Selective laser sintering (SLS) has emerged as a versatile 3D printing process enabling applications from rapid prototyping to end-use part production. In this beginner’s guide, we’ll explore how SLS printing works, its unique benefits, and the wide range of possibilities this technology unlocks.

A Primer on the Fundamentals of Selective Laser Sintering

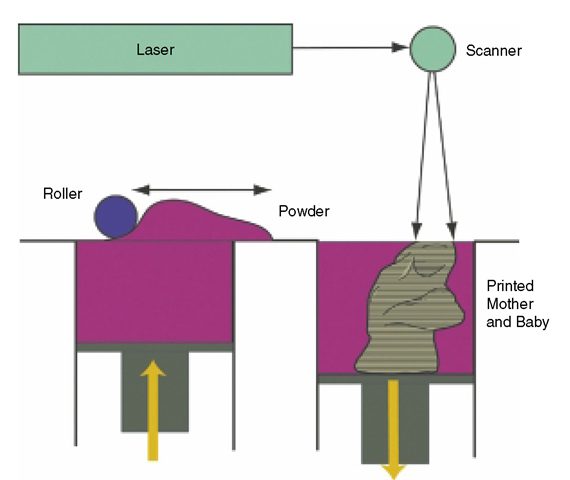

SLS 3D printing utilizes a laser to selectively fuse powdered material and build up parts layer-by-layer. Here are the key aspects of how the process works:

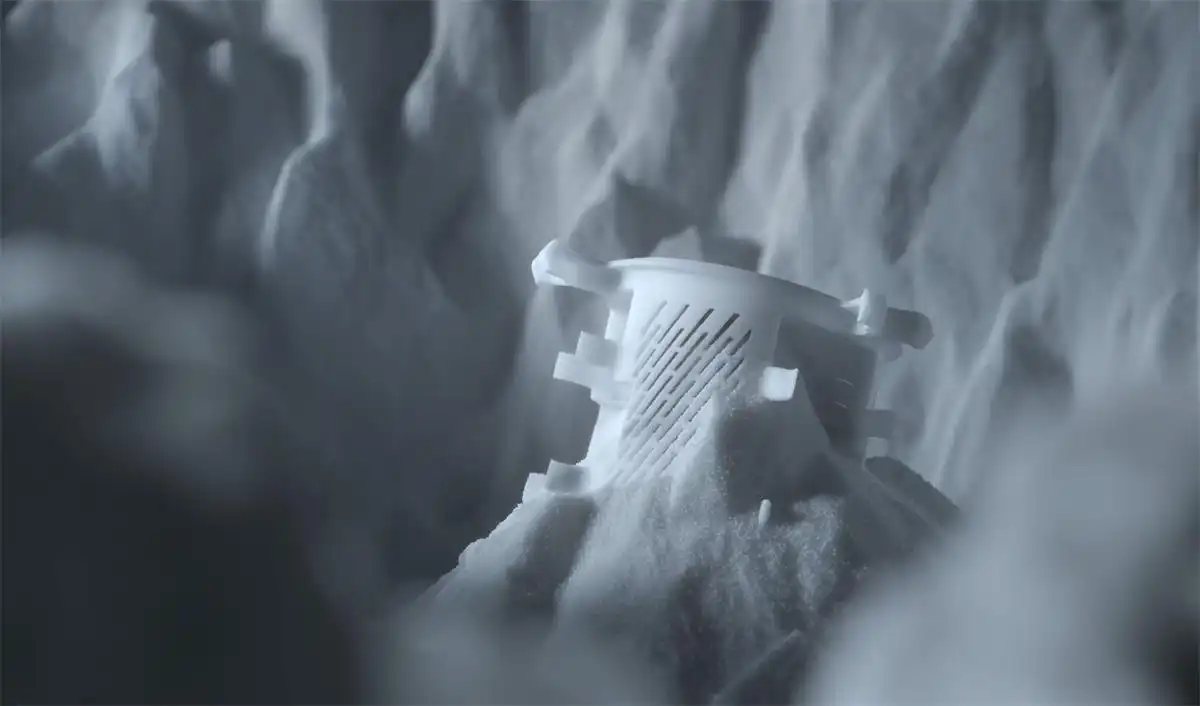

- Powder Bed – SLS printers spread a thin layer of polymer powder over a build platform. Common materials are nylon, thermoplastic elastomers, and composites.

- Laser Sintering – A laser traces each layer of the part, elevating the temperature to melt powder particles. Unfused powder provides support.

- Layering – After fusing a layer, the platform lowers and powder recoats. The process repeats until the part is complete.

- Cooling and Removal – Parts require gradual cooling before removal to prevent warping. Unfused powder is recycled for future builds.

The layer-by-layer SLS process enables intricate geometries impossible with conventional manufacturing. Next we’ll explore the advantages this unlocks.

