In the ever-evolving landscape of manufacturing and technology, few innovations have captured the imagination and potential of industries quite like 3D printing. Among the various methods of 3D printing, Selective Laser Sintering (SLS) stands out as a game-changer, revolutionizing how products are designed, prototyped, and manufactured. But what is it about SLS 3D printing that has led to its rapid expansion in the market? And why are industries across the globe increasingly turning to this technology?

Imagine a world where complex geometries and intricate designs can be brought to life with precision and efficiency, where the constraints of traditional manufacturing are no longer barriers but mere stepping stones to innovation. This is the promise of SLS 3D printing—a technology that not only enhances creativity but also drives economic growth and sustainability.

As we delve into the fascinating world of SLS 3D printing, this article will explore the key drivers behind its market expansion, the challenges it faces, and the future outlook that promises even more groundbreaking advancements. From technological innovations to strategic opportunities for businesses, we’ll uncover the multifaceted aspects of this burgeoning market. Whether you’re a seasoned industry professional or a curious newcomer, join us on this journey to understand how SLS 3D printing is reshaping the future of manufacturing.

Understanding SLS 3D Printing: A Comprehensive Guide

Selective Laser Sintering (SLS) 3D printing is not just a technological marvel; it’s a transformative force reshaping industries and redefining possibilities. But what exactly is SLS 3D printing, and why is it gaining such momentum? In this article, we’ll dive deep into the mechanics, advantages, and applications of SLS 3D printing, providing you with a thorough understanding of this groundbreaking technology.

How SLS 3D Printing Works

At its core, SLS 3D printing is a process that uses a high-powered laser to fuse small particles of polymer powder into a solid structure. Here’s a step-by-step breakdown of how it works:

1.Preparation of the Powder Bed: A thin layer of powder is spread across the build platform.

2.Laser Sintering: A laser selectively fuses the powder by scanning cross-sections generated from a 3D digital model.

3.Layer-by-Layer Construction: The platform lowers, and a new layer of powder is applied. The process repeats until the object is complete.

4.Cooling and Post-Processing: The finished part is allowed to cool before being removed and cleaned of excess powder.

Key Materials Used in SLS Printing:

- Nylon (Polyamide): Known for its strength and flexibility.

- Alumide: A blend of nylon and aluminum, offering a metallic finish.

- Glass-Filled Nylon: Enhanced stiffness and thermal resistance.

Advantages of SLS 3D Printing

SLS 3D printing offers several compelling benefits that set it apart from other 3D printing technologies:

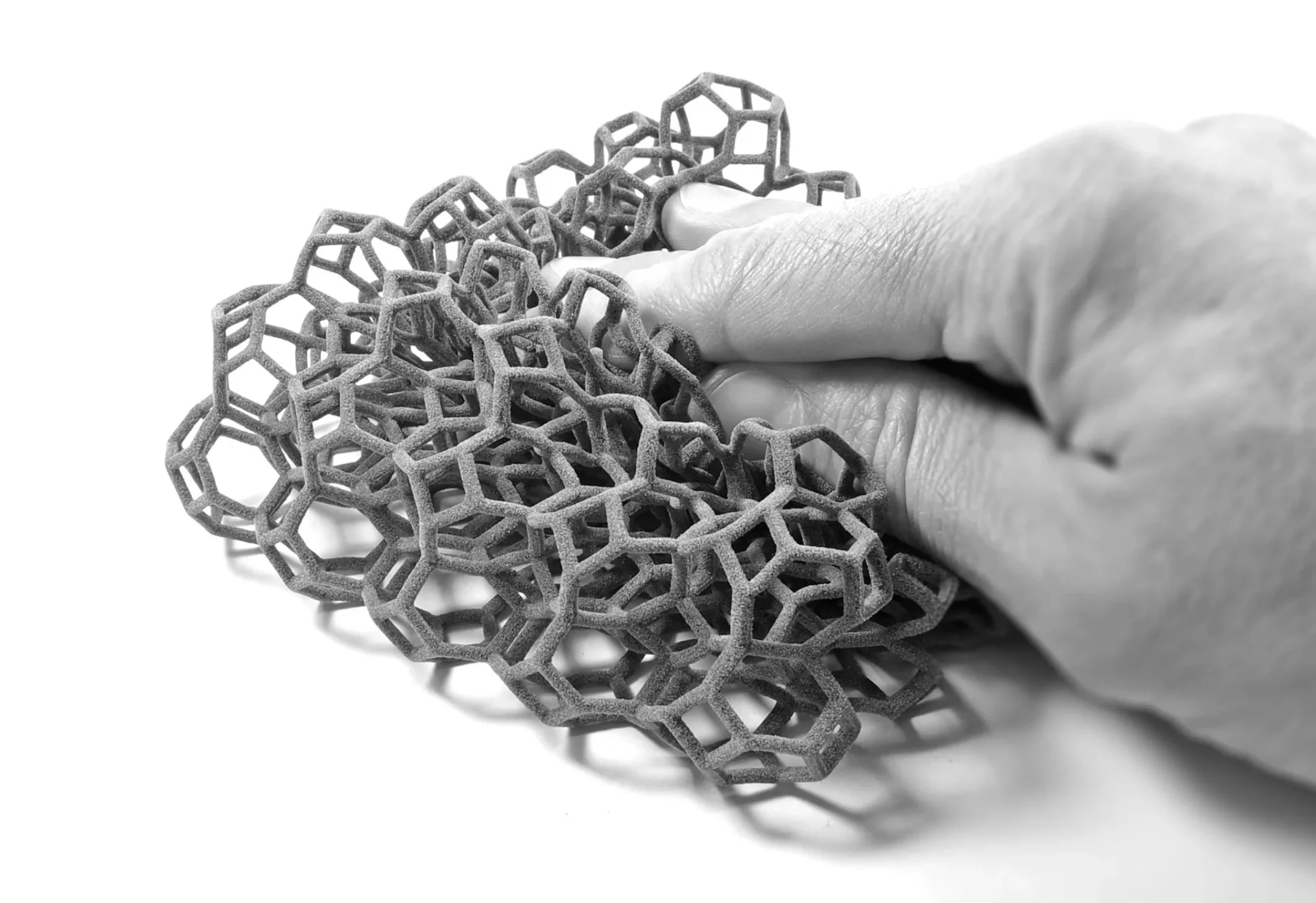

- Complex Geometries: SLS can create intricate designs without the need for support structures.

- Material Efficiency: Unused powder can be recycled, minimizing waste.

- Durability and Strength: Parts produced are robust and suitable for functional testing.

- Versatility: Applicable across various industries, from automotive to healthcare.

| Feature | SLS 3D Printing | Other 3D Printing Methods |

| Support Structures | Not required | Often required |

| Material Waste | Minimal | Varies |

| Part Strength | High | Varies |

| Surface Finish | Rough, can be smoothed | Varies |

Applications in Various Industries

SLS 3D printing’s versatility makes it a valuable tool across multiple sectors:

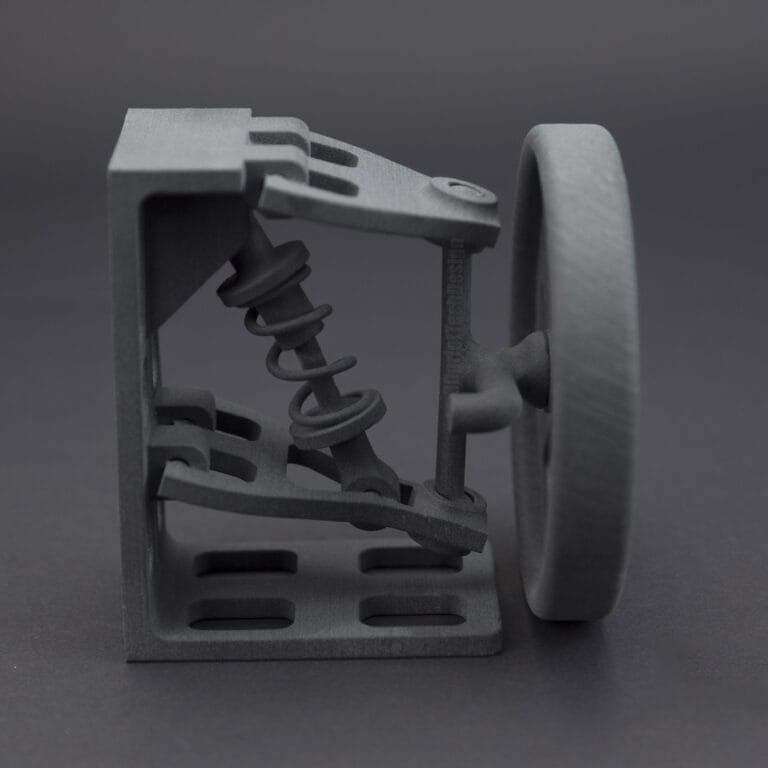

Automotive

Prototyping and production of lightweight components.

Aerospace

Manufacturing complex parts with high precision.

Healthcare

Custom prosthetics and medical devices.

Consumer Goods

Production of unique and customizable products.

Selective Laser Sintering is more than just a method of 3D printing; it’s a catalyst for innovation and efficiency. By understanding the mechanics, advantages, and applications of SLS, businesses and individuals can harness its full potential to drive growth and creativity. Whether you’re looking to innovate in product design or streamline manufacturing processes, SLS 3D printing offers a world of possibilities waiting to be explored.

Key Drivers of SLS 3D Printing Market Expansion: What’s Fueling the Boom?

Ever wondered why SLS 3D printing is suddenly the talk of the town? It’s like the cool kid in the tech world, and for good reason. Let’s dive into the juicy details of what’s driving this market to new heights.

Technological Advancements: The Magic Wand

First up, let’s talk tech. Imagine having a magic wand that keeps getting better and better. That’s what’s happening with SLS technology. Here’s how:

- Laser Precision: The lasers used in SLS are becoming more precise, allowing for even more intricate designs.

- Material Innovation: New materials are being developed that are stronger, lighter, and more versatile. Think of it as upgrading from a flip phone to the latest smartphone.

- Software Smarts: Advanced software is making it easier to design and print complex structures. It’s like having a GPS for your 3D printing journey.

Increasing Demand Across Industries: The Domino Effect

Industries are jumping on the SLS bandwagon faster than you can say “3D print.” Why? Because SLS offers solutions that traditional manufacturing just can’t match. Here’s a peek at who’s loving SLS:

- Automotive: Need a lightweight, durable part? SLS has got you covered.

- Aerospace: For those sky-high ambitions, SLS delivers precision and reliability.

- Healthcare: Custom prosthetics and medical devices? SLS is a lifesaver, literally.

- Consumer Goods: From fashion to gadgets, SLS is making waves.

Cost Efficiency and Production Speed: The Winning Combo

Let’s face it, time is money. And SLS is saving both. Here’s how:

Faster Production: SLS can produce parts quickly, reducing lead times. It’s like having a fast-forward button for manufacturing.

Cost Savings: By minimizing waste and using less material, SLS is a budget-friendly option. Who doesn’t love saving a few bucks?

Analogy: Think of SLS as the microwave of manufacturing—quick, efficient, and oh-so-convenient.

The Future Looks Bright

So, there you have it! The SLS 3D printing market is booming, and it’s not slowing down anytime soon. With technological advancements, increasing demand across industries, and unbeatable cost efficiency, SLS is set to keep making waves. Whether you’re in the industry or just curious, it’s an exciting time to be part of this 3D printing revolution. Who knows what the future holds? One thing’s for sure—SLS is here to stay, and it’s only getting better.

