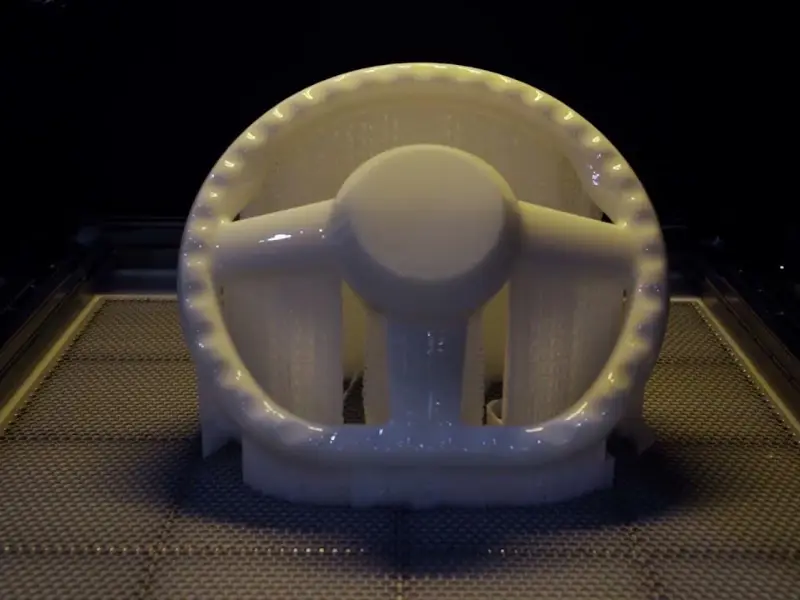

- Prototyping and Design Validation: The ability of SLA to produce highly accurate and detailed prototypes allows automotive designers to iterate quickly, testing form and function before committing to expensive tooling.

- Custom Parts and Components: SLA facilitates the production of custom parts that can be tailored to specific requirements without the need for large-scale manufacturing setups.

Benefits for the Automotive Sector

The integration of SLA 3D printing in automotive manufacturing offers several compelling advantages:

- Reduced Lead Times: Traditional prototyping can take weeks, if not months. SLA significantly cuts down this timeline, enabling faster design cycles and quicker market entry.

- Cost-Effectiveness in Small Batch Production: For low-volume or customized parts, SLA offers a cost-effective solution, eliminating the need for expensive molds and dies.

- Design Flexibility: Complex geometries that are difficult or impossible to achieve with traditional manufacturing methods are easily realized with SLA.

Case Studies: Automotive Companies Utilizing SLA Technology

- Ford Motor Company: Ford has integrated SLA 3D printing into its design and development processes, using it to produce prototypes of vehicle parts that require high precision and detail. This has enabled more efficient testing and reduced time-to-market for new models.

- BMW Group: BMW employs SLA technology for the rapid prototyping of components, particularly in its MINI division. By leveraging the speed and accuracy of SLA, BMW has streamlined its design validation process, resulting in faster innovation cycles.

- Volkswagen Group: In its pursuit of sustainable production methods, Volkswagen utilizes SLA for producing tooling and jigs, reducing the environmental impact associated with traditional manufacturing processes.

| Company | Application | Benefits |

| Ford | Prototyping, design validation | Faster testing, reduced time-to-market |

| BMW | Rapid prototyping | Streamlined design, faster innovation cycles |

| Volkswagen | Tooling, jigs | Sustainable production, reduced environmental impact |

While challenges remain, the benefits of SLA 3D printing in the automotive sector are significant. By enabling rapid prototyping, reducing costs, and offering unparalleled design freedom, SLA is set to play a pivotal role in the future of automotive manufacturing. As automakers continue to embrace this technology, the road ahead promises to be one of **innovation and transformation**.

Revolutionizing Healthcare with SLA 3D Printing

In the realm of healthcare, where precision and customization are paramount, SLA 3D printing is emerging as a transformative force. This technology is not only reshaping how medical devices and surgical tools are manufactured but also enhancing patient care through personalized medicine. Let’s delve into the myriad ways SLA 3D printing is revolutionizing healthcare.

Role of SLA 3D Printing in Medical Device Manufacturing

SLA 3D printing is being harnessed to produce a wide array of medical devices with exceptional precision. These include:

- Surgical Instruments: Custom tools designed for specific procedures, improving surgical outcomes.

- Orthopedic Implants: Tailored to fit individual patients, leading to better integration and recovery.

- Hearing Aids and Dental Appliances: Mass customization allows for rapid production of patient-specific devices.

