A world where one could generate complex objects almost at the press of a button is SLA 3D printing technology. This fascinating process takes digital designs and turns them into solid physical objects with unprecedented accuracy. As we are at the dawn of a new era in manufacturing, it becomes imperative to be cognizant of the trends that are asserting their emergence in SLA 3D printing. It isn’t just about creating those cool gadgets-it’s transforming industries from healthcare to aerospace and opening up great solutions and possibilities.ajax.

“We’re going to discuss exciting developments that will shape the future of SLA 3D printing in this blog post. We’ll cover where developingset it apart from other 3D printing methods, and the new innovations on the horizon. It doesn’t matter if you’re a geek, an industry professional, or just curious about the future of manufacturing; this article will guide you on SLA technology’s transformative potentials in our world.”

Understanding SLA 3D Printing

SLA 3D printing, or Stereolithography, is a fascinating technology that has revolutionized the way we create objects. It’s like a magic wand for engineers and designers, allowing them to turn digital dreams into physical reality with remarkable precision. In this article, we’ll take a closer look at what makes SLA 3D printing so special, how it compares to other 3D printing technologies, and why it’s a game-changer in the world of manufacturing.

1.1 What is SLA 3D Printing?

Definition and Basic Principles

SLA 3D printing is a process that uses a laser to cure liquid resin into solid objects. Here’s how it works:

- Design Phase: A 3D model is created using computer-aided design (CAD) software.

- Layering: The model is sliced into thin layers.

- Curing: A laser beam traces each layer on the surface of a vat of resin, hardening it.

- Building: This process is repeated layer by layer until the entire object is formed.

Historical Context and Evolution of SLA Technology

SLA was the first 3D printing technology to be developed, invented by Charles Hull in 1986. Since then, it has evolved significantly:

- 1980s: Introduction of the first commercial SLA printer.

- 1990s: Improvements in laser technology and resin materials.

- 2000s: Development of desktop SLA printers, making the technology more accessible.

- Today: Advanced SLA printers with faster speeds and a wider range of materials.

1.2 Comparison with Other 3D Printing Technologies

SLA is just one of many 3D printing techniques. Let’s see how it stacks up against two popular methods: FDM and SLS.

| Technology | Process | Materials | Advantages | Disadvantages |

| SLA | Laser curing resin | Photopolymer resins | High precision, smooth surface finish | Limited material options, post-processing required |

| FDM | Extruding thermoplastic | Thermoplastics | Cost-effective, versatile | Lower precision, visible layer lines |

| SLS | Laser sintering powder | Nylon, metals | Strong, durable parts | Expensive, rough surface finish |

Advantages and Disadvantages of SLA Over Other Methods

Advantages:

- High Precision: SLA can produce intricate details and smooth surfaces, making it ideal for prototypes and models.

- Versatile Applications: Used in industries like healthcare, automotive, and consumer goods.

Disadvantages:

- Material Limitations: Primarily uses photopolymer resins, which may not be suitable for all applications.

- Post-Processing: Requires additional steps to clean and cure the printed parts.

In conclusion, SLA 3D printing stands out in its precision and versatility, notwithstanding some constraints added on holistic material offerings and post-processing. Given the continued development of technology, more of such challenges are summarized with promise for further applications and innovation. Whether you create a prototype with some good intricacy or just any sophisticated component, you should have enough information on SLA 3D printing to recognize its full potential.