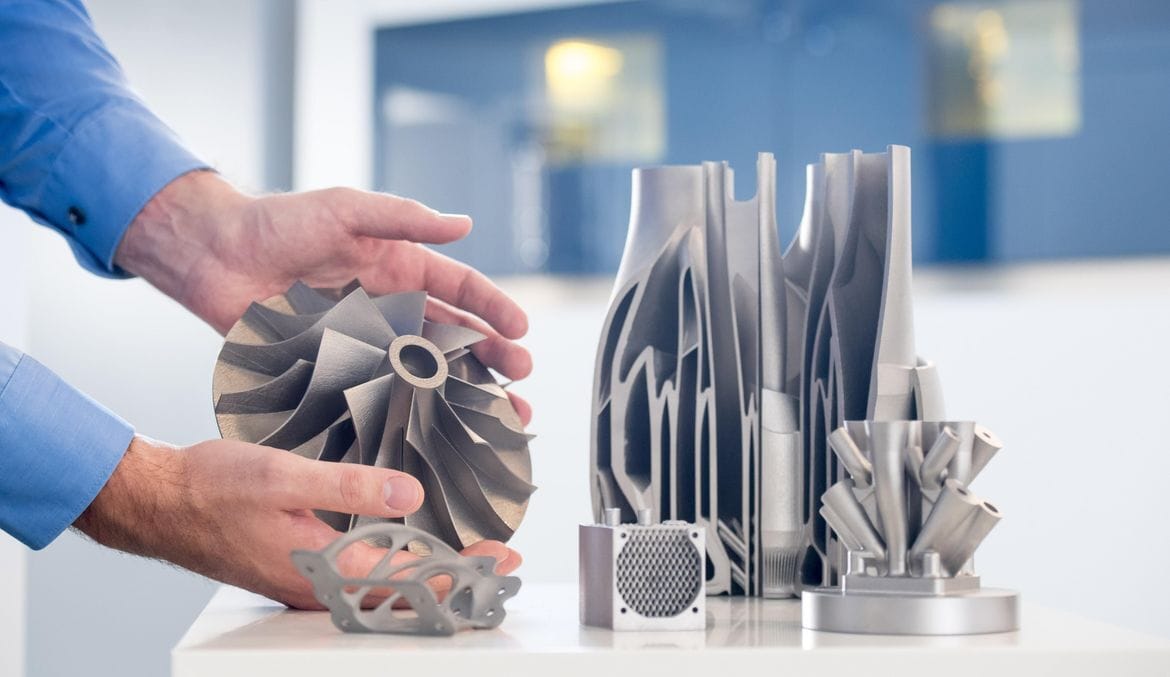

Unmatched Design Freedom: SLS Permits Complex Shapes and Consolidated Parts

A key benefit of SLS 3D printing is the elimination of constraints imposed by traditional production methods:

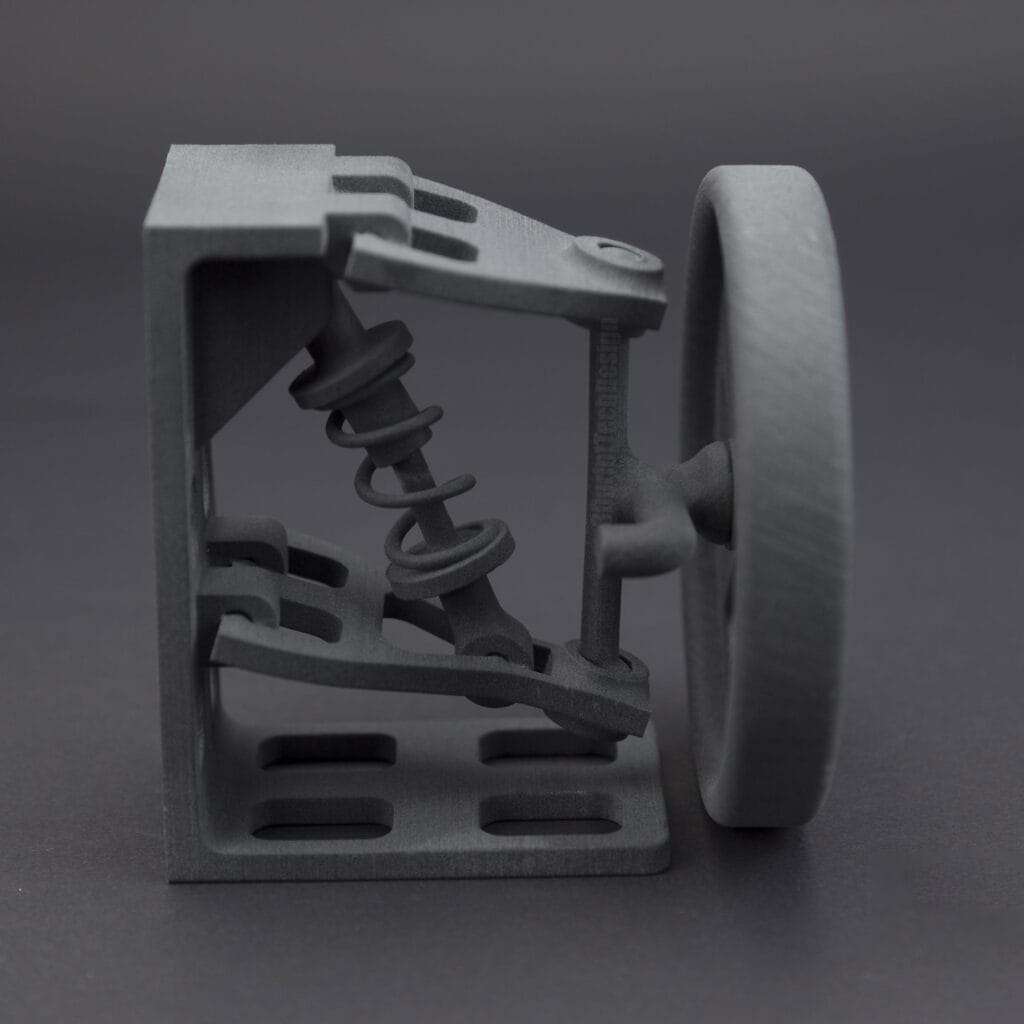

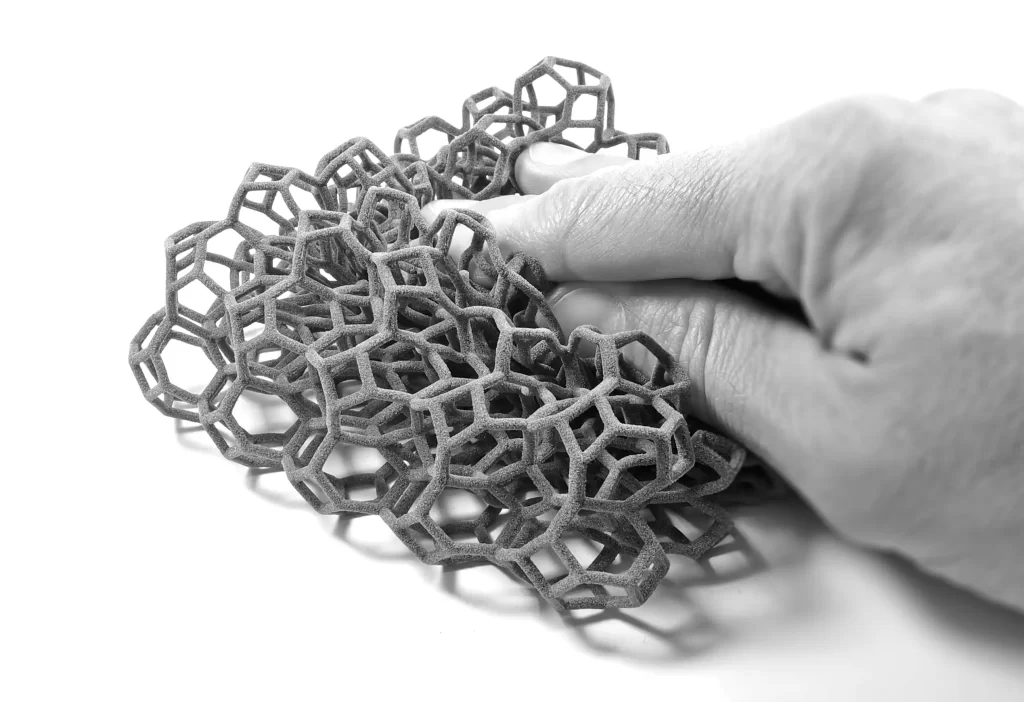

- No Supports Needed – Unfused powder surrounding the part during printing provides inherent support, enabling undercuts and complex interlocking geometry.

- Part Consolidation – Multiple components can be printed as a single part for reduced assembly. SLS allows dense, nested components.