Production of Customized Prosthetics and Implants

One of the most impactful applications of SLA 3D printing in healthcare is in the production of customized prosthetics and implants. The benefits include:

- Personalization: Prosthetics and implants can be designed to match the unique anatomy of each patient, improving comfort and functionality.

- Cost Efficiency: Traditional manufacturing methods for custom prosthetics can be prohibitively expensive; SLA offers a more affordable alternative.

- Speed: The ability to quickly produce these devices ensures patients receive their prosthetics sooner, enhancing their quality of life.

Impact on Surgical Planning and Education

SLA 3D printing is not only revolutionizing the tools and devices used in healthcare but also transforming how surgeries are planned and medical professionals are trained:

- Surgical Planning Models: High-fidelity anatomical models can be printed for pre-surgical planning, allowing surgeons to practice complex procedures before entering the operating room.

- Educational Tools: Medical students and professionals can benefit from realistic 3D printed models that provide hands-on experience with human anatomy.

Challenges and Considerations in Medical Applications

While the advantages of SLA 3D printing in healthcare are significant, certain challenges must be addressed to fully realize its potential:

- Biocompatibility: Ensuring that the materials used are safe for human use is a critical consideration.

- Regulatory Compliance: Medical devices produced using SLA must meet stringent regulatory standards, which can be a complex and lengthy process.

- Durability: Some resins may not have the long-term durability required for certain medical applications.

| Application | Benefits | Challenges |

| Medical Devices | Precision, customization, cost efficiency | Biocompatibility, regulatory compliance |

| Prosthetics and Implants | Personalization, speed | Material durability, cost |

| Surgical Planning and Education | Improved outcomes, enhanced training | Ensuring model accuracy, cost of high-quality materials |

In summary, SLA 3D printing is not just a tool for innovation; it’s a catalyst for a paradigm shift in healthcare. By offering new ways to produce customized, precise, and cost-effective medical solutions, it is paving the way for a future where patient care is more personalized and effective. As we continue to explore and harness this technology, the possibilities for improving health outcomes are boundless.

Empowering Consumer Goods with SLA 3D Printing

In today’s fast-paced world, the consumer goods industry is under constant pressure to innovate and meet ever-evolving consumer demands. SLA 3D printing is emerging as a game-changer, offering unparalleled flexibility and creativity in product design and manufacturing. Let’s explore how this cutting-edge technology is empowering the consumer goods sector.

Enhancing Product Design and Customization

One of the most significant impacts of SLA 3D printing in consumer goods is its ability to revolutionize product design and customization:

- Design Freedom: SLA allows for the creation of intricate and complex geometries that are difficult to achieve with traditional manufacturing methods.

- Rapid Prototyping: Designers can quickly iterate and test new concepts, accelerating the product development cycle.

- Mass Customization: With SLA, companies can easily offer personalized products, meeting individual consumer preferences without significant cost increases.

Applications in Various Consumer Products

SLA 3D printing is already making waves across a variety of consumer goods categories:

- Fashion and Accessories: From bespoke jewelry to customized eyewear, SLA enables the production of detailed and unique pieces that cater to personal tastes.

- Home Decor and Furniture: Intricate designs and complex shapes in lamps, vases, and furniture components can be produced with ease, offering consumers unique decor options.

- Electronics: Custom cases and components for electronic devices can be produced with precision, enhancing both aesthetics and functionality.

Benefits for Consumer Goods Manufacturers

The adoption of SLA 3D printing offers numerous advantages for manufacturers in the consumer goods sector:

- Cost Reduction: By minimizing the need for tooling and molds, SLA reduces production costs, especially for low-volume and custom items.

- Sustainability: Additive manufacturing processes generate less waste than traditional subtractive methods, aligning with growing consumer demand for sustainable practices.

- Time-to-Market: The speed of SLA printing allows manufacturers to bring new products to market faster, gaining a competitive edge.

Challenges and Considerations

Despite its advantages, the integration of SLA 3D printing into the consumer goods industry comes with challenges:

- Material Limitations: While SLA offers a range of resins, not all are suitable for consumer goods that require durability and long-term wear.

- Scale of Production: For high-volume production, SLA may not be as efficient as other manufacturing methods.