Current Trends in SLA 3D Printing

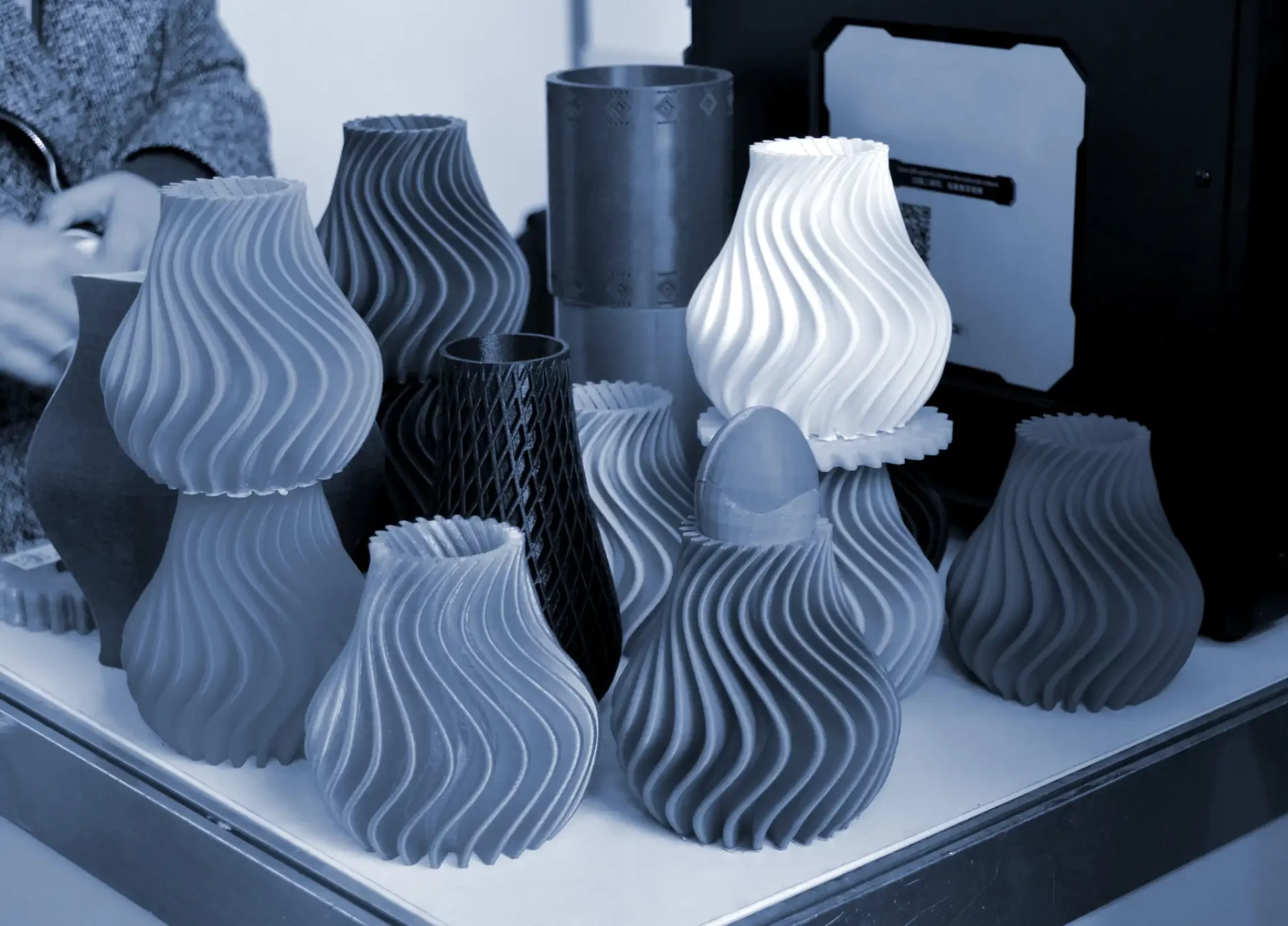

SLA technology is continuously advancing with intense developments that dare to promise special functionalities and operations. Generally speaking, these advances are both strengthening SLA’s potency and providing new opportunities in several industries. The article will discuss the prevailing trends in the SLA 3D printing space, namely speed improvements, material advances, and technology integration.

2.1 Speed Enhancements

One of the most exciting developments in SLA 3D printing is the improvement in printing speeds. Faster production times mean quicker prototyping and manufacturing, which is crucial for industries that rely on rapid iteration and development.

Parallel Processing and Its Impact on Production Times

Parallel Processing is a technique where multiple parts of a model are printed simultaneously. This approach significantly reduces the overall print time. Here’s how it works:

- Multiple Lasers: Utilizing more than one laser to cure different sections of the resin at the same time.

- Segmented Printing: Dividing the print bed into sections that can be processed simultaneously.

Benefits of Parallel Processing:

- Increased Efficiency: More parts can be produced in a shorter time frame.

- Cost-Effective: Reduces energy consumption and operational costs.

Innovations in Curing Methods That Reduce Print Time

Innovative Curing Techniques have emerged, enhancing the speed of SLA printing:

- Continuous Liquid Interface Production (CLIP): A method that continuously cures layers without stopping, resulting in faster prints.

- High-Intensity Lasers: Using powerful lasers to cure resin more quickly and efficiently.

2.2 Material Advancements

Material innovation is at the heart of SLA 3D printing’s growth. New resins and materials are expanding the capabilities and applications of this technology.

Introduction of Smart Resins and Functional Materials

Smart Resins are materials engineered to have specific properties that respond to environmental changes, such as:

- Temperature Sensitivity: Resins that change properties with temperature shifts.

- Biocompatibility: Materials safe for medical applications, like implants.

