In general, 3D printing has evolved and continues to evolve as one of the most profound innovations into this world of technology. Any of the existing approaches could be considered quite versatile and powerful; however, among those, Selective Laser Sintering (SLS) would probably form one of the most pertinent. It allows for everything from rapid prototyping to end-use parts production. Like any ground-breaking technology, SLS is usually perceived not only from the perspective of what it represents at the moment but additionally envisioning trends defining the very evolution of SLS.

A million-dollar question is: Are you keeping pace with the rapid advancements in 3D printing SLS? Or are you on the verge of being left behind in a field that has a great chance of revolutionizing several industries?

This article equips you to understand the trends shaping the future of SLS 3D printing. They include advanced materials, improved speed of printing, bit by bit solutions for aerospace, healthcare, fashion, and other sectors. The article will tell how corporations are breaking down barriers to adaptation, what sustainability means in promoting innovation, and what businesses must do if they are to keep themselves thriving through such trends.

Understanding the Basis of SLS 3D Printing

Being one of the basic technologies in the world of 3D printing, SLS has outstripped many others in revolutionizing manufacturing ventures in numerous areas. Its uniqueness is in the fabrication of highly detailed, durable, and highly functional parts, free from the processes of molding or complex tooling. Before exploring the future trends of SLS, the basic essence of its rather game-changing technology needs to be understood.

How Does SLS 3D Printing Work?

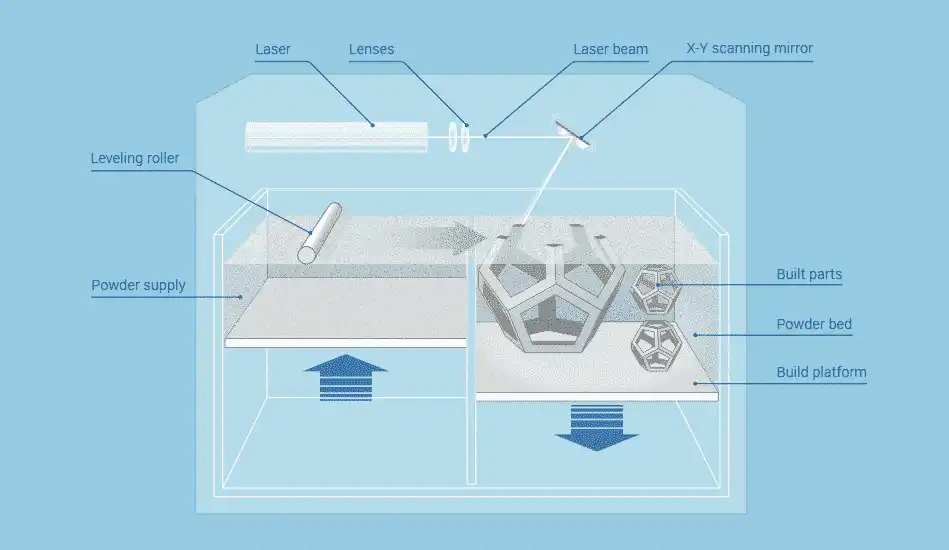

At its core, SLS 3D printing is a powder bed fusion (PBF) process. It employs a high-powered laser to selectively fuse powdered material layer by layer, enabling the creation of complex parts with remarkable precision. The process unfolds as follows:

- Preparation of the Powder Bed: A thin layer of powdered material (such as nylon or polyamide) is spread evenly across the build platform. This material serves as the “ink” for the printing process.

- Laser Sintering: A high-powered laser precisely heats and fuses the powder in specific areas, following the digital design (CAD file). The unfused powder acts as a natural support structure, eliminating the need for external supports.

- Layer-by-Layer Fusion: Once the first layer is sintered, the build platform slightly lowers, and another layer of powder is spread. The laser continues to sinter each subsequent layer until the part is fully constructed.

- Cooling and Post-Processing: The completed part is left to cool inside the machine to prevent warping. After cooling, the unfused powder is removed (and often recycled), and the part undergoes post-processing steps like cleaning, polishing, or dyeing.

What Materials Are Used in SLS 3D Printing?