- Quality Assurance: Ensuring consistency and quality across batches of 3D printed products requires careful monitoring and control.

| Application | Benefits | Challenges |

| Fashion and Accessories | Customization, unique designs | Material durability, cost for mass production |

| Home Decor and Furniture | Design complexity, sustainability | Scale of production, material strength |

| Electronics | Precision, enhanced aesthetics | Quality assurance, regulatory compliance |

In conclusion, SLA 3D printing is not just a manufacturing tool; it is a driver of creativity and innovation in the consumer goods sector. By enabling greater design freedom, reducing costs, and fostering sustainability, SLA is helping companies meet the demands of modern consumers in new and exciting ways. As this technology progresses, the consumer goods industry will continue to be transformed, offering products that are not only functional but also uniquely tailored to individual tastes and lifestyles.

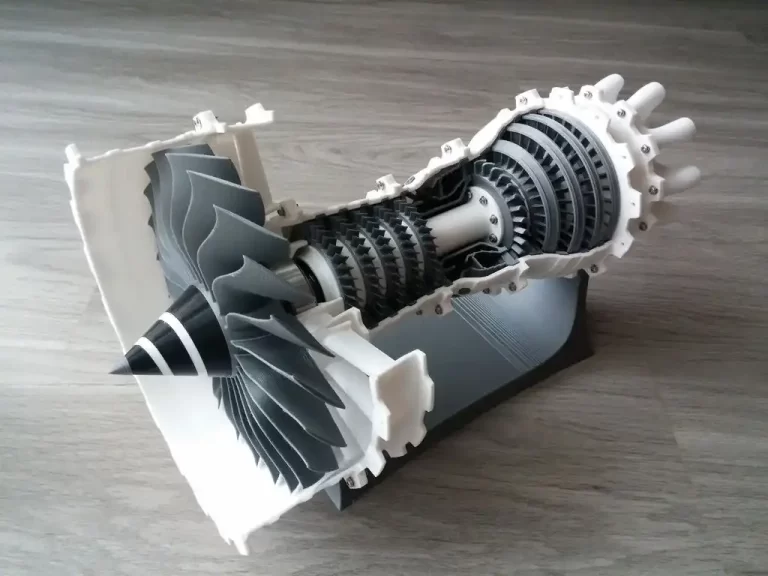

Transforming the Aerospace Industry with SLA 3D Printing

The aerospace industry, known for its rigorous standards and complex engineering, is embracing the capabilities of SLA 3D printing to push the boundaries of innovation. This technology is revolutionizing how aerospace components are designed, tested, and manufactured, offering significant advancements in efficiency, performance, and sustainability.

Advanced Component Design and Manufacturing

SLA 3D printing is at the forefront of transforming component design and manufacturing in the aerospace sector:

- Complex Geometries: SLA allows for the fabrication of intricate and lightweight structures that are difficult to produce using traditional methods, leading to improved performance and fuel efficiency.

- Rapid Prototyping: Engineers can swiftly create and test prototypes, facilitating faster design iterations and reducing the time required to bring new technologies to market.

- Tooling and Fixtures: Custom tools and fixtures used in the assembly and maintenance of aircraft can be quickly produced, enhancing operational efficiency.

Key Applications in Aerospace

Several critical applications of SLA 3D printing in aerospace highlight its transformative potential:

- Engine Components: Complex parts like fuel nozzles and turbine blades can be manufactured with high precision, improving engine performance and reducing emissions.

- Cabin Interiors: Custom and lightweight cabin components, such as seat frames and panels, contribute to overall weight reduction and fuel savings.

- Unmanned Aerial Vehicles (UAVs): Lightweight and aerodynamic structures for drones can be produced, enhancing flight performance and versatility.

Benefits for the Aerospace Industry

The integration of SLA 3D printing into aerospace manufacturing offers numerous advantages:

- Weight Reduction: The ability to produce lightweight components contributes to significant fuel savings and reduced emissions.

- Cost Savings: By eliminating the need for expensive tooling and reducing material waste, SLA can lower production costs.

- Flexibility and Customization: The technology enables the rapid production of custom parts, supporting the diverse needs of aerospace applications.

Challenges and Considerations

Despite its advantages, SLA 3D printing in aerospace faces several challenges that must be navigated:

- Material Certification: Ensuring that 3D printed materials meet the stringent safety and performance standards required in aerospace is a complex process.

- Production Speed: While suitable for prototyping and small batches, SLA may not match the speed required for high-volume production.

- Quality Control: Maintaining consistency and quality across batches of printed components is critical, requiring rigorous testing and validation.

| Application | Benefits | Challenges |

| Engine Components | Improved performance, precision | Material certification, quality control |

| Cabin Interiors | Weight reduction, fuel savings | Production speed, cost for large-scale production |

| Unmanned Aerial Vehicles | Lightweight structures, enhanced performance | Regulatory compliance, material durability |

In summary, SLA 3D printing is poised to play a pivotal role in the future of aerospace manufacturing. By enabling the production of complex, lightweight, and custom components, it is driving innovation and efficiency across the industry. As the technology continues to advance, the aerospace sector will benefit from unprecedented design freedom and operational flexibility, paving the way for the next generation of aviation and space exploration.