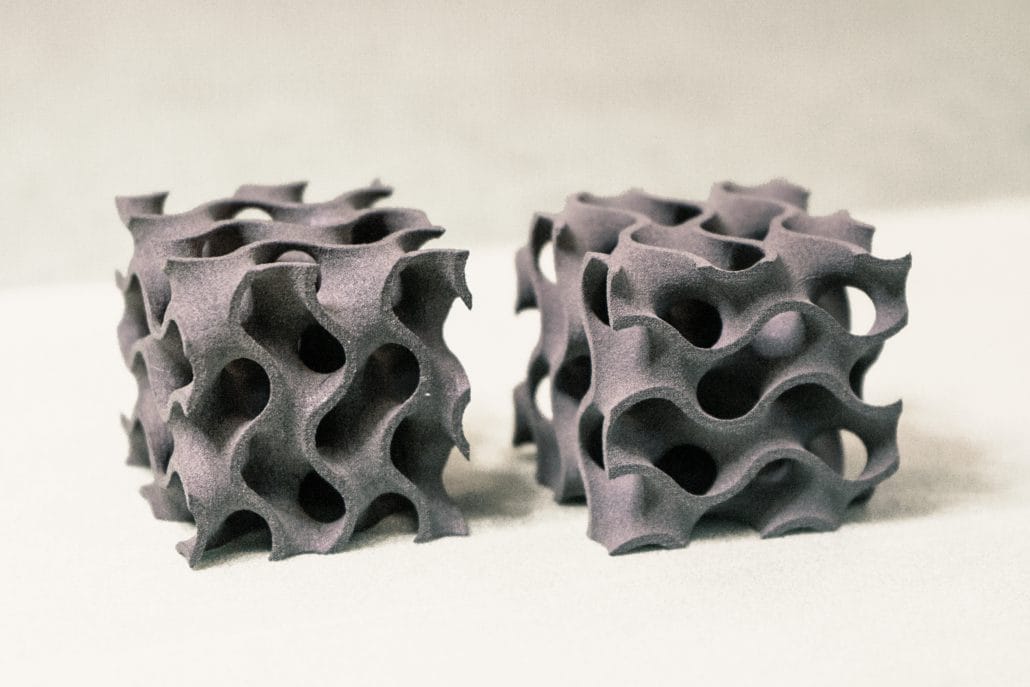

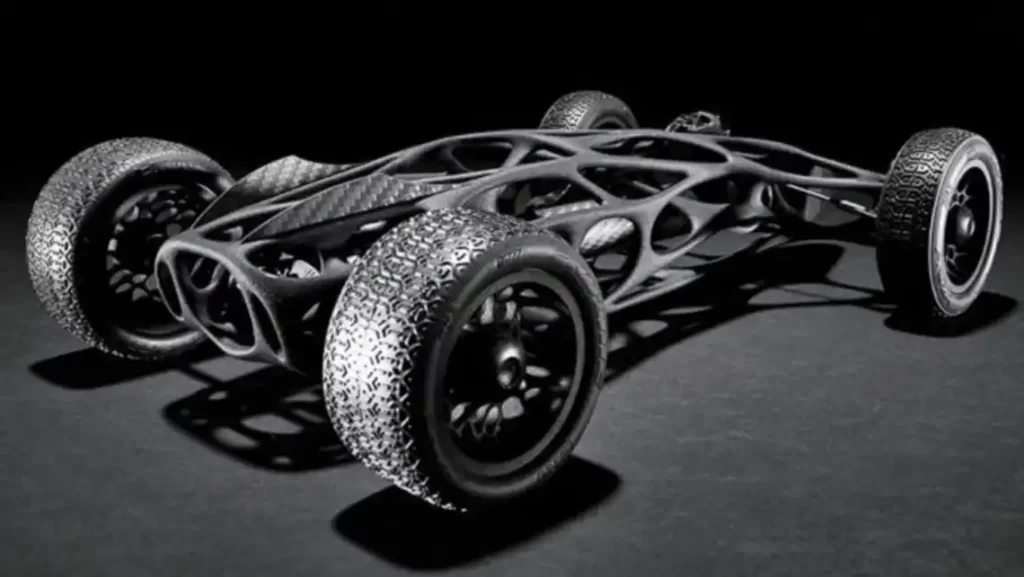

- Lightweighting – Parts can incorporate internal honeycomb or lattice structures to reduce weight while maintaining strength.

- Customized Geometry – Organic, bionic shapes that mimic nature’s designs can enhance performance and aesthetics.

SLS technology permits designers to think beyond the limits of conventional manufacturing and leverage additive’s unique advantages.

Technical Prowess: Robust Materials and Proven Performance

In addition to design freedom, SLS offers robust materials and mechanical properties surpassing traditional plastics manufacturing:

- Engineering Thermoplastics – From glass-filled nylon to flame-retardant or chemically resistant composites, SLS materials match plastics used in injection molding.

- Isotropic Strength – Laser sintering creates dense, isotropic parts with strength resembling production plastics, not prototyping materials.

- Bearing-Ready Capability – SLS materials like DuraForm ProX FR meet specifications for low-friction bearings and sliding contact applications.

- Production-Level Repeatability – Advanced SLS printers deliver consistent mechanicals and accuracy for end-use parts manufacturing.

Thanks to continual materials innovation and process refinements, SLS can produce durable parts for the most demanding applications.

Optimized for Manufacturing: From Prototyping to Serial Production

A common misconception is that SLS is used solely for prototyping. While ideal for prototypes, recent advances make laser sintering suitable for production:

- Low Volume Production – Due to no tooling requirements, SLS excels at low to mid-volume manufacturing of up to 10,000’s of parts cost-effectively.

- Mass Customization – SLS enables economical batches of custom parts with variations in geometry or text printed directly on parts.

- Reliable Serial Production – Repeatable process controls and minimal manual labor allow high-volume automated SLS production runs.