Functional Materials include resins with enhanced mechanical properties for specific uses:

- Flexible Resins: Ideal for creating rubber-like parts.

- High-Strength Resins: Suitable for industrial applications requiring durability.

Multi-Material Printing Capabilities and Their Applications

Multi-Material Printing allows for the creation of complex objects with different materials in a single print job. This capability is revolutionizing design and manufacturing:

- Complex Assemblies: Printing parts with varying properties, like hard and soft sections, in one go.

- Innovative Designs: Enabling the creation of products with integrated functions, such as hinges or joints.

2.3 Integration of Advanced Technologies

The integration of cutting-edge technologies like AI and sensors is pushing the boundaries of what SLA 3D printing can achieve.

Real-Time Monitoring with Integrated Sensors

Integrated Sensors provide real-time feedback during the printing process, ensuring quality and precision:

- Error Detection: Identifying and correcting issues during printing, reducing waste.

- Process Optimization: Adjusting parameters on-the-fly for optimal results.

Use of AI and Machine Learning for Process Optimization

AI and Machine Learning are transforming SLA 3D printing by optimizing processes and enhancing efficiency:

- Predictive Maintenance: Using AI to predict when parts need maintenance, minimizing downtime.

- Automated Adjustments: Machine learning algorithms that automatically tweak settings for the best outcomes.

In a nutshell, a wide spectrum of recent trends in SLA 3D printing is contingent upon pushing the technology for speed, versatility, and intelligence. These advances can provide improved SLA printing efficiency, but they also have the ability to help SLA find wider application in industry. While we continue to look at those innovations, it will soon begin to dawn that SLA 3D printing could usher in a new revolution in the world of manufacturing and design.

Future Directions for SLA Technology

Looking forward into the future, we expect SLA 3D printing to transform tremendously, which could provide a redefinition for allowed manufacturing as well as beyond. The integration of nanotechnology, advancements in bioprinting, and the exploration of space application possibilities will alter the streets of SLA technology…. We’ll explore the possibilities for exciting future directions within which these technologies might develop and how they might change the world.

3.1 Nanotechnology in SLA Printing

Nanotechnology is a field that deals with materials and devices on an atomic or molecular scale. When combined with SLA 3D printing, it offers incredible potential for creating materials with enhanced properties.

Potential Benefits of Integrating Nanotechnology

Nanotechnology can revolutionize SLA printing in several ways:

- Enhanced Material Strength: Incorporating nanoparticles can create resins with superior mechanical properties.

- Improved Conductivity: Developing conductive materials for electronic applications.

- Tailored Properties: Creating materials with specific characteristics, such as hydrophobicity or thermal resistance.

Examples of Enhanced Material Properties Through Nanotechnology

- Nanocomposites: Resins infused with carbon nanotubes for increased strength and durability.

- Antimicrobial Surfaces: Using silver nanoparticles to create surfaces that resist bacterial growth.

3.2 Bioprinting Developments

Bioprinting is an exciting frontier in SLA technology, with the potential to revolutionize healthcare by creating tissues and organs.

Current State of Bioprinting with SLA Technology

Bioprinting involves using SLA technology to print biological materials:

- Tissue Engineering: Creating scaffolds that support cell growth for tissue regeneration.

- Drug Testing Models: Developing accurate models for testing new drugs.

Future Implications for Healthcare and Organ Transplantation

The future of bioprinting holds incredible promise:

- Organ Printing: The potential to print fully functional organs for transplantation, reducing the need for donors.

- Personalized Medicine: Creating patient-specific tissues and organs based on individual genetic profiles.

3.3 Space-Based Applications

As humanity sets its sights on space exploration, SLA 3D printing offers unique opportunities for manufacturing in extraterrestrial environments.

Exploration of SLA Printing in Space Missions

Space Missions can benefit from SLA technology in several ways:

- On-Demand Manufacturing: Creating tools and parts on-site, reducing the need for extensive cargo.

- Resource Utilization: Using local materials, like lunar or Martian soil, as printing materials.

Benefits of On-Demand Manufacturing in Extraterrestrial Environments

- Reduced Payloads: Lowering the weight and cost of space missions by manufacturing parts as needed.

- Adaptability: Quickly producing custom solutions to unforeseen challenges in space.

In summary, the future directions of SLA 3D printing brim with exhilarating possibilities, from advanced materials processed with nanotechnology to health care revolutionized through bioprinting to space exploration with digital on-demand manufacturing, where SLA technology will have its crucial say in arrival into the future. At the same time these advances are growing, it provides a clarity of vision of SLA 3D printing becoming a pivotal technology in altering the landscape of industries and enhancing lives.