The versatility of SLS stems largely from the wide variety of materials it can work with. While polymers are commonly used, advancements in material science are expanding the range to include metals, ceramics, and composites. Here is an overview:

| Material | Properties | Applications |

| Nylon (PA 12, PA 11) | Durable, lightweight, and flexible | Prototyping, functional parts, medical devices |

| Polyamide Composites | Enhanced stiffness and strength | Aerospace, automotive |

| TPU (Thermoplastic Polyurethane) | Elastic and impact-resistant | Footwear, medical prosthetics |

| Metal Powders | High strength and heat resistance | Aerospace, automotive, industrial tools |

| Ceramics | High thermal and chemical resistance | Medical implants, electronics |

Emerging Trend: Sustainable and biodegradable materials, such as bio-based polymers, are gaining popularity as they help reduce environmental impact.

Advantages of SLS 3D Printing

SLS offers several unique features that make it ideal for both prototyping and end-use part production:

- No Need for Support Structures: Unlike other 3D printing techniques like FDM or SLA, SLS does not require additional support structures. The surrounding powder provides inherent support during the printing process.

- High Design Freedom: With SLS, it is possible to create complex geometries, interlocking parts, and intricate details that are difficult or impossible to achieve with traditional manufacturing methods.

- Durable and Functional Parts: SLS parts are known for their strength, flexibility, and thermal resistance, making them suitable for demanding applications.

- Efficient Material Utilization: Unused powder can often be recycled, reducing waste and lowering overall material costs.

- Scalability: SLS is well-suited for low- to medium-volume production, bridging the gap between prototyping and mass manufacturing.

Limitations of SLS 3D Printing

Despite its capabilities, SLS also has some challenges:

- High Initial Costs: SLS machines and materials are relatively expensive, representing a significant investment, especially for small and medium-sized businesses.

- Material Limitations: Although SLS supports a variety of materials, the options are still more limited compared to traditional manufacturing processes.

- Post-Processing Requirements: Parts typically require additional steps like cleaning, polishing, or dyeing after printing, which increases both time and cost.

- Learning Curve: Designing for SLS demands specialized knowledge of CAD software and the SLS process to optimize parts for functionality and efficiency.

Why SLS Matters: Setting The Stage for Future Trends

Understanding the basics of SLS printing is crucial to explain and underpin such rapid advances we are seeing-from new materials and the speed of printing to applications in the high-end sectors including aerospace and health care, every trend builds on these core principles. Understanding the technology, its materials of use, and its advantages and disadvantages puts you in a greater position to comprehend how these emerging trends can effectively change the way you do work or pursue your career. SLS is not just a manufacturing tool; it is the very platform of innovation.

Emerging Trends in SLS 3D Printing: Transforming the Future of Manufacturing

SLS is now no longer just another promising technology; it has, however, risen to a critical enabler changing various industries-from aerospace to healthcare. But real excitements arise from the emergence of the trends that will define the way forward. SLS burst forward impressively, from advanced materials to efficiency and affordability, is no longer a static technology but one that possesses some versatility in its rapidly changing circumstances.

1. Advanced Materials: Expanding SLS Applications

One of the most significant trends in SLS is the expansion of material options. Traditionally, SLS has been dominated by polymers like nylon (PA 12). While these remain popular, new high-performance materials are now enabling applications that were previously out of reach.

| Material | Key Properties | Applications |

| High-Temperature Polymers (e.g., PEEK) | Exceptional heat resistance, chemical stability | Aerospace, automotive, medical devices |

| Flexible Materials (e.g., TPU) | Elasticity, impact resistance | Footwear, prosthetics, consumer goods |

| Composite Powders | Enhanced strength, lightweight | Aerospace, structural parts |

| Metal Powders | High strength, heat resistance | Industrial tools, aerospace components |

| Bio-Based Polymers | Sustainable, biodegradable | Eco-friendly consumer goods, medical uses |

Trend Spotlight:

- Sustainability is driving innovation in material science. Manufacturers are developing recyclable and biodegradable powders to address environmental concerns and meet global sustainability goals.

- Research into conductive materials for use in electronics and wearables is opening up new possibilities for integrating SLS into the production of smart devices.