- Just-in-Time Manufacturing – Parts can be produced on-demand as needed, eliminating inventory and forecasting requirements.

With its minimal setup times, SLS enables both highly flexible prototyping as well as scalable manufacturing strategies.

Supplier Ecosystem: SLS Solutions Tailored to Your Needs

A mature network of SLS equipment, materials, software, and service providers exist to deliver tailored solutions:

- Printer Manufacturers – Leading makers offer systems scaled from compact desktop to high-capacity including EOS, 3D Systems, and Sinterit; Of course, there’s also the new generation SLS 3D printer 3540Pro developed and designed by ZONGENG3D.

ESO P 396 3D Printer

3D System SLS 380 Printer

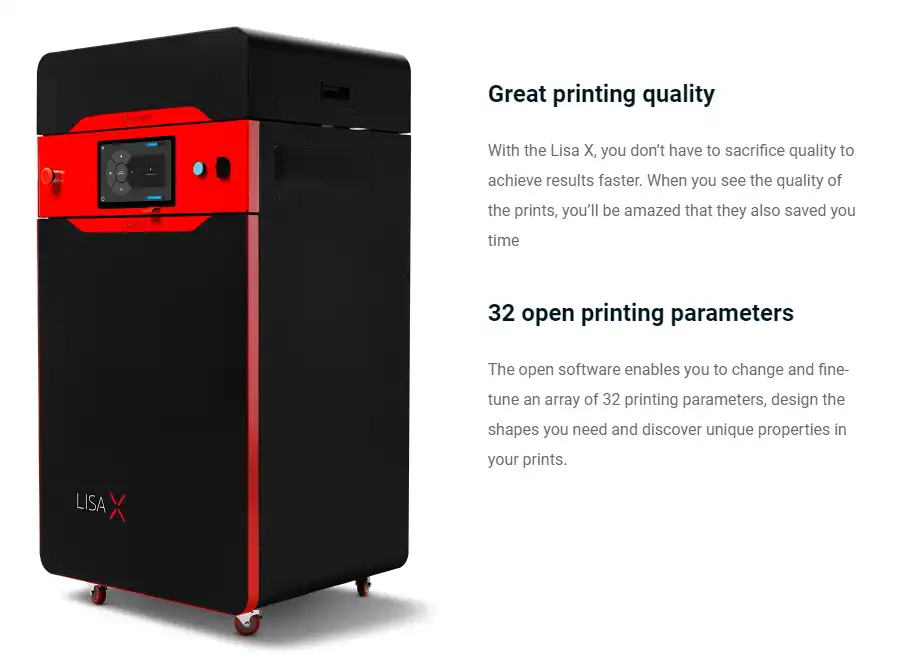

LisaX 3D Printer

ZONGHENG SLS 3540 PRO

- Materials Suppliers – Large materials companies develop specialized SLS powders including Duraform, PA11, and composites.

- Software Partners – SLS printers utilize software for build preparation, optimization, and management like Materialise Build Processors.

- Service Bureaus – Contract manufacturers provide professional SLS prints leveraging an array of processes and materials.

This robust supplier ecosystem provides accessible SLS solutions no matter your specific prototyping and manufacturing needs.

Streamlined Workflows: User-Friendly Print Preparation and Post-Processing

Today’s SLS solutions emphasize optimized workflows for ease of use:

- Slicing Software – Print preparation software automates supports, build optimization, and print configuring to streamline pre-processing.

- Operator Convenience – Features like fast powder recycling and gantry-mounted lasers simplify machine operation and maintenance.

