In the dynamic world of manufacturing, the evolution of technology continuously reshapes how we conceive, create, and cost our processes. Among these technologies, Stereolithography (SLA) 3D printing emerges as a beacon of innovation, particularly in the industrial sector where precision and scalability are paramount. This sophisticated method, known for transforming liquid resins into solid plastics through a laser-based curing process, is not just about pushing the boundaries of what’s possible; it’s also about understanding the economic implications that come with its adoption.

Why does SLA 3D printing matter so much in today’s industrial landscape? The answer lies not only in the quality and intricacy of the objects it can produce but also in the potential cost savings and operational efficiencies it offers. As industries strive to reduce waste, shorten production cycles, and improve product performance, SLA 3D printing stands out as a critical tool in the arsenal of modern manufacturing techniques.

However, integrating SLA 3D printing into an industrial setting is not without its costs. From the initial investment in machinery to ongoing expenses such as materials and maintenance, the financial outlay can be substantial. This article aims to demystify the cost structure of industrial SLA 3D printing, guiding you through the initial, ongoing, and operational costs, and highlighting the cost-effectiveness of this technology in a competitive market. By the end, you’ll have a comprehensive understanding of why and how SLA 3D printing could be the game-changer for your manufacturing needs.

In the following sections, we will explore each cost category in detail, providing insights into how businesses can not only manage but also capitalize on these expenses to maximize their return on investment.

The Initial Investment: Unpacking the Costs of Industrial SLA 3D Printers

When considering the adoption of Stereolithography (SLA) 3D printing in an industrial setting, the first hurdle that businesses encounter is the initial cost. This investment not only encompasses the price of the printers themselves but also the necessary ancillary equipment and software to run them effectively. Understanding these costs in detail is crucial for businesses to make informed decisions about integrating this technology into their manufacturing processes.

Price Range of SLA Printers

Industrial SLA 3D printers represent a significant technological advancement over their desktop counterparts, designed for robustness, larger build volumes, and finer details, which naturally comes at a higher cost. The market offers a wide range of SLA printers, with prices generally dictated by the size, precision, and speed of the printer.

Entry-Level Industrial Printers: Starting from ZONGHENG3D’ SuperMaker SLA-300 suited for entry-level manufacturers, entrepreneurs, and educational institutions to achieve low-cost complex product design verification and pre-mold development preparation.