Why This Matters

Advanced materials are extending the reach of SLS into industries that demand extreme performance, such as aerospace and healthcare. These materials are making it possible to replace traditional manufacturing methods with lighter, stronger, and more sustainable alternatives.

2. Increased Automation: Smarter and More Efficient Processes

Automation is transforming SLS, making it faster, more intelligent, and more efficient. From machine learning algorithms to robotic part handling, automation is addressing some of the major challenges in SLS, such as labor-intensive post-processing and inconsistent quality.

Key Developments in Automation

- AI-Powered Print Optimization: Machine learning algorithms can automatically optimize laser paths, reducing material waste and increasing print speed. Predictive maintenance systems monitor machine health, minimizing downtime and costs.

- Automated Powder Handling: Advanced systems now handle powder recycling and distribution, ensuring consistent material quality with minimal human intervention.

- Post-Processing Automation: Robots and specialized systems are taking over time-consuming tasks like part removal, cleaning, and surface finishing.

- Integrated Workflow Systems: End-to-end software solutions now connect design, printing, and post-processing, streamlining production for faster turnaround times.

Benefits of Automation

- Faster Production Cycles: Automation eliminates manual bottlenecks, reducing lead times.

- Consistent Quality: Advanced monitoring ensures parts are printed to exact specifications.

- Reduced Costs: Efficient use of materials and labor cuts overall production expenses.

3. Faster Printing Speeds: Scaling SLS for Mass Production

Speed has long been a bottleneck in additive manufacturing, but emerging SLS technologies are breaking down this barrier. With new advancements, SLS is no longer limited to prototyping; it is becoming viable for low- to medium-volume production.

Innovations Driving Faster Printing

- Multi-Laser Systems: Modern SLS printers now incorporate multiple lasers working simultaneously, significantly reducing build times.

- Improved Laser Scanning Technology: High-speed scanning mirrors and advanced optics enable faster and more precise laser movement.

- Layerless Printing: Experimental techniques like continuous powder deposition allow for smoother and faster production without discrete layers.

Why This Matters

Faster printing speeds are making SLS more attractive for industries like automotive, aerospace, and consumer goods, where time-to-market is critical. By bridging the gap between prototyping and production, these advancements are opening up new opportunities for mass customization and on-demand manufacturing.

4. Cost Reductions: Making SLS Accessible to More Businesses

While SLS has traditionally been associated with high upfront costs, innovations are driving down expenses, making it more accessible to small and medium-sized businesses.

How Costs Are Dropping

- Affordable Compact SLS Printers: Companies like Formlabs are developing desktop SLS machines, reducing the initial investment costs for businesses.

- Improved Powder Recyclability: New material formulations allow for higher rates of powder reuse, cutting down on material waste and cost.

- Cloud-Based Services: Distributed SLS printing services enable companies to outsource production, eliminating the need for in-house equipment.

| Cost Reduction Factor | Impact |

| Affordable desktop SLS machines | Expands adoption among small businesses |

| Efficient powder recycling | Reduces long-term material costs |

| Outsourced SLS services | Eliminates need for in-house expertise/equipment |

Impact

These innovations are democratizing SLS technology, enabling more businesses to experiment with and benefit from it.

5. Customization and On-Demand Manufacturing: The Future is Personal

One of the most powerful trends in SLS is its ability to enable mass customization and on-demand production. This flexibility is transforming industries that rely on personalized products.

Industries Leveraging SLS Customization

- Healthcare: Customized prosthetics and orthotics, patient-specific surgical guides and implants.

- Fashion and Footwear: On-demand production of unique designs, custom-fit footwear tailored to individual biomechanics.

- Consumer Goods: Personalized eyewear and jewelry, low-volume runs of niche products.

- Automotive: Custom interior components for luxury vehicles, specialized parts for racing or restoration projects.

6. Software and Workflow Enhancements: Closing the Gap Between Design and Production

Modern SLS systems are increasingly paired with powerful software tools that streamline the entire production process, from design to final part delivery.