Industry Impact of SLA 3D Printing

SLA 3D printing is not only an amazing technology; it is also a true force for change in virtually every industry on the planet. Ranging from a handful of processes transforming the manufacturing industry to altering the boundaries of the healthcare and architectural industries, SLA technology has an extensive and groundbreaking effect. In this article, we’ll elaborate on how SLA 3D printing is making a big splash across the board in various sectors and the impact each brings with them.

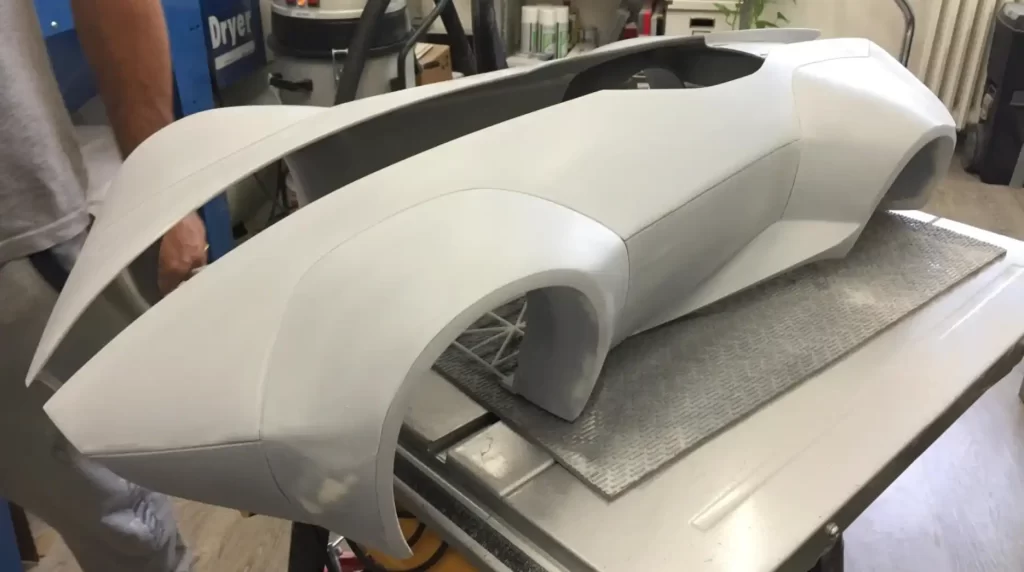

4.1 Manufacturing Sector

The manufacturing industry is at the forefront of adopting SLA 3D printing, leveraging its precision and versatility to enhance production processes.

How SLA is Revolutionizing Prototyping and Production Processes

Prototyping and Production are being transformed by SLA technology in several ways:

- Rapid Prototyping: Quickly creating detailed prototypes to test designs and concepts.

- Custom Tooling: Producing specialized tools and jigs tailored to specific manufacturing needs.

Benefits for Manufacturers:

- Reduced Time-to-Market: Faster prototyping and iteration lead to quicker product launches.

- Cost Savings: Minimizing waste and material usage through precise production techniques.

Case Studies from Automotive and Aerospace Industries

Automotive Industry:

- Ford: Utilizes SLA for rapid prototyping of car parts, reducing development time significantly.

- BMW: Employs SLA to create custom tools, improving manufacturing efficiency.

Aerospace Industry:

- Airbus: Uses SLA to produce lightweight components, enhancing fuel efficiency and performance.

- NASA: Explores SLA for creating parts with complex geometries that traditional methods can’t achieve.

