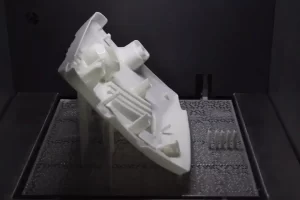

Gone are the days of 3D printed parts that look obviously layered and feel flimsy in your hands. With the rise of Stereolithography (SLA) 3D printing technology, you can now produce detailed 3D printed objects with smooth, intricate details and excellent mechanical properties.

SLA 3D printing works by using an ultraviolet laser to cure and solidify liquid photopolymer resin layer-by-layer until the object is complete. The high laser precision enables remarkably fine resolution, so SLA can create crisper details and more attractive surface finishes than other popular 3D printing methods like Fused Deposition Modeling (FDM). Parts also come out smooth, robust, and ready to handle functional loads.

But just how much better is SLA than other forms of 3D printing? In this article, we’ll compare the advantages of SLA 3D printing to highlight why it has emerged as a top choice technology for applications from rapid prototyping to end-use production. We’ll specifically look at how SLA beats out other technologies in categories like resolution, mechanical properties, materials, precision, and surface finish.

By the end, you’ll understand exactly why SLA produces the highest quality 3D printed parts suitable for diverse applications from aerospace components to intricate jewelry. Let’s explore the details of this powerful 3D printing method!

Higher Resolution and Detail – A Key Benefit of SLA 3D Printing

One of the main advantages of SLA 3D printing is the incredibly high resolution and level of detail it can achieve. Let’s take a closer look at how SLA attains much finer details than other 3D printing methods.

How SLA 3D Printing Works

SLA utilizes photopolymer resin as the printing material. This resin is contained in a vat where it is exposed to precise ultraviolet laser beams.

- The UV laser solidifies each layer of the resin in a process called photopolymerization

- The build platform lowers, more resin covers the top, and the laser cures the next layer

- This repeats until the full object is constructed from the liquid resin

The precision of the laser allows for very thin 25-100 micron layers. FDM printers deposit thicker melted plastic layers at 100-400 microns.

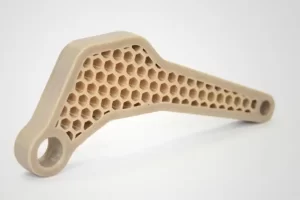

Higher Resolution Results

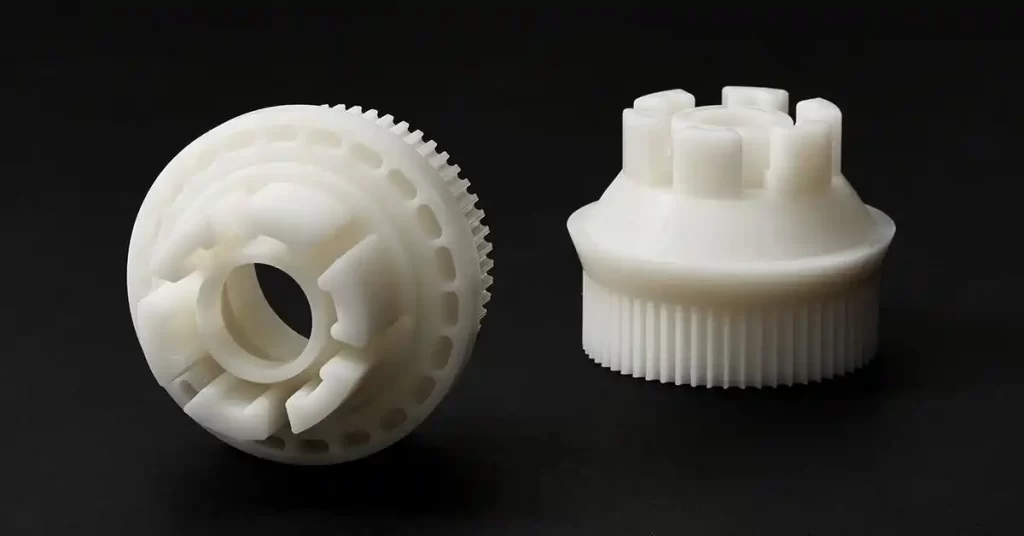

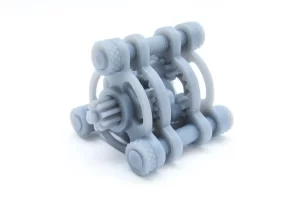

With such thin layers, SLA can produce very intricate details and achieve exceptionally high resolution down to 50 microns.