Advances in SLS Software

- Design Optimization Tools: CAD software now includes features tailored to SLS, enabling the creation of lighter, stronger parts through lattice structures and topology optimization.

- Simulation and Predictive Analysis: Advanced simulation software predicts potential print failures, reducing waste and improving success rates.

- Workflow Automation: Integrated software platforms connect design, slicing, printing, and post-processing, creating a seamless production workflow.

Industries Embracing SLS: Present and Future Applications

SLS is not just a prototyping tool; it represents a disruptive manufacturing technology that, alongside 3D printing, will undoubtedly change the future for certain industries. With its ability to make functional, durable, and extremely complex parts, there was a whole new world of possibilities that opened up to manufacturers surpassing those drawn up by traditional ways in the past. As SLS continues to evolve, various industries find inventive ways to embrace its possibilities, pushing boundaries and redefining what is possible.

1. Aerospace: Flying High with Lightweight Precision

The aerospace industry was among the first to adopt SLS technology, and for good reason. The sector demands lightweight, high-strength parts that can withstand extreme conditions, and SLS fits the bill perfectly, offering both precision and performance.

Key Applications in Aerospace

- Lightweight Structural Components: SLS enables the production of lightweight parts with complex geometries, such as brackets and frames. Materials like high-temperature polymers (e.g., PEEK) and metal powders are ideal for aerospace applications.

- Rapid Prototyping: Engineers can quickly iterate on designs, reducing the development cycles for new aircraft and spacecraft.

- End-Use Parts: Cabin components, such as air ducts and seat parts, are increasingly being produced using SLS due to its cost-effectiveness and speed.

| Aerospace Benefits of SLS | Impact |

| Lightweight materials | Reduced fuel consumption and emissions |

| Complex geometries | Improved aerodynamics and structural performance |

| High-strength materials | Components that withstand extreme conditions |

Future Potential

SLS could play a crucial role in space exploration, enabling on-demand manufacturing of parts in space to reduce payload weight.

2. Healthcare: Revolutionizing Personalized Medicine

In healthcare, customization is of utmost importance, and SLS delivers like no other technology. From creating patient-specific implants to manufacturing prosthetics, SLS is helping medical professionals provide better, faster, and more cost-effective care.

Key Applications in Healthcare

- Prosthetics and Orthotics: Custom-fit prosthetics and braces can be produced quickly, ensuring optimal comfort and functionality for patients.

- Surgical Guides: SLS is used to create patient-specific surgical tools, such as guides for bone surgery or dental implants, improving surgical precision.

- Medical Implants: Biocompatible materials, like medical-grade polyamide, allow for the creation of implants tailored to the patient’s anatomy.

- Medical Device Prototyping: SLS accelerates the development of innovative devices, such as wearable health monitors and diagnostic tools.

| Healthcare Benefits of SLS | Impact |

| Customization | Tailored solutions for individual patients |

| Faster production | Reduced lead times for critical medical equipment |

| Biocompatible materials | Safe and effective use in the human body |

Future Potential

SLS could enable organ scaffolding for tissue engineering and advanced drug delivery systems, ushering in a new era of regenerative medicine.

3. Automotive: Driving Innovation with Efficiency

The automotive industry is embracing SLS for its ability to create high-performance parts quickly and affordably. From prototyping to production, SLS is helping automakers innovate while reducing costs and environmental impact.

Key Applications in Automotive

- Rapid Prototyping: Designers and engineers can test concepts rapidly, allowing for faster design iterations and innovation.

- Functional Parts: End-use parts, such as air intake manifolds and interior components, are now being produced using SLS.

- Customization: Luxury and performance car manufacturers are using SLS to produce customized interior components for premium customers.

- Spare Parts: SLS makes it possible to produce low-volume spare parts on demand, reducing inventory costs and waste.

| Automotive Benefits of SLS | Impact |

| Rapid prototyping | Faster innovation cycles |

| Customization | Personalized options for premium customers |

| Low-volume production | Cost-effective manufacturing for niche models |

Future Potential

With the rise of electric vehicles (EVs), SLS could play a significant role in creating lightweight battery housings and thermal management systems.