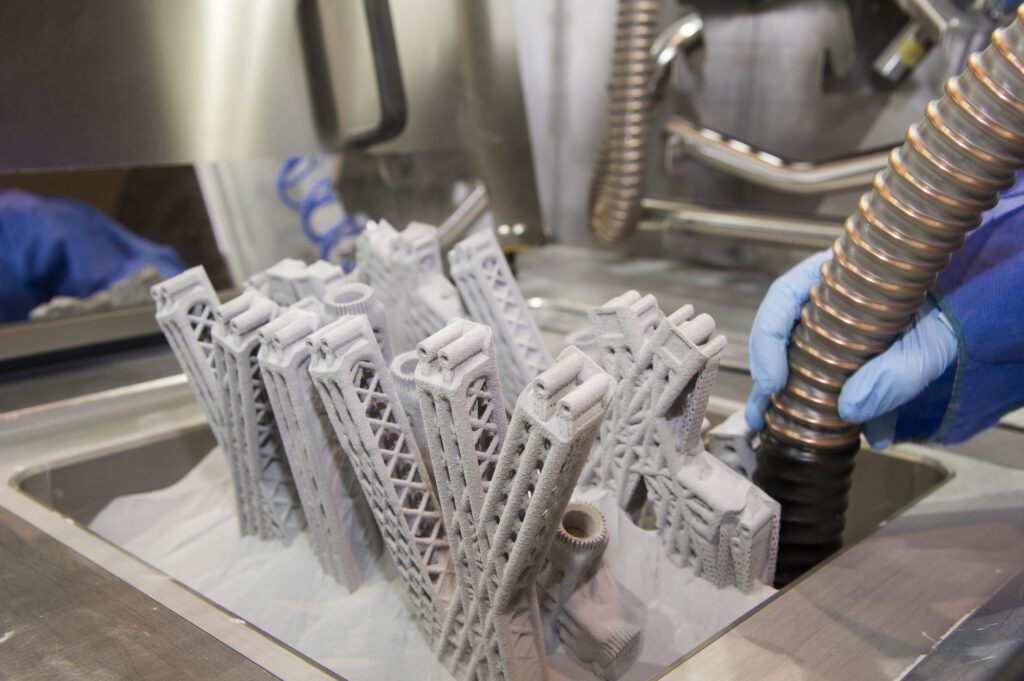

- Depowdering Equipment – Vibratory, thermal, or chemical depowdering equipment removes excess powder from printed parts.

- Powder Management – Systems collect, sieve, blend, and store partially used powder batches for reuse.

- Parameter Optimization – Print settings can be dialed-in for specific parts and materials to ensure optimal quality.

Refinements like these lower total cost of ownership while delivering consistent, high-quality print results.

Unlocking New Applications: How SLS 3D Printing Enables Breakthroughs Across Industries

Once considered an exotic prototyping technique, SLS printing now drives innovation across diverse sectors thanks to its unique capabilities.

Aerospace: Driving the Next Generation of Aircraft Design

SLS empowers aerospace engineers to print lightweight, high-strength components for improved performance:

- Complex Geometries – Organic lattices and bionic shapes developed through topology optimization slash weight while retaining strength.

- Part Consolidation – Reducing component count via integrated designs improves reliability and efficiency.

- Customization – SLS enables customized interior components, ducting, and panels matched to each airframe.

- Quick Iteration – Making design tweaks and new prototypes possible without delays of conventional tooling.

Automotive: Accelerating Concept Cars and Customization

Automakers harness SLS for design flexibility and speed:

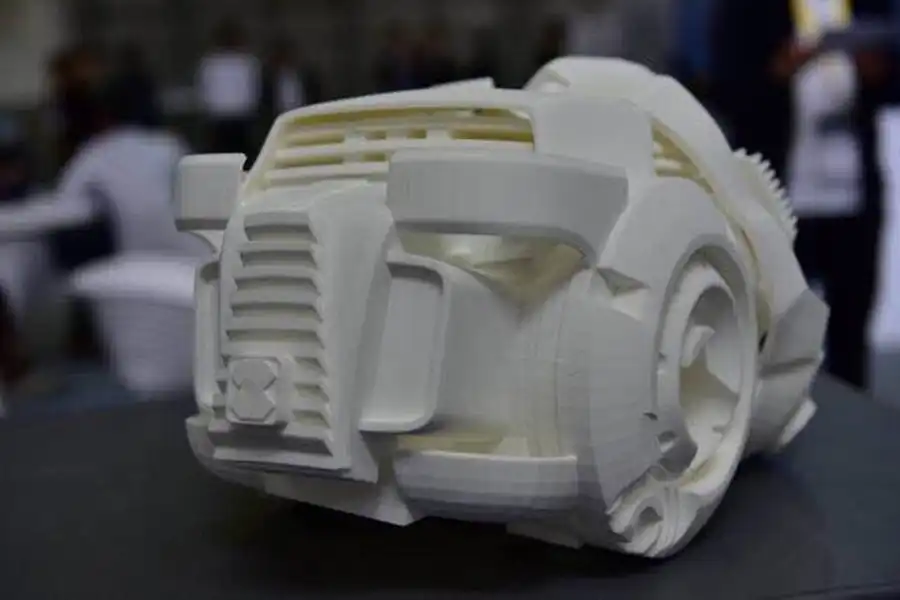

- Rapid Concept Models – SLS prints realistic models for early evaluation of styling and ergonomics.

- Custom Interiors – Unique geometries and custom-textured surfaces provide bespoke interiors.

- Functional Prototypes – Strong thermoplastics enable underhood components to be tested on concept vehicles.

- Agile Development – Engineers can quickly iterate changes and new versions of parts without tooling constraints.

SLS capabilities align perfectly with automotive demands for personalization and accelerated development cycles.