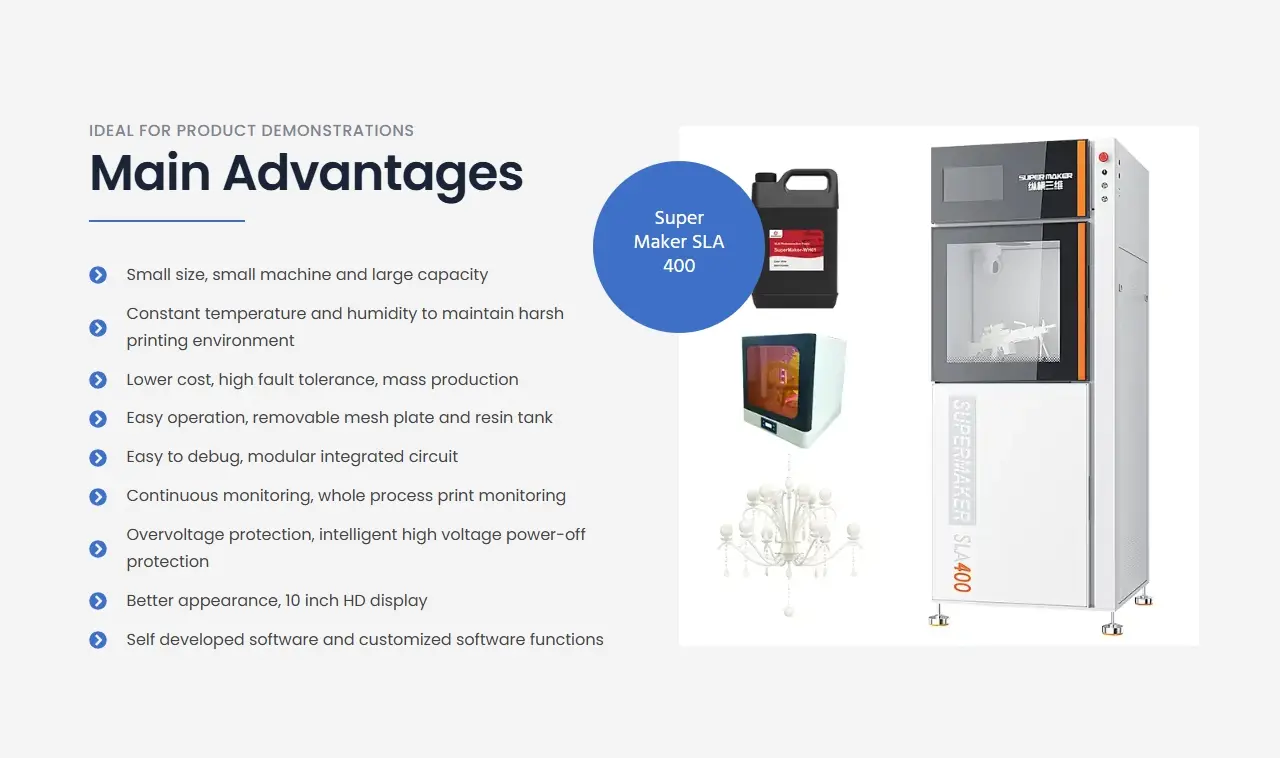

Mid-Range Models: ZONGHENG3D’ SuperMaker SLA-400 Priced between$17,000 to $27,000, these printers offer greater versatility and are capable of handling medium-scale production with more refined details.

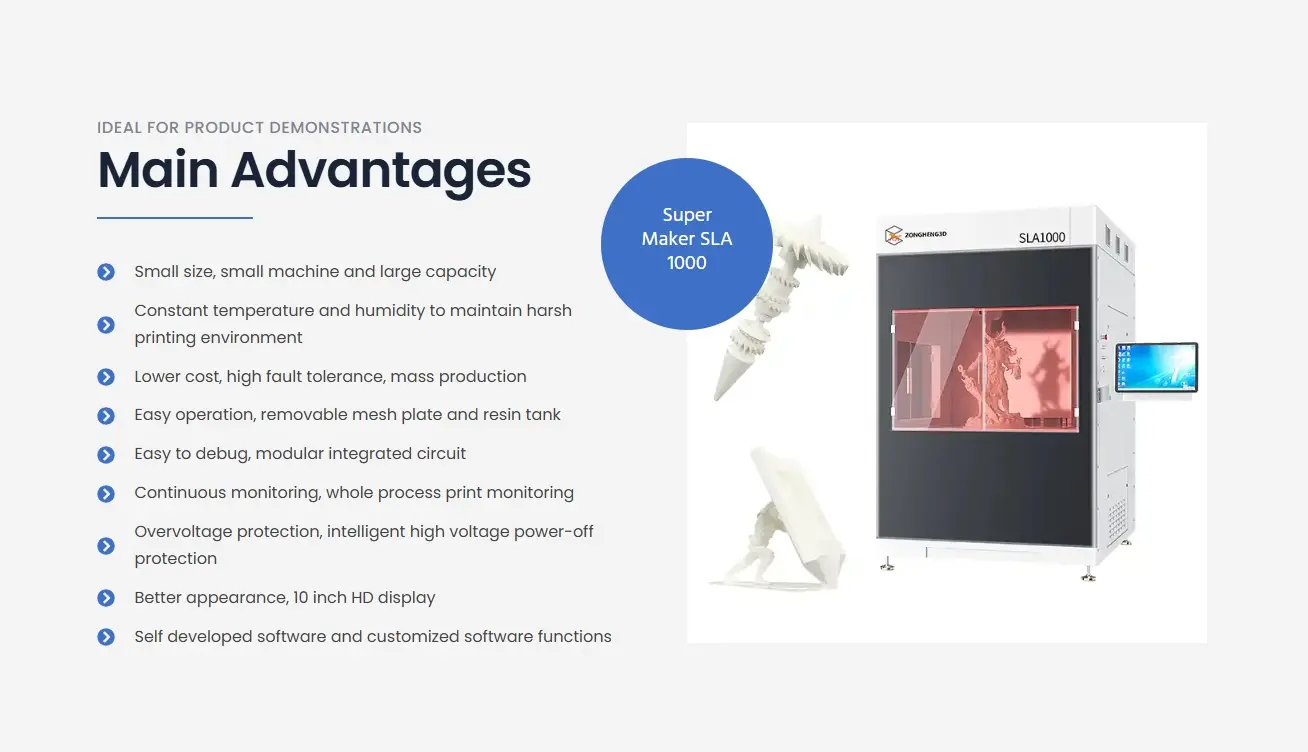

High-End Models: These can exceed ZONGHENG3D’ SuperMaker SLA-1000 are typically used in high-volume, high-precision industrial applications. They boast the fastest print speeds, largest build sizes, and highest resolution.