Challenges Facing SLS 3D Printing: Navigating the Bumps in the Road

Alright, let’s get real for a moment. While SLS 3D printing is like the superhero of the manufacturing world, even superheroes face their fair share of challenges. So, what are the hurdles that SLS needs to leap over? Let’s break it down and see what’s standing in the way of this tech marvel.

First up, let’s talk materials. While SLS is pretty versatile, it’s not without its limitations. Here’s the scoop:

Limited Material Options: Unlike other 3D printing methods, SLS primarily uses polymers. It’s like having a wardrobe full of T-shirts but no jackets or shoes.

Material Costs: Some of the advanced materials can be pricey, making it a bit of a splurge for certain applications.

Surface Finish and Post-Processing: The Beauty Routine

Let’s face it, not everything comes out of the printer looking perfect. SLS parts often need a little TLC to get that smooth finish. Here’s what you need to know:

- Rough Surface Finish: Parts often come out with a grainy texture, requiring additional work to smooth them out.

- Time-Consuming Post-Processing: Smoothing, dyeing, and finishing can add time and cost to the production process. It’s like getting ready for a big night out—sometimes, it takes a little extra effort.

Technical Expertise: The Learning Curve

SLS isn’t exactly plug-and-play. It requires a certain level of know-how to get things just right. Here’s why:

Complex Setup: Setting up an SLS printer can be a bit like assembling IKEA furniture—tricky and sometimes frustrating.

Skilled Operators Needed: To get the best results, you need skilled operators who know the ins and outs of the technology.

Analogy: Think of SLS as a high-performance sports car—it can do amazing things, but you need the right driver behind the wheel.

Environmental Concerns: The Green Factor

In today’s world, sustainability is key. While SLS is more efficient than some traditional methods, it still has room for improvement:

Energy Consumption: The lasers used in SLS can consume a lot of energy, raising concerns about environmental impact.

Recycling Challenges: While unused powder can be recycled, the process isn’t always straightforward.

So, there you have it. SLS 3D printing is facing some challenges, but they’re not insurmountable. With ongoing research and innovation, these hurdles can be overcome. Whether it’s expanding material options, improving surface finishes, or enhancing sustainability, the future looks promising. After all, every superhero has their kryptonite, but that doesn’t stop them from saving the day. SLS is no different—it’s ready to tackle these challenges head-on and continue revolutionizing the world of manufacturing.

Future Prospects of SLS 3D Printing: What’s on the Horizon?

Emerging Technologies: The Next Big Thing

The world of technology never stands still, and SLS is no exception. Here’s what’s cooking in the innovation kitchen:

Multi-Material Printing: Imagine printing with multiple materials in a single go. It’s like having a printer that can whip up a pizza with all your favorite toppings at once.

Enhanced Automation: Automation is set to streamline the entire process, making SLS more efficient and user-friendly. Think of it as having a personal assistant for your 3D printing needs.

Expanding Applications: Beyond the Horizon

SLS is already making waves in various industries, but the future holds even more potential. Here’s a glimpse of what’s to come:

- Bioprinting: The medical field is exploring SLS for bioprinting tissues and organs. It’s like something straight out of a sci-fi movie.

- Construction: Imagine printing entire buildings or structures. SLS could revolutionize the way we think about construction.

So, what’s the takeaway? The future of SLS 3D printing is as exciting as a rollercoaster ride, full of twists, turns, and endless possibilities. With emerging technologies, expanding applications, and a focus on sustainability, SLS is poised to continue its upward trajectory. Whether you’re a tech enthusiast, a business leader, or just someone curious about the future, there’s plenty to look forward to. The sky’s the limit, and SLS is ready to soar. So buckle up and enjoy the ride—it’s going to be an exhilarating journey!