Barriers to Adoption and How the Industry is Overcoming Them

SLS 3D printing is a revolutionary technology, but like any innovative solution, it faces several challenges. While its ability to create complex, durable, and functional parts has transformed industries, barriers such as cost, material limitations, and technical complexity have hindered its widespread adoption.

In this section, we will examine the key obstacles to SLS 3D printing adoption, the solutions the industry is implementing, and how these efforts are paving the way for broader acceptance. Whether you are a business owner exploring SLS or a professional in additive manufacturing, understanding these barriers and how they are being overcome is crucial for harnessing the full potential of this transformative technology.

1. High Equipment and Operational Costs

The Problem

One of the most significant barriers to SLS adoption is its high upfront cost. Industrial SLS machines are expensive, with many models priced above $100,000, making them a major investment for small and medium-sized businesses (SMBs). Additionally, operational costs, including materials, maintenance, and energy consumption, add to the financial burden.

| Cost Factor | Impact |

| High equipment costs | Limits access for startups and SMBs |

| Expensive materials | Increases per-part production costs |

| Maintenance and energy usage | Adds to long-term operational expenses |

The Solution

- Affordable Desktop SLS Machines: Companies like Formlabs and Sinterit are developing compact and reasonably priced SLS printers, with prices starting at around $10,000. These machines make SLS more accessible to smaller businesses and startups.

- Improved Material Efficiency: Advances in powder formulations and recycling techniques now allow for higher rates of powder reuse, reducing material waste and lowering costs.

- Cloud-Based and Outsourced Printing: Businesses can utilize SLS service providers to outsource production, eliminating the need for in-house equipment. Cloud-based manufacturing platforms enable companies to order parts without investing in costly hardware.

Key Takeaway

Cost is no longer the insurmountable barrier it once was. Smaller, more affordable SLS machines and outsourcing options are making the technology accessible to businesses of all sizes.

2. Limited Material Options

The Problem

While SLS offers greater material versatility compared to other additive manufacturing technologies, its range is still narrower than that of traditional manufacturing methods. Industries that require specialized materials, such as those with high conductivity, extreme heat resistance, or biocompatibility, may find current SLS materials insufficient.

| Material Limitation | Industry Impact |

| Limited availability of metals | Limits adoption in aerospace and automotive |

| Lack of biodegradable options | Challenges sustainability goals |

| Limited flexibility for electronics | Slows innovation in wearables and IoT |

The Solution

- Development of Advanced Materials: Material scientists are continuously expanding the library of SLS-compatible powders, including:

- High-performance polymers such as PEEK for aerospace and automotive.

- Bio-based and biodegradable polymers for eco-friendly manufacturing.

- Conductive materials for electronics and wearables.

- Open Material Ecosystems: Printer manufacturers are increasingly adopting open material platforms, allowing third-party developers to create custom powders tailored to specific industries.

- Material Partnerships: Collaborations between printer manufacturers and material suppliers are accelerating the development of industry-specific materials.

Key Takeaway

The SLS material ecosystem is rapidly expanding, and future breakthroughs will unlock applications in electronics, sustainability, and high-performance industries.

3. Technical Complexity and Knowledge Gaps

The Problem

Adopting SLS requires specialized knowledge of both the technology and its workflow. From understanding how to design for SLS (e.g., accounting for shrinkage and sintering behavior) to managing post-processing, the learning curve can be steep.

| Challenge | Impact |

| Lack of expertise | Slows adoption in non-specialist industries |

| Complex design requirements | Increases risk of failed prints |

| Post-processing difficulties | Adds time and cost to production |

The Solution

- Educational Initiatives: Training programs, certifications, and workshops are being offered by organizations like the Additive Manufacturing Users Group (AMUG) to help engineers and designers gain expertise in SLS.

- Simplified Software Tools: Modern design software now includes features that automate and optimize the SLS workflow:

- Topology optimization for lightweight designs.

- Automated support-free design checks to avoid failures.

- Simulation tools to predict and correct print errors before production.

- Outsourcing to Experts: Businesses new to SLS can partner with experienced service providers to handle design, printing, and post-processing while gaining hands-on experience.