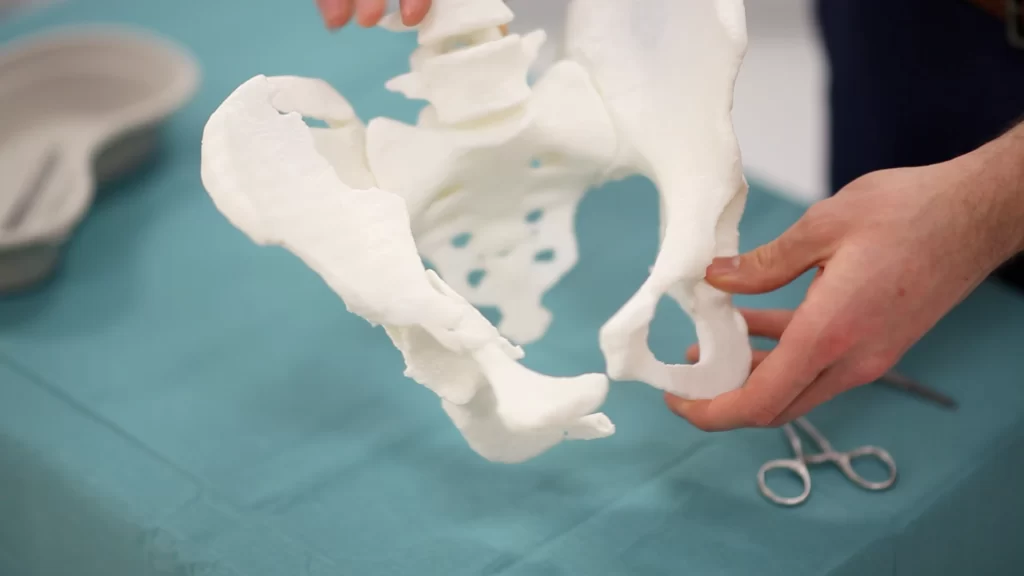

4.2 Healthcare Innovations

In the healthcare sector, SLA 3D printing is driving innovations that improve patient outcomes and customize medical solutions.

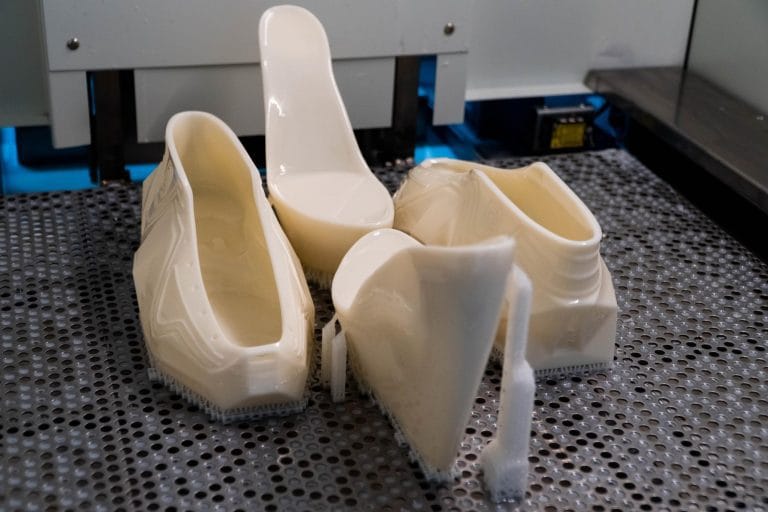

Custom Medical Devices and Prosthetics Produced via SLA

Medical Devices and Prosthetics benefit greatly from SLA’s precision:

- Tailored Prosthetics: Creating prosthetics that fit patients perfectly, enhancing comfort and functionality.

- Surgical Guides: Producing accurate guides for complex surgeries, improving precision and outcomes.

Impact on Surgical Planning and Patient-Specific Solutions

Patient-Specific Solutions are becoming more accessible:

- Anatomical Models: Printing models of patient anatomy for pre-surgical planning, reducing risks.

- Implantable Devices: Developing implants that match the patient’s unique anatomical structure.

4.3 Architectural Applications

Architecture is another field where SLA 3D printing is making significant strides, enabling the creation of intricate designs and models.

Use of SLA in Creating Complex Architectural Models

Architectural Models benefit from SLA’s ability to produce detailed and accurate representations:

- Conceptual Models: Bringing architectural visions to life with precise scale models.

- Detailed Facades: Creating intricate facade designs that showcase architectural creativity.

Potential for Constructing Buildings Using Large-Scale SLA Printers

Large-Scale Printing offers exciting possibilities for construction:

- On-Site Printing: Building components directly on-site, reducing transportation costs and time.

- Innovative Designs: Allowing for complex structures that traditional methods can’t achieve.

In conclusion, SLA 3D printing is transforming the industries. SLA technology, by advancing manufacturing processes, assisting healthcare innovations, and driving architectural creativity, turns into a powerful force transforming the future. As these industries keep on accepting SLA printing, the potential for further advancements and ameliorations is growing more evident.

The Transformative Potential of Emerging Trends in SLA Printing

As we discovered in our Xia series articles, SLA 3D printing technology is pioneering a new era of Might. From its unmatched precision to its vast applications across industries, SLA printing is sure to bring fresh energy and innovation. To conclude, we will summarize the transformative potential of the upcoming trends in SLA printing and speculate on what future will hold.

The future is really bright for SLA 3D printing as vast innovative avenues have just opened up. With technology evolving, one expects SLA printing to play a bigger role in boosting efficiency, creativity, and sustainability in other sectors.