Detailed Overview of ZONGHENG 3D’s SLA Models

To illustrate, let’s consider two models from ZONGHENG 3D—a well-regarded manufacturer in the industrial SLA printer market:

1.SLA300 Model

Price: Approximately $18,000

Build Volume: 300×300×300mm

Features: High-resolution printing with minimal layer visibility, equipped with a built-in temperature and humidity control system, adaptable to a variety of work environments, suitable for detailed prototypes and end-use parts.

2.SLA400 Model

Price: Around $17,000 to $27,000

Build Volume: 400×400×350mm

Features: Enhanced speed and a larger build volume, ideal for automotive and aerospace components requiring precision.

3.SLA1000

Price: Around $60,000

Build Volume: 1000×1000×600mm

Features: Capable of large-scale batch printing, ideal for industrial manufacturing sectors. Common applications by previous clients include automotive center console designs, door panels; and in aviation, engine auxiliary components and pipes.

Additional Equipment Costs

Beyond the printers, there are several ancillary costs associated with setting up an SLA printing station:

- Necessary Accessories: Including resin tanks, build platforms, and post-processing equipment such as UV curing chambers and wash stations. These are essential for the operation of SLA printers and can add up to 10-20% of the printer’s cost.

- Software and Licensing Fees: SLA printers require sophisticated software to prepare models for printing and manage the printing process. These software solutions can range from 500to500to2,000 per year depending on the complexity and features offered.

Considerations for Total Initial Cost

Here is a simplified breakdown of the total initial costs you might expect when setting up an SLA printing operation:

| Component | Cost Range |

| SLA Printer | 20,000~60,000+ |

| Accessories | 200−500−2000+ |

| Software Licensing | 200~500/year |

The initial costs of integrating SLA 3D printing into an industrial environment are considerable but vary widely based on the scale and specifics of the intended use. Companies must evaluate their needs against the capabilities of different SLA printers and consider the full range of necessary expenditures, including those for additional equipment and software. This financial insight lays the groundwork for businesses to assess whether SLA 3D printing is a viable and cost-effective solution for their manufacturing challenges.

Navigating the Waters of Ongoing Costs in Industrial SLA 3D Printing

While the initial investment in Stereolithography (SLA) 3D printing technology can be significant, the ongoing costs play a crucial role in the overall economic feasibility of integrating this technology into industrial production. Understanding these recurring expenses is vital for companies to effectively budget and strategize for long-term operational efficiency.

Resin and Consumables

The lifeblood of any SLA 3D printer is the resin. These photopolymer resins come in various formulas, each suited for different applications and offering varying levels of durability, flexibility, and detail. The costs of these materials can vary significantly based on the type and quality required.

- Entry-Level Resin Costs: Typically used for basic prototypes and non-functional parts. Prices range from $25 ~ $35 /KG.

- Professional Resin Costs: These are high-performance resins capable of producing industrial-grade parts. Depending on the properties (e.g., temperature resistance, mechanical strength), costs can range from $70 ~ $90 /KG.

Comparison of Resin Types

Understanding the trade-offs between different types of resins is critical for managing costs effectively. Here, we’ll delve into a Cost vs. Quality Analysis and a case study to illustrate these principles.

Cost vs. Quality Analysis

- Standard Resins: Cheaper but less durable, suitable for visual models.

- Engineering Resins: Pricier, designed for functional parts requiring high precision and strength.

- Specialty Resins: Highest cost, used for specific applications like high-temperature environments or biocompatible products.

Case Study: Industrial Application

Consider a company specializing in automotive prototypes using SLA 3D printing. By switching from standard to engineering resins, they noticed a 25% increase in the cost of materials but a reduction in post-processing and failure rates, leading to overall savings in time and costs.

Operational Costs Breakdown

The ongoing operational expenses encompass more than just materials. They include:

- Maintenance: Regular upkeep and occasional repairs are necessary to keep SLA printers running efficiently.

- Energy Consumption: SLA printers, particularly industrial models, can consume a considerable amount of electricity.

Maintenance Expenses

Regular maintenance is crucial to prevent costly repairs and downtime. Typical maintenance costs can include:

- Regular Cleaning and Calibration: Necessary for optimal printing conditions, costing about $200~$500 annually (Primarily labor costs).

- Unexpected Repair Costs: Depending on the issue, repairs can range from a few hundred to several thousand dollars.

Energy Consumption

The power usage of SLA printers can vary, but industrial models typically use between 1 to 3 kW per hour. With energy prices averaging 0.10to0.10to0.20 per kWh, operating an SLA printer for 2,000 hours a year could cost between 200to200to1,200 annually.

Cost-SavingTips

To manage and potentially reduce these ongoing costs, consider the following strategies:

- Optimize Print Jobs: Grouping smaller jobs together can reduce resin and power usage.

- Regular Maintenance: Keeping the printer in top condition prevents more significant, costly issues.