Medical: Enabling Personalized Devices and Instruments

SLS aids medical progress through customized and complex designs:

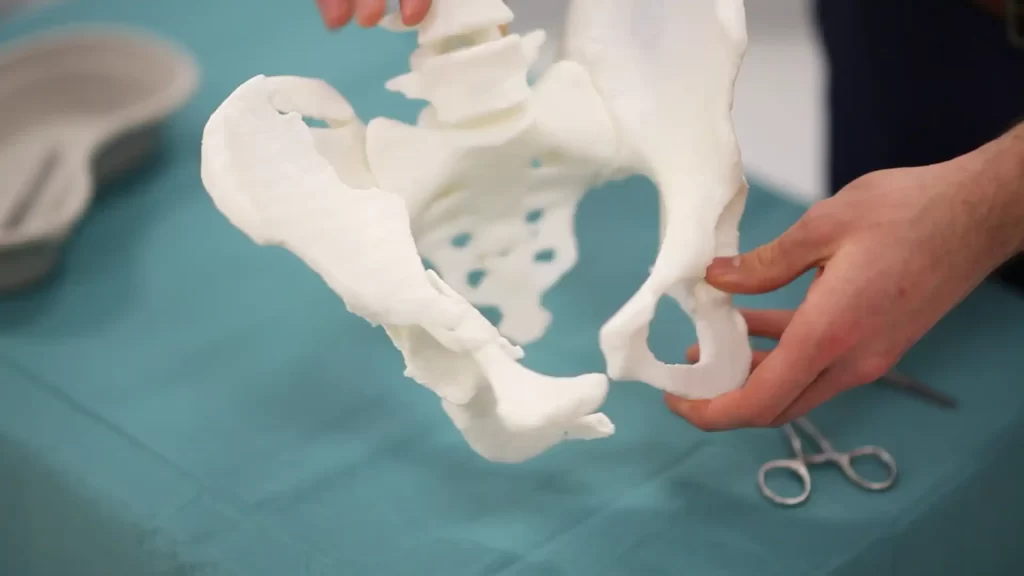

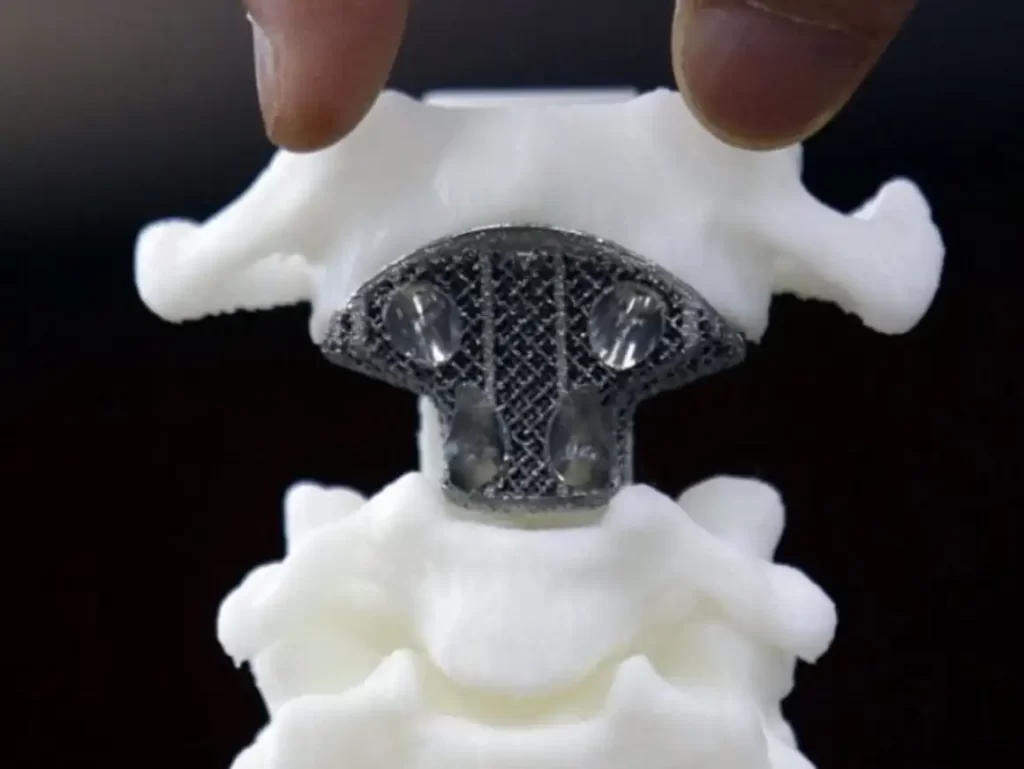

- Patient-Matched Devices – SLS enables braces, prosthetics, and implants tailored to scan data.

- Bio-Modeling – Realistic organs and anatomies printed from CT/MRI scans aid surgical planning.

- Ergonomic Tools – SLS prints design aids and surgical instruments matched to a physician’s grip.

- Microlattices – Ultra-porous structures mimic bone tissue for enhanced osseointegration.

By enabling personalized geometries impossible with conventional means, SLS advances medical innovation.

The unique capabilities of the technology continue driving breakthroughs across diverse sectors and applications. SLS removes prior constraints, permitting a new realm of design freedom ready to be unlocked by forward-thinking adopters.

Pushing the Boundaries: How Advances Are Unleashing SLS 3D Printing’s Full Potential

Ongoing improvements in materials, hardware, software, and design tools ensure SLS additive manufacturing continues marching toward its full disruptive potential.