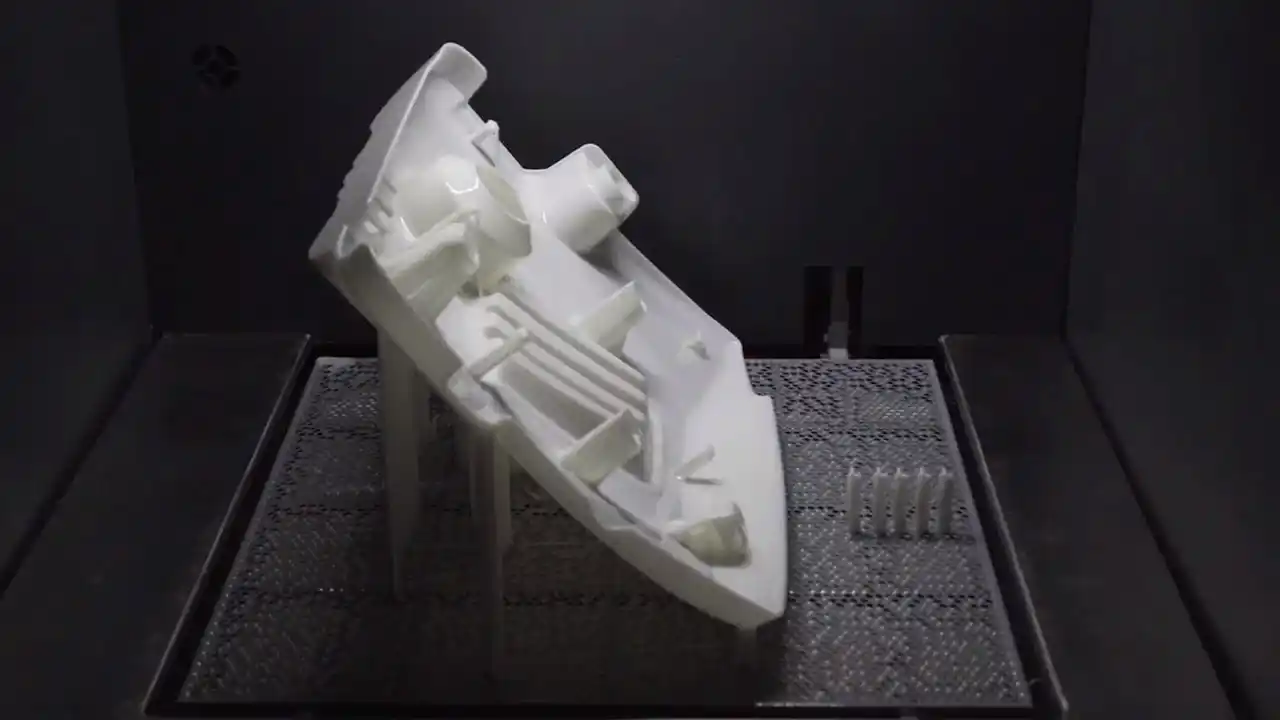

Streamlining the Automotive Industry with SLA 3D Printing

The automotive industry is undergoing a transformation driven by the need for innovation, efficiency, and customization. SLA 3D printing is at the forefront of this revolution, offering manufacturers new ways to design, prototype, and produce components. This technology is unlocking significant advancements in vehicle design, production processes, and sustainability.

Revolutionizing Vehicle Design and Prototyping

SLA 3D printing is a game-changer in the automotive sector, particularly in the design and prototyping phases:

- Rapid Prototyping: Engineers can quickly produce and test prototypes, accelerating the design cycle and reducing time-to-market for new models.

- Complex Geometries: SLA allows for the creation of intricate and lightweight designs that enhance vehicle performance and aesthetics.

- Customization: Manufacturers can offer personalized vehicle components, tailored to meet specific customer preferences and needs.

Enhancements in Production and Assembly

Beyond design and prototyping, SLA 3D printing is transforming production and assembly processes:

- Tooling and Fixtures: Custom tools, jigs, and fixtures can be printed on demand, improving assembly line efficiency and reducing costs.

- Spare Parts: On-demand printing of spare parts reduces inventory costs and ensures quick availability of components.