- Select Appropriate Resin: Choose the best resin for the job to avoid waste and reduce the need for reprints.

Managing operational costs effectively is crucial for leveraging the full potential of industrial SLA 3D printing. By understanding and optimizing maintenance routines, energy consumption, and leveraging the inherent efficiencies of SLA technology, businesses can improve their bottom line and enjoy the advanced capabilities of 3D printing with financial savvy.

Evaluating the Cost-Effectiveness of Industrial SLA 3D Printing

As businesses weigh the advantages and operational costs of integrating Stereolithography (SLA) 3D printing into their production processes, it becomes essential to understand the broader economic implications. This section explores the cost-effectiveness of SLA 3D printing, focusing on its potential for reducing post-processing costs, delivering high-quality surface finishes, and offering long-term economic benefits in industrial applications.

Low Post-Processing Costs

One of the significant advantages of SLA 3D printing is the minimal post-processing required compared to other 3D printing technologies. This efficiency can lead to substantial savings in both time and labor, crucial factors in high-volume production environments.

Minimal Finishing Requirements

- Surface Quality: SLA printers produce parts with smooth surfaces and fine details, reducing the need for extensive sanding or surface treatments.

- Support Removal: SLA support structures are generally easier to remove and leave less residue on the final product, minimizing damage during clean-up and reducing the need for additional finishing work.

Time and Labor Savings

- Efficiency: The streamlined post-processing of SLA prints allows for faster turnaround times from printing to final product readiness.

- Labor Costs: Reduced manual labor for finishing can significantly lower the overall production costs, particularly beneficial in labor-intensive sectors.

High Surface Finish Quality

The high-resolution capabilities of SLA 3D printing make it an ideal choice for applications where aesthetic details and precision are paramount.

Benefits in Industrial Applications

- Visual Prototyping: For industries such as automotive and consumer goods, the high-quality finish of SLA prints is perfect for creating detailed prototypes that closely mimic the final product.

- Customization: The precision of SLA allows for the production of custom parts and tools with complex geometries that would be cost-prohibitive or impossible with traditional manufacturing.

Long-term Economic Advantages

Investing in SLA 3D printing technology offers several long-term economic benefits that can justify the initial and operational costs.

Scalability and Flexibility

- Adaptability: SLA printing setups can be easily scaled or adapted to different production volumes or materials, allowing businesses to respond quickly to market changes or product demand without significant additional investment.

- Material Efficiency: SLA printing reduces material waste compared to subtractive manufacturing methods, offering cost savings in raw materials.

Cost Recovery Through Innovation

- Product Development: Faster prototyping and the ability to test concepts quickly reduce the time and cost associated with new product development.

- Market Response: The agility provided by SLA technology enables companies to react swiftly to market needs or customer feedback, potentially leading to higher sales and customer satisfaction.

The cost-effectiveness of SLA 3D printing in industrial applications extends beyond the simple calculation of print costs versus traditional manufacturing costs. It includes the broader impacts on the production lifecycle, including reduced labor and material costs, enhanced product quality, and the ability to innovate rapidly. By considering these factors, businesses can make informed decisions about integrating SLA 3D printing into their production strategies, ensuring that they capitalize on its strengths while managing its costs effectively. This strategic approach not only enhances operational efficiency but also positions companies for future growth and success in a competitive marketplace.

Future Trends in Industrial SLA 3D Printing

As the technology evolves, several trends are likely to influence the cost and application of SLA 3D printing in the industry:

- Advancements in Resin Technology: Ongoing research and development are likely to produce new resins that offer greater durability and versatility at lower costs, broadening the range of applications for SLA printing.

- Energy Efficiency Improvements: As environmental sustainability becomes a greater concern, SLA printers are expected to become more energy-efficient, which will further reduce operational costs.

- Integration with Industry 4.0: SLA 3D printing is set to become a key component of the smart factory environment, integrating with other digital manufacturing technologies to enhance automation and data exchange across the production lifecycle.

Embracing SLA 3D Printing in Your Business

For businesses considering SLA 3D printing, the decision should be based on a comprehensive analysis of how the technology fits into their existing manufacturing ecosystem and future growth plans. The ability to produce complex parts quickly and cost-effectively is a compelling advantage, particularly for industries where customization and rapid prototyping are critical.

Conclusion

In conclusion, while the upfront and operational costs of SLA 3D printing can be significant, the long-term benefits—ranging from reduced cycle times and material costs to improved product quality and market responsiveness—make it a worthwhile investment for businesses looking to innovate and stay competitive in the fast-evolving industrial landscape. As we look towards the future, the ongoing advancements in SLA technology promise to further enhance its attractiveness and accessibility, making now an opportune time to consider how it can be integrated into your production strategies.