Selective Laser Sintering (SLS) technology offers advanced capabilities for producing durable, functional components. This guide provides a structured analysis to assist in selecting the most suitable SLS 3D printer by evaluating technical specifications, operational costs, and application requirements.

Understanding SLS Technology

Process Overview

SLS employs a powder-bed fusion method where a high-powered laser sinters thermoplastic polymers (e.g., nylon, TPU) into solid structures. The sequential process involves:

- Powder deposition (0.05–0.2 mm layer thickness)

- Laser sintering at sub-melting temperatures

- Platform lowering and recoating

- Part cooling and powder recovery

Material Compatibility

Standard materials:

- Polyamide (PA12, PA11)

- Filled composites (glass/carbon fiber reinforced)

- Flexible elastomers (TPU)

- Specialty polymers (PP, PEBA)

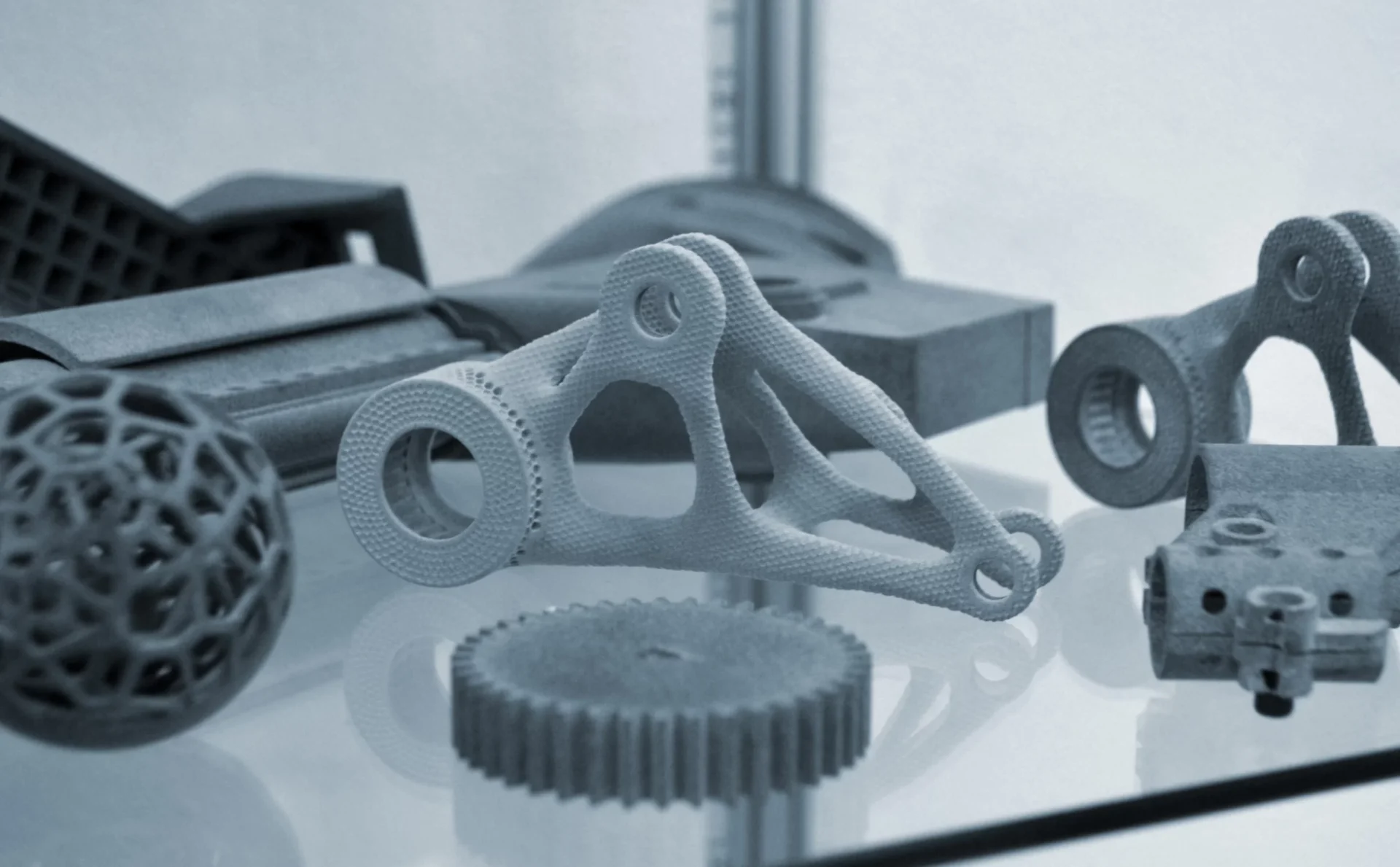

Advantages of SLS Technology

Design Freedom

- Natural powder support eliminates post-processing for complex geometries

- Enables intricate internal features and undercuts

Mechanical Performance

- Isotropic strength (45–60 MPa tensile)

- High impact resistance (Izod 5–8 kJ/m²)

- Thermal stability up to 180°C

Production Efficiency

- Batch manufacturing capability (up to 1,000 parts per build)

- 90% powder recyclability

Disadvantages and Limitations

- High initial investment ($5k–$500k+)

- Surface roughness (Ra 10–25 µm) requiring post-finishing

- Material costs ($25–$150/kg)

Key Selection Criteria

Build Volume

- Desktop: 150x150x150 mm (e.g., Formlabs Fuse 1+)

- Business:200x200x300 mm (e.g., Zongheng3d SLS 2030)

- Industrial: 500x500x500 mm (e.g., EOS P 396)

Resolution Parameters

- Laser spot size: 0.1–0.3 mm

- Layer thickness: 0.05–0.2 mm

Throughput Factors

- Laser scanning speed: 5–15 m/s

- Recoating time: 5–15 seconds per layer

Cost Analysis

| Cost Component | Typical Range |

| Material Refresh Rate | 10–30% per build cycle |

| Energy Consumption | 2–8 kWh per build |

| Annual Maintenance | $$2k$$20k |

Application Scenarios

Prototyping

- Functional testing of snap-fit mechanisms

- Aerospace wind tunnel models

End-Use Parts

- Automotive brackets (PA12 GF30)

- Medical orthotics (PA12)

Tooling

- Custom jigs with integrated hinges

- High-temperature fixtures (PA12 HT)

Conclusion

SLS 3D printers provide unique advantages for demanding applications requiring structural integrity and design complexity. When evaluating systems, prioritize build volume, material flexibility, and total cost of ownership. For production environments, consider scalable solutions with automated powder handling and advanced process control.

FAQs

- Material Recycling: Up to 90% of unsintered powder can be reused, reducing material costs.

- Surface Finish: Post-processing options include vapor smoothing (Ra 3–5 µm) and bead blasting.

- Metal SLS: Direct Metal Laser Sintering (DMLS) is a variant for metallic components.