Key Takeaway

The industry is closing the knowledge gap with better tools, training programs, and outsourcing options, enabling businesses to adopt SLS without requiring in-depth technical expertise upfront.

4. Post-Processing Challenges

The Problem

While SLS eliminates the need for support structures during printing, post-processing remains labor-intensive. Removing unfused powder, improving surface finishes, and dyeing or painting parts can significantly increase time and cost.

| Post-Processing Task | Impact |

| Powder removal | Labor-intensive and time-consuming |

| Surface finishing | Adds costs and delays |

| Part coloring or treatment | Requires additional equipment and expertise |

The Solution

- Automated Post-Processing Systems: Robotic systems and specialized equipment now handle tasks like powder removal and surface finishing, reducing manual labor. For example:

- Vibratory tumblers smooth surfaces.

- Automated dyeing systems color parts uniformly.

- Powder-Free Alternatives: Emerging technologies are exploring the possibility of powder-free SLS-like systems, which could eliminate post-processing altogether.

- Hybrid Solutions: Combining SLS with complementary technologies like surface coating machines or CNC machining can streamline finishing processes.

Key Takeaway

Automation and hybrid solutions are making post-processing faster and less costly, enhancing the scalability of SLS for production.

5. Environmental Concerns

The Problem

While SLS is more resource-efficient than traditional manufacturing, concerns remain about the environmental impact of unused powders, high energy consumption, and non-recyclable materials.

| Environmental Challenge | Impact |

| Non-recyclable powders | Contributes to waste |

| High energy consumption | Increases carbon footprint |

| Limited use of sustainable materials | Slows adoption in eco-focused industries |

The Solution

- Improved Powder Recycling: New systems allow for greater reuse of leftover powders, reducing material waste and costs.

- Energy-Efficient Printers: Manufacturers are developing low-energy SLS systems that minimize electricity usage while maintaining high performance.

- Sustainable Material Development: Bio-based and biodegradable powders are becoming more common, enabling the production of eco-friendly parts.

Key Takeaway

Sustainability is becoming a priority in SLS, with recyclable powders and energy-efficient systems addressing environmental concerns.

Conclusion: Breaking Down Barriers to SLS Adoption

Although SLS 3D printing faces challenges such as high costs, limited materials, technical complexity, and environmental concerns, the industry is making significant progress in overcoming these obstacles. Affordable printers, advanced materials, training programs, and automated systems are making SLS more accessible and a viable solution for businesses of all sizes.

As these barriers continue to fall, SLS is poised to become a mainstream manufacturing technology across industries. The key is to stay informed, invest in training, and explore new advancements that meet your needs.

Are you ready to break through these barriers and embrace the future of SLS 3D printing? The tools, resources, and innovations you need are already emerging.

The Future of SLS 3D Printing: Trends That Will Redefine Manufacturing

As Selective Laser Sintering (SLS) continues to evolve, it is clear that we are on the cusp of a manufacturing revolution. From technological advancements to the growing demand for sustainable solutions, SLS 3D printing is set to play a central role in shaping industries and redefining production.

Advancements in SLS Technology: Faster, Smarter, and More Efficient

The future of SLS lies in enhanced performance – machines that are faster, more intelligent, and more efficient than their predecessors. These technological advancements will bridge the gap between prototyping and large-scale manufacturing, making SLS a key player in mass production.

Key Technological Trends

- Multi-Laser Systems: Machines equipped with multiple lasers will dramatically increase printing speed by working simultaneously on different sections of the build plate. This will make SLS a viable solution for high-volume production, significantly reducing lead times.

- Real-Time Monitoring and AI Integration: AI-powered monitoring systems will enable real-time quality control, detecting and correcting errors during the printing process. Machine learning will also optimize laser paths and material usage, improving both efficiency and precision.

- Hybrid Manufacturing Solutions: Future machines may combine SLS with other technologies, such as CNC machining or SLA, to offer multi-process capabilities in a single system. This integration will allow for the production of parts with diverse requirements, such as high precision on one side and mechanical strength on another.

- Compact and Accessible Systems: Desktop SLS printers will become more powerful and affordable, making the technology accessible to smaller businesses and educational institutions.