- Tiny details like embossed text or the thinnest of walls can be replicated.

- Printed objects have smooth, finished looking surfacesinstead of a layered, striated appearance.

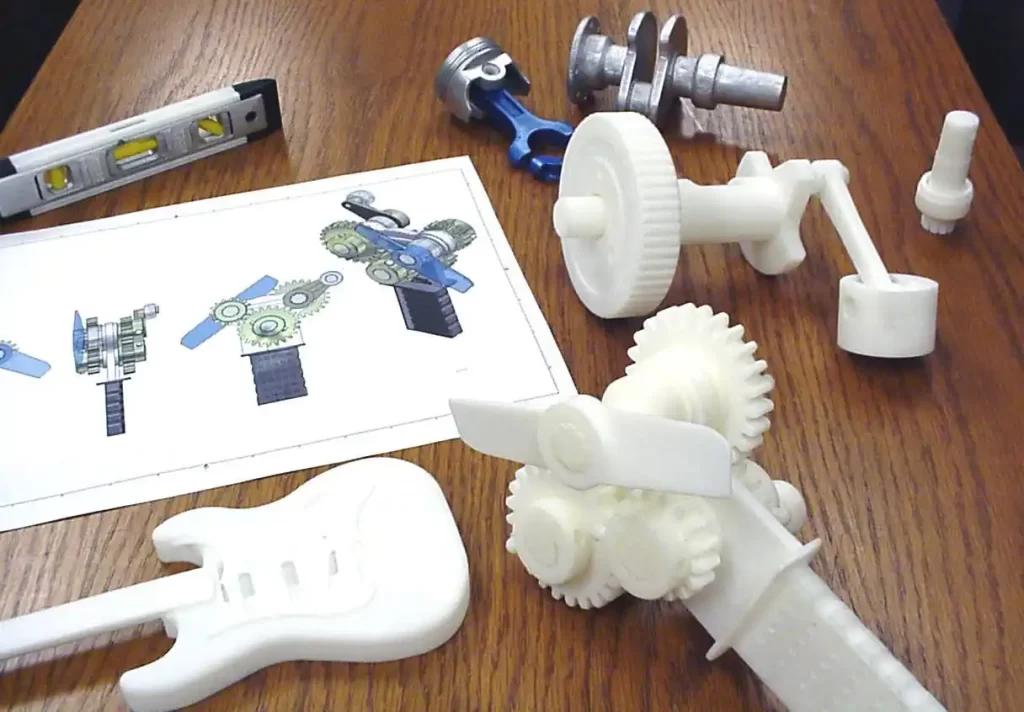

- Moving parts with tight tolerances like gears or joints assemble precisely.

This enables applications like:

- Jewelry with delicate filigree or thin walls

- Dental aligners and appliances with tiny crimps and indentations

- Intricate art sculptures with fine details

No other common 3D printing process can match SLA’s stunning resolution capabilities. This makes it the top choice for applications requiring a high level of detail and finesse.

The Strength of SLA 3D Printed Parts

SLA also stands out for its ability to create strong, functional 3D printed parts suitable for prototypes or end-use applications. Let’s examine why SLA parts have excellent mechanical properties.

Uniform Part Structure

The key is that SLA produces uniform plastic parts with consistent material properties throughout. This is because:

- Each layer is fully cured by the UV laser

- This eliminates weak points between layers

- Parts have evenly distributed photopolymer material

In contrast, FDM printing leaves small gaps and weaknesses between the extruded filament layers.

High Tensile Strength

SLA printed parts can have tensile strength comparable to injection molded plastics.

- Tensile strength measures resistance to breaking under tension.

- SLA parts stretching strength typically ranges from 50-70 MPa.

- This approaches ABS at 40 MPa and exceeds PLA at around 50 MPa.

Engineers can even formulate photopolymer resins to achieve specific mechanical properties like:

- Heat resistance up to over 200°C

- Flexibility and impact resistance

- Bio-compatibility for medical uses

Functional Applications

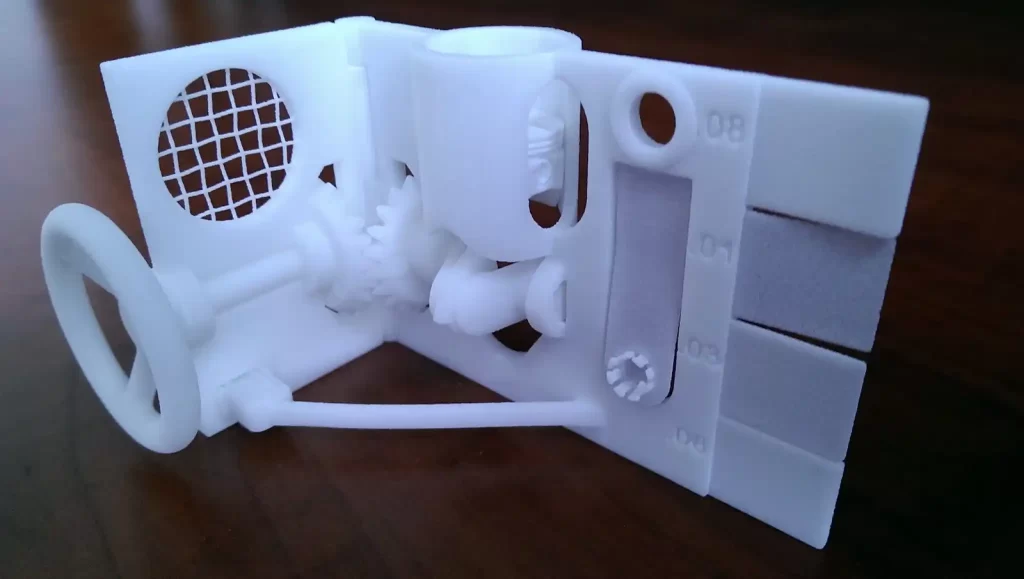

This high strength enables many functional uses for SLA printed parts:

- Functional prototypes– test models close to production quality

- Manufacturing tools– jigs, fixtures, gauges

- End-use parts– drones, plastic hinges, tech components

So if you need strength for prototyping or production, SLA is a top choice over other 3D printing methods.

Diverse Material Options with SLA 3D Printing

SLA 3D printing also provides more diverse material options compared to other methods like FDM. Let’s look at the range of materials possible with SLA.

Photopolymer Resin Types

There are many formulations of photopolymer resin available for SLA printing, including:

- Standard Resins– For detailed models and prototypes

- Engineering Resins– Heat and chemical resistant, flexible, bio-compatible

- Composite Resins– Mix in ceramic, wood, or metal particles

This gives SLA capabilities beyond basic plastics like ABS and PLA for FDM.

Specialized Applications

Medical

Custom surgical guides, dental appliances

Automotive

Under-the-hood prototypes with heat resistance

Aerospace

Lightweight components with high strength

Consumer

Realistic prototypes with multiple materials

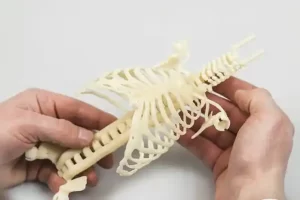

Composite Capabilities

Composite resins allow mixing in particles to achieve unique properties:

Plastic-ceramic

Improved thermal and mechanical properties

Plastic-wood

Wood appearance with polymer strength

This facilitates applications like customized metal-infused plastic parts.

Customized Resins

SLA resin can even be formulated for highly specific needs:

- Tuning mechanical properties like tensile strength

- Optimizing thermal abilities and glass transition temperatures

- Achieving certification for biocompatibility

So SLA provides far more material options compared to the limited plastics in FDM printing.

The Precision of SLA 3D Printing

Another key advantage of SLA 3D printing is the unmatched precision and consistency it offers compared to other methods.

Exact Reproduction

The SLA process results in extremely precise, predictable outcomes:

- Each layer is uniformly cured by the laser

- This minimizes defects like layer misalignment or warping

- The final parts closely match the original CAD models

Dimensional accuracy is within 0.1-0.2% deviation.

Reliable Outcomes

This precision enables reliable application-based results:

Aerospace

Turbine blades replicated precisely

Quality Control

Measurement tools like go/no-go gauges

Medical

Surgical guides that fit anatomy correctly

Scientific

Micron-precise lab equipment

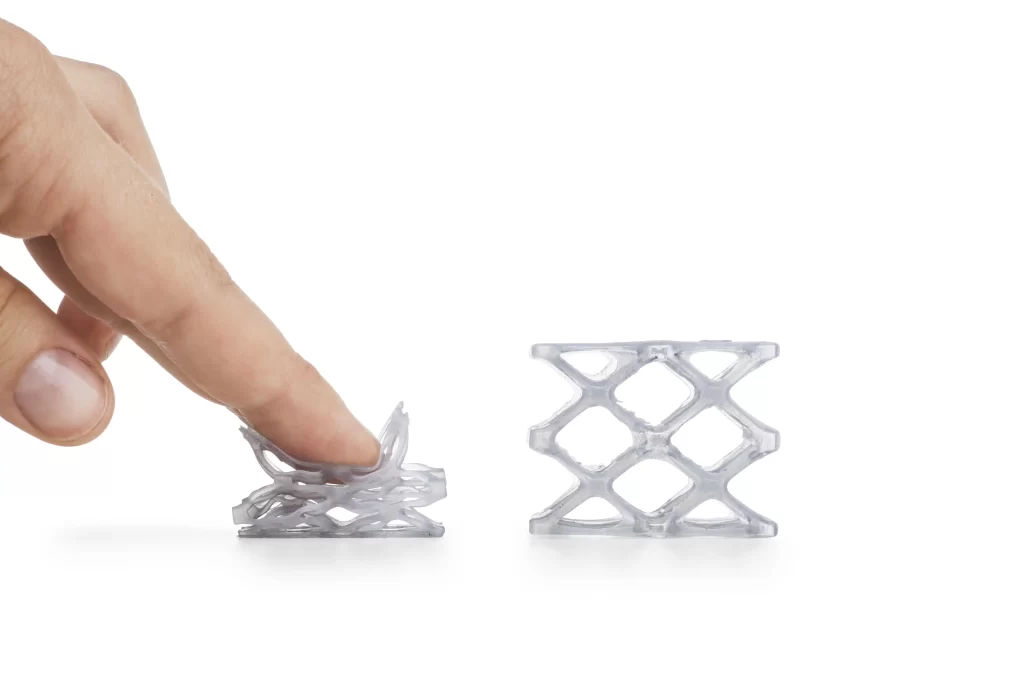

Easy Post-Processing

Unlike FDM, SLA parts come out smooth and complete:

- No layer misalignments requiring sanding

- No warping or shrinkage issues

- Minimal need for filler, painting, or post-curing

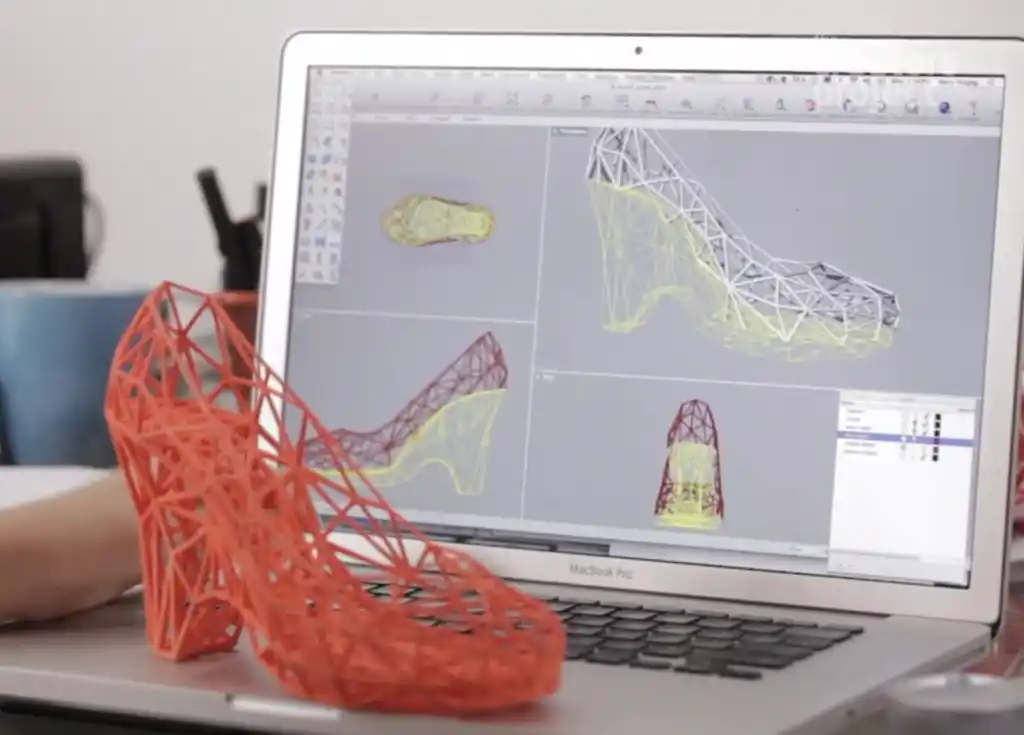

Quick Iterations

The precision lends itself well to agile product development:

- Rapid prototypes with no deviations from CAD

- Identify and fix issues faster

- Quickly test new iterations

SLA is unmatched for precision prototypingapplications requiring reliability and consistency.

Smooth Surface Finishes with SLA 3D Printing

One of the most visually impressive advantages of SLA 3D printing is the incredibly smooth surface finishes it can produce.

No Layer Lines

Unlike the obvious layer lines of FDM 3D printing, SLA parts have a continuous smooth finish.

- Each photopolymer layer is precisely cured by the laser

- This eliminates any visible stair-stepping effect

- Surfaces come out glossy smooth

Parts have a polished, injection molded-like appearance.

Minimal Post-Processing

The smooth surfaces require almost no manual post-processing:

- No sanding or filling layer lines

- No acetone baths or vapor smoothing

- Just some light sanding to remove supports

This saves significant time and effort.

Ideal for Visual Prototypes

The glossy finishes are perfect for prototypes being used for visual evaluation:

- Auto and aircraft models to assess styling

- Consumer product prototypes for focus groups

- Architectural scale models

- Marketing props for trade shows

SLA produces prototypes that look like finished products.

Versatile Options

Surface appearance can also be tuned:

- Standard resins for glossy finishes

- Matte resins to mimic painted plastic

- Flexible resins for rubber-like surfaces

This further expands prototype possibilities.

So for beautiful, ready-to-present 3D printed models, SLA is the top choice over lower quality FDM prints.

Conclusion

In summary, SLA 3D printing has several key advantages making it a premier choice for diverse applications:

- Exceptional resolution– Crisp, highly detailed prints down to 25 microns

- Excellent mechanical properties– Strong, functional parts with tensile strength up to 70 MPa

- Diverse material options– From basic to engineering resins, composites, and customized formulations

- Precision and consistency– Dimensional accuracy within 0.1-0.2%, no warping or defects

- Smooth surface finishes – Glossy, injection molded-like surface quality

Whether you need detailed jewelry prints, functional prototypes, or beautiful visual models, SLA outperforms other methods like FDM. The precision laser curing process enables unparalleled part quality and diverse applications.

As SLA technology and material options continue advancing rapidly, we can expect its use to grow for everything from rapid prototyping to end-use production. For both professionals and hobbyists, SLA represents the new gold standard for high-resolution 3D printing.