SLS 3D Printing Technology: A Prominent Advance in Industrial Manufacturing

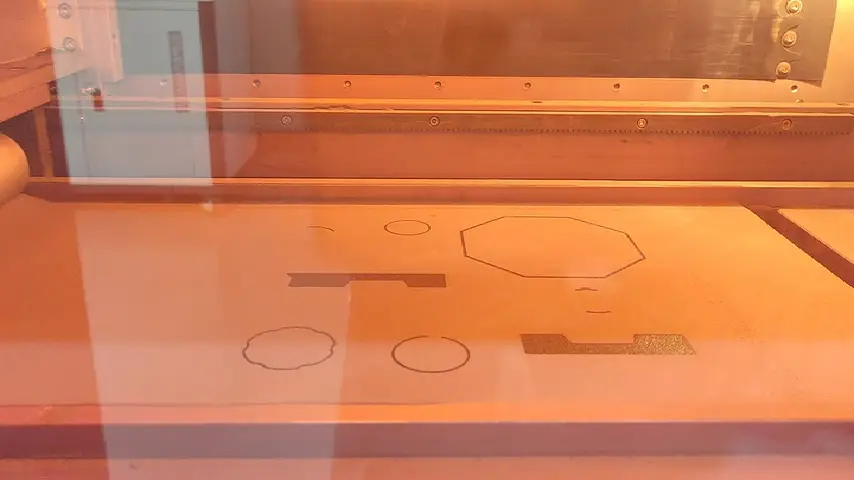

SLS, an abbreviation for Selective Laser Sintering, represents a pivotal subset of 3D printing technology. In recent years, it has garnered substantial attention within the industrial manufacturing domain. This technology employs a high – energy laser beam to sinter and solidify powder materials, including plastics and metals, in a layer – by – layer fashion, following a pre – determined model path. Through this process, a three – dimensional solid model is constructed. It transcends the limitations inherent in traditional manufacturing processes, introducing an unprecedented degree of flexibility and innovation to product design and manufacturing methodologies.

II. Zongheng3D: The Pioneer of SLS 3D Printing for Drone Frames

As a leading company in the industrial 3D printer manufacturing field, Zongheng3D has keenly perceived the huge potential of SLS 3D printing technology in drone frame manufacturing and successfully applied it to actual production. Relying on advanced technical equipment and a professional R & D team, Zongheng3D has achieved the efficient transformation of SLS 3D – printed drone frames from design to production, providing high – performance and customized frame solutions for the drone industry.

III. Advantages of SLS 3D – Printed Drone Frames

(I) Boosting Traditional Manufacturing Efficiency

Traditional drone frame manufacturing requires going through complex processes such as mold design, mold opening, and multiple machining operations. This is time – consuming, labor – intensive, and has a long production cycle. In contrast, SLS 3D printing technology simplifies the process. Simply import the designed 3D model, and the equipment can automatically print layer by layer according to the program, significantly shortening the production cycle. From design finalization to product formation, it can be completed within a few hours. Compared with traditional manufacturing methods, the efficiency is remarkably enhanced.

(II) Cost Reduction

In traditional manufacturing, the costs of mold design and manufacturing are exorbitant, especially for small – batch production of drone frames. The mold cost allocated to each product is extremely high. SLS 3D printing eliminates the need for molds. It directly prints according to the model, saving the mold manufacturing cost and effectively reducing the production cost. Moreover, 3D printing has a higher material utilization rate, reducing waste and further cutting costs.

(III) Elevating the Product Development Process

SLS 3D printing technology liberates drone frame design from the constraints of traditional manufacturing processes. Designers can fully unleash their creativity and achieve more complex and lightweight structural designs, thereby enhancing the performance of drones. For example, by optimizing the internal structure of the frame, it is possible to reduce weight while ensuring strength, improving flight endurance and maneuverability. During the product development process, if design modifications are required, simply adjust the model in the software and re – print, eliminating the need to re – open the mold. This accelerates the product iteration and upgrading speed, elevating the product development to a new level.

(IV) Materializing Concepts and Ideas

For drone researchers, developers, and enthusiasts, SLS 3D printing technology is like a magical tool that can rapidly transform the creative ideas in their minds into physical products. Unique shape designs or innovative functional structures, as long as they are converted into printable models through 3D modeling software, can be realized with the help of SLS 3D printing technology. This ability to quickly materialize concepts stimulates innovation vitality and propels the continuous advancement of drone technology.

IV. Application Prospects of SLS 3D – Printed Drone Frames

With the maturation and development of SLS 3D printing technology, its prospects in the drone frame manufacturing field are promising. Besides the consumer – grade drone market, in the industrial – grade drone fields such as surveying, inspection, and logistics, SLS 3D – printed drone frames, with their high – performance and customized advantages, will also occupy an important position. In the future, SLS 3D printing technology is expected to continue leading the development of the drone manufacturing industry.

In conclusion, SLS 3D printing technology has significant advantages in drone frame manufacturing. It not only improves traditional manufacturing efficiency and reduces costs but also injects vitality into product development, materializing numerous concepts and ideas. As a forerunner, Zongheng3D is driving the drone industry to new heights. We look forward to SLS 3D – printed drone frames achieving more remarkable results in the future.