- Lightweight Components: Production of lightweight parts contributes to overall vehicle weight reduction, enhancing fuel efficiency and performance.

Benefits for Automotive Manufacturers

The adoption of SLA 3D printing offers numerous benefits to automotive manufacturers:

- Cost Efficiency: Reduced need for traditional tooling and decreased material waste lead to significant cost savings.

- Sustainability: Additive manufacturing minimizes waste and supports sustainable production practices.

- Innovation: The technology encourages innovative designs and faster development of new features and models.

Challenges and Considerations

Despite its advantages, SLA 3D printing in the automotive industry faces several challenges:

- Material Durability: Ensuring printed components meet the durability and performance standards required for automotive applications.

- Production Volume: SLA may not be suitable for high-volume production compared to traditional manufacturing methods.

- Regulatory Compliance: Meeting industry standards and regulations for safety and performance can be complex.

| Application | Benefits | Challenges |

| Rapid Prototyping | Accelerated design cycle, innovation | Material properties, cost of high-quality resins |

| Tooling and Fixtures | Cost efficiency, on-demand production | Durability, precision requirements |

| Spare Parts | Inventory reduction, quick availability | Production speed, regulatory compliance |

In summary, SLA 3D printing is a catalyst for change in the automotive industry, driving advancements in design, production, and sustainability. By enabling rapid prototyping, customization, and efficient production processes, this technology is helping manufacturers meet the demands of a dynamic market. As the technology continues to evolve, the automotive sector will benefit from increased innovation, flexibility, and competitiveness, paving the way for the future of mobility.

Optimizing the Manufacturing Industry with SLA 3D Printing

The manufacturing industry is experiencing a transformation driven by the need for increased efficiency, flexibility, and innovation. SLA 3D printing is at the forefront of this change, offering manufacturers new ways to design, produce, and optimize components and processes. This technology is unlocking significant advancements in product development, production efficiency, and customization.

Innovations in Product Development and Prototyping

SLA 3D printing is revolutionizing product development and prototyping in manufacturing:

- Rapid Prototyping: Manufacturers can quickly produce and test prototypes, accelerating product development cycles and reducing time-to-market.

- Complex Designs: SLA allows for the creation of intricate and lightweight designs that would be challenging to achieve with traditional methods.

- Customization: The technology enables the production of customized components tailored to specific customer requirements and market demands.

Streamlining Production Processes

Beyond prototyping, SLA 3D printing is enhancing production processes across the manufacturing industry:

- Tooling and Fixtures: Custom tools, jigs, and fixtures can be 3D printed on demand, improving production line efficiency and reducing costs.

- Spare Parts: On-demand production of spare parts reduces inventory costs and ensures quick availability of components.

- Lightweight Components: The ability to produce lightweight parts contributes to overall efficiencies, such as reduced material usage and energy consumption.

Benefits for Manufacturers

The adoption of SLA 3D printing offers numerous benefits to manufacturers:

- Cost Savings: Reduced need for traditional tooling and decreased material waste lead to significant cost reductions.

- Sustainability: Additive manufacturing minimizes waste and supports sustainable production practices.

- Innovation: The technology encourages innovative designs and faster development of new products and solutions.

Challenges and Considerations

Despite its advantages, SLA 3D printing in manufacturing faces several challenges:

- Material Properties: Ensuring printed components have the necessary strength and durability for industrial use.

- Production Volume: SLA may not be suitable for high-volume production compared to traditional manufacturing methods.

- Quality Control: Maintaining consistency and quality across batches of printed components is critical.

| Application | Benefits | Challenges |

| Rapid Prototyping | Accelerated development cycle, innovation | Material properties, cost of high-quality resins |

| Tooling and Fixtures | Cost efficiency, on-demand production | Durability, precision requirements |

| Spare Parts | Inventory reduction, quick availability | Production speed, regulatory compliance |

The Future of SLA 3D Printing in Manufacturing

The future of SLA 3D printing in the manufacturing industry promises continued evolution and innovation:

- Advanced Materials: Development of more durable and heat-resistant resins will expand SLA applications in manufacturing.

- Integration with Smart Manufacturing: Combining 3D printing with IoT and AI technologies will enhance the efficiency and capabilities of manufacturing processes.

In summary, SLA 3D printing is a catalyst for change in the manufacturing industry, driving advancements in product development, production processes, and sustainability. By enabling rapid prototyping, customization, and efficient production, this technology helps manufacturers meet the demands of a competitive market. As SLA 3D printing continues to evolve, the manufacturing sector will benefit from increased innovation, flexibility, and competitiveness, paving the way for the future of production.