Stronger, More Diverse Materials Expand Possibilities

SLS thermoplastics continue to gain performance nearing engineering-grade plastics used for manufacturing:

- High Heat Options – New polyamide blends resist temperatures exceeding 200°C, expanding use-cases.

- Improved Toughness – Impact resistance and layer bonding have increased, broadening viable applications.

- Functional Composite – Fillers like glass beads or carbon fiber allow tailoring of desired material characteristics.

- Biocompatible Grades – SLS materials compliant with medical device regulations enable greater medical uses.

The expanding SLS material toolbox unlocks more demanding applications.

Bigger, Faster Printers Boost Productivity

New production-focused SLS systems feature advanced capabilities:

- Large Build Volumes – Chambers over 1 meter long enable high-volume output and large parts.

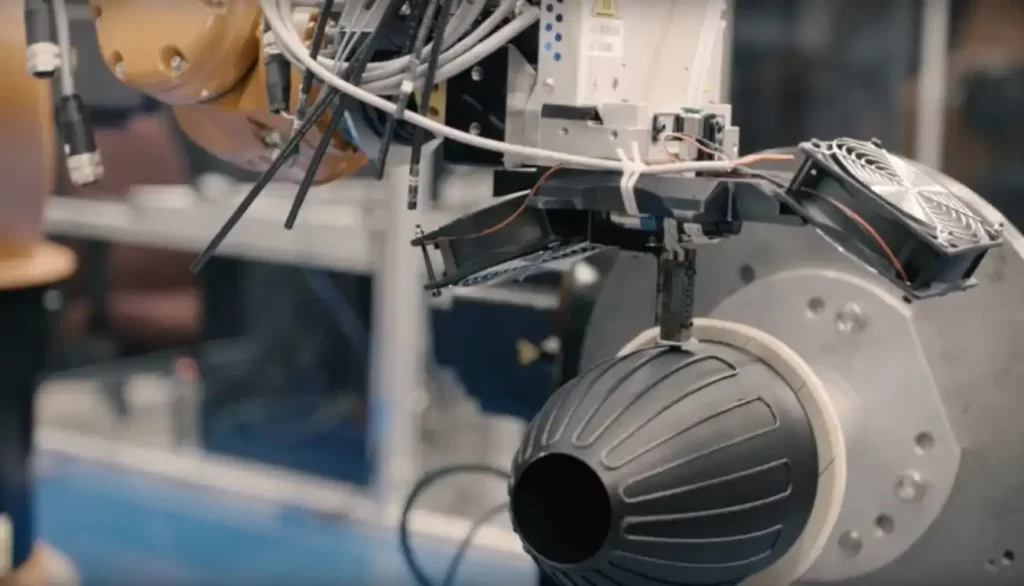

- Multi-Laser Configs – Multiple lasers cut production times by building parts in parallel.

- Repeatable Processes – Sophisticated controls, powder handling, and sensors reduce variability.

- Automated Workflows – Features like powder recycling and loading minimize manual effort for lights-out production.

These systems make SLS highly viable for serial manufacturing requiring significant print volume.

Software Enhancements Drive Optimization

SLS software gains ever-more intelligence to automate and optimize:

- Specialized Design Tools – Software featuring topology optimization and lightweight lattice design produce high-performing geometry.

- Print Simulation – Physics-based modeling helps engineers predict performance before printing physical iterations.

- Build Processors – Advanced algorithms automatically optimize build packing, part orientation, and print parameters for reliability.

- Production Management – Software analyzes trends and provides early warning of potential issues across systems.

Continued software improvements further tap into SLS capabilities while minimizing trial-and-error.

New Design Thinking Recognizes Unique Potential

A paradigm shift towards design for additive manufacturing (DfAM) principles recognizes SLS capabilities:

- Consolidated Assemblies – SLS enables simplifying assemblies into single complex parts never before possible.

- Internal Structures – Lattice networks reduce weight and customize properties inside printed parts.

- Bionic Designs – Generative programs produce shapes inspired by nature’s high-performing organic designs.

- Customized Geometry – Designers now consider how to best leverage SLS strengths rather than work around its limitations.

Embracing these additive-first design approaches unleashes benefits unique to SLS printing.

Ongoing advances ensure laser sintering technology remains at the forefront, providing designers, engineers, and manufacturers with ever-expanding possibilities. The days of SLS being viewed as niche are over; it has proven itself as a transformative manufacturing process.

Harness the True Potential of SLS 3D Printing

SLS provides an unmatched combination of design freedom, high-performance materials, and scalability from prototyping to production. Unconstrained by conventional limitations, SLS opens the door to groundbreaking innovations across industries. Ongoing advances will continue expanding the possibilities – the key is properly leveraging the technology’s distinct capabilities rather than simply replicating traditional manufacturing. With an open mind to additive manufacturing’s new potential, businesses can fully capitalize on the benefits